Plunger Poster

advertisement

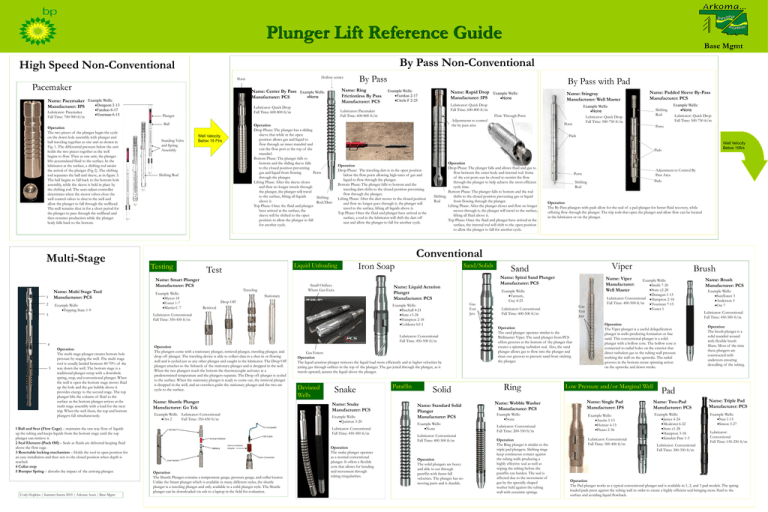

Plunger Lift Reference Guide By Pass Non-Conventional High Speed Non-Conventional Hollow center Ports Pacemaker Fazekas 6-17 Yourman 6-15 Operation The two pieces of the plunger begin the cycle on the down hole assembly with plunger and ball traveling together as one unit as shown in Fig. 1. The differential pressure below the unit holds the two pieces together as the well begins to flow. Then as one unit, the plunger lifts accumulated fluid to the surface. In the lubricator at the surface, a shifting rod awaits the arrival of the plunger (Fig 2). The shifting rod separates the ball and sleeve, as in figure 3. The ball begins to fall back to the bottom-hole assembly, while the sleeve is held in place by the shifting rod. The auto-adjust controller determines when the motor valves close the well control valves to shut in the well and allow the plunger to fall through the wellhead. The well remains shut in for a short period for the plunger to pass through the wellhead and then resumes production while the plunger body falls back to the bottom. Multi-Stage Lubricator: Quick Drop Fall Time: 600-800 ft/m Plunger Ball Standing Valve and Spring Assembly Well Velocity Below 15 Ft/s Shifting Rod 1 2 Example Wells: Topping State 1-9 Operation The multi stage plunger creates bottom hole pressure by staging the well. The multi stage tool is usually landed between 40-70% of the way down the well. The bottom stage is a traditional plunger setup with a downhole spring, stop, and conventional plunger. When the well is open the bottom stage moves fluid up the hole and the gas bubble above it provides energy to the second stage. The top plunger lifts the column of fluid to the surface as the bottom plunger arrives at the multi stage assembly with a load for the next trip. When the well shuts, the top and bottom plungers fall simultaneously. 1 Ball and Seat (Flow Cage) – maintains the one way flow of liquids up the tubing and keeps liquids from the bottom stage until the top plunger can retrieve it. 2 Seal Element (Pack Off) – Seals as fluids are delivered keeping fluid above the flow cage. 3 Resettable locking mechanism – Holds the tool in open position for an easy installation and then sets to the closed position when depth is reached. 4 Collar stop 5 Bumper Spring – absorbs the impact of the arriving plunger. Cody Hopkins | Summer Intern 2010 | Arkoma Asset | Base Mgmt Name: Stingray Manufacturer: Well Master Lubricator: Quick Drop Fall Time: 600-800 ft/m Adjustments to control the by pass area Operation Drop Phase: The plunger has a sliding sleeve that while in the open position allows gas and liquid to flow through an inner mandrel and exit the flow port at the top of the mandrel. Bottom Phase: The plunger falls to bottom and the sliding sleeve falls to the closed position preventing gas and liquid from flowing Ports through the plunger. Lifting Phase: After the sleeve closes and flow no longer travels through the plunger, the plunger will travel to the surface, lifting all liquids Shifting above it. Rod/Dart Top Phase: Once the fluid and plunger have arrived at the surface, the sleeve will be shifted to the open position to allow the plunger to fall for another cycle. Name: Padded Sleeve By-Pass Manufacturer: PCS Example Wells: None Lubricator: Quick Drop Fall Time: 500-750 ft/m Flow Through Ports Ports Shifting Rod Example Wells: None Lubricator: Quick Drop Fall Time: 500-750 ft/m Ports Pads Well Velocity Below 10ft/s Pads Operation Drop Phase: The traveling dart is in the open position below the flow ports allowing high rates of gas and liquid to flow through the plunger. Bottom Phase: The plunger falls to bottom and the traveling dart shifts to the closed position preventing flow through the plunger. Lifting Phase: After the dart moves to the