Case Studies on Vibrations

advertisement

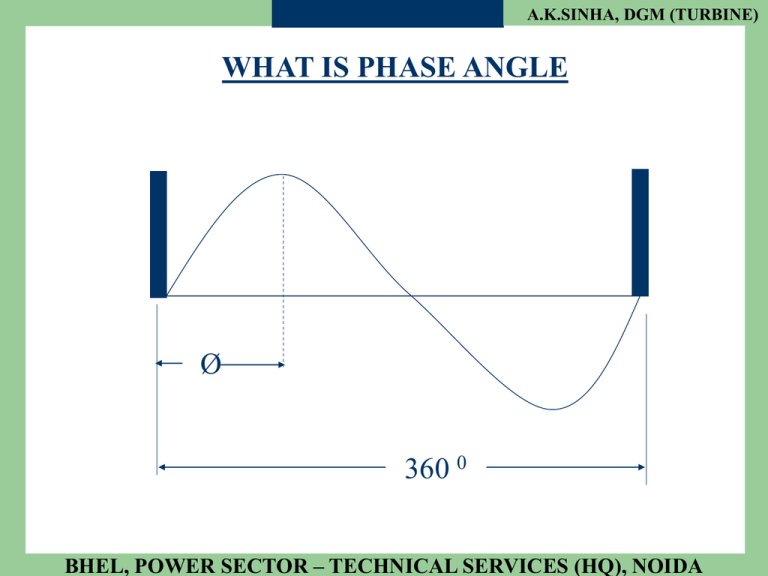

A.K.SINHA, DGM (TURBINE) WHAT IS PHASE ANGLE Ø 360 0 BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) USES OF PHASE ANGLE MEASUREMENT 1. BALANCING 2. STRUCTURE MOTION STUDY 3. DETECTION OF RESONANCE FREQUENCY RUN UP & RUN DOWN BEHAVIOUR BODE PLOT 4. HEALHINESS OF MATING SURFACES OF TWO VIBRATING MASSESS 5. UNDERSTANDING THE DEFLECTION MODE OF THE SHAFT BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) STRUCTURE MOTION STUDY REAR 245 228 0 220 FRONT 1 230 165 FRONT 212 2 170 245 REAR 220 209 127 138 107 101 87 71 3 112 120 96 94 4/5 6 7 LEFT SIDE 53 19 9 63 19 10 24 20 15 11 16 12 ` 11 7 21 16 12 -14 17 18 22 17 -23 23 10 15 -9 22 51 56 14 11 21 9 14 33 20 RIGHT SIDE 8 13 13 -25 23 18 BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) STRUCTURE MOTION STUDY BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HEALHINESS OF MATING SURFACES OF TWO VIBRATING MASSESS 3 2 1 9 6 8 7 5 4 GENERATOR SIDE D LEFT 21 C 20 14 15 13 BASE PLATE B A 11 12 RIGHT 10 18 17 19 16 SECONDARY GROUT TURBINE SIDE BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) UNDERSTANDING THE DEFLECTION MODE OF THE SHAFT B1 B2 B3 B4 BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) Case Studies on Vibration Problems in Steam Turbine Generators BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 500 MW TG SETS BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 500 MW TG SETS PROBLEM HIGH HP FRONT SHAFT AND BEARING PEDESTAL VIBRATION OBSERVATIONS (A) FREQUENCY ANALYSIS CARRIED OUT WHICH INDICATED PREDOMINANT 1-X VIBRATION COMPONENTS FOR BOTH SHAFT AND BEARING PEDESTAL VIBRATION STEADY PHASE ANGLE (B) BEARING PEDESTAL VIBRATIONS AND SHAFT VIBRATIONS WERE HAVING RISING TENDENCY AT RATED SPEED HOWEVER, THEIR RATIO WAS FOUND TO BE ALMOST CONSTANT BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 500 MW TG SETS ANALYSIS PREDOMINANT 1-X VIBRATION WITH SLIGHT CHANGE IN PHASE ANGLE INDICATED THERE WAS UNBALANCE IN THE ROTOR SYSTEM LEADING TO INITIATION OF MINOR RUB MAIN SOURCE OF VIBRATION WAS HIGHER DYNAMIC LOADING FROM THE SHAFT WHICH WAS GETTING TRANSMITTED TO BEARING ACTION TAKEN • TO REDUCE THE HP FRONT SHAFT VIBRATION LEVEL, INSITU BALANCING WAS CARRIED OUT USING LP ROTOR BALANCING PLANES BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 500 MW TG SETS RESULT OF INSITU BALANCING HP SHAFT VIBRATION BROUGHT DOWN TO STEADY VALUE OF 120 MICRONS, 0-PK FROM EARLIER VALUE OF 150 - 200 MICRONS, 0-PK HP FRONT BEARING VIBRATION CAME DOWN INITIALLY TO 15 MICRONS, 0-PK AT 3000 RPM FROM EARLIER VALUE OF 25 – 40 MICRONS, 0-PK LATER, WITHIN 2-3 HOURS OF OPERATION, HP FRONT BEARING VIBRATION INCREASED BEYOND ALARM VALUE (35 MICRONS, 0-PK). DURING THIS PERIOD, NO INCREASE IN SHAFT VIBRATION WAS OBSERVED BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 500 MW TG SETS INTREPRETATION OF RESULTS AFTER INSITU BALANCING AS HP FRONT BEARING PEDESTAL VIBRATION INCREASED, EVEN WHEN HP FRONT SHAFT VIBRATION