Solar Cell

advertisement

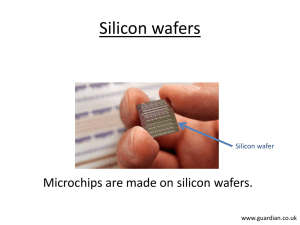

Solar Cell Chapter 7: Manufacturing Silicon Solar Cells Nji Raden Poespawati Department of Electrical Engineering Faculty of Engineering University of Indonesia Contents 7.1. Silicon Wafers and substrates 7.2. Silicon Solar Cell Fabrication Technologies Silicon Wafers and substrates Types of Silicon Silicon or other semiconductor materials used for solar cells can be: 1. 2. 3. 4. single crystalline, multicrystalline, polycrystalline or amorphous. Silicon Wafers and substrates Terminology for various crystalline silicon (c-Si). (continued) types of Descriptor Symbol Grain Size Common Growth Techniques Single crystal sc-Si >10cm Czochralski (CZ) float zone (FZ) Multicrystalline mc-Si 1mm-10cm Cast, sheet, ribbon Polycrystalline pc-Si 1mm-1mm Chemical-vapour deposition Microcrystalline mc-Si <1mm Plasma deposition Silicon Wafers and substrates (continued) Single Crystalline Silicon The majority of silicon solar cells are fabricated from silicon wafers, which may be either single-crystalline (better material parameters but are also more expensive) or multicrystalline. Figure 1 shows the regular arrangement of silicon atoms in single-crystalline silicon produces a welldefined band structure. Single crystalline silicon is usually grown as a large cylindrical ingot producing circular or semi-square solar cells(see Figure 2). Silicon Wafers and substrates (continued) Czochralski Silicon Single crystalline substrates are typically differentiated by the process by which they are made. Czochralski (CZ) wafers are the most commonly used type of silicon wafer, and are used by both the solar and integrated circuit industry. disadvantages : a large amount of oxygen in the silicon wafer. It reduces the minority carrier lifetime in the solar cell, thus reducing the voltage, current and efficiency. In addition, the oxygen and complexes of the oxygen with other elements may become active at higher temperatures, making the wafers sensitive to high temperature processing. Silicon Wafers and substrates (continued) Float Zone Silicon To overcome these problems, Float Zone (FZ) wafers may be used. (see Figure 3) Silicon Wafers and substrates (continued) Multicrystalline Silicon • • more simple, and therefore cheaper. the material quality of multicrystalline material is lower than that of single crystalline material due to the presence of grain boundaries (introduce localised regions of recombination and reduce solar cell performance by blocking carrier flows and providing shunting paths for current flow across the p-n junction. Figure 4 shows a multicrystalline silicon. Silicon Wafers and substrates (continued) Amorphous silicon (a-Si) silicon in which some atoms in the structure remain unbonded, lacks long-range order (even more cheaply than multicrystalline silicon)(see Figure 5). Silicon Solar Cell Fabrication Technologies Screen-Printed Solar Cells Screen-printed solar cells were first developed in the 1970's. The key advantage of screen-printing is the relative simplicity of the process. Some techniques have already been introduced into commercial production while others are making progress from the labs to the production lines: Phosphorous Diffusion Surface Texturing to Reduce Reflection Antireflection Coatings and Fire Through Contacts Edge Isolation (plasma etching, laser cutting, or masking the border to prevent a diffusion from occurring around the edge in the first place. Rear Contact Substrate Figure 6 shows Screen-Printed Solar Cells Silicon Solar Cell FabricationTechnologies(continued) Solar Cell Production Figure 7 – Figure 15 show a commercial screen printed solar cell fabrication plant. Silicon Solar Cell FabricationTechnologies (continued) Buried Contact Solar Cells The buried contact solar cell is a high efficiency commercial solar cell technology based on a plated metal contact inside a laser-formed groove. Compared with screen printed solar cell : 1. 2. Its performance up to 25% better on a large area device, a screen printed solar cell may have shading losses as high as 10 to 15%, while in a buried contact structure, the shading losses will only be 2 to 3%. These lower shading losses allow low reflection and therefore higher short-circuit currents. A schematic of a buried contact solar cell is shown in the figure 16. Silicon Solar Cell FabricationTechnologies(continued) High Efficiency Solar Cells Some of the techniques and design features used in the laboratory fabrication of silicon solar cells, to produce the highest possible efficiencies include: 1. 2. 3. 4. 5. 6. 7. 8. 