Cheese Production

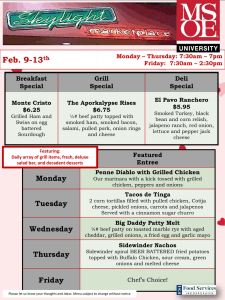

advertisement

Kerry E. Kaylegian, Ph.D. May 2014 What is Cheese? Frozen Desserts Ice Cream Gelato Sherbet Other Flavored Milks Pudding Creams Butter Fermented Products Yogurt Buttermilk Acidophilus Milk Kefir, Koumiss Sour Cream Cream Cheese Cheddar, Colby Mozzarella, Provolone & Italian types Emmental, Gruyere & Swiss types Brie, Camembert Blue cheeses Munster, Brick Dairy Fermentation Bacteria Milk + Molds Yeasts Microbial Processing + Metabolism Conditions Products with a Variety of Flavors, Textures & End Uses Variables in Cheesemaking • • • • • • • • • • • Type of cheese Type of milk Milk composition Heat treatment Microorganisms used Time Temperature pH Salting method Other handling Other ingredients • Environment – – – – – sanitation water quality native flora (good & bad) storage temperature storage humidity • Production consistency – acidity development – flavor & texture Defining Varieties … By Manufacturing Technique By Cheese Characteristics • • • • • • • • • • • • • • • • • • Acid set Rennet set Fresh/Aged Cheddar type Pasta filata Cheese with eyes Natural rind Washed-rind Mold-ripened Fresh Semi-soft Soft-ripened Surface-ripened Semi-hard Hard Blue Washed-rind Milk type (cow, goat, sheep) How can you govern a country that has 246 varieties of cheese? Charles de Gaulle French President, 1958-1969 2013: 1794 entries (cheese, yogurt, butter), 100 categories 2012: World Championship, 2504 entries, 81 categories 2013: US Championship, 1702 entries, 81 categories 2014: World Championship, 2619 entries, 90 categories (cheese, butter) Cheese Standards • Code of Federal Regulations – 21 CFR 133 • http://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch. cfm?cfrpart=133 – contains Standards of Identity (SoI) for many cheeses – regulations can be very specific on cheese composition, make procedures and ingredients • Pennsylvania Code – Title 7 Part III Ch. 57 – § 57.71 Cheese and related cheese products • Cheese and related cheese products shall comply with 21 CFR 133 (relating to cheese and related cheese products). Cheddar Cheese Standard 21 CFR 133.113 Cheese – Pasteurized or Raw 7 CFR 58 General Cheese Making Steps Raw Milk Pasteurize/Heat Inoculate with Starter & Non-Starter Bacteria and Ripen Add Rennet and Form Coagulum Cut Curd & Cook Drain Whey Texture Curd Dry Salt/Brine Form Cheeses Store and Age Major Steps in Cheese Making Step Purpose Key Factors Setting Milk Prepare milk for coagulation Ripen starter culture Coagulation Temperature Protein Calcium Sanitation (phage) Coagulation Acid Coagulation Rennet Coagulation • Function of isoelectric properties • at pH 6.6 the net charge on the proteins is negative, casein micelles repel • pH 4.6 is the isoelectric point and the net charge is neutral, casein micelles interact • soft, delicate curds • Function of enzyme activity • 1st step cleaves -casein – net negative charge is reduced – steric repulsion is decreased • 2nd step requires ionic (free) Ca – Ca forms bridges to stabilize the aggregation – at lower pH, the casein micelles are depleted of Ca • firmer, stronger curds – at higher pH, the Ca is still present in the casein micelles Major Steps in Cheese Making Step Purpose Key Factors Setting Milk Prepare milk for coagulation Ripen starter culture Rennet coagulation Temperature Protein Calcium Sanitation (phage) Cutting the Curd Speed whey expulsion Assist in uniform cooking Assist with moisture control Curd firmness Size of curd particles Uniformity of curd particles Major Steps in Cheese Making Step Purpose Key Factors Setting Milk Prepare milk for coagulation Ripen starter culture Rennet coagulation Temperature Protein Calcium Sanitation (phage) Cutting the Curd Speed whey expulsion Assist in uniform cooking Assist with moisture control Curd firmness Size of curd particles Uniformity of curd particles Cooking the curd Remove whey Curd size Establish moisture level in cheese Time & temperature profile Influence texture Stirring rate pH Major Steps in Cheese Making Step Purpose Key Factors Setting Milk Prepare milk for coagulation Ripen starter culture Rennet coagulation Temperature Protein Calcium Sanitation (phage) Cutting the Curd Speed whey expulsion Assist in uniform cooking Assist with moisture