closed position and flow no longer goes through it, the plunger will travel to the surface, lifting all liquids above it. Top Phase: Once the fluid and plunger have arrived at the surface, a rod in the lubricator will shift the dart off seat and allow the plunger to fall for another cycle. Operation Drop Phase: The plunger falls and allows fluid and gas to flow between the outer body and internal rod. Some of the exit ports can be closed to restrict the flow through the plunger to help achieve the most efficient cycle time. Bottom Phase: The plunger falls to bottom and the rod Shifting shifts to the closed position preventing gas or liquid Rod from flowing through the plunger. Lifting Phase: After the plunger closes and flow no longer moves through it, the plunger will travel to the surface, lifting all fluid above it. Top Phase: Once the fluid and plunger have arrived at the surface, the internal rod will shift to the open position to allow the plunger to fall for another cycle. Testing Example Wells: Myton 18 Foster 1-7 Martin C 7 Liquid Unloading Test Traveling Iron Soap Small Orifices Where Gas Exits Sand/Solids Adjustment to Control By Pass Area Pads Ports Shifting Rod Operation The By-Pass plungers with pads allow for the seal of a pad plunger for better fluid recovery, while offering flow through the plunger. The trip rods that open the plunger and allow flow can be located in the lubricator or on the plunger. Drop Off Gas Exit Jets Example Wells: Paschall 4-21 State c3-28 Hampton 2-18 Coblentz b3-1 Retrieval Operation The plungers come with a stationary plunger, retrieval plunger, traveling plunger, and drop off plunger. The traveling device is able to collect data in a shut-in or flowing well and is cycled just as any other plunger and caught in the lubricator. The Drop Off plunger attaches to the fishneck of the stationary plunger and is dropped in the well. When the two plungers reach the bottom the thermocouple activates at a predetermined temperature and the plungers separate. The Drop off plunger is cycled to the surface. When the stationary plunger is ready to come out, the retrieval plunger is dropped in the well, and an overshot grabs the stationary plunger and the two are cycle to the surface. Name: Shuttle Plunger Manufacturer: Go Tek Example Wells: Lubricator: Conventional Orr 2 Fall Time: 350-450 ft/m Gas Enters Operation The liquid aeration plunger removes the liquid load more efficiently and at higher velocities by jetting gas through orifices in the top of the plunger. The gas jetted through the plunger, as it travels upward, aerates the liquid above the plunger. Deviated Wells Snake Name: Snake Manufacturer: PCS Example Wells: Quinton 3-20 Lubricator: Conventional Fall Time: 450-500 ft/m Operation The Shuttle Plunger contains a temperature gauge, pressure gauge, and collar locator. Unlike the Smart plunger which is available in many different styles, the shuttle plunger is a traveling plunger and only available in a solid plunger style. The Shuttle plunger can be downloaded via usb to a laptop in the field for evaluation. Operation The snake plunger operates as a normal conventional plunger. It offers a flexible core that allows for bending and movement through tubing irregularities. Paraffin Solid Name: Standard Solid Plunger Manufacturer: PCS Example Wells: None Lubricator: Conventional Fall Time: 400-500 ft/m Operation The solid plungers are heavy and able to cut through paraffin with faster fall velocities. The plunger has no moving parts and is durable. Viper Sand Name: Spiral Sand Plunger Manufacturer: PCS Name: Liquid Aeration Plunger Manufacturer: PCS Lubricator: Conventional Fall Time: 450-500 ft/m 4 5 Name: Rapid Drop Example Wells: Manufacturer: IPS None Example Wells: Fazekas 2-17 Circle F 2-25 Lubricator: Pacemaker Fall Time: 600-800 ft/m Lubricator: Conventional Fall