WAS CONSTANT, INDICATED THAT THE CAUSE OF HIGH BEARING PEDESTAL VIBRATION WAS SOME FACTORS APART FROM UNBALANCE OF THE SHAFT ANALYSIS DONE • BASED UPON THE VIBRATION BEHAVIOUR OF BEARING PEDESTAL AND SHAFT VIBRATION, IT WAS DECIDED TO SCAN FRONT BEARING PEDESTAL BY PORTABLE VIBRATION ANALYSER BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 500 MW TG SETS RESULTS OF SCANNING OF FRONT PEDESTAL VIBRATION ON LEFT AND RIGHT HAND SIDE OF FRONT BEARING PEDESTAL (NEAR HP CASING FRONT PALMS) IN THE VERTICAL DIRECTION WERE HAVING LARGE VARIATION (LHS VIBRATION IS ABOUT 5 TIMES MORE THAN RHS VIBRATION) HP CASING PALM VIBRATION AMPLITUDE IN VERTICAL DIRECTION ON LEFT AND RIGHT PALM WAS FOUND TO BE OF LOWER MAGNITUDE AND SAME SCANNING INDICATED THAT THERE WAS NO PROBLEM WITH BASE PLATE, SECONDARY GROUT & FOUNDATION MATING SURFACES BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HP CASING PAM (RIGHT HAND SIDE) HP FRONT BEARING PEDESTAL BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 500 MW TG SETS ANALYSIS SCANNING DATA INDICATED THAT LOAD DISTRIBUTION BETWEEN PALMS OF HP CASING WAS NOT PROPER THERE WAS GAP BETWEEN CASING PALM AND PEDESTAL ON LEFT HAND SIDE ACTION TAKEN • 0.15 MM SHIM WAS ADDED BELOW LEFT HAND SIDE PALM WHEREAS 0.1 MM SHIM WAS REMOVED FROM RIGHT HAND SIDE PALM FOR IMPROVING THE LOADING PATTERN OF HP CASING ON PEDESTAL BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 500 MW TG SETS RESULT OF CORRECTION IN SHIMS VIBRATIONS ON BEARING PEDESTAL REDUCED FROM 35 MICRONS, 0PK TO 15 MICRONS, 0-PK AND NO INCREASING TENDENCY WAS OBSERVED HP FRONT SHAFT VIBRATION WAS FOUND TO BE REDUCED FROM 120 MICRONS, 0-PK TO 90 MICRONS, 0-PK AND BEARING VIBRATION SETTLED DOWN TO 10 MICRONS, 0-PK AT FULL LOAD RATIO OF LEFT AND RIGHT HAND SIDE VIBRATION ON FRONT PEDESTAL IN VERTICAL DIRECTION CAME DOWN TO 2:1 FROM EARLIER VALUE OF 5:1 HENCE, UNBALANCE OF ROTOR SYSTEM & UNLOADING OF LEFT SIDE PALM WAS FOUND TO BE THE ROOT CAUSE OF THE HIGH HP FRONT SHAFT AND BEARING PEDESTAL VIBRATION BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) CONCLUSION VIBRATION IMPORTANT SCANNING TOOL FOR IS A VERY DIAGNOSTICS PURPOSES VIBRATION SCANNING SHOULD BE USED AS FREQUENTLY AS POSSIBLE IT HELPS IN RULING OUT OR PIN POINTING CERTAIN DEFECTS BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 210 MW TG SETS BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 210 MW TG SETS BACKGROUND MACHINE IS OF KWU DESIGN STEAM TURBINE COUPLED WITH LMW GENERATOR (LP REAR BEARING AND GENERATOR FRONT BEARING IS LOCATED IN COMMON PEDESTAL) VIBRATION BEHAVIOUR WAS FOUND TO BE NORMAL DURING FIRST COMMISSIONING ON ALL BEARINGS AND LATER ON VIBRATION ON BEARING NO. 4 / 5 PEDESTAL DETERIORATED GRADUALLY BEYOND ALARM LEVELS (35 MICRONS, 0-PK) BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 210 MW TG SETS PROBLEM HIGH LP REAR BEARING VIBRATION HIGH GENERATOR FRONT BEARING VIBRATION OBSERVATIONS FREQUENCY ANALYSIS CARRIED OUT WHICH INDICATED PREDOMINANT 1-X VIBRATION COMPONENT FOR BOTH