control Curd firmness Size of curd particles Uniformity of curd particles Cooking the curd Remove whey Curd size Establish moisture level in cheese Time & temperature profile Influence texture Stirring rate pH Draining or Dipping Separate whey from curds Moisture control pH Major Steps in Cheese Making Step Purpose Key Factors Curd Knitting Form characteristic texture Acid development Moisture control Temperature Time Major Steps in Cheese Making Step Purpose Key Factors Curd Knitting Form characteristic texture Acid development Moisture control Temperature Time Pressing Expel whey Shape cheese Influence texture Temperature Pressure Acidity development Major Steps in Cheese Making Step Purpose Key Factors Curd Knitting Form characteristic texture Acid development Moisture control Temperature Time Pressing Expel whey Shape cheese Influence texture Temperature Pressure Acidity development Salting Influence flavor Influence texture Control moisture Method of salting Curd size Temperature Major Steps in Cheese Making Step Purpose Key Factors Curd Knitting Form characteristic texture Acid development Moisture control Temperature Time Pressing Expel whey Shape cheese Influence texture Temperature Pressure Acidity development Salting Influence flavor Influence texture Control moisture Method of salting Curd size Temperature Special Applications Apply appropriate practices to give cheese its characteristics (pasta filata, mold-ripened, washed-rind, aged) Depends on the application Flavoring Cheese • • • • • • • • Herbs Spices Fruit pieces Vegetable pieces Smoke Beer Wine (Microbial smears) www.images.google.com Washed-Rind Cheese • Outer surface flavor & color – beer • Chimay Ale – wine • Drunken Goat • Complex flavor & rind development – microbial smears (Brevibacterium linens) – yeasts – sequence of organism development – specific to organisms used Cheese Aging = Affinage • The ripening of a young cheese to a mature cheese – development of complex flavors and textures Cheese Aging • Cheese Variables – cheese type – microflora • Environment Variables – – – – – – temperature humidity air flow air turnover shelving type proximity to other cheeses – native flora – sanitation • Handling – – – – – time turning brushing washing sanitation Cheese Aging – Environmental Conditions • Drying – 57-64°F, 60-80% RH • Ripening – – – – 52-77°F, natural rind cheeses 46-52°F, bloomy cheeses 46-48°F, blue cheeses 90-98% RH, natural rind cheeses • Warm (eye development) – 68-72°F, 80-85% RH • Cool storage – 38-48°F, flavor development – 38-40°F, 60-80% RH, storage prior to sale – 90-95% RH, natural rind cheeses Cheddar Type Cheese Make Steps Lactococcus lactis subsp. lactis or cremoris Raw Milk Lactobacillus casei, Lactobacillus plantarum Pasteurize/Heat Inoculate with Starter & Non-Starter Bacteria and Ripen Add Rennet and Form Coagulum Cut Curd & Cook Wash curd for Colby & Jack pH 6.4 100°F (38°C) Drain Whey Texture Curd 1 month to 5+ years 86-90°F (30-32°C) Dry Salt Cheddaring & Milling OR Stirred Curd pH 5.1 – 5.5 Form Cheeses Store and Age Hoop & Press Cheese with Eyes Make Steps S. thermophilus, L. helviticus L. delbrueckii subsp. bulgaricus Raw Milk Proprionibacterium freudenreichi Pasteurize/Heat Inoculate with Starter & Non-Starter Bacteria and Ripen Add Rennet and Form Coagulum Cut Curd & Cook curd is pressed in hoops, acid begins to form pH 5.1-5.2 1-2 wk, 60°F (15°C) drying 3-7 wk, 70-77°F (21-25°C) eye formation 4-12 wk, 41°F (5°C) aging Drain Whey Texture Curd Form Cheeses Brine Store and Age 118-135°F (48-52°C) rapid cook pH 6.4 cheeses placed in hoops before draining 60°F (15°C), 2 d Blue Veined Cheese Make Steps Raw Milk L. lactis subsp. lactis L. lactis subsp. cremoris Penicillium roqueforti spores Pasteurize/Homogenize/Heat Inoculate with Starter & Non-Starter Bacteria and Ripen Add Rennet and Form Coagulum Cut Curd & Cook Dip Curd/Form Cheese Drain Whey ripen and cure 50-60°F (10-15°C), 95% RH mold growth 2-4 mo cure 2-4 mo 1 hr 90°F (32°C) firm curd, open texture put into hoops drain 1-7 d, 68°F (20°C), 80% RH Dry Salt/Brine pierce with needles Texture Curd Store and Age ? Kerry E. Kaylegian, Ph.D. Dairy Foods Research & Extension Associate Pennsylvania State University Department of Food Science kek14@psu.edu 814-867-1379 foodscience.psu.edu