Live Replacement of 400kv Busbar Insulators in Brasov

advertisement

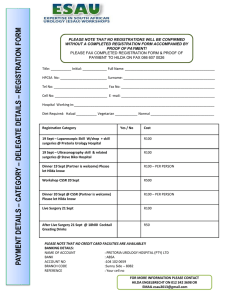

Live Replacement of 400kv Busbar Insulators in Brasov Substation Live Replacement of 400kv Busbar Insulators in Brasov Substation Dr. Ing. Stelian Alexandru Gal- CN Transelectrica SA- Romania Ing. Marius Nicolae Oltean- SC Smart SA- Romania Ing. Ioan Sevastre- SC Smart SA- Romania Ing. Lucian Brabete- SC Smart SA- Romania Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation General wiew The replacement of 400kV insulator strings was the first investement project realized in LW technology in a substation in Romania. The work was performed in bare hand method, using an aluminum lather. It was the proper technology for replacement of porcelain insulators with composite insulators. The work was performed by a crew from Smart Company- Sibiu Branch, and it lasted for four months. May, 2011 Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation Starting inputs : Brasov Substation Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation For the 400kV busbar, the connection to the devices is made of ACSR twin conductors, as follows: - Busbars- system 1 and 2, 2x970/228 mm2 ACSR - Transfer couple - 2x450/75 mm2 ACSR - Transversal couple and the connections to the devices 2x450/75 mm2 ACSR The substation is placed in: - Meteorological zone: II, - pollution zone: II; - From the wind action point of view: zone B; - From the snow action point of view: zone B; Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation Caracteristicile lanţurilor de izolatoare There are 6 types of insulator strings: - simple suspension string 400kV, 12 pieces - double suspension string 400kV, mounted in ”V”, 3 pieces - double suspension string 400 kV, mounted in „V”, equipped with yoke99 pieces. - double suspension string 400 kV, mounted in „V”, without yoke- 81 pieces. - double suspension string 400 kV, mounted in ”parallel”, with yoke- 9 pieces. - double suspension string 400 kV, mounted in „parallel”, without yoke15 pieces. Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation Busbar insulation in 400kV Brasov substation Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation LW method justification By analyzing power readigs on each breezeway (night gap, morning peak, day gap, evening peak) for two calendar days (working dayWendesday, resting day- Sunday) of each month (January-August 2005) on each 400kV bay, from Brasov substation, we had the following observations: - The transmission of active power usually works from the 400kV OHL Sibiu and Bradu to the 400kV OHL Gutinas and Darste - The transmission of reactive power usually works from the 400kV OHL Gutinas to Brasov to the other 400kV OHL Sibiu, Bradu and Dârste - One 250MVA 400/110kV transformer provides the power demand for 110kV consumers in Brasov substation, so any transformer (150MW) can be deenergised - The simultaneous deenergising of more 400kV OHL may influence the system’s stability and should be approved by the National Dispatch Center (NDC). Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation Conclusions on the deenergising of the equipment The replacement of suspension strings in Brasov substation may be done with deenergised equipment for the following works: - For the busbar system 2 – 15 Double Parallel Strings and 54 Double V string may be replaced - The consecutive deenergizing of T1 and T2 transformers (51 Double V Strings in total). Other works which will imply the deenergising of equipments are not possible to perform; the National Dispatch does not allow simultaneous withdrawal from service of more equipments The remaining works should only be done in LW technology (68% of the work volume). Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation Nr. Criterii de comparatie Executia lucrarilor cu retragerea Executia lucrarilor crt. ( apreciere ) din exploatare a instalatiei cu tehnologia LST 1 Durata totala de executie a lucrarilor 81 zile lucratoare a 8 ore 135 zile lucratoare a 8 ore cu 1 din care : cu 2 echipe a cate 4 electricieni echipa LST ( 9 electricieni )+ 2 zile - fara retragerea din exploatare 6 zile 135 zile - cu retragerea din exploatare a unor instalatii 56 zile 2 zile - cu retragerea totala a statiei 19 zile - 2 Costul lucrarilor ( fara TVA ) 1.461.201,00 RON 1.412.649,00 RON 3 Conditionarea executiei lucrarilor de Aprobarea DEN pentru retragerea Obtinerea mai facila a obtinerea aprobarilor DEN pentru din exploatare a unor instalatii aprobarii DEN pentru executia lucrarilor retragerea din exploatare a unor se va obtine foarte dificil sau pentru instalatii de 400 kV unele chiar nu se va da Conditionarea executiei lucrarilor de Conditii meteo mai permisive Conditii meteo mult mai restrictive - inlocuirea lanturilor de izolatoare Numai inlocuirea lanturilor de izolatoare 4 conditiile meteo 5 Tipul lucrarilor care se pot executa - inlocuirea cordoanelor de legatura la aparataje si a clemelor de derivatie - alte lucrari 6 Continuitatea in alimentarea Sunt necesare numeroase manevre de Se poate asigura continuitatea in consumatorilor retragere din exploatare a unor alimentarea consumatorilor instalatii care afecteaza continuitatea in alimentarea consumatorilor 7 Pierderi de energie ( putere ) in Pierderi suplimentare datorita Cele existente in schema normala retelele de 400 si 110 kV abaterilor de la schema normala de functionare Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation Executed Works - only the insulated strings were replaced, (the tension clamps and the yokes remained irretrievable); -The insulator strings were formed with composite insulators Hi Lite EPG 400-160-4203-22, 95-NN20 type (manufactured by Eximprod Group Buzau under Chance license); -for the string make-up, we reused the existing fittings (yokes, ball eyes OSDr-20) and the compression tension clamps, - the new mounted strings were built-up so that the length of a new string with spreader and a new string without spreader to be the same with the length of an existing string, with or without spreader. Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation Before After Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation LW technology The works were complied with Transelectrica’s Operational Procedure TEL 07.12/2003 „Performing Live Working in Transelectrica’s High Voltage Equipments” and the technical procedures belonging to S.C. Smart S.A. The basic working team consisted of: - A LW foreman with the authorization type I 3T. - Eight (8) LW workers with the authorization type I 1T. The work was executed by the bare hand method Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation It is necessary that the equipment is in Special Exploitation Regime (SER): -verifying that the Differential Busbar Protection is in operation; -ensuring radio or telephone connections between the working area and the dispatch center; -manually connecting to energize the equipment, can be done only with the agreement of the foreman; - it is forbidden to operate the switchgears in the substation, as this may affect the status of the busbar. Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation Minimum Approach Distances Rated VoltageUn [kV] Voltage distance dt [m] Safety distance dp [m] Minimum distanceD [m] 400 2,00 0,50 2,50 Weather Conditions It is forbidden to start the work in the following weather conditions: - Showers (rain, snow, drizzle, hail,) or relative humidity higher than 80%, - Thick fog, - Strong wind (over 9.5 m/s), - Lightning (storm) in the working area. Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation Risk Analysis and Prevention Measures -The foreman owns: - the Working Authorization (ALST) - the Technical Instruction (SMART-IT-LST 66) - the Specific Safety Instruction (SMART-ISSM-66). The foreman - ensures that the equipment identifying conditions and the access conditions in the working area are respected. -indicates the way and the route for the workers to climb on the portal and the way to manipulate the access tools - is supervising the working area throughout the whole procedure. Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation Work Preparation The foreman identifies the equipment on which the crew will work and compares the working area with the one mentioned in the LW authorization. The foreman identifies the weather conditions in the working zone. The tools and the devices are prepared on rack and on the canvas. The insulating sections of the tools are cleaned and greased with silicone oil. The 3 workers which will work at height will dress with electro conductive suits, anti-UV goggles, electro conductive boots and climbing systems. The working tools and the safety devices are checked. The foreman also checks the workers’ physical and psychical condition. The foreman is distributing the specific tasks for each worker and is reminding them of the work method and the risks which may occur. He is checking that things are well understood by the crew. The workers are signing the papers. Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation Working Method Two workers are climbing on the crossarm. They will carry up and mount the strain carriers on the crossarm. Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation -The access ladder is mounted on the conductors. - The mobile part of the ladder is descended on the ground. -The worker climbs from the ground to the conductors, on the ladder. He is fastening the mobile part of the ladder to the firm one. Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation The workers are mounting the strain carrier assembly. They are relieving strain from the insulating string, dismantling the string. The insulating string is descended to the ground. The new insulation strig is raised and mounted. The strain is relieved on strain carrier. Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation Conclusions It was for the firs time that a designer has thoroughly analyzed the comparative costs for an investement project. When starting a project it is mandatory to take into account the costs involved by the working teams and by manipulation of devices, as well as the costs of congestions, own technological consumption and maneuvers. One shouldn’t forget the advantages of network reliability, the increase of work safety, less operating conditions demands for the transmission network and the dispatch demands on the redundancy. This was the first LW technology project performed in a Romanian substation. Sept, 2011, Salta CITTES 2011 Live Replacement of 400kv Busbar Insulators in Brasov Substation THANK YOU FOR YOUR KINDLY ATTENTION ! Sept, 2011, Salta CITTES 2011