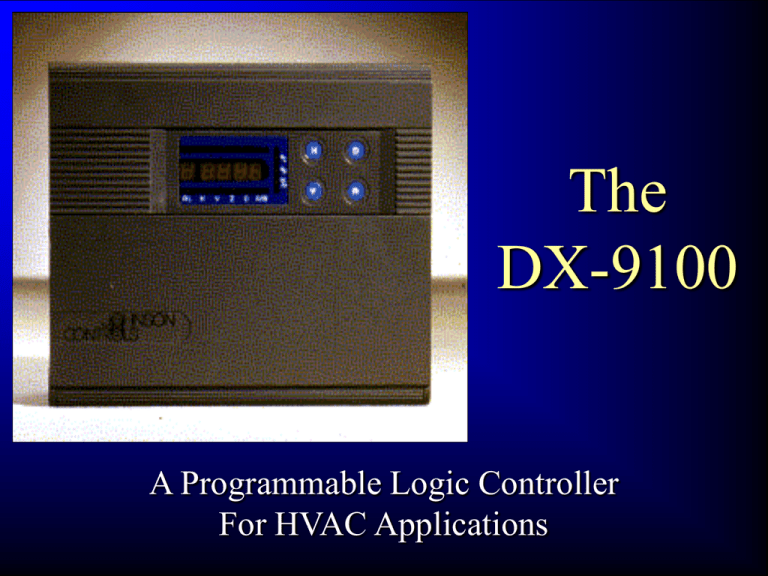

8 Analog Outputs

advertisement

The DX-9100 A Programmable Logic Controller For HVAC Applications DX-9100 Hardware ANALOG OUTPUTS 8+8 24 VAC 3+3 Terminal Cover 35 DIGITAL INPUTS 8+8 TRIAC OUTPUTS 6+6 RD X D Y XT Z A TD XT Omega Rail 35 mm/1 3/8 in. 12 5 m m AL C DIN/EN 50022 K A/M E ESC RS232 XT N2 ANALOG INPUTS Terminal BUS BUS 12+12 Cover D emdxt10 DIN rail mounted backplate for I/O connections DX-9100 Hardware Bus connector (provided) HOT GND NEUT RS485 EXP A B CA B C EXP AI1 AI2 AI3 AI4 ADDRESS EXP +15V max AO7 min TR9100 FUSE max AO8 min XT9100 XP9102 D O1 D O2 D O3 D O4 EXP DO1 DO2 DO3 DO4 DO5 Power RD TD EXP DO6 DO7 DO8 XP9103 FUSE COM 24V TR COM 24V XT AI5 AI6 V AO7 AO8 XP1 C 24V DO5 DO6 DO 7 DO8 XP2 emtxt-4 Expansion modules add to point capacity DX-9100 Hardware Basic controller supports 30 I/O points 8 Digital Inputs (Voltage-free contacts) 8 Analog Inputs (0-10VDC, 0-2-mA, 1000 6 Digital Outputs (Isolated triac, 24VAC) 8 Analog Outputs (0-10VDC, 4-20mA) Expansion Modules add up to 64 I/O 6 AI / 2 AO 4 DI / 4 DO 8 DO 8 DI DX-9100 Hardware RS-485 (polling) or LonWorks™ (peer to peer) bus to allow connection to supervisory controller or modem dialer (RS-485 only) RS-485 bus connects basic controller to up to eight expansion modules Port for service module connection RS-232 port for connection to PC with graphical programming tool DX-9100 Software Control Menu Box Minimize/Maximize Buttons Title Bar GX9100 - [Untitled] File Edit View Action Controller Window Menu Bar Help Tool Bar AI1 2 Analog AI2 Outputs AO1 AO2 DO3 AI3 AI4 8 Analog AI5 Inputs AI6 DO4 6 Digital Outputs DO5 DO6 AI7 DO7 AI8 DO8 DI1 DI2 DI3 DI4 DI5 8 Digital Inputs Scroll Bar DI6 DI7 DI8 09:19:37 Tuesday, July 05, 1994 gxscre2 Graphical programming environment place modules and draw connections DX-9100 Software Points Field I/O points Data points (8 analog, 32 binary) Shared points (16 AI, 8 DI, 16AO, 8 DO) 12 Definable Function Modules plus Ladder Logic 8 Time Schedules 2 Adaptive Optimal Start Algorithms DX-9100 Software Analog Inputs User Name / Description Input Signal / Range Measurement Units Enable Square Root Enable Alarms Alarm Limits Filter Value Analog Outputs User Name / Description Type of Output Source (numeric / incremental) High / low range Forcing mode / level Hold / Auto on power-up Output limits / enable limits DX-9100 Software Digital Inputs User Name / Description Prescaler (used with pulse count only) Output limits / enable limits PAT stroke time / DAT cycle time PAT deadband / DAT minimum on/off time Digital Outputs User Name / Description Type of Output Source (numeric / incremental) Feedback source High / low range Forcing mode / level Hold / Auto on power-up DX-9100 Software HHDA LLDA HDA OB@ OB PB@ PB PV@ PV RV@ RV RS@ RS LDA CMH CML EF STA SOF HOLD f=(PB,TI,TD,EDB) OCM OUTPUT LSP REM OF@ OF SB@ SB RA@ RA EF@ EF F (Modes, BSB,BOF) CMP Supervisory Modes: Limiting And Forcing W SP COMPUTER HIL LOL STAE