CJS Coiled Tubing Supply June 2009

advertisement

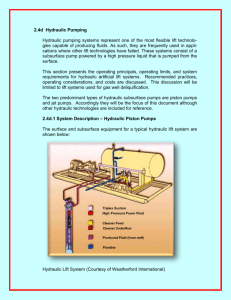

CJS Production Technologies Inc. “Committed to Production Solutions for the Energy Industry” Innovative Energy Technology July 2014 CJS FlatPak / ArmorPak Umbilical Is ... An coiled tubing umbilical system containing tubes to convey, actuate and receive production from downhole electric and hydraulic submersible pumps. A system that can optionally include components to inject chemicals and receive downhole data. Used to facilitate low maintenance artificial lift from conventional, deviated and horizontal wells Robust and versatile enabling the umbilical to convey artificial lift systems for permanent production and to perform wellbore cleanouts Conveyed using conventional coiled tubing units Patented and patent pending technology ArmorPakTM All metal banded umbilical for deeper well depths and thermal well applications Fatigue and stress testing evidences ArmorPak will extend umbilical life eliminating potential for wear on the outer thermoplastic jacket Manufacturing is performed in Canada facilitating improved delivery time frames FlatPak is Conveyed With ... Conventional coiled tubing units Modified arch rollers and injector components Specialized snubbing & blowout prevention systems CT unit modifications to permit fluid pumping operation Modified wellhead apparatus including modified tubing hanger Typical Completion Stack FlatPak / ArmorPak Field Service Operations FlatPak / ArmorPak Supports ... Hydraulic Submersible Piston Pumps- HydraPak HSP Hydraulic Progressive Cavity Pumps – HydraPak PCP Modified Jet Pumps – JetPak & JetVak Electric Submersible Pumps – HydraPak ESP HydraPak HSP - Rod-less Artificial Lift Advantages • Eliminates service rigs cutting maintenance costs substantially • Pumps can be run under “live” well conditions using conventional coiled tubing units • Can include downhole sensors for pressure monitoring • Operates in vertical or horizontal (90 degrees) and deviated environments • Eliminates rod and tubing wear reducing pump downtime • Pumps natural gas very effectively and operates in a “pumpedoff” state – no gas locking • Handles sand / formation fines via sand screen • Can be used to pump oil or dewater natural gas wells • Scalable from .1 m3 to 25 M3 per day depth dependent • Versatile OD of 3.6” • Versatile Power Source Electricity, Propane, Field gas, Wind/Solar • Effective heat tracing system for surface piping HydraPak HSP - Rod-less Artificial Lift • The pump is a positive displacement piston style device • Pump assembly consists of two main chambers: • • • Hydraulic Power End Production Pump End The adjacent chambers are linked to each other via a rigid piston and rod assembly with piston and seals on each end (one in the production barrel and one in the hydraulic power end barrel) • Three lines are required from surface: One for production and two for hydraulic power fluid • A complete pump stroke is comprised of the following: • Intake Stroke (left image) • • • • • The piston down-stroke hydraulic line is energized and move the power end piston down by pushing from the top The wellbore fluid enters the chamber from above the production end piston Cooling fluid (produced fluid) is displaced from the chamber below the production piston and flushes the intake screen At the end of piston stroke the WanFlu valve on the surface unit switches to the piston up stroke hydraulic line Production Stroke (right image) • • With the production barrel full the piston up-stroke hydraulic line is energized The hydraulic power piston and consequently the production piston are displaced upward • In turn the production fluid is displaced from production barrel, above the discharge check valves and into the production tubing • Behind the production piston a new volume of flush line fluid is filling the production barrel for the next stroke HydraPak HSP - Rod-less Artificial Lift • • • • The surface unit supplies the hydraulic power to the submersible pump and is comprised of: • Prime Mover (Natural gas engine, Electric motor, Solar Power) • Hydraulic pump coupled to prime mover • WandFlu valve