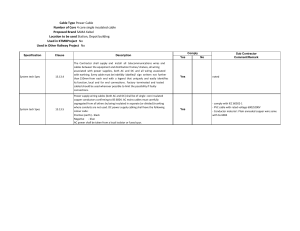

Confidential External SPECIFICAT ION INSTALLATION REQUIREMENTS FOR LV AND MV (13.8 kV, 22 kV and 33 kV), UNDERGROUND C ABLES N EO M -NDS-ST D - 20 2 R ev 01. 00 , ©NEOM [2023]. All rights reserved. 4 Confidential External Oct 202 3 Confidential External Document History Revision code Description of changes Purpose of issue Date Published Version Issued for Implementation 02.10.2023 01.00 Document Approval Prepared by Reviewed by Approved by Name Hussain Alsuwaidan / Atif Haq Willaim Woods Richard Saxon Job Title Principal Engineers DSO Senior Manager – Operational Standards Head of Engineering Document Preface Key Stakeholders: ETSD, Projects / Regional (All regions), Environment, All Sectors (Line, OXAGON etc.), ENOWA Added Value: This document details technical requirements in relation to distribution cable installation for use on NEOM ENOWA Electrical Distribution Network. Impact: Ensures that the equipment meets the requirements of this document which in turn will result in safe, reliable and cost effective ENOWA Electrical Distribution Network. Amendments Distribution System Operator (DSO) documents are reviewed periodically. Any request to update part of or a whole document shall be made in writing addressed to the Author of the document via the DSO mailbox (DSO_Publications_Feedback@neom.com). Disclaimer: As DSO’s documents are subject to ongoing review, the information contained in this document may be amended by DSO at any time. It is possible that conflict may exist between versions of documents. In this event, the most recent version published to the NEOM Online Library shall prevail. Interpretation In the event that the user of this Document considers any of its provisions uncertain, ambiguous or otherwise in need of interpretation, the user shall request DSO to clarify the provision(s) in writing via DSO_Publications_Feedback@neom.com mailbox. DSO’s interpretation shall then apply as though it was included in the published document and is final and binding. No correspondence will be entered into with any person disputing the meaning of the provision published in the Document or the accuracy of DSO’s interpretation. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 2 OF 36 Confidential External Contents 1 PURPOSE............................................................................................................. 6 2 SCOPE ................................................................................................................. 6 2.1 Excluded from Scope............................................................................................. 6 3 DEFINITIONS........................................................................................................ 6 3.1 Terms.................................................................................................................... 6 3.2 Abbreviations......................................................................................................... 7 4 REFERENCES ...................................................................................................... 7 4.1 Incorporated Documents........................................................................................ 7 4.2 NEOM Documents................................................................................................. 8 4.3 Other Documents .................................................................................................. 8 5 GENERAL REQUIREMENTS................................................................................ 8 5.1 Safety Requirements in Trenches and Pits............................................................. 8 5.2 Rights of Way ........................................................................................................ 9 6 CABLE INSTALLATION DESIGN REQUIREMENTS............................................. 9 6.1 Cable Route Planning............................................................................................ 9 6.1.1 LV Service Cables ............................................................................................... 11 6.1.2 LV Mains Cables ................................................................................................. 11 6.1.3 MV Mains Cables ................................................................................................ 12 6.1.4 Location of Cable Trenches ................................................................................. 12 7 CORRECTION FACTORS................................................................................... 12 7.1 Correction Factors for Ducted Cable Systems ...................................................... 13 7.2 Correction Factors for Ambient Air Temperatures ................................................. 13 7.3 Correction Factors for Ambient Ground Temperatures.......................................... 14 7.4 Correction Factors for Burial Depth ...................................................................... 14 7.5 Correction Factors for Soil Thermal Resistivity ..................................................... 14 7.6 Correction Factors of Backfill Types ..................................................................... 15 7.7 Separation from other Heat Sources and Adjacent Cable Circuits......................... 16 7.7.1 Correction Factors Single Core and 3-Core Cables .............................................. 16 8 CABLE INSTALLATION METHODS ................................................................... 16 8.1 Direct Buried Ducted Cable System ..................................................................... 17 8.1.1 Duct Size and Bend Considerations ..................................................................... 17 8.1.2 Duct Joints .......................................................................................................... 18 8.1.3 Duct Inspection and Cleaning .............................................................................. 19 8.1.4 Duct Installation and Formation............................................................................ 19 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 3 OF 36 Confidential External 8.1.5 Provision of Spare Ducts...................................................................................... 19 8.2 Direct Buried Cables............................................................................................ 21 8.3 Duct Banks.......................................................................................................... 21 8.4 Surface Troughs.................................................................................................. 22 8.5 Buried Troughs.................................................................................................... 23 8.6 Tunnels and Culverts........................................................................................... 23 8.7 Horizontal Directional Drilling ............................................................................... 24 9 CABLE TRENCH SPECIFICATION..................................................................... 25 9.1 General Requirements......................................................................................... 25 9.2 Cable Trench Depth............................................................................................. 26 9.3 Trench Bedding ................................................................................................... 27 9.4 Laying Cables at Reduced Depth......................................................................... 27 9.5 Separation Between Parallel Circuits and Other Utilities ....................................... 27 9.6 Bedding and Backfilling........................................................................................ 28 9.7 Joint Bays............................................................................................................ 29 10 CABLE LAYING.................................................................................................. 30 10.1.1 Cable Installation Requirements........................................................................... 30 10.1.2 Drum inspection and Positioning .......................................................................... 31 10.1.3 Cable Protection from Damage ............................................................................ 31 10.1.4 Cable Pulling ....................................................................................................... 31 10.2 Cable Protection.................................................................................................. 32 10.2.1 Warning Tapes, Protection Tapes, Protection Tiles, and Marker Posts.................. 32 10.3 Reinstatement ..................................................................................................... 33 11 REQUIREMENTS FOR CROSSINGS.................................................................. 33 11.1 Road Crossing..................................................................................................... 