LP REAR AND GENERATOR FRONT VERTICAL AND AXIAL VIBRATION VERTICAL VIBRATION AT LP REAR AND GENERATOR FRONT BEARING WAS OF THE ORDER OF 100 MICRONS, PK-PK AXIAL VIBRATION WAS ABOUT 200 MICRONS, PK-PK FOR BOTH LP REAR BEARING AND GENERATOR FRONT BEARING BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 210 MW TG SETS ANALYSIS BASED ON VIBRATION SYMPTOMS, FOLLOWING CHECKS WERE SUGGESTED IN PLANNED OVERHAUL LP / GENERATOR ALIGNMENT BEARING ASSEMBLY CHECKS RESULT OF ABOVE WORKS AFTER CARRYING OUT THE ABOVE MENTIONED CHECKS & CORRECTIONS DURING PLANNED OVERHAUL, VIBRATION LEVEL DID NOT IMPROVE BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 210 MW TG SETS ACTION TAKEN FOLLOWING WORKS WERE CARRIED OUT VIBRATION ANALYSIS SCANNING OF LP REAR BEARING PEDESTAL AND ITS SECONDARY GROUT AND BASE PLATE AREA OBSERVATIONS / ANALYSIS • FREQUENCY BEHAVIOUR OF BEARING VIBRATION FOUND SIMILAR TO EARLIER OBSERVATION • WIDE DIFFERENCE IN PHASE ANGLE IN VERTICAL DIRECTION ACROSS BASE PLATE OF LP REAR PEDESTAL AND SECONDARY GROUTING WHICH INDICATED THAT VERTICAL LOAD TRANSFER FROM BEARING TO FOUNDATION IS NOT AS EXPECTED BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) SCANNING OF PEDESTAL 3 2 1 9 6 8 7 5 4 GENERATOR SIDE D LEFT 21 C 20 14 15 13 BASE PLATE B A 11 12 RIGHT 10 18 17 19 16 SECONDARY GROUT TURBINE SIDE BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 210 MW TG SETS ACTION PLAN SUGGESTED REGROUTING OF LP REAR PEDESTAL REPLACEMENT OF FOUNDATION BOLTS OF LP REAR PEDESTAL AND PROPER MATCHING OF ANCHOR PLATES IN-SITU BALANCING OF GENERATOR ROTOR TO REDUCE EXCITATION FORCES TO MINIMUM DUE TO TIME CONSTRAINT AND POWER REQUIREMENT, FOLLOWING WORKS CARRIED OUT • EPOXY GROUTING (PRESSURE GROUTING) OF LP REAR PEDESTAL • RESTRETCHING OF FOUNDATION BOLTS OF LP REAR PEDESTAL • LP / GENERATOR REALIGNMENT • BEARING INSPECTION BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 210 MW TG SETS RESULT OF ABOVE WORKS AFTER CARRING OUT THE ABOVE MENTIONED CHECKS DURING NEXT OVERHAUL VIBRATION LEVEL FOUND REDUCED TO 25 MICRONS, 0-PK ON BEARING NO. 4 / 5 PEDESTAL PHASE DIFFERENCE WAS FOUND TO BE MINIMUM BETWEEN BEARING PEDESTAL BASE PLATE AND SECONDARY GROUTING BUT AFTER FEW DAYS OF OPERATION, • VIBRATION LEVEL STARTED INCREASING GRADUALLY AND TOUCHED ALARM VALUE OF 35 MICRONS, 0-PK • PHASE ANGLE DIFFERENCE WAS ALSO FOUND TO BE INCREASING BETWEEN BASE PLATE AND SECONDARY GROUTING BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 210 MW TG SETS ANALYSIS EPOXY GROUTING WAS INSUFFICIENT TO CURE THE VIBRATION PROBLEM ON PERMANENT BASIS AT THIS POINT OF TIME, CIVIL EXPERT ALSO CONDUCTED STUDIES ON FOUNDATION WHICH CONFIRMED THE BAD CONDITION SECONDARY GROUT BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA OF A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 210 MW TG SETS ACTION PLAN SUGGESTED: ONCE AGAIN THE PREVIOUS ACTION PLAN WAS SUGGESTED, THAT IS, REMOVAL OF LP REAR BEARING PEDESTAL AFTER BREAKING SECONDARY GROUTING COMPLETELY REPLACEMENT OF FOUNDATION BOLTS