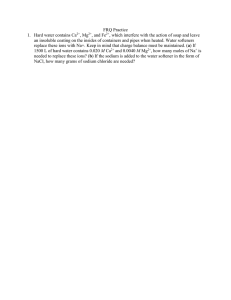

Ion ExchangeIon exchange is a water softening process that involves the removal of calcium and magnesium ions from water by exchanging them with sodium ions. This process typically uses a resin bed containing sodium ions, which attract and replace the calcium and magnesium ions in the water. As the hard water passes through the resin bed, the calcium and magnesium ions are captured by the resin, and sodium ions are released into the water, resulting in softened water. Zeolite Exchange Zeolite exchange is another method of water softening that utilizes zeolite minerals to remove hardness-causing ions from water. Zeolites are crystalline aluminosilicates with a porous structure that can selectively exchange ions. In this process, zeolite minerals are used as an ion exchange medium to remove calcium and magnesium ions from water, similar to ion exchange resins. Organic Ion Exchange Organic ion exchange is a water softening process that involves using organic compounds as ion exchange materials to remove hardness-causing ions from water. These organic ion exchange materials can be synthetic or natural compounds that have functional groups capable of exchanging ions with calcium and magnesium ions in water. Lime-soda Process The lime-soda process is a traditional method of water softening that involves adding lime (calcium hydroxide) and soda ash (sodium carbonate) to hard water. The calcium and magnesium ions in the water react with the lime and soda ash to form insoluble precipitates, which can then be removed through sedimentation or filtration, resulting in softened water. Phosphate Conditioning Phosphate conditioning is a water treatment process that involves adding phosphate compounds to water to inhibit the precipitation of calcium and magnesium salts. Phosphates form complexes with calcium and magnesium ions, preventing them from forming scale deposits or interfering with soap lathering, thus helping to soften the water. Silica Removal Silica removal is a process used to eliminate silica compounds from water. Silica can cause scaling issues in industrial processes and reduce the efficiency of equipment. Various methods such as coagulation, filtration, or ion exchange can be employed to remove silica from water. Deaeration Deaeration is a process that removes dissolved gases such as oxygen and carbon dioxide from water. These gases can cause corrosion in pipelines and equipment or affect certain industrial processes. Deaeration methods include mechanical deaeration using vacuum systems or chemical deaeration using oxygen scavengers. Water Purification Water purification refers to the process of removing contaminants, impurities, and microorganisms from water to make it safe for consumption or specific industrial applications. Common purification methods include filtration, disinfection (e.g., chlorination), distillation, reverse osmosis, and UV treatment. Municipal Water Conditioning Municipal water conditioning involves treating water at a centralized facility before distributing it to households and businesses within a city or town. The goal is to ensure that the water meets regulatory standards for quality, safety, and aesthetics by removing impurities, adjusting pH levels, disinfecting, and softening if necessary. Industrial Water Conditioning Industrial water conditioning focuses on treating water used in various industrial processes to meet specific quality requirements. This may involve removing contaminants, adjusting pH levels, softening hard water, controlling corrosion, preventing scaling, or addressing other issues relevant to industrial operations.