for alternately energizing the hydraulic oil lines • Hydraulic Oil Storage Tank • Electronic Controls Chassis for this unit will likely serve as the chassis for the TDSP surface unit General purpose classification meaning that the surface unit is placed more than 7-m radial distance from the wellhead HydraPak HSP HydraPak HSP Case Study Alberta Shallow Gas Well HydraPak Rod-less PCP HydraPak PCP Rod-less Artificial Lift Advantages • Eliminates service rigs cutting maintenance costs substantially • Pumps can be run under “live” well conditions using conventional coiled tubing units with specialized running equipment • Operates in vertical or horizontal (90 degrees) and deviated environments; • Eliminates rod and tubing wear and pump downtime • Creates a greater variety of well service options to deal with solids production etc. • Can include downhole pressure monitoring sensors to eliminating well “pump off” and protect the pump • Can include chemical injection at the pump intake treating torque, scale, wax, H2S and corrosion • Can be used pump oil and dewater natural gas wells HydraPak PCP Technology Overview • System developed by CJS Q4 2010 • System incorporates CJS FlatPak / ArmorPak and downhole hydraulic drive motor delivering 400 ft/lbs of continuous torque; 800 Ft/lbs intermittent torque • First systems run in Canada into 800 meter CHOPS wells near Lloydminster • Version 2 of HydraPak system proves a minimum 8 months runtime equivalent to pump life • System can accommodate down to 5.5” OD casings with future designs for 4.5” OD casings • New 1200 ft/lb torque motor presently in development HydraPak PCP Field Installations HydraPak PCP Pumping Rate vs. Depth - 5M3 from 1800 meters @ pump speeds approximating 100 to 200 rpm HydraPak PCP Pumping Rate vs. Depth - 11M3 from 1800 meters @ pump speeds approximating 70 to 180 rpm HydraPak PCP Case Study HydraPak PCP 800 Meter Alberta Heavy Oil Well 7 6 5 4 3 2 1 0 Heavy Oil Production M3/D Production Month 1 2 3 4 5 6 ArmorPak Conveyed ESP •Coiled tubing dual CJS ArmorPak that conveys electric submersible pumps •Facilitates live well installation and subsequent service of electric pumps •Substantially reduces servicing time, cost and lease footprint •Eliminates requirement for service or work over rigs •Eliminates cable spool unit when conveying electric pumps •Reduced equipment mobilization and associated cost •Eliminates tubing connections reducing corrosion points •First system to be installed in August 2014 for Conoco in Alaska ArmorPak ESP ArmorPak Conveyed ESP – Termination and Hanger ArmorPak Conveyed ESP - Field Test Dry Run June 2014 ArmorPak Conveyed ESP - BOP Testing June 2014 “JetVak” A Hydraulic Wellbore Cleanout System JETVAK • Wellbore cleanout system developed in 2009 by CJS and partners • The primary function of this technology is to create a low pressure environment in the well bore to pump the fluid and/or solids to surface • Hundreds of jobs performed with the JetVak cleanout system since development of this technology • System methodology increases post cleanout well production via evacuation of near wellbore fluid and solids blockages. Typical JetVak Cleanout Husky CHOPS Hz well cleanout with JetVak •1550 meter measured depth •0.8m3 sand •Recovered 30%; 3.5m3 of fluid • • This well was 1yr old and did not produce Post cleanout the well produced at 10m3/day FlatPak Application History • Canada & United States - over one hundred 800 to 2,500 meter HydraPak HSP & HydraPak PCP pump installations - Installations including vertical, deviated and horizontal oil and natural gas wells - Pump run lives up to many years - hundreds of 1,000 to 3,000 meter vertical & horizontal well JetVak cleanouts - horizontal reach in horizontal leg to over 2,000 meters • China - HydraPak PCP pump landings in coal bed methane wells • Oman - JetVak cleanouts to take place in 2014 Operations for companies such as Shell, Conoco, Devon, Total, Nexen, Suncor, Husky, Encana CJS PRODUCTION TECHNOLOGIES “Committed to Production Solutions for the Energy Industry” Scott Kiser – Business Development Director – Calgary, AB, Canada, scott@cjsflatpak.ca (403) 463-4740