Time: 350-450 ft/m 3 By Pass with Pad Conventional Name: Smart Plunger Manufacturer: PCS Name: Multi Stage Tool Manufacturer: PCS By Pass Name: Ring Frictionless By Pass Manufacturer: PCS Name: Center By Pass Example Wells: None Manufacturer: PCS Name: Pacemaker Example Wells: Dungeon 2-13 Manufacturer: IPS Lubricator: Pacemaker Fall Time: 700-900 ft/m Base Mgmt Name: Viper Manufacturer: Well Master Example Wells: Varnum, Guy 4-25 Gas Exit Jets Lubricator: Conventional Fall Time: 400-500 ft/m Operation The sand plunger operates similar to the Wellmaster Viper. The sand plunger from PCS offers grooves at the bottom of the plunger that creates a spinning turbulent seal. Also, the sand plunger allows gas to flow into the plunger and clean out grooves to prevent sand from sticking the plunger. Ring Name: Wobble Washer Manufacturer: PCS Example Wells: None Lubricator: Conventional Fall Time: 200-350 ft/m Operation The Ring plunger is similar to the triple pad plungers. Shifting rings keep continuous contact against the tubing walls producing a highly effective seal as well as wiping the tubing before the paraffin can harden. The seal is affected due to the movement of gas by the specially shaped washer held against the tubing wall with eccentric springs. Brush Example Wells: Smith 7-20 State c2-28 Dunagan 1-13 Lubricator: Conventional Hampton 2-18 Fall Time: 400-500 ft/m Yourman 7-15 Foster 1 Operation The Viper plunger is a useful deliquification plunger in wells producing formation or frac sand. This conventional plunger is a solid plunger with a hollow core. The hollow core is connected to radial holes on the exterior that direct turbulent gas to the tubing wall pressure washing the wall on the upstroke. The radial grooves in the bottom create spinning action on the upstroke and down stroke. Low Pressure and/or Marginal Well Name: Single Pad Manufacturer: IPS Example Wells: Austin 5-13 Heitner 4-13 Picaro 2-36 Lubricator: Conventional Fall Time: 300-400 ft/m Name: Brush Manufacturer: PCS Example Wells: Sunflower 3 Anderson 3 Orr 7 Lubricator: Conventional Fall Time: 450-500 ft/m Operation The brush plunger is a solid mandrel wound with flexible brush fibers. Most of the time these plungers are constructed with undercuts ensuring descalling of the tubing. Pad Name: Two-Pad Manufacturer: PCS Example Wells: James 4-24 Mcalester 6-22 State c1-28 Hampton 3-18 Kinnkin Pate 1-3 Lubricator: Conventional Fall Time: 300-350 ft/m Name: Triple Pad Manufacturer: PCS Example Wells: Nan 1-15 Simon 3-27 Lubricator: Conventional Fall Time: 150-250 ft/m Operation The Pad plunger works as a typical conventional plunger and is available in 1, 2, and 3 pad models. The spring loaded pads press against the tubing wall in order to create a highly efficient seal bringing more fluid to the surface and avoiding liquid flowback. Plunger Lift Reference Guide Life Cycle of the Well Base Mgmt Common Plunger Lift Setup 2-3/8", 4.7 ppf Tubing (ID 1.995") Stage 1: Well is flowing above critical rate with all flow in mist flow, no liquid gradient at anytime. Flow Rate (Mcf/day) • No deliquification Required Stage 2: Well begins to bubble and slug when rates fall below critical. •If velocity > 15ft/s the well is a candidate for a high speed non-conventional plunger such (i.e. pacemaker). •The wells normally still have high Gas to Liquid Ratios, meaning that they do not require and shut in time. The high GLR also allows for flow of gas to sales after the arrival of the plunger at the lubricator (after-flow). •The after-flow allows the two pieces of the plunger to distance themselves, creating a large by-pass area and reducing shut-in time. The reduced shut-in time, means more trips per-day and more water brought to surface. Stage 3: Well begins to have difficulty maintaining seal due to velocity getting below 15ft/s but greater than 