9. lightly phosphorus diffused emitters, to minimise recombination losses and avoid the existence of a "dead layer" at the cell surface; closely spaced metal lines, to minimise emitter lateral resistive power losses; very fine metal lines, typically less than 20 µm wide, to minimise shading losses; polished or lapped surfaces to allow top metal grid patterning via photolithography; small area devices and good metal conductivities, to minimise resistive losses in the metal grid; low metal contact areas and heavy doping at the surface of the silicon beneath the metal contact to minimise recombination; use of elaborate metallization schemes, such as titanium/palladium/silver, that give very low contact resistances; good rear surface passivation, to reduce recombination; use of anti-reflection coatings, which can reduce surface reflection from 30% to well below 10%. Silicon Solar Cell FabricationTechnologies(continued) Two approaches that have been used by niche markets such as solar cars are (see Figure 17): the PERL cells produced at University of New South Wales, and the rear-contact cells developed at Stanford University and SunPower. Thank You Figure 1. The regular arrangement of silicon atoms in single-crystalline silicon produces a well-defined band structure. Each silicon atom has four electrons in the outer shell. Pairs of electrons from neighbouring atoms are shared so each atom shares four bonds with the neighbouring atoms. Figure 2. Single crystalline silicon is usually grown as a large cylindrical ingot producing circular or semi-square solar cells. The semi-square cell started out circular but has had the edges cut off so that a number of cells can be more efficiently packed into a rectangular module. Figure 3. Schematic of Float Zone wafer growth. (a) (b) Figure 4. (a) At the boundary between two crystal grains, the bonds are strained, degrading the electronic properties (b) A multicrystalline wafer. Figure 5. Amorphous silicon has short-range order to give it semiconductor properties. Extra bonds are terminated on hydrogen atoms. The change in average atomic spacing and presence of hydrogen gives amorphous silicon different electronic properties to crystalline silicon. (a) (c) (b) (d) Figure 6. (a) Close up of a screen used for printing the front contact of a solar cell. During printing, metal paste is forced through the wire mesh in unmasked areas. The size of the wire mesh determines the minimum width of the fingers. Finger widths are typically 100 to 200 µm(b) Close up of a finished screen-printed solar cell. The fingers have a spacing of approximately 3 mm. An extra metal contact strip is soldered to the busbar during encapsulation to lower the cell series resistance(c) Front view of a completed screen-printed solar cell. As the cell is manufactured from a multicrystalline substrate, the different grain orientations can be clearly seen. The square shape of a multicrystalline substrate simplifies the packing of cells into a module(d) Rear view of a finished screen-printed solar cell. The cell can either have a grid from a single print of Al/Ag paste with no BSF, or a coverage of aluminium that gives a BSF but requires a second print for solderable contacts. Figure 7. Crystallisation furnace for the manufacture of multicrystalline ingots. Large silicon slabs of approximately 0.5m by 0.5m and 20cm thick are routinely produced. By carefully controlling the cooling of the liquid, silicon material is produced with large grains and few crystal defects (photograph courtesy of Eurosolare S.p.A.). Figure 8. The large ingot produced by the crystallisation furnace is sawn into smaller 10cm by 10cm blocks. The smaller blocks are then sliced to produce 10 cm by 10 cm wafers (photograph courtesy of Eurosolare S.p.A.). Figure 9. View of the production line at Eurosolare. While solar cell manufacture requires clean conditions, the requirements are nowhere near as strict as those for integrated circuit (IC) manufacture. Hence it is not necessary for staff to wear full cleanroom suits (photograph courtesy of Eurosolare S.p.A.). Figure 10. Automatic loading of the diffusion furnace with wafers already coated with phosphorous. Note that the wafers just about to enter the diffusion furnace on the right were cut from the same ingot and have a similar distribution of crystal grains (photograph courtesy of Eurosolare S.p.A.). Figure 11. Automated unloading of the diffusion furnace. The use of robotic equipment has improved the reliability of cell manufacture and reduced costs (photograph courtesy of Eurosolare S.p.A.). Figure 12. Production line screen-printer. (photograph courtesy of Eurosolare S.p.A.). Figure 13. Advanced screen-printing machine that uses video cameras to quickly and accurately align the metal contact print pattern (photograph courtesy of Eurosolare S.p.A.). Figure 14. After measuring the efficiency of each finished cell, they are sorted to minimise mismatch on module interconnection. (photograph courtesy of Eurosolare S.p.A.). Figure 15. Array structure before lamination viewed from the rear (photograph courtesy of Eurosolare S.p.A.). Figure 16. Cross-section of Laser Grooved, Buried Contact Solar Cell. Figure 17. Schematic of high efficiency laboratory cell.