THE RELATIONSHIP BETWEEN ENERGY SAVINGS & LIGHTING

advertisement

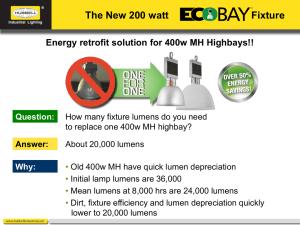

THE RELATIONSHIP BETWEEN ENERGY SAVINGS & LIGHTING LED/SSL Lighting: The Present and The Future 1. 2. 3. 4. Know the differences between what is on the marketplace. What makes a good LED fixture? What components are absolutely necessary in order to get optimum performance? The photometric layout and the standards put in place by the Illuminating Engineering Society are your key to getting the correct fixture. IESNA LM-80 L70 which designates the life hours of the LED fixture must be part of every specification provided with LED lighting. Increase light levels while decreasing energy usage and maintenance costs. What is an L.E.D.? • Accepted Terminology – Accepted standard definitions and nomenclature; UL8750 Section 3 and IESNA RP-16. Philips Lumileds Luxeon K2 • Mechanical Package (high power) – Diode (aka Die or LED Chip) – Thermal transfer slug (metal or ceramic) – Electrical connection (bond wire or flip chip) – Optical extraction method (silicone filled lens) Lens LED Chip Cathode Lead Silicon Submount Thermal Heatsink Outer Package Bond Wire Thermal Effect of Light Output • Instantaneous Effect – Junction temperature directly relates to luminous flux – Light measurements are to be tested “in-situ” at full thermal load WHAT IS IESNA LM-80 L70 AND WHY IS IT IMPORTANT? 1. 2. 3. 4. 5. The IESNA (Illuminating Engineering Society of North America) is the lighting industry standard bearer that regulates what are and aren’t appropriate lighting standards. IESNA LM80 sets the standards for uniform test methods for LED manufacturers under controlled conditions for measuring LED lumen maintenance while controlling the LED’s case temperature, the forward voltage and forward current to the LED. It also requires the LED manufacturer to measure at a 55°C, 85°C and one other case temperature chosen by the manufacturer, typically at 110°C. It also requires the lumen maintenance data for at least 6,000 hours of constant DC mode operation. The preferred method is 10,000 hours. LM80 does not speak to this issue, but LED manufacturers then extrapolate this data to provide lumen maintenance out to L70 or useful lumens life. At this time IESNA is working on TM21 that will standardize this extrapolation method for all LED manufacturers. Traditional lamps have a lamp life expressed in a 50% mortality rate. In other words half of the lamps will have ceased to operate at X hours. While traditional lamps experience lumen deprecation over their life, this is usually taken into consideration during the calculation phase of the design. Since LED’s could theoretically operate forever the industry has established the L70 standard or where the lumen output of the LED system will have depreciated to 70% of initial lumens. This is the theoretical extrapolation that is done using the LM80 information and the lighting manufacturers tested TJ. These numbers are usually in the range of 30,000 to 50,000 hours and beyond. Ten questions to ask when designing a system: 1) Is the manufacturer using a reliable LED chip manufacturer? 2) What operating temperature is the fixture designed for and what is the maximum junction temperature (Tj) of the LEDs across that range? 3) Will the manufacturer provide an IESNA LM-80 test report that measures the lumen maintenance of the LED? 4) What is the fixture’s L70 lifetime curve and how was it calculated? 5) Can the manufacturer supply an IESNA LM-79 photometric test report from a third party laboratory along with a properly formatted .ies data file? 6) What is the fixture’s actual delivered lumens and lumens per watt (LPW)? 7) What is the fixture’s actual power factor and how much power does it consume during “off” periods? 8) Does the fixture meet current meet current DOE CALiPer standards? 9) Is the product mercury free, lead free and RoHS compliant? 10) What is the product warranty and can the manufacturer stand behind it? PHOTOMETRIC LAYOUTS 1. 2. 3. LED lighting is much different than any other source of lighting, therefore if you do not have a photometric drawing done for each and every project there are chances you will not have the proper lighting levels. Ask for details with your layouts…what is the current footcandle levels? What will the new footcandle levels be? The primary objective in doing this is to ensure that the end user is getting as good if not better lighting than what they presently have. Langley Air Force Base POW/MIA Memorial 1. 2. 