33 11.2 Highway Crossings.............................................................................................. 33 11.3 Pipelines and other Cables Crossing.................................................................... 33 12 CABLE DUCT SEALING SYSTEMS ................................................................... 34 13 APPENDICES ..................................................................................................... 36 Appendix A Details of Cable Trenches Appendix B Details of Cable Marker Post Appendix C Traditional and Non-Traditional Cable Backfill Material D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 4 OF 36 Confidential External List of Tables Table 1 Correction Factors CF1A...................................................................................... 13 Table 2 Correction Factors CF2B...................................................................................... 13 Table 3 Correction Factor CF3C ....................................................................................... 14 Table 4 Correction Factor CF4D ....................................................................................... 14 Table 5 Correction Factor CF5E ....................................................................................... 15 Table 6 Correction Factor CF6F........................................................................................ 15 Table 7 Permissible underground cable installation methods............................................. 17 Table 8 Minimum Duct Sizes for ENOWA DSO Approved Cables...................................... 18 Table 9 Minimum trench depth / cover for LV cables ......................................................... 26 Table 10 Minimum trench depth/cover for 13.8 kV and 33 kV cables.................................. 26 Table 11 Minimum Joint Bay Size .................................................................................... 29 Table 12 Traditional and Non-Traditional Cable Backfill; Maximum Dried-Out Thermal Resistivity (TR)................................................................................................................. 55 List of Figures Figure 1 Minimum Separation of LV and MV Cables from other Utilities............................. 10 Figure 2: 2 x 33kV Cable Circuits with an Example of the 50°C Isotherm. Soil Thermal Resistivity Within Isotherm Modelled as STR Fully Dried and Normal STR Value of Known Native Soil Outside Isotherm Modelled.............................................................................. 15 Figure 3 Correction Factor CF7G...................................................................................... 16 Figure 4 Typical spare ducts arrangement......................................................................... 20 Figure 5 Typical spare duct arrangement where duct cannot be laid horizontally................ 21 Figure 6 Typical Single Circuit HDD with one spare duct – three core or single core cable in trefoil................................................................................................................................ 25 Figure 7 Typical 13.8 kV Joint Bay Layout......................................................................... 29 Figure 8 Joint Bay design for 33 kV continuously rated single core cables ......................... 30 Figure 9 Examples of Duct Sealing Systems ..................................................................... 34 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 5 OF 36 Confidential External 1 Purpose This standard provides the minimum requirements for the installation of 13.8 kV, 22 kV, and 33 kV and LV underground cables compliant to NEOM-NDS-SPC-001 & NEOM-NDS-SPC004. It is intended to provide minimum technical requirements to ensure saf e and ef f icient installation of underground cables to meet the distribution grid saf ety and reliability requirements. 2 Scope This document applies to the installation of 13.8 kV, 22 kV,33 kV, and LV underground cables on NEOM electrical distribution network. 2.1 Excluded from Scope This standard does not include the f ollowing. 3 • Underground cable installation within customer premises that are beyond the meter. • Cable installation inside indoor/outdoor distribution substations • Cable installation inside Ring Main Unit and metering units • Submarine cables installation • Cables installation inside high-rise buildings (ref er to NEOM-NDS-EMR-200) • Cables installation inside substation buildings Definitions • 3.1 For a comprehensive list of definitions for the terms and abbreviations used at NEOM, see the List of Definitions and Abbreviations (NEOM-NEN-SCH-006). Terms Term Definition Company The owner of Neom region, named “NEOM” Conduit Another name given for cable duct Continues Loading The actual load is almost constant with time and the load does not change significantly in steps. Contractor/Cable Contractor means a person or an entity who is going to undertake the construction work for cable installation ENOWA A subsidiary of the Company High Voltage means a nominal voltage exceeding 1,000V ac Low Voltage means a nominal voltage equal to 1000V ac or below May/Might Donates a deviation from the Specification that is not preferred but which DSO may accept if there are compelling reasons to do so D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 6 OF 36 Confidential External Term Definition Must/Shall Denotes a requirement that is mandatory. These are pass/fail criteria Native Soil The soil that could surround a cable or duct unless special backfill material is used and within 50°C isotherm contour Should Denotes a requirement for which Tenderers may put forward an alternative proposal. Requirements denoted by ‘should’ are pass/fail criteria unless the Company (at its own discretion) accepts the alternatives proposed Soil Dry Out When the native soil is exposed to a cable oversheath (or cable duct) that is operating at a temperature of 50°C or above Soil Thermal Resistivity Measures the capacity of the native soil to conduct or dissipate heat. The heat produced by current flowing through an underground power cable must be properly dissipated. The thermal resistivity of the native soil will determine whether a buried power cable remains cool or overheats Standard 3.2 A voluntary document, established by a consensus of subject matter experts and approved by a recognized body, which provides rules and best practices for a material, product, process, or service Abbreviations Abbreviation Definition CBS Cement Bound Sand CF Correction Factor GRP Ground Penetrating Radar HDD Horizontal Directional Drilling HDPE High Density Polyethylene LV Low Voltage MV Medium Voltage (13.8 kV, 22 kV and 33 kV) OD Outer Diameter PVC Polyvinyl Chloride R.O.W Right of Way RMU Ring Main Unit SDR Standard Dimension Ratio STR Soil Thermal Resistivity 4 References 4.1 Incorporated Documents The latest revisions of the following documents must be considered as incorporated as part of this document in part or whole in the context to which they are ref erenced. In case of any D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 7 OF 36 Confidential External conf lict between the requirements of this standard and these documents, this standard must prevail. 4.2 4.3 NEOM Documents Document no. Document title NEOM-NEN-SCH-001 NEOM occupational safety, health, and fire safety requirements for contactors NEOM-NDS-EMR-003 Distribution System Design Standard for MV Grids Part 03 NEOM-NDS-SPC- 001 Technical Specification for XLPE insulated Power Cables for rated voltages of 13.8 kV and 33kV (MV Cables) NEOM-NDS-SPC- 004 Technical Specification for XLPE Insulated Low Voltage Power Cables for Rated Voltages up to 1000 V NEOM-NDS-SPC- 005 Technical specification for HDPE Conduits NEOM-NDS-SPC- 006 Specification for MV Cable Accessories NEOM-NDS-SPC- 022 Specification for Warning Tapes, Protection Tapes and Protection Tiles for Buried LV and MV cables NEOM-NDS-SPC- 023 Specification for Cable Duct Sealing System NEOM-NDS-EMR-200 Cable installation requirements inside High Rise Buildings using cable ladder and trays system Other Documents Document no. Document title SDCS-02-17 Construction Standard for Underground distribution Network Part 17: Cable Trenches ASTM-2103 Standard Specification for Polyethylene Film and Sheeting ASTM-C-150 Specification for Portland cement EN 61386 Conduit system for cable management 5 General Requirements 5.1 Safety Requirements in Trenches and Pits All work must be carried out to meet the requirements of NEOM occupational safety, health, and f ire safety requirements for contactors (NEOM-NEN-SCH-001). In addition, all trench work shall comply with safety requirements related to trench saf ety requirements including but not limited to: • Ensure a survey has been carried out to identif y the existing services. • Placing the warning signs at the beginning and at the end of the excavation. Use of proper warning signs that are clear and in compliance with local authority requirement in NEOM. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 8 OF 36 Confidential External 5.2 • Providing proper barriers, and warning flashing lights, when trenches are kept open overnight. • Providing warning written signs f or pedestrians f rom both directions. • Providing adequate lighting during night f or distance of 2 meters. • The sand resulting from excavation must be piled safely away from the edge of the trench. • Ensure avoiding collapse of trench during rainy season. • Ensure proper ventilation during the work inside the trench. • When working in the vicinity of traffic, traffic management plan must be submitted to NEOM. • If the trench size is more than 1500mm, the shoring, benching or sloping needs to be properly designed and signed of f by a competent civil engineer. • Obtain Permit to work (excavation), including conf ined space working or interf ace/coordination with other service departments. Rights of Way The right of way for the proposed cable route described in Section 6.1 must be obtained f rom NEOM concerned authorities during the engineering stage of the project. The procedure f or obtaining the R-O-W includes the f ollowing: • Prepare R-O-W drawing showing the proposed route of the underground cable, cross-section of the trench or duct bank (if required) and location of other utilities (e.g. telephone, water, sewer) lines along the proposed route • Submit R-O-W drawing to the concerned authorities within NEOM through land use permit system. • The actual construction work shall not be started until the digging permit f rom the concerted authority is granted. 6 Cable Installation Design Requirements 6.1 Cable Route Planning The Contractor shall be responsible for determining an appropriate cable route or agreeing in principle to a proposed cable route which must be reviewed by ENOWA DSO. All cables shall be proposed to be installed on public land unless engineering dif f iculties dictate otherwise. When routing new cables, the Contractor must consider the potential f or f uture network extensions to cater f or load development. Where practicable, the cable route shall avoid sections of shallow installations. If sections of shallow cables are unavoidable, they should have a level of protection suitable f or the security risk at that site as detailed in Section 8.4 Laying cables at a reduced depth. The Contractor shall ensure that the cable routes are simple, direct with minimal bends and the minimum of cross-over particularly in the open trench work of substations. New D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 9 OF 36 Confidential External substations with newly installed cable circuits shall have no crossovers between cable circuits leaving the switch room. Consideration shall also be given to minimizing the volume of joints required as part of the installation. Where practical and economic, the Contractor shall ensure that the cables are laid on a route that is separate f rom other cables supplying or providing security to the NEOM ENOWA network. Where cables are laid in proximity to existing cables or other heat sources, suf f icient spacing should be allowed to prevent increased de-rating of either circuit. Where multiple cables enter a building (e.g., switch room), these cables shall be laid directly to minimize the ef f ect of mutual heating. All measures shall be taken to avoid damage to other utilities and third-party plants and equipment. Figure 1 illustrates the minimum separation of ENOWA DSO cables in relation to other utilities apparatus, in a 2-meter-wide footpath. The location of new LV and MV cables shall f ollow this guidance wherever possible unless a greater depth is required, ref er to Section 9.2. Where cables are installed above each other, the lower cable may be installed deeper with the correct de-rating factor applied to achieve minimum separation (refer to Section 7.4) as shown in the diagram. Figure 1 Minimum Separation of LV and MV Cables from other Utilities All other statutory undertakers and the local authorities shall be contacted to determine the position and depth of their apparatus in the proposed route before any trial holes, excavation or cable installation is carried out. Trial hole and core samples will need to be taken from the pref erred route f or the purpose of : • Thermal resistivity sampling at pref erred intervals of 250 m or at changes in soil type, f or cable rating and de-rating calculations. See Section 7.5. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 10 OF 36 Confidential External • The f ootpath or road make-up, details of layer materials and thickness f or restoration purposes. • Characterization of soil layers and environmental testing, for work method planning. GPR survey(s) can be employed. Trial holes will need to be excavated at the survey stage to gain details of known obstructions / pinch points that may affect route viability and waste classif ication. The Contractor shall determine the position of the trial holes along the proposed cable route(s) and arrange for excavations to establish the final joint bay and auxiliary equipment positions such as Link Pillars. The Contractor must inspect the cable route to ensure that the f ollowing criteria is met: • Depth of installation – The cable(s) shall be laid in accordance with the agreed plan throughout the route. Ref er to Section 9.2 and Appendix A. • Cable circuit separation – Double (or more) 13.8 kV, 22 kV and 33 kV cable circuits shall meet the minimum separation requirements as illustrated in Appendix A. The Contractor must consider the appropriate correction factor based on the separation distance. • Cable conduits (if proposed) – All conduits (ducts) that are intended to house cables up to and including 33 kV shall comply with NEOM-NDS-SPC-005. • Cable marker posts – ENOWA DSO approved cable marker posts shall be installed in the f ollowing locations: a. Crossings of dual carriageways, motorways or railways. b. At the entry/exist of cable culverts and tunnels. c. Where cables have been laid at a reduced depth. 6.1.1 • Protection cable covers and tiles – The cable systems up to 33 kV including the joints and backfill must be protected by covers and tiles as detailed in Section 9.2. • Utility information – All other utility inf ormation and drawings along the proposed cable route corridor shall be obtained and included on the cable route layout drawing. Utility drawings shall be no more than 12-weeks old. LV Service Cables All LV service cable installations shall only run within the boundaries of the properties it supplies, i.e., a service to any one property shall not cross land belonging to another. 6.1.2 LV Mains Cables All new mains cables shall be laid in the first installation in a f ootpath and/or verge to an LV distribution pillar in accordance with Table 7 Permissible underground cable installation methods Surface type Direct buried cables Direct buried ducts Duct banks Footway Permitted Permitted Not permitted Undeveloped land Permitted Permitted Not Permitted D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 11 OF 36 Confidential External Surface type Direct buried cables Direct buried ducts Duct banks Road with heavy vehicular traffic Not permitted Permitted Permitted Road without Heavy vehicular traffic Not Permitted Permitted Permitted Road crossing Not Permitted Permitted Permitted . The LV mains cables shall not be routed within the boundaries of private properties. 6.1.3 MV Mains Cables All MV mains cables up to and including 33 kV shall be in the first instance proposed to be installed in a footpath and/or verge via a direct buried or a suitable duct arrangement as per Table 7 Permissible underground cable installation methods 6.1.4 Surface type Direct buried cables Direct buried ducts Duct banks Footway Permitted Permitted Not permitted Undeveloped land Permitted Permitted Not Permitted Road with heavy vehicular traffic Not permitted Permitted Permitted Road without Heavy vehicular traffic Not Permitted Permitted Permitted Road crossing Not Permitted Permitted Permitted Location of Cable Trenches Having decided upon the cable route including the requisite clearances f rom other utility equipment, the Contractor shall establish trench locations and depths as described in Section 8. 7 Correction Factors Correction factors (also known as de-rating factors) is a multiplier that shall be applied to the cables’ ampacity rating to change the value depending on various operating conditions such as: • Ducting more than 15 meters • Ambient Air Temperature • Ground Temperature • Burial Depth D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 12 OF 36 Confidential External • Soil Thermal Resistivity • Backf ill Type • Separation f rom other heat sources and adjacent cable circuits Applying correcting factors is essential to choose the suitable cable for the load. Correction f actors (otherwise known as De-rating factors) shall be used in the Contractors cable rating calculations to manage the cable’s current carrying capacity and increase the safety margin between the cable’s specification limit and the maximum load. This will also provide extra protection to ensure the cable does not f ail when the temperature or other external conditions change. Applying proper cable derating will mean decreasing the maximum current that cables were designed to carry for the purpose of protecting the XLPE insulation of the cable against deterioration caused by extreme heat. The Contractor shall consider and apply, when appropriate, the de-rating f actors in the f ollowing situations described in this section. 