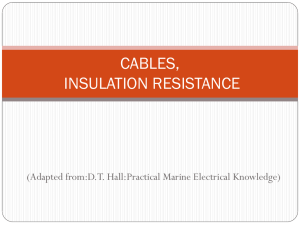

Thermo-Hanf - AHK Slowenien

advertisement

Speaker: Blaž Primožič Hock GmbH & Co. KG – The Company 1996 The cultivation of hemp varieties with a low THC level is allowed again in Germany Product idea by Carmen Hock-Heyl 1997 Development of Thermo-Hanf® 1998 Thermo-Hanf® gains the technical approval Hock GmbH is created in Stutensee and consists of 3 employees Thermo-Hanf® is produced externally, according to the specifications of Carmen Hock-Heyl 1999 Phase of introduction on the market, participation on numerous fairs and training of retailers, craftsmen, architects and end consumers 2003 Renate Künast and Carmen Hock-Heyl initiate an end consumer subvention for insulation made of “renewable raw materials“ Acquisition of the production facility in Nördlingen 2004 Extension of the distribution network and development of foreign markets 2005 Relocation of the complete distribution to Nördlingen Hock GmbH & Co. KG – The Company 2006 2007 2008 2009 2010 2011 2012 R+D project with Hock, Deutsche Bundesstiftung Umwelt (German federal environment foundation) and Fraunhofer Institute for the development of a completely biogenous insulation Extension of the sales team Start-up of our own impregnation line, to impregnate hemp fibres with soda for fire protection Acquisition of the Heraflax production line Begin of dismantling in Simbach and reconstruction in Nördlingen Expiry of the end consumer subvention Triplication of the production capacity Significant price decrease for Thermo-Hanf® Market launch of the ProCrea® clay panels from our own production in Lippetal Market launch of the ProCrea® clay plasters from our own production in Nördlingen Market launch of Thermo-Hanf® Plus Hock employs more than 60 people Market launch of Thermo-Hanf® Xtra Market launch of Thermo-Hanf® Block and Thermo-Hanf® Fill About the History of Hemp On the U.S.S. Constitution there were at least 50 tons of hemp: Banners, sails, rigging, sealing compound, flags, sea charts, bibles, logbooks, clothing, uniforms, paper ... Hemp means to the Environment • Protection of the non-renewable resources • Enrichment of the biodiversity in the cultural landscape • Cultivation without chemical pest management • Binding and storage of CO2 • A very good field for bees and insects during the bloom • Hemp products can be manufactured with a low energy input • Short transportation distances through cultivation in Germany Protect the climate with Thermo-Hanf®! Compared to the total energy input, there is so much storage potential per one cubic meter Thermo-Hanf® Plus that a building owner, who opts for Thermo-Hanf® Plus, already reduces the amount of CO2 in the atmosphere by approximately 14.4 kg per cubic meter. Example: A typical single family house with approximately 100m² floor space and an insulation need of appr. 35m³ is to be insulated with Thermo-Hanf® Plus. If the family insulates its house with Thermo-Hanf® Plus they will achieve, already when installing the insulation, a CO2 reduction of appr. 500 kg. CO2 balance of a passive house in regards to the insulation used and the energy for its production Specifications: Living space: 150 m² Insulation: 150 m³ Energy consumption: 150 x 15 kWh = 2250 kWh ------------------------------------------------------------CO2 emission for the production of one KWh In the energy mix in Germany: 0.645 kg/kWh Climate Change Report 08/2008 Case 1: Mineral wool insulation Average energy for the production of 1 m³ mineral wool: Average energy for the production of 150 m³ mineral wool: 500 kWh 75.000 kWh CO2 emission for the production through its energy consumption: 75.000 x 0,645 = 48,38 t CO2 storage in the product: 0,00 t -------------------------Sum of the CO2 emission for the production 48,38 t A car with a CO2 emission of 175 g/km has released the same amount of CO2 after 276.457 km CO2 balance of a passive house in regards to the insulation used and the energy for its production Specifications: Living space: 150 m² Insulation: 150 m³ Energy consumption: 150 x 15 kWh = 2250 kWh ------------------------------------------------------------CO2 emission for the production of one KWh In the energy mix in Germany: 0.645 kg/kWh Climate Change Report 08/2008 Case 2: Wood fibre insulation Average energy for the production of 1 m³ wood fibre: Average energy for the production of 150 m³ wood fibre: 1500 kWh 225.000 kWh CO2 emission for the production through its energy consumption: 225.000 x 0,645 = 145,13 t CO2 storage in the product: 140 kg/m³ x 150 m³ x 1.500 kg 31,50 t -------------------------Sum of CO2 emission for the production 113,63 t A car with a CO2 emission of 175 g/km has released the same amount of CO2 after 649.314 km CO2 balance of a passive house in regards to the insulation used and the energy for its production Specifications: Living space: 150 m² Insulation: 150 m³ Energy consumption: 150 x 15 kWh = 2250 kWh ------------------------------------------------------------CO2 