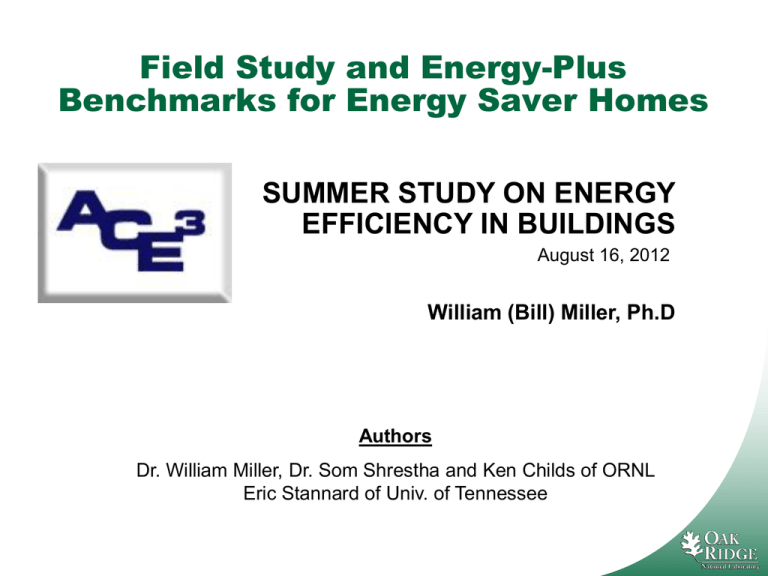

summer study on energy efficiency in buildings

advertisement

Field Study and Energy-Plus Benchmarks for Energy Saver Homes SUMMER STUDY ON ENERGY EFFICIENCY IN BUILDINGS August 16, 2012 William (Bill) Miller, Ph.D Authors Dr. William Miller, Dr. Som Shrestha and Ken Childs of ORNL Eric Stannard of Univ. of Tennessee Project consists of four houses with different equipment and envelope systems “Structural Insulated Panel” “Advanced Framing” “Dynamic Insulation - Phase Change Material” “Exterior Insulation Finishing SIP Strategy OVF Strategy PCM Strategy EIFS Strategy Pair of Homes • Two-story on Crawlspace N Pair of Homes • Two-story with Basement Wolf Creek Subdivision, Oak Ridge, TN ZEBRAlliance established to promote Cost-Effective Energy Efficiency in Buildings Functions as a public-private research project to promote an energy-efficiency education campaign SIP House OVF House PCM House EIFS House Miller, et al. 2009 “Advanced Residential Envelopes for Two Pair of Energy-Saver Homes,” ACEEE Summer Study, 2009. Objectives DOE Building Technologies (BT) program Residential Building Integration Accelerate progress toward Zero-Energy-Home (ZEH) Whole-house 50% saver homes in mixed humid climate DOE BT: Building Envelope R&D Showcase different envelope approaches Best practices portfolio: materials and construction DOE BT: Analysis Tools and Designs Data acquisition for Foundation Heat Exchanger (FHXs) Benchmark FHX data against analytical tools DOE BT: Space Conditioning and Refrigeration Characterize HVAC, Water heating and Appliance systems Accelerate for-sale status to better penetrate market Demonstration Homes in Oak Ridge, TN SIP and OVF Pair of Homes Blower Door Tests Tracer Gas Experiments IR Thermography Diagnostics Construction Verified Using IR Thermography OVF House FLIR Systems S65 IR Camera Min -4.4HS Max -1.5 Min -7.2 Max 1.2 SIP ASTM Standard C1060 • ΔT >10°C for 4 hrs • No Irradiance for 3 hrs Min -7.8 Max -5.9 • Wind Speed < 15 mph Min -7.4 Max 1.8 Min -7.9 Max 1.,3 Min -5.9 Max -2.8 SIP House SIP House Min -11.1 Max 4.6 Min -3.7 Max -0.7 Min -11.5 Max 2.0 Min -5.7 Max 2.0 Min -6.1 Max -3.4 OVF House Kaushik Biswas, Kosny and Miller. “Thermal Integrity Assessment of Building Envelopes of Experimental Houses Using Infrared Thermography,” InfraMotion 2010, Las Vegas, Nevada. Revenue Meter Readings Verify all Homes used 50% less energy than Home Built to IECC 2006 SIP Strategy Optimal Value Framing Strategy PCM Envelope EIFS Envelope Builders House1 46 47 47 50 101 Annual (kWh per ft2 per year) 4.66 4.50 5.43 5.70 11.14 ACH2 at 50 Pa 1.23 1.74 3.18 2.18 5.7 0.05/0.09 0.05/0.13 0.11/0.14 0.08/0.07 NA Description HERS Tracer Gas3ACH 1 International Energy Conservation Code (2006). Air exchanges per hour (ACH) measured by blower door testing conducted at 50 Pa. 3 Tracer gas test using concentration decay method and R-134a refrigerant. Measured values in summer/winter 2011. 