IN-SITU BALACNING OF GENERATOR ROTOR DISMANTLING OBSERVATION • DURING REMOVAL OF LP REAR PEDESTAL, SECONDARY GROUT MATERIAL WAS FOUND IN PIECES • OIL SEEPAGE WAS OBSERVED UNDER PEDESTAL BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) HIGH VIBRATION IN 210 MW TG SETS RESULT OF ABOVE WORKS AFTER THE ABOVE MENTIONED WORKS CARRIED OUT (INCLUDING IN-SITU BALANCING OF GENERATOR ROTOR) IN THE NEXT PLANNED OVERHAUL, VIBRATION LEVEL OF LP REAR AND GENERATOR FRONT IMPROVED IN BOTH VERTICAL AND AXIAL DIRECTION MACHINE IS RUNNING SATISFACTORILY SINCE THEN HENCE, LOOSENESS / VOID BETWEEN LP REAR PEDESTAL AND SECONDARY GROUTING WAS FOUND TO BE THE ROOT CAUSE OF HIGH LP REAR PEDESTAL AND GENERATOR FRONT VIBRATION BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) CONCLUSION HISTORY OF THE PROBLEM SHOULD BE GIVEN DUE WEIGHTAGE FOR ANALYSING THE PROBLEM ATTENTION SHOULD BE PAID TO INTERFACE AREAS BETWEEN MACHINE AND SUPPORTING SYSTEM / STRUCTURE ADDITION TO MAIN MACHINE BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA IN A.K.SINHA, DGM (TURBINE) TIPS FOR BETTER DIAGNOSTICS HISTORY OF MACHINE WITH RESPECT TO ITS DYNAMIC BEHAVIOUR SHOULD BE STUDIED REGULAR VIBRATION READING ON BEARING PEDESTAL AT PRESCRIBED LOCATIONS SHOULD BE TAKEN FOR ASSESSING THE TREND OF VIBRATION BEHAVIOUR ACCURATELY SHAFT VIBRATION IN TWO ORTHOGONAL DIRECTIONS SHOULD BE MEASURED FOR ORBIT ANALYSIS BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) RECOMMENDED LOCATIONS OF VIBRATION MEASUREMENTS ON BEARINGS AS PER ISO BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) RECOMMENDED LOCATIONS OF SHAFT VIBRATION MEASUREMENTS AS PER ISO Measuring Amplifier Measuring Amplifier 45O L PROXIMITY PICK-UP 45O SHAFT VERTICAL R OR L SHAFT R HORIZONTAL BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) TIPS FOR BETTER DIAGNOSTICS EVERY UNIT SHOULD HAVE KEY PHASOR ARRANGEMENT FOR VIBRATION ANALYSIS. SCANNING OF VIBRATION PRONE AREAS INCLUDING SYSTEM / FOUNDATION AROUND THE PROBLEMATIC AREA SHOULD BE CONDUCTED DEVIATION IN OPERATING PARAMETERS SHOULD BE RECORDED AND ANALYSED FOR THEIR EFFECT ON VIBRATION BEHAVIOUR BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) TIPS FOR BETTER DIAGNOSTICS RUN UP & RUN DOWN VIBRATION BEHAVIOUR SHOULD BE RECORDED FOR ALL BEARINGS AND SHAFT POSITIONS FOR REFERENCE WHICH CAN BE USED DURING TROUBLESHOOTING PRE-OUTAGE SURVEY SHOULD OVERHAUL FOR BETTER BE CONDUCTED PRIOR TO PLANNING OF ADDITIONAL ACTIVITIES / SPARES, IF REQUIRED RECORD OF PREVIOUS BALANCING AT SITE SHOULD BE MAINTAINED FOR REFERENCE PURPOSES BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) TIPS FOR BETTER DIAGNOSTICS LAST BUT NOT THE LEAST, DURING TROUBLESHOOTING, EVERY FEEDBACK / OBSERVATION NEEDS TO BE CONFIRMED. IF EVERYTHING IS ALRIGHT, VIBRATION PROBLEM WOULD NOT HAVE BEEN THERE. SO VERIFY EACH & EVERY POSSIBILITY AND CONFIRM FROM WRITTEN DOCUMENTS BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA A.K.SINHA, DGM (TURBINE) Thank you BHEL, POWER SECTOR – TECHNICAL SERVICES (HQ), NOIDA