emission for the production of one KWh In the energy mix in Germany: 0.645 kg/kWh Climate Change Report 08/2008 Case 3: Thermo-Hanf®, hemp fibre insulation Average energy for the production of 1 m³ Thermo-Hanf®: Average energy for the production of 150 m³ Thermo-Hanf®: 65 kWh 9750 kWh CO2 emission for the production through its energy consumption: 9.750 x 0,645 = 6,29 t CO2 storage in the product : 38 kg/m³ x 150 m³ x 1.500 kg 8,55 t -----------------------Sum of CO2 emission for the production - 2,26 t The owners of this house can drive 12.914 km with their car and they will still be CO2 neutral regarding the insulation Quality from Germany Thermo-Hanf® is produced in Nördlingen, Bavaria, and guarantees a high degree of flexibility and dependability as well as a reliable delivery period. Our own quality control at the factory as well as external quality control by the F.I.W. (Research Institute for Heat Protection) ensure a constant product quality. We continuously carry out research and development work in our own laboratory. Hock – The Assortment Insulations: Thermo-Hanf® Thermo-Hanf® Thermo-Hanf® Thermo-Hanf® Thermo-Hanf® Premium Plus Xtra Wool Step Thermo-Hanf Block® Thermo-Hanf Fill® Opti-Plan® Cutting tools for Thermo-Hanf ® Air and Wind Seals: Air seals Wind seals Fasteners ProCrea® Clay Products: Clay panels Clay blocks Clay bricks Clay plasters & mortar Clay finishing plaster Clay painting plaster Clay paints Primers & Reed products Classic: Thermo-Hanf® Premium For more than a decade, this product has been the market leader in quality and quantity within the natural fibre insulations in Europe. Thermo-Hanf® Premium has been assessed “the best insulation material made of renewable raw materials“ by Stiftung Warentest. As supporting fibre, we use a bi-component fibre on polyester basis. Components: 83-87% Hemp fibres 10-12% Polyester bi-component fibres 3-5% Soda as fire protection Thermo-Hanf® Premium is available as mats and rolls. Innovation: Thermo-Hanf® Plus Thermo-Hanf® Plus was developed at Hock in Nördlingen within a project funded by the German Environment Foundation. This insulation is the consequent product advancement within the company strategy for sustainability. The supporting fibre used in Thermo-Hanf® Plus is made of corn starch. Components: 83-87% Hemp fibres 10-12% Corn starch bi-component fibres 3-5% Soda as fire protection Thermo-Hanf® Plus is only available as mats. The Façade Insulation System: Thermo-Hanf® Xtra Perfect Insulation. Perfect Façade. Perfect Climate Protection. Thermo-Hanf® Xtra is the alternative to traditional systems and offers numerous advantages: • Possible to construct every type of façade • Construction up to 320mm possible • Installation almost without cold bridges • Use in new buildings and renovation • Fixing possible on all surfaces • Irregularities can easily be evened • Free statics analysis by Hock • Free installation plan by Hock • Climate protection through positive CO² balance already when installing the insulation Customised Manufacturing Without Surcharge It is convenient to fit insulation mats quickly without the annoying and time consuming cutting. You may obtain Thermo-Hanf® even in small quantities cut exactly to your specifications – and you do not have to pay extra for this service. = Quick and easy installation without itching and scratching Certificates Best insulation made of renewable raw materials for insulation between the rafters. The life cycle of the product has been tested in regards to environment, health and function. Full declaration of all materials used. Full declaration of the resources used in ThermoHanf®: fossil (red), mineral (yellow), renewable (green). Assessed “good“ for heat insulation and material composition. Total evaluation “very good“. . Tested in regards to health, low emissions, positive effect on the indoor climate and comfort, improvement of the air quality and further building biological criteria. Advantages for the Customer and the Craftsmen Thermo-Hanf® • enables easy and quick installation without itching and scratching • guarantees protection against the cold in the winter as well as heat in the summer • creates an agreeable indoor climate – through good diffusion capacity – through moisture regulating effect • is manufactured already in small quantities to your specifications - without a surcharge • is manufactured and processed with a low energy input • is recyclable • convinces by a good price-performance ratio and a high long-term functionality • has the European Technical Approval and many certificates Thermo-Hanf® in Slovenia • • • Proform d.o.o. has been an authorized dealer for Thermo-Hanf® and other Hock products in Slovenia since 2007 The aim is to increase the recognisability of the products Another goal is to set up a distribution network across the country to increase the access to Thermo-Hanf® and other Hock products for architects, construction companies and end consumers