10ft/s. •Candidate for by-pass style, non-convention al plunger 2000 1800 1600 1400 1200 1000 800 600 400 200 0 In this range for actual production, the recommendation would be to install a high speed non-conventional plunger (i.e. pacemaker). At lower flow rates (below 10ft/s), a conventional style of plunger would be recommended 0 •These wells may still require a lot of trips to remain unloaded, but need little or no flow time after each trip. Pacemaker wells running with significant off time or wells that have just begun “slug – flow” conditions are indicators of this life cycle stage. 200 400 600 800 Critical Flow Stage 4: 15 ft/s 10 ft/s Poly. (Critical Flow) 3-1/2" Tubing (ID 2.992") 2-7/8" Tubing (ID 2.441") Well has velocity < 10ft/s Stage 5: Well has such low bottom-hole pressure that a conventional plunger doesn’t work. 2000 Flow Rate (Mcf/day) •The conventional plunger comes in many different styles in order to adapt to well conditions such as: sand, fluid load, tubing irregularities, or scale. Flow Rate (Mcf/day) •Candidate for conventional style plunger (i.e. iron soap, pad, viper, etc). •This stage of the life cycle occurs when GLR decrease and pressure build up is required to trip the plunger. 1500 1000 500 0 •Candidate for multi stage plunger 0 •This is the final stage in a wells life, when the GLR drops so low that a conventional plunger won’t cycle. •The Multi-Stage plunger stages the well into parts and creates bottom hole pressure by reducing the distance any single plunger has to travel. 100 200 300 400 500 600 700 800 900 2500 2000 1500 1000 500 0 0 1000 100 200 Critical Flow 15 ft/s 10 ft/s 300 400 500 600 Poly. (Critical Flow) Critical Flow 15 ft/s 10 ft/s Poly. (Critical Flow) Lubricators Bumper Spring Assembly The lubricator is installed on top of the tree or master valve to cushions the plunger upon arrival into the wellhead to prevent damage. The spring inside absorbs the impact of the plunger. The catcher holds the plunger in place and allows for safe removal of the plunger or inspection. All lubricators are available with on or two outlets. Fazekas #5 PCS Conventional Lubricator IPS Pace Maker Lubricator Pace Maker Setup Conventional Setup Top View Cap Lubricator Cap Spring Master Valve Pace Maker text is right side up, indicating it is for use with the pace maker Bumper plate Spring Bumper plate Spring Threaded to Remove Plunger Outlet Shifting Rod Pace Maker text is upside down Threaded to Remove Plunger Outlet Catcher Catcher (once plunger is at the surface, it can be caught by shifting the handle) Cody Hopkins | Summer Intern 2010 | Arkoma Asset | Base Mgmt 700 Wellhead Pressure (psi) Wellhead Pressure (psi) Surface Equipment Controller / Motor Valve 1000 Wellhead Pressure (psi) •These non-conventional plungers can reach the bottom almost as quick as the pacemaker, but do not require any after- flow since it is one piece. Flow Line to Sales In this range, the recommendation would be to run a bypass style nonconventional plunger In this set-up the shifting rod is inserted into the spring. During the operation the spring and rod will be assembled as shown inside the lubricator. Outlet Catcher Ledges to hold the spring or shifting rod in the lubricator. To change from the Pace Maker setup to this conventional setup, the upper portion must be unscrewed and flipped around. The shifting rod also must be pulled out and a second bumper spring ( not pictured) must be placed inside the existing spring. PCS Bumper Spring Features: • Standard Fishing Neck • Tapered body • Spring -Helps prevent down hole damage due to plunger fall 4. Mandrel 5. Standing Valve Cage - ball and seat are used to hold liquid in the tubing 6. “No-Go” -prevent fall through seating nipple 7. Cups -sits in the seating nipple 8. Locking Mechanism 7. Orifice - allows flow through the bumper spring assembly Standing valves