SOFE START UP SHUT OFF HOLD emdxt23 Powerful PID control algorithm DX-9100 Software Proportional or ON/OFF action Single or Dual (heat/cool) option Deviation alarms Single Proportional Module BOF BOF Output BSB Output PB 100 % High-high High Low Low-low PB BSB 100 % HIGH LIMIT (HIL) HIGH LIMIT (HIL) LOW LIMIT (LOL) 0% LOW LIMIT (LOL) 0% Process Variable Process Variable Off Standby Off Standby Comfort Comfort emdxt24 Dual ON/OFF Module BOF1 Output BSB1 DIF1 BOF2 DIF2 BSB2 100 % Process 0% Variable Off Off Standby Standby Comfort Comfort emdxt32 DX-9100 Software Average* Minimum* Maximum* Line Segment Psychometric (English or Metric)* Inputs are temperature, humidity, atmospheric pressure Output is enthalpy, wet bulb, dew point Input Selector (4 channel)* Calculator (+, -, x, * * Output range can be limited DX-9100 Software Timer Function Pulse, Triggerable Pulse, On Delay, Off Delay, On Delay With Memory Totalization DI event, DI time, AI consumption Comparator (with differential) Greater than, less than, equal, rate of change DX-9100 Software Sequencer module Input source is numeric or incremental Output is 8 / 16 DO Mode is last on / first off, first on / first off, equal run-time, binary code Minimum on-time, minimum off-time, interstage delays and maximum cycles per hour can be specified Load factor for each stage used to produce interstage analog output DX-9100 Software Real-time clock Year, month, day of month, hour, minute, second, day of week (Mon … Sun + Holiday) Daylight savings Time schedules Start time, stop time, days of week DX-9100 Software Module updates building factor. Temperature Control Range (Comfort Zone) Zone Air Setpoint (SP) delta Time Warmup Curve delta Temp Purge Time Zone Air Temperature (ZT) Purge Time Maximum Startup Time Start Plant (0SnOUT=1) (0SnPRE=1) (TSnOUT=0) Occupancy (TSnOUT=1) (0SnPRE=0) (0SnOUT=1) Time emdxt21a Adaptive Optimal Start calculates minimum time to reach setpoint DX-9100 Software Ladder Logic Control Module Load AND OR AND Block OUT SET COS Load NOT AND NOT OR NOT OR Block OUT NOT RESET END DX-9100 Software DI1 DI3 XT2DI1 B XT2DI2 PM1SOF LRS1 L L DI2 XT4DI5 XT4DI6 XT4D17 L D17 L LRS2 D18 COS SET LRS1 DCO1 L LRS2 RST emdxt57 Eight pages, each page with eight lines of eight instructions DX-9100 Keypad Operation 1 2 3 K 4 5 6 7 X Y Z D A/M K E 8 RD TD AL XT + - X D Y XT Z A A/M ESC Powerful, yet easy to use interface on each DX-9100 controller DX-9100 Keypad Operation Display / modify time schedules Display / modify date / time / holidays Display AI point value / alarm status Display / modify AI alarm limits Display DI status Display / modify DI counter value Display / modify analog / digital outputs Display / modify analog / digital data DX-9100 Keypad Operation Display / modify P, I, D, Bias terms for PID control loop Display / modify control action, bias, differential terms for ON/OFF control Display / modify output and run-time for sequencer module Display / modify value of totalization module