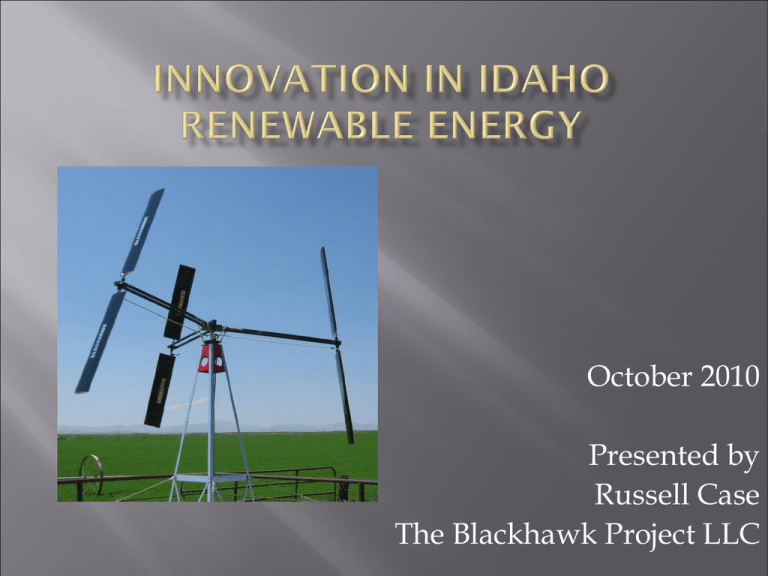

New Small and Mid-Size Design Unique Vertical Axis Wind Turbine

advertisement

October 2010 Presented by Russell Case The Blackhawk Project LLC Brilliant discovery & creativity …. … pure practicality Identify Solve Improve Solve the Issue Improve on the Solution Manufacturers were competing based on exotic materials, sophisticated aerodynamic blade design, wind forecasting and size Increasingly complex turbines need high-cost manufacturing, on-site technicians, large land areas for deployment and expensive transmission Dramatic increases in wind energy generation require an efficient and cost-effective wind turbine design that was simple to manufacture in a variety of different sizes and energy outputs Widespread deployment achievable only with near-silent operation, low tower heights, durable operation characteristics and maintenance and repair by the consumer or the local mechanic Look Back Look Around Apply Your Knowledge Main Rotor Tilt controls Pitch of Airfoils Patent Issued March 16, 2010: US Patent #7,677,862 Production ready, scalable TR-10 tested and ready for direct or licensed manufacturing, distribution, sales and operation Tower/Turbine Dimensions: 3 meter diameter/blade height mounted on 10m standard tower, total weight 55kg (turbine + generator) Energy generation: 1.2kW at 46kph (29mph) Generator: proprietary integrated, non-cogging axial flux generator Parts: non-exotic materials; standardized airfoil designs Control systems: no electronic control systems; selfstarting Scalability: prototype development and modeling demonstrates increased stability and exponential energy generation at larger sizes Durability and performance metrics confirmed through year-long off-grid and grid-tied field testing in harsh Idaho climates Field tested to 160kph (with increasing energy generation at higher wind speeds) Continued operation in subzero temperatures, snow and ice Cost of manufacture costs captured through production test runs Cost/watt competitive at TR-10 configuration (1. kW) Cost/watt advantages at TR-20 (5.6kW), TR-40 (25kW) and TR-80 (100kW) configurations Positive Aesthetic/Consumer Differentiators: Near silent operation with minimal structural vibration enables urban, suburban and rural deployment Visually appealing design Low tower+blade height Fits onto standard towers (monopole, tri-pole) Designed for Distributed Worldwide Manufacturing and Use Non-exotic materials and airfoil design Simple manufacture, machining, assembly and installation Scalability enables multiple deployment options: Stand-alone Multiple use/community grid Tandem , over-under (with utility grade turbines) Off-grid and grid-tie compatible Technology Available for License, Acquisition or Investment Please contact Russell Case to learn more about: Opportunities to manufacture, distribute, acquire or invest in the Blackhawk patented VAWT/AR technology Investing in Idaho innovation through the US EB-5 investment program The advantageous business and living environment that exists in the State of Idaho The extensive technical and scientific expertise offered by the Idaho National Laboratory, the Center for Advanced Energy Studies and the Idaho university system Russell Case +1.208.321.2520 +1.208.991.8317 rc@russell-case.com