2 SIP House Equipment Characteristics WAHP: 2-ton (7kW) capacity – Cooling COP 4.0 highstage – Heating COP 5.4 highstage – 2-Stage scroll compressor – Rated as per ANSI/AHRI/ISO 13256-1 – Brine Pump (1/6)hp (147 W) WWHP: 1.5-ton (5.3 kW) – COP 3.1 (based on EWT 32oF (0oC)and load EWT 100oF (37.8oC) – 1-Speed rotary compressor – Brine Pump (1/6)hp (147W) – DHW Pump (1/25)hp (30W) Water Tank: 80 gal (303L) – ~60 g/d (220L/d) water @ 120oF (49oC) Heating Capacity vs. Entering Water Temperature (EWT) High Stage: 5% of total run time M. Ally, J. Munk, V. Baxter, A. Gehl ASHRAE Summer Meeting San Antonio, TX, June 23-27, 2012 Cooling Capacity versus EWT High Stage: 3% of total run time M. Ally, J. Munk, V. Baxter, A. Gehl ASHRAE Summer Meeting San Antonio, TX, June 23-27, 2012 OVF Home Salient Features Exterior Insulation Finishing System The EIFS has 2x4 stick-built wood-framing, 16-in on center with 5-in of EPS exterior insulation on all exterior walls to reduce thermal bridging losses. A trowel applied weather resistive barrier minimizes the infiltration and/or exfiltration heat and moisture loads. Crawlspace of the home is insulated and sealed (not vented to the outdoor ambient). Weather Resistive Barrier Performance After a full year of exposure to the elements both WRB systems are adequately protecting the sheathing on the south-facing wall Phase Change Material (PCM) Home E+ Model of PCM Home Exterior Double Wall Assembly PCM applied in the insulation will provide thermal buffering in wall PCM - Cellulose 24” OC 2 by 4 studs ZIP Panel Cellulose Fabric Mesh Gypsum board 24” OC Summer Temperatures Measured in the East and South Wall of the PCM Home Temperatures Measured in Blown Fiber Insulation in the Attic of the PCM Home Winter Field Data Summer Field Data E+ Benchmarks of Attic Floor Heat Flux SIP and OVF Homes have cathedral ceilings PCM and EIFS Homes have conventional ventilated attics E+ predicted roof heat flux (W/m2) better for summer data than for winter Avg Seasonal Differences SIP OVF EIFS Summer (W/m2) 0.22 0.25 0.54 Winter (W/m2) 1.73 0.28 0.85 E+ Benchmarks of East Wall Heat Flux Winter data shows continual heat loss to the cold outdoors E+ predicted SIP and OVF wall flux better than EIFS (low-e foil) Rising Sun Heating Wall E+ differences between measured and predicted east wall heat flux (W/m2) Avg Seasonal Differences SIP OVF EIFS Summer (W/m2) 0.30 0.11 NA Winter (W/m2) 0.24 0.36 NA South Wall Conclusions East Wall HERS scores and revenue meter data prove all Fully Partially Fully Partially homes consume only about half the energy 2 Active1 Active Active1compliant Active2 consumed by conventional IECC (2006) house out of Year 0 130 the WRB 31 which140 Days Driving rains do not penetrate provide good protection from moisture intrusion Percent of Days predicted out E+ (v7.0) heat flux through 8% the roofs38% and 0% 36% of Year attics matched better with summer field measured data compared to that in winter – does an acceptable job in matching the trends in summer and winter PCM in East Tennessee’s climate showed the PCM fully active in an east oriented wall but only partially active in the south-facing wall Actual and Standard costs for the Four ZEBRA Houses House 1 SIP House Costs Items Labor~ Supervision/ Administration~ Architectural* Engineering° Total Costs House 2 OVF House House 3 PCM House House 4 EIFS House Actual Standard Actual Standard Actual Standard Costs Costs Costs Costs Costs Costs $ $ $ $ $ $ 11,659 6,750 8,222 6,750 7,376 6,750 74,115 27,000 36,326 27,000 46,639 27,000 Actual Standard Costs Costs $ $ 5,455 6,750 39,181 27,000 14,880 26,566 2,455 4,735 596,000 557,900 158 20,094 2,894 3,052 412,800 422,000 Total Costs ($) Total Square Footage Total Cost Per Square Foot ($) 1,502 25,795 2,035 3,537 526,700 541,700 260 21,227 2,686 2,945 444,800 445,800 House 1 SIP House House 2 OVF House House 3 PCM House House 4 EIFS House $557,900 3,713 150 $541,700 3,713 $145 $445,800 2,721 $163 $422,000 2,721 $155