3. Originally this was designed around HID lighting sources, but when LED fixtures started being installed all around the base, S&S Sales was tasked by the contractor with coming up with an LED design. All of the fixtures on the POW/MIA Memorial are LED, featuring 3 flag pole floods maintaining a constant 1 Footcandle on the American flag, a narrow flood on the medallion itself and 16 LED step lights lighting Code of Conduct monoliths as well as the walkway around the memorial. The original design called for 2120 watts of electricity to be used on this memorial. With the LED fixtures, we are using a total of 192 watts, a savings of 85% energy while giving very good, if not better light output. Dam Neck Naval Station Building 420 Parking Lot 1. 2. 3. 4. This parking facility was extremely dark when we first took the measurements and foot candle readings. Dam Neck Naval Station reduced the number of fixtures alongside the building while at the same time increasing the foot candle levels in the parking lot. Reduced energy usage from 55,190 kW per year to 13,845 kW per year, a savings of 41,345 kW or over $2,900.00 per year in energy costs. Maintenance savings are also greatly reduced as all these fixtures are IP66 rated whereas previous fixtures were being replaced every 3 years due to salt corrosion. Surfside Hotel Atlantic Avenue Canopy 1. 2. 3. 4. The lighting before was being supplied by eight 100w CFL fixtures. The light levels were below 1 foot candle throughout the canopy area. The new layout uses six 55 watt LED canopy fixtures and increases the light levels to a uniform 2.1 to 2.6 foot candles throughout the canopy area. Energy reduction was from 3500 kW per year to 1445 kW per year, helping the customer to reduce energy by almost 60%. Now that this first facility is completed the hotel chain plans on replacing all six garages and canopy areas with Beta LED fixtures over the next year. Naval Station Norfolk Piercy Avenue 1. 2. 3. The first Naval Base installation in Hampton Roads featured only two fixtures but proved that LED lighting is more than capable of delivering great results. Replaced 400w HPS cobra heads with 168w LEDway fixtures saving the Navy over 50% on energy costs per year. Another feature not often talked about but equally important is that the second fixture is buried in the trees as obvious from this facility but it is still putting out over 2.5 Fc below the fixture and has reduced the dark spot in between fixtures to the smallest part possible. With the tree trimmed there are virtually no shadows between fixtures. Chesapeake Bay Bridge & Tunnel 1. 2. One of the harshest facilities in the Hampton Roads area, Beta LEDway fixtures are standing the test of time. CBBT began with three test fixtures that were prototype IP66 rated fixtures. Whereas, there have been challenges with the prototype IP66 fixtures, there have been no challenges with the quality of light from these fixtures. CBBT now has nine fixtures, the prototype fixtures were replaced with new ones by Beta LED at no charge to CBBT and these fixtures continue to undergo harsh testing in every known weather condition. Langley Air Force Base LaSalle Avenue Gate 1. 2. 3. Langley Air Force Base formerly used 400w HPS fixtures at their main entrance gate and last year replaced these fixtures with 168w LED fixtures. The first night the fixtures were retrofitted S&S Sales personnel were on hand to take foot candle readings when one of the guards at the gate exclaimed that from 40 feet away he could tell what color base sticker the car had on it. The higher CRI of LED fixtures makes it much easier to not only tell what color of car is approaching the gate but also what kind of base sticker the vehicle has so the guards can be ready to salute before it approaches the gate. The energy savings on these fixtures is adding to the over 300,000 kW the Air Force expects to save first year just from the retrofit LED fixtures currently in place. City of Virginia Beach 9th Street Parking Garage 1. 2. 3. 4. Replaced 140 150w HPS garage and roof top fixtures with 140 104w LED garage and roof top fixtures. Resulted in an annual energy reduction from 115,282 kW to 63,773 kW, an energy savings of 51,509 kW saving the city over $3,600.00 per year in energy costs. Maintenance costs drastically reduced as previous maintenance for re-lamping and re-ballasting had to rope off sections of the garage to ensure no cars were parked underneath. City of Virginia Beach Police Department has already commented on the increased safety from the LED lighting system. Presented by: Mike Horner S&S Sales, Inc. 748 Lord Dunmore Drive, Suite 105 Virginia Beach, VA 23464 (757) 495-7233; Fax (757)-495-5515; Cell (757) 773-8885 Email: mhorner@ss-sales.com