7.1 Correction Factors for Ducted Cable Systems The Contractor shall check if the cable ratings used are f or direct buried or f or ducted cable system. If the ratings obtained are for ducted system, the correction f actors in Table 1 are not applicable. Table 1 Correction Factors CF1A 7.2 Installation CF1A Laid Direct – three core cable, 3 single cored cables laid in a tight trefoil or LV 1.00 Laid in Duct. Laid in trefoil and runs less than 15 meters 1.00 Laid in unfilled HDPE duct. Runs longer than 15 meters – three or four core cable or 3 x single core cables in tight trefoil in same duct 0.82 Laid in unfilled HDPE duct. Runs longer than 15 meters – 3 x single core cables laid in separate ducts with the ducts installed in trefoil formation 0.80 Correction Factors for Ambient Air Temperatures The Contractor shall use CF2B when proposing ventilated and unventilated cable tunnels and culverts. Table 2 Correction Factors CF2B Maximum Conductor Ambient Air Temperature °C Temperature °C 20 25 30 35 40 45 50 55 60 1.08 1.04 1.00 0.96 0.91 0.87 0.82 0.76 0.71 90 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 13 OF 36 Confidential External 7.3 Correction Factors for Ambient Ground Temperatures Table 3 Correction Factor CF3C Maximum Conductor Ambient Ground Temperature °C Temperature °C 10 15 20 25 30 35 40 45 50 1.07 1.04 1.00 0.96 0.93 0.89 0.85 0.80 0.76 90 7.4 Correction Factors for Burial Depth The Burial Depth is the ‘X’ distance shown in the Trench Drawings found in Appendix A i.e., f rom the top of the cable to the f inal surf ace level. For Burial Depth greater than 3 meters and/or HDD installations, the Contractor shall use ENOWA DSO recommended propriety sof tware program ‘CYMCAP’ and/or DIG silent to simulate the proposed greater burial depth to establish the de-rating on the cable(s). Table 4 Correction Factor CF4D 7.5 Burial Depth (m) Voltage CF4D 0.45 LV 1 0.5 MV 1.03 0.6 13.8 1 0.6 33 1.01 0.8 13.8 0.98 0.8 33 1 1.0 MV 0.96 1.25 MV 0.94 1.5 MV 0.93 1.75 MV 0.90 2.0 MV 0.89 2.5 MV 0.86 3 MV 0.80 Above 3 meters MV CYMCAP/DIG Silent Simulation required Correction Factors for Soil Thermal Resistivity The Contractor shall note that one of the major risks to a cable’s operating temperature and to network reliability is soil dry out. Soil dry out will begin when the native soil is exposed to a cable oversheath (or cable duct) that is operating at a temperature of 50°C or above. There may be some locations that include sandy soils where dry out occurs when the soil is exposed to less than 50°C. The risk of the native soil drying out is it will increase the soil thermal resistivity, which will decrease the ability to transf er heat f rom the cable and may result in thermal runaway. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 14 OF 36 Confidential External Theref ore, the Contractor shall carry out soil thermal resistivity testing during detailed design to obtain a more accurate on-site dry out STR value. The Contractor may either use a propriety software program such as CYMCAP/DIG Silent to simulate and establish the 50°C isotherm or f or simpler installations incorporate the correction factors in Table 5 (CF5E) below as part of the cable’s installation and ratings assessment. The contour that depicts the 50°C isotherm modelling in CYMCAP must be included in the rating reports and submitted to ENOWA DSO. Ref er to f igure 2 below f or guidance. Table 5 Correction Factor CF5E Correction Factor Values of Soil Thermal Resistivities (°C m/W) CF5E 0.7 0.8 0.9 1.0 1.2 1.5 2.0 2.5 3.0 1.15 1.12 1.10 1.07 1.0 0.90 0.85 0.79 0.72 Figure 2: 2 x 33kV Cable Circuits with an Example of the 50°C Isotherm. Soil Thermal Resistivity Within Isotherm Modelled as STR Fully Dried and Normal STR Value of Known Native Soil Outside Isotherm Modelled 50°C isotherm modelling is only required for the normal rating, not the abnormally switched (emergency) rating. One of the methods to manage the risk of the native soil drying out is to use a stabilized backfill as per Appendix C where the calculated temperature in the ground is 50°C or greater. Where stabilized backfill is used, the 50°C isotherm must be contained within the stabilized backf ill. Another method to mitigate the risk, is to consider the drying out effect as part of the cable rating calculations by assuming that the backf ill and native soil within the 50°C isotherm (50°C isotherm is determined through CYMCAP modelling) will completely dry out and then use a f ully dried value for the thermal resistivity within this zone and the normal soil thermal resistivity value of the known native soil outside the 50°C isotherm. 7.6 Correction Factors of Backfill Types The Contractor shall ref er to Section 8.6 f or more guidance on Backf ill Types. Table 6 Correction Factor CF6F D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 15 OF 36 Confidential External Backfill Type Summer Soil Thermal Resistivity CF6F Stabilized Backfill such as CBS as per Appendix C 1.20 1 Selected backfill i.e., builders’ sand 2.5 0.79 Unknown thermal resistivity backfills Assumed 3.0 0.72 7.7 Separation from other Heat Sources and Adjacent Cable Circuits 7.7.1 Correction Factors Single Core and 3-Core Cables * The Contractor shall note ENOWA DSO minimum separation f or MV cables is 300 mm. Figure 3 Correction Factor CF7G Spacing Number of Cable Circuits 8 Spacing Spacing between cable circuits (mm) CF7G Touching Trefoil Laid Flat 0.2 0.3* 0.4 0.5 0.6 0.7 0.8 2 0.73 0.77 0.81 0.85 0.88 0.89 0.90 0.91 0.92 3 0.60 0.66 0.70 0.76 0.79 0.82 0.83 0.85 0.86 4 0.54 0.63 0.65 0.72 0.75 0.79 0.80 0.82 0.84 5 0.49 0.59 0.60 0.68 0.72 0.76 0.78 0.80 0.82 6 0.46 0.57 0.57 0.66 0.70 0.74 0.76 0.79 0.81 Cable Installation Methods Cables shall only be installed underground with the one of f ollowing installation types: • Direct buried ducts • Direct buried cable • Duct banks • Surf ace and buried troughs • Culverts and tunnels • Horizontal directional drill The Contractor shall select the cable installation method in accordance with Table 7. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 16 OF 36 Confidential External The Contractor must seek approval from ENOWA DSO for cable installation proposals that do not comply with the below. Table 7 Permissible underground cable installation methods Surface type Direct buried cables Direct buried ducts Duct banks Footway Permitted Permitted Not permitted Undeveloped land Permitted Permitted Not Permitted Road with heavy vehicular traffic Not permitted Permitted Permitted Road without Heavy vehicular Not Permitted Permitted Permitted Not Permitted Permitted Permitted traffic Road crossing 8.1 Direct Buried Ducted Cable System Direct buried ducted cable systems should be pref erred method of cable installation in accordance with Table 7, except where on-site conditions dictate otherwise. New cable ducts shall be black with red co-extruded color longitudinal striped identif ication and marked with the legend NEOM ENOWA ELECTRICITY on two diametrically opposite sides. The Contractor is responsible f or installing new cable ducts in a manner which will ef f ectively prevent future movement of the cable duct once in operation, by being embedded in sand, selected excavated granular material, imported granular material, mass or reinf orced concrete as appropriate. The entry of a cable into a duct shall be arranged so that no damage is caused either during or after installation by the cable scraping or resting on the lip of the duct. 8.1.1 Duct Size and Bend Considerations The duct must not restrict the cable during the pulling nor during its operation. During pulling, if the clearance between the outside diameter of the cable and the inside diameter of the duct is too small, the cable will be more restrained at the bends, leading to higher pulling tensions and sidewall bearing pressures. Cables with larger outside diameters tend to be stif f er and require more energy to bend. Theref ore, the Contractor shall ensure that there is enough clearance between the cable and the inside diameter of the duct as if this is too small, it will cause the cable to behave more like a straight bar as opposed to a f lexible element and will not allow cable snaking to take place because of thermal expansion. This will ultimately result in higher thrust forces at the joints and terminations. The Contractor shall ref er as guidance to Table 8 which details the minimum duct sizes required f or installations in accordance with the trench sections shown in Appendix A. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 17 OF 36 Confidential External Table 8 Minimum Duct Sizes for ENOWA DSO Approved Cables Voltage Cabe Size (mm)² Cable Type Minimum OD/ID SDR11 Cable Duct Size (mm) OD ID LV 16 2 and 4-Core 40 32 LV 25-50 4-Core 50 40 LV 70-300 4-Core 140 113 LV 35 Single Core 75 60 LV 120-500 Single Core 160 129 13.8 185-300 3-Core 180 145 13.8 95-400 Single Core 180 145 13.8 500-630 Single Core 200 162 13.8 800-1000 Single Core 250 203 33 185-300 3-Core 180 145 33 95-300 Single Core 180 145 33 400-630 Single Core 200 162 33 800-1000 Single Core 250 203 The radius of bends in ducts shall be as large as reasonably practical and generally shall have radii of at least 20 times inside diameter. The radius of bends in ducts adjacent to cable terminations may approach the minimum value specified for the cable. Bends of signif icant severity at other positions shall not be proposed to ENOWA DSO. The Contractor shall install a draw pit to negotiate the change of direction in such situations. 8.1.2 Duct Joints For HDPE ducts, the most commonly used jointing methods shall be: • Socket Joints with Sealing Rings • Electro-Welded Joint • Butt Welded Joints In the event of joints having to be devised on site, the Contractor shall make sure the joints are made in a workmanlike manner and effectively exclude water, gas and vermin f rom the pipe. If the jointing process leaves a significant bead inside and outside the duct: such a bead shall be removed, at least inside to provide a smooth inner surf ace. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 18 OF 36 Confidential External 8.1.3 Duct Inspection and Cleaning Cable ducts must be tested by the Contractor for freedom from obstructions after installation by drawing a mandrel of appropriate size through the bore. A shallow pit shall be dug at duct entry positions to ensure that stones etc. are not dragged into the duct bef ore any cables are installed. Following the mandrel test a draw wire shall be placed in the ducts, and the ends shall be capped to ensure the ducts remain clean and dry. Where reasonably practicable, before a cable is installed, all duct lines shall be checked and cleared of all obstructions. To ensure that the duct is suitable f or the type of cable to be installed, a 3-meter length of the cable to be installed shall be pulled through the complete length of duct. This shall then be examined for damage before any attempt is made to install the complete cable. If the sample of cable is found to have deep scores and tears in its outer sheath, which are more than half the thickness of the outer sheath, the duct route shall be repaired bef ore any attempt is made to install the f inal length of cable. In all cases no beads, protrusions or steps shall be present inside the ducts, that may damage the cable outer sheath and increase the f orces during pulling. It must also be verif ied if duct joints can prevent pulling in one of the two possible directions. 8.1.4 Duct Installation and Formation Service cables and LV mains cables shall be installed one cable per duct. It is however permissible to install two service cables in the same duct in a road crossing. 13.8 kV and 33 kV 3-core and Triplex cables shall be laid in a single duct. For a large cross-sectional area (e.g., transformers to primary switchgear), cables may be installed as single cores in a single duct. 33 kV single core cables shall be installed in a single duct if the cores are adequately secured to ensure that they remain in a tref oil f ormation without damaging the cables. Larger 33 kV single core cables may be installed one cable per duct, with the ducts arranged in a trefoil formation however, it is preferred that the Contractor select a large duct as per Table 9 to accommodate 3 single cores in the one duct. Ducts required for ENOWA DSO protection and telecommunication circuits shall normally be laid to the side of the power cable in accordance with Appendix A. The pilot cable shall be laid nearest to their associated power cable. Ducts installed for road crossings shall normally be installed at right angles to the kerb and must extend approximately 150 mm beyond the kerb foundation into the pavement or verge. Ducts will be laid in such a manner to avoid any permanent obstructions located within one meter of the duct ends. A draw rope suitable f or purpose shall be installed. Immediately af ter installation, the Contractor shall ensure the ducts must be rodded clean and sealed. Spare ducts shall be f illed with a suitable plug before sealing. If the ground is to be backf illed bef ore the duct is used, the position of the duct ends shall be clearly marked with yellow marker paint. 8.1.5 Provision of Spare Ducts A minimum of one spare duct will be laid f or each voltage level installed in the f ollowing situations: • Horizontal directional drills. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 19 OF 36 Confidential External • Road crossings. • Motorway, railway and river crossings. • Where cables are installed greater than 1.5 x standard laying depths (even if the cable is direct buried). • Thick concrete surfacing (in excess of 50 mm thick) and the like, with or without reinf orcing. This list is not exhaustive and where anything which could lead to engineering difficulties f or repair could be encountered additional ducts must be provided. Spare ducts shall normally be laid adjacent to the used duct and spaced in accordance with the trench prof iles. This arrangement is shown Figure 3, which although showing a dual voltage installation is also representative of a single voltage installation. Figure 4 Typical spare ducts arrangement The vertical arrangement in Figure 4, can be used where the provision of a spare duct horizontally cannot be done. There are three important points the Contractor must take into account f or in the design: • The top duct must be the spare duct and laid at a depth appropriate to the voltage level of the used duct. • The vertical separation between the top and bottom duct must be the same as shown on the trench sections f or the horizontal separation f or dual cables of the same voltage. • An additional de-rating factor shall be applied to the lower cable as applicable to the depth of laying in accordance with Section 7. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 20 OF 36 Confidential External Figure 5 Typical spare duct arrangement where duct cannot be laid horizontally 8.2 Direct Buried Cables Direct buried cable systems shall be the preferred method of cable installation in f ootpaths, verges and in new substations (as per Table 7) due to its cost eff ectiveness, except where on-site conditions dictate otherwise. For direct buried double LV and MV cable circuits, there shall be a minimum separation of 200 and 300mm respectively (f rom cable center to cable center) however the Contractor should consider a 500 mm separation between adjacent circuits to enable a cable to be repaired while the adjacent cable circuits remain energized. Greater separation may be required to meet thermal ratings. 8.3 Duct Banks The Contractor may choose to install duct banks that are encased in concrete however the thermal resistivity of the concrete shall be 1.0 K-m/W or less. The thermal resistivity of the concrete in the duct bank shall be measured if the Contractor takes a sample to be measured or calculates the thermal resistivity if the concrete mixture used in the duct bank is known. The cables shall be installed in the duct banks in the same manner as f or the direct buried cable systems as per section 8. Ref er to the trench designs f ound in Appendix A. If the Contractor should propose single core cables in single ducts in a f lat f ormation, this will need approval from ENOWA DSO. The Contractor will make certain that the out of tref oil section(s) are short as possible, and the single core cables returned to tref oil as soon as possible to avoid circulating currents. The specif ication of the duct bank shall be as f ollow: • The duct bank shall consist of either hot dip galvanized rigid steel or HDPE conduit, encased in concrete. • All concrete surfaces in contact with ground shall be provided with two (2) layers of polyethylene vapor barrier / Each layer shall be six (6) Mil Thickness and in Accordance with ASTM-2103 • In laying HDPE conduit, each piece of conduit shall be inspected f or breakage. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 21 OF 36 Confidential External 8.4 • Conduit runs within the duct bank shall be made continuous, using threaded couplings. • Where jointing conduits, the conduit end without socked only shall be coated with solvent cement and the conduits joined with a twisting motion to spread the cement. • As f ar as possible, conduits shall be installed so that the cable will enter and leave through the socket ends of the conduits. In case of dif f iculty in arranging this, a straight coupling shall be installed on the plain end of the conduit and cable shall be pulled through this coupling. • Construction of a concrete encased duct bank consists of installing the conduits on spacers or fixing them to the reinforcing steel bars driven inside the ground along the trench length and pouring the concrete encasement. Spacers or bars f or supporting the conduit are installed at intervals or approximately 2.5 meters. • Concrete specification shall be type V (sulphate resistant) conf irming to ASTM C150 • If the concrete mix is sloppy, it may be necessary to weight or brace the duct assembly to prevent it from floating. Sandbag or other weights can be placed over the conduit spacers. This is not required if conduits are already f ixed to the reinf orcing steel bars. • If it is necessary to interrupt the concrete pouring for any appreciable time, as f rom one workday until the next, the joint between the pouring shall be made as near vertical as possible and shall be reinf orced with 12 mm dia. Concrete reinf orcing bars which extend into the concrete at least 600 mm on each side of the joint. Bars shall be placed at each corner of the duct bank, and they shall have a minimum cover of 80 mm of concrete. • Concrete f or duct bank construction shall conf orm to the specif ication given on Section 8.3 and shall be colored or painted red on the top surf ace (5 mm minimum thickness). • The end(s) of ducts and conduit terminating below grade or in open air shall be sealed with duct sealing putty or an equivalent compound. • At least 20% Spare conduits must be provided (minimum one), and it must be sealed against ingress of water and f oreign objects. Surface Troughs Surf ace troughs shall be installed at ground level or slightly recessed to provide stability without the need for any backfilling. The Contractor may choose to backfill depending on the cable ampacity requirements. Surf ace Troughs shall be made of concrete either precast or cast in situ. The Contractor must ensure the surf ace troughs are installed on stabilized sand or crushed road base bedding (blinding) when slightly recessed to ensure that one section of the trough does not subside in relation to the adjacent unit. The cables shall be installed in the trough in the same manner as f or the direct buried troughs, ref er to the trench designs f ound in Appendix A. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 22 OF 36 Confidential External Where the troughs are f illed with a thermally stable material having no cementitious component, there is a possibility that the cable will move in the vertical plane may take place, resulting in the lifting of the trough lids. In such cases, the Contractor must take care and ensure that the lids are either heavy enough, or f ixed to the trough, to resist such f orces. In those installations where the troughs are unfilled, it is likely that the cables will need to be snaked (generally in the horizontal plane) and cable cleats installed to cater f or thermomechanical effects This kind of trough in commonly used f or LV and MV cables in substations. 8.5 Buried Troughs For buried troughs, the civil work shall include the excavation of a trench and shoring when required by ground conditions. The troughs shall be made of reinforced concrete and must be installed in the open trench. Af ter installation of the cable and sealing of the trough, the Contractor shall backf ill the trench and layers of backf ill material (possibly the native soil) are compacted (where required). Care must be taken to leave no voids between the outer surface of the trough and the trench wall. Buried Troughs will have the same limits as for directly buried cables with an additional limit concerning the trough bending radius which is generally 70 times the cable outside diameter. The Contractor may have to carry out additional civil works if the excavated ground is unstable in any way. The installation of a blinding layer of concrete, stabilized sand or road base may be necessary to provide stability. From a thermal point of view, the Contractor must demonstrate the buried troughs method is better than direct buried method because of the improved heat flow provided by the use of concrete trough. The Contractor must consider the Troughs material and backf illing materials inside and outside of the troughs in the detailed design so that the thermal resistivity of the native soil is taken into account. 8.6 Tunnels and Culverts Although ENOWA DSO default position is to avoid culverts and tunnels, tunnels and culverts shall only be proposed by the Contractor when one or all the f ollowing conditions are encountered: • There are a significant number of cables required within a relatively conf ined area. • The number of circuits required need to have a high rating that cannot be achieved by having many cables in proximity in a direct ducted system, duct bank or direct laid situation. • Where the civil requirements of constructing duct-lines through urban environments using traditional techniques becomes cost prohibitive (civil requirement). • The selected route for the cable is already too congested with other services; and • The construction of a direct ducted system or duct bank is not f easible due to the location, resulting in unacceptable traffic congestion and general public disruptions. Since the tunnel construction method is much more expensive than the installation of ducts by open cut method, it is necessary f or the Contractor to evaluate the construction cost. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 23 OF 36 Confidential External Where a tunnel option is proposed, the Contractor shall select the appropriate tunneling technique based on a combined assessment of ground conditions, electrical requirements, required tunnel prof ile and the length of the required cable route. Tunnels should be designed so that they can be constructed through virtually any type of ground condition, so in instances where it has been assessed that the required cable route cannot feasibly be constructed using traditional techniques (direct buried, duct, duct banks etc.), the key consideration for the Contractor becomes a combined assessment of what type of tunnel will meet the electrical requirements of the cables while addressing the budget constraints. The Contractor shall also consider as part of the budget assessment, allowances f or f uture maintenance activities, given that these costs can dif f er considerable depending on the tunneling technique chosen. The use of tunnels and culverts to house cables over short distances, for example, beneath rivers and railways should not be considered over alternative and less expensive techniques such as HDD unless there is appropriate justification, which will be subject to ENOWA DSO approval. If cable culvert is to be used, it shall be designed according to the requirements presented in NEOM-NDS-EMR-003. The Contractor must provide all materials required f or the excavation including, but not limited to pumping equipment, shoring, backfill, etc. The equipment must be provided for the entirety of the project. 8.7 Horizontal Directional Drilling The Contractor shall use HDD only if other alternative means of crossing are not possible. Ampacity adequacy via CYMCAP or DigSILENT simulations shall verify the suitability of the HDD installation. The Contractor shall submit a directional drilling package containing the justif ication f or the proposed cable formation/ spacing, HDPE SDR conduit, filling compound (if any) and pipe size that will attain the required cable MVA rating f or technical review and approval of ENOWA. Site conditions shall be investigated by the Contractor. The Contractor shall take f ull responsibility f or maintaining and protecting all existing site utilities, soil condition and stability. It is the Contractor’s responsibility to provide and install a de-watering system if f ound necessary due to the high ground water table. The Contractor shall be also responsible f or disposing of f the ground water using water tankers. A minimum of one circuit run of spare ducts shall be provided in every directional drilling installation. All spare ducts shall have a 13 mm (112’’1 Nylon ) rope installed inside and all cable ducts shall be sealed with the use of duct sealing. HDPE conduit shall be terminated with end bells. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 24 OF 36 Confidential External Figure 6 Typical Single Circuit HDD with one spare duct – three core or single core cable in trefoil Test mandrel (6mm less in diameter than the normal inside diameter of the duct) and wire brush cleaner (6mm larger than the duct) shall be pulled through to each duct. A nylon pull line (13 mm diameter) should be installed in each duct line (power and communication) after cleaning, construction drawings which indicate duct line, length and routing shall be verif ied and f ield noted in conjunction with duct testing operation. 