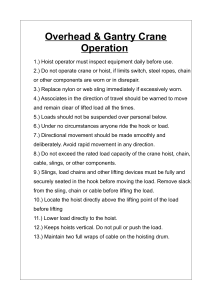

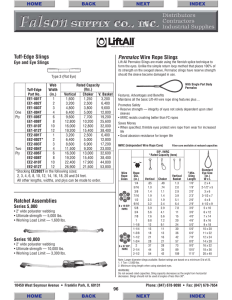

Understanding Chain Slings: Types, Uses, and Benefits Chain slings are vital components in heavy lifting and material handling operations, commonly used in industrial, construction, and transportation sectors. These slings provide exceptional strength and durability, making them ideal for lifting heavy loads in various challenging environments. This blog explores the different types of chain slings, their applications, benefits, and essential safety considerations. What is a Chain Sling? A chain sling is a lifting device composed of metal chains and fittings designed to lift and move heavy loads safely. Chain slings are typically made from high-strength steel alloys to ensure durability and performance in extreme conditions. These slings are commonly used with cranes, hoists, and other lifting equipment for transporting loads in industrial settings. Types of Chain Slings Chain slings are classified based on their configuration and design. The type of chain sling you choose depends on the lifting application and the nature of the load. Here are the most common types of chain slings: 1. Single-Leg Chain Sling A single-leg chain sling consists of one chain connected to a lifting hook or master link. It is designed to lift lighter loads or small items with a balanced center of gravity. Advantages: ● Easy to use and handle ● Ideal for vertical lifting ● Cost-effective Disadvantages: ● Limited to lighter loads ● Not suitable for unstable loads 2. Double-Leg Chain Sling A double-leg chain sling features two chains connected to a master link, allowing for greater load stability and increased lifting capacity. It is commonly used for lifting larger and heavier loads. Advantages: ● Enhanced stability ● Higher load capacity ● Balanced load distribution Disadvantages: ● Requires proper load balancing ● Slightly heavier than single-leg slings 3. Three-Leg Chain Sling A three-leg chain sling comprises three chains attached to a master link, offering excellent load stability for irregularly shaped loads. This type is widely used in construction and heavy manufacturing. Advantages: ● Provides excellent load balance ● Ideal for lifting large and uneven loads ● Increased lifting capacity Disadvantages: ● Complex to operate ● Heavier weight 4. Four-Leg Chain Sling A four-leg chain sling consists of four chains attached to a master link, making it suitable for extremely heavy or large loads. This type is highly preferred in industrial operations that require superior load control. Advantages: ● Maximum load capacity ● Best for large and heavy loads ● Increased stability Disadvantages: ● Heavy to carry and operate ● Requires proper load balancing 5. Adjustable Chain Sling Adjustable chain slings offer flexibility by allowing operators to adjust the length of the chains. This feature is helpful when lifting loads of different sizes and shapes. Advantages: ● Versatile and flexible ● Reduces the need for multiple slings ● Suitable for uneven loads Disadvantages: ● Slightly higher cost ● Requires frequent adjustment Applications of Chain Slings Chain slings are widely used across various industries for heavy lifting and material handling tasks. Here are some key applications: 1. Construction Industry In construction sites, chain slings are used for lifting and moving heavy materials such as steel beams, concrete blocks, and construction equipment. 2. Manufacturing Industry Manufacturing facilities use chain slings to transport raw materials, heavy machinery, and finished products from one point to another. 3. Shipping and Logistics In shipping yards and ports, chain slings facilitate the loading and unloading of heavy cargo containers and equipment. 4. Oil and Gas Industry The oil and gas sector relies on chain slings for lifting drilling equipment, pipes, and large mechanical components. 5. Mining Industry In mining operations, chain slings are used for handling heavy mining equipment, extracting materials, and transporting raw materials. Benefits of Using Chain Slings The popularity of chain slings in heavy lifting operations is attributed to their numerous benefits. Some of the key advantages include: 1. High Strength and Durability Chain slings are made from high-strength steel alloys, offering superior durability and load-bearing capacity. This makes them suitable for handling extremely heavy loads. 2. Versatility Chain slings come in various configurations, including single-leg, double-leg, three-leg, and four-leg, allowing for a wide range of lifting applications. 3. Adjustable Length Adjustable chain slings provide flexibility in handling different load sizes and shapes, reducing the need for multiple slings. 4. Heat and Corrosion Resistance High-quality chain slings are resistant to heat and corrosion, making them ideal for use in harsh environments such as construction sites, manufacturing plants, and offshore facilities. 5. Improved Load Control Multi-leg chain slings offer excellent load control, reducing the risk of load shifting or imbalance during lifting operations. Factors to Consider When Choosing a Chain Sling Choosing the right chain sling is essential for ensuring safety and efficiency in lifting operations. Here are key factors to consider: 1. Load Weight: Determine the maximum weight of the load to select a chain sling with the appropriate load capacity. 2. Load Shape and Size: For irregularly shaped loads, a multi-leg chain sling is more suitable. 3. Work Environment: Consider the working environment, including temperature, corrosion exposure, and operating conditions. 4. Sling Length: Choose the appropriate sling length to ensure safe and stable lifting. 5. Hook and Link Type: Select the right type of hook and link to match the lifting equipment and load. Safety Tips for Using Chain Slings Ensuring safe operation of chain slings is crucial to prevent accidents and equipment damage. Here are essential safety tips: 1. Inspect Before Use Always inspect the chain sling for signs of wear, damage, or corrosion before each use. Replace any damaged components immediately. 2. Proper Load Balancing Ensure the load is balanced and secure to prevent shifting during lifting. Use multi-leg chain slings for uneven loads. 3. Avoid Overloading Never exceed the load capacity of the chain sling. Overloading can lead to sling failure and accidents. 4. Use Proper Lifting Techniques Train operators to use the correct lifting techniques and avoid sudden jerks or shocks while lifting. 5. Store Properly When not in use, store chain slings in a dry, clean place to prevent rust and corrosion. 6. Regular Maintenance Schedule regular maintenance and inspection of chain slings to ensure optimal performance and safety. Conclusion Chain slings play a critical role in heavy lifting and material handling operations across various industries. With different types of chain slings available, choosing the right one based on load weight, shape, and operating environment is essential for safe and efficient operations. Regular inspection, proper maintenance, and adherence to safety practices further enhance the durability and performance of chain slings, ensuring smooth and secure lifting processes.