9 Cable Trench Specification 9.1 General Requirements Trenches shall be kept as straight as possible, and each trench shall be excavated to the dimensions which will be sufficient to allow cables to be installed at the depth and spacing specified in this document including the installation of protection tape/protection tiles as specif ied in this section. The trenches shall have vertical sides which shall be timbered, sheet piled, or trench sheeted where necessary so as to avoid subsidence and damage or possible injury. The contractor shall take all reasonable precautions to prevent damage to the carriageway or ground surf ace f rom a slip or breaking away of the side of the trench. Excavation and filling in shall be executed that all underground assets including but not limited to railways, tramways, walls, roads, sewers, drains, pipes, cables, tree roots, structures shall be reasonably secure against risk of subsidence or injury. The work shall be carried out to the satisf action of the Authorities concerned. Where a change of level is necessary, the bottom of the trench shall rise or f all gradually; there shall never be any step changes in the bottom level of a trench. The Contractor shall deal with and dispose of water so as to prevent any risk of the cable and other materials to be laid in the trenches being detrimentally affected. The Contractor shall provide pumps and appliances required and shall carry out the necessary pumping and bailing in a saf e, clean and environmentally f riendly manner. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 25 OF 36 Confidential External 9.2 Cable Trench Depth The minimum depth of burial requirements for LV cable systems is specified in Table 9 and Table 10 describes the minimum requirements for 13.8 kV, 22 kV and 33 kV cable systems. Cables shall not be laid less than the minimum depth unless it is not f easible. Appendix A provides the typical trench layout/dimension which must be maintained, for different types of installations. The specif ied cable depths can only be decreased f ollowing the completion of a risk assessment and once approved by ENOWA DSO, the cable installation proposal shall include any additional protective measures required to mitigate the risk associated with any reduced depth of cover. Ref er to Section 9.4. There is no specific maximum depth for cables to be laid, but consideration must be given to the load rating of the cables. If cables are installed at greater depth f or any reason, then a de-rating factor will need to be applied in accordance with Section 7. The need f or f uture works shall be considered so that they are carried out in a saf e manner. The standard trench sections presented in Appendix A show the minimum trench width f or various cable combinations. In addition, it shows the depth to the top of the cable or duct, the separation between circuits, and the clearance f rom edge of the trench. The Contractor shall request a design deviation from ENOWA DSO if the proposed cable trench design dif f ers f rom what is depicted in this standard. Table 9 Minimum trench depth / cover for LV cables Low Voltage Surface type Minimum cover of cable (mm) Minimum depth of trench Undeveloped land 450 600 Footpath 450 600 Carriageway 600 750 Agricultural Land 1000 1150 (mm) Table 10 Minimum trench depth/cover for 13.8 kV and 33 kV cables 13.8kV cable Surface type Minimum cover of cable (mm) 22 kV and 33 kV cable Minimum depth of trench Minimum cover of cable (mm) (mm) Minimum depth of trench (mm) Undeveloped land 600 910 800 1080 Footpath 600 910 800 1080 Carriageway 750 1060 900 1130 Agricultural Land 1000 1310 1100 1380 R EVISION : 01.00 PA GE 26 OF 36 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 ©NEOM [2023]. All rights reserved. Confidential External Confidential External 9.3 Trench Bedding LV, 13.8 kV and 22 kV cables shall be installed on a smooth bedding (e.g., sand or f inef ill). The depth of the trench may need to be increased by the appropriate amount to ensure that the required minimum cover is achieved. All 33kV cables shall be laid on a bed of stabilized backf ill such as a cement bound sand bed, complying with the requirements of Appendix C shall be installed, except where cable rating calculations prove that a stabilized backf ill material is not required and a selected backf ill is used instead. 9.4 Laying Cables at Reduced Depth Where the provided standard trench depths cannot be met due to un-avoidable site obstruction, the Contractor shall adhere to the f ollowing installation methods: • For low voltage cables, use of plastic cable cover or install the cable in steel pipe (with warning marked on the pipe) • For medium voltage cables (33 kV, 22 kV, 13.8 kV), use steel plate (with warning marking) or steel pipe (with warning marking) The steel plate shall be at least 5 mm thick and must cover the full width of the cable trench. There must be clear warning marking on the top of steel plate. For the LV and MV cables installed in a steel pipe, the Contractor shall ensure the steel pipe/duct size shall be the same internal diameter as the HDPE ducts that are normally used f or the type of cable to be installed and have a smooth internal bore with no welds or burns. The depth of the cover for the reduced depth of burial must be reviewed and approved by ENOWA/DSO in a case-by-case approach. 9.5 Separation Between Parallel Circuits and Other Utilities The Contractor must use correction factors in accordance with Section 7 when two or more cables running along the same route are installed in the same cable trench. The Contractor shall ensure the width of the cable marker tape tile will cover and protect all the cables laid in the trench as per Section 9.2 andAppendix A, as cables that are laid in the same trench are all at risk of the same f ault in the event of damage by a third party. LV cables shall have a minimum separation of 200 mm between cable centres and 13.8 kV 33 kV circuits shall have a 300 mm minimum separation centre to centre. The Contractor should make every effort to exceed the minimum spacing requirements detailed above, where practicable to permit subsequent jointing on the cables. The Contractor must also determine suitable spacing between the centres of two or more three core cables or group of single core cables to ensure f ailure of one cable does not damage any other cable. Minimum spacing’s may need to be increased depending on actual cable sizes, number of cable circuits and soil conditions, in which case a specif ic installation standard f or the particular installation shall be produced with the agreement of ENOWA DSO. Where more than 3 cable circuits are installed or when LV and MV cables are installed in the same trench, the depths shall be in accordance with Table 9 and/or Table 10 but the Contractor shall confirm the minimum horizontal separation of 300 mm using ENOWA DSO recommended propriety sof tware program CYMCAP or DigSILENT to simulate such a proposal. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 27 OF 36 Confidential External Where more than 4 circuits are laid in the same trench, the circuit configuration and spacing shall be simulated in CYMCAP or DigSILENT. The Contractor shall validate their design proposal using the recommended sof tware and a detailed report must be submitted f or approval to ENOWA DSO bef ore work commences. Third party ducts may cross ENOWA ducts provided that ENOWA/DSO can get access beneath the third-party ducts. The other ducts must have minimum vertical separation of 300 mm, The risk assessment and installation method statement need to be reviewed and approved by ENOWA/DSO prior to installation. ENOWA DSO owned LV cables/duct may be installed directly over ENOWA DSO MV cable ducts, ref er to Appendix A. Where multiple circuit need to be laid in the same trench f or any limitations, the circuit conf iguration and spacing must be reviewed and approved by ENOWA DSO bef ore work proceeds. The Contractor must use ENOWA DSO recommended propriety sof tware program CYMCAP or DigSILENT to simulate such a proposal. 9.6 Bedding and Backfilling The f ollowing types of backf ill shall be used by the Contractor as specif ied in trench standard drawings in Appendix A: • Fine fill. It is a mixture of fine (dust) with larger particles with no particles larger than 10 mm diameter. This material can be the material excavated f rom the trench. • Selected Backfill. This shall be builder’s sand which in the dried-out state does not have a thermal resistivity of more than 2.7 °C m/W. For LV, 13.8 kV and 33 kV cables subject to cyclic rating most builder’s sand is suitable. Flints or other sharp stones are not permitted. The selected fill shall be free from clay or organic matter. • Stabilized Backfill. Stabilized backfill shall consist of Cement Bound Sand (CBS) with a dried out thermal resistivity of not more than 1.2 °C m/W. Sample testing of stabilized backf ill shall be carried out. Deviation f rom the use of CBS must be agreed in advance of installation with ENOWA. • Backfill. This is the material that was excavated f rom the trench with the likes of brick and concrete removed. This material shall not be installed directly on cables or ducts but can be laid directly on f ill, selected, or stabilized backf ills. The Contractor must extend the excavation of the cable trench to 75 mm below the cable and must be covered by fine fill or stabilized backfill as per the requirements below and as shown in Appendix A. For LV cables, the Contractor shall place 75 mm layer of fine fill below the cable or duct and place 100 mm above the cable or duct. Ducts shall be surrounded by f ine f ill as shown in standard drawings in Appendix A. The f ine f ill needs to be compacted. For 13.8kV and 33 kV, cables and ducts shall be surrounded by selected or stabilized backfill material, depending on the cable installation design. The Contractor shall apply 75 mm layer of the backfill below the cable or duct(s) and 100 mm shall be placed above the cable or duct(s). The Contractor shall ensure that all backfill material to be installed shall be f ree f rom large rocks, paving material, sharp substances, and corrosive material. Any materials that have f allen into the trench during cable laying must be removed. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 28 OF 36 Confidential External 9.7 Joint Bays The Contractor shall design and construct joint bays so that they are large enough to accommodate the size and type of joint to be installed in them. Joint bays shall have the minimum sizes as shown in Table 11 . Table 11 Minimum Joint Bay Size Voltage Straight Joint (m) Pot End (m) LV 1.5 x 1.2 0.9 x 0.9 13.8 kV 2.5 x 1.2 1.2 x 0.9 33 kV 5.5 x 2.0 1.5 x 1.5 The Contractor shall ensure that 3-core cable joints shall be in the center of the joint bays. Single phase cable joints shall be staggered to maintain, as best as possible, the tref oil conf iguration of the cables. For continuously rated cables the staggering of the joints is mandatory. Figure 7 Typical 13.8 kV Joint Bay Layout D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 29 OF 36 Confidential External Figure 8 Joint Bay design for 33 kV continuously rated single core cables Where reasonably practicable, all exposed cables and joints in joint bays shall be blinded with sand or covered with sandbags, bef ore they are energized, to protect them against mechanical damage and to prevent the possible spread of f ire. 10 Cable laying 10.1.1 Cable Installation Requirements 13.8 kV and 33 kV single core cables shall be installed in touching trefoil, regardless of the length of the installation. Where the single core cables are installed in individual ducts, the ducts shall also be installed in touching trefoil. ENOWA DSO preference is to install a single duct f or 33 kV single core cables in a touching tref oil f ormation. Single core cables or duct trefoil groups of all voltages shall be installed in tight tref oil and bound every 3-meters using cable ties. The correct size of duct shall be used during installation. The level of circulating current is inf luenced by the proportion of the total circuit length, which is out of trefoil, thus short cable circuit installations are particularly susceptible if trefoil installation is not strictly observed. Where single core cables have to be installed out of D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 30 OF 36 Confidential External tref oil (for example going into flat formation for a bridge crossing or breaking out of tref oil to go to terminations), the contractor will make certain that the out of trefoil section(s) are short as possible, and the single core cables returned to tref oil as soon as possible. 10.1.2 Drum inspection and Positioning Bef ore installation, the cable drum shall be inspected to ensure it is free of damage and the cable is free from damage, and to ensure it is the correct size, length, and voltage level that is required f or the job. Proud nails etc shall be removed as a saf ety precaution. Cable winches, drum trailers, drum stands etc shall be checked prior to use to ensure that they are f ree f rom defects. The equipment shall be suitable for the weight or tension of the proposed cable. The drum should be mounted on jacks, cable trailer or cable stands. Drum trailers and stands shall be located on a flat surface. Cables shall always exit over the top of a drum. For during cable installation, it is necessary to caref ully check the cable f or any sign of damage as it leaves the drum, especially f or the outer layers of the cable. During the installation of external MV power cables located in the cable trench system, cable drums shall be supported on cable drum screw jacks and spindles. 10.1.3 Cable Protection from Damage During cable pulling, rollers must be used to protect the cable f rom any abrasions and the rolling service must be f ree of damage. When cable changes its direction, horizontal and vertical rollers should be used to ensure smooth cable pulling. Minimum cable bending radius per cable specification/installation guide must be observed during the laying process to avoid cable mechanical damage. Should any sheath damage occur during the cable installation all cable installation activity shall immediately cease, and DSO shall be informed. DSO shall assess the severity of the damage and shall instruct the Contractor whether sheath repairs will be acceptable, or cable replacement shall occur. Any cable replacement deemed necessary will be at the Contractor’s expense. The ends of each cable must be protected against moisture ingress immediately af ter installation. 10.1.4 Cable Pulling Where the Contractor uses a winch, the hawser must have a swivel eye f itted. The swivel eye must be in good working order and freely rotate to prevent the cable twisting. Curved steel plates or corner rollers must be used while pulling cables around bends in the cable trench. At corners or when pulling cables into ducts, specialized rollers must be used. Sharp edges in the trenches or at the ends of the cable ducts shall be covered such that no damage to the cable occurs. The Contractor must only pull cable by winch where there is a calibrated and accurate dynamometer or an adjustable tension limiting switch f itted. The maximum pulling f orce must not exceed the values stated by the manuf acturer in their cable datasheets. The Contractor shall normally pull LV and 13.8 kV cables by the nose. A cable stocking shall be f ully pulled onto the cable to ensure a good grip. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 31 OF 36 Confidential External More difficult pulls may require the use of an American pulling eye or cable lug attached to the conductors. Rollers shall always be used when pulling cables. All rollers used must be in serviceable condition, moving easily on their spindle and with rolling surf aces f ree f rom damage. The rollers shall be placed at approximately f our-meter intervals. A leading roller shall be placed at the trench side at the pulling end, with slide rollers on bends and hoop rollers along straight sections. Inverted skid plates shall be used to prevent the cable or pull wire rising into obstructions. At duct entries, a bell mouth shall be attached at each end of the duct with rollers positioned to give central access into the bell mouth. Cables shall be continuously pulled from the upper side of the drum in the opposite direction of rolling direction as indicated by the arrow on the cable drum flange. To avoid abrasion, a suitable number of cable rollers shall be positioned along cable length. Rollers shall be spaced between the cable drum, and within the cable trench at intervals as required to prevent cable sheath contact either with the ground or contact with sharp edges. Immediately following installation and testing of cables, the ends of each cable shall be inspected for damage and secured against the ingress of moisture by f itting heat shrink or cold shrink caps. Cables shall not be laid with the drums located on excavators, lorry loaders and the like unless the machine is designed for such an application and is not moved as the cable is being laid. Wherever possible single core cables of all voltages shall be installed in tight tref oil and bound every 3 meters cable ties. 10.2 Cable Protection 10.2.1 Warning Tapes, Protection Tapes, Protection Tiles, and Marker Posts The Contractor must ensure a protection tile shall be placed a minimum of 100 mm above the 13.8 kV and 33 kV power cables including the associated f iber optic cables, in accordance with the standard drawings presented in Appendix A. The Contractor shall note a specific warning tape for the fiber optic cable is not deemed necessary by ENOWA DSO. The protection tile when used shall be cut cleanly and installed so that it f ully covers the cable or duct including the fiber duct installed below it along its whole length. There will be no dedicated warning tape f or f iber optics. Similarly, any protection tile that is coming off a drum shall be installed so they f ully cover the cable or duct including the fiber duct below them and any gaps between the individual protection tile shall be covered by an additional tile which must be applied over the top. Protection tape shall be installed over all LV cables and ducts as shown in Appendix A. The Contractor must make certain that the cable or duct including the fiber duct is f ully covered by the protection tape. The Contractor shall refer to NEOM-NDS-SPC-022 for more guidance on the specif ication f or warning tape, protection tape and protection tile. Permeant above ground cable marker posts must be installed along the cable route in order to clearly mark the location of the cable. Marker posts and signs shall be according to typical posts presented in Appendix B. The requirement f or cable marker posts shall be used in the f ollowing locations: • Crossing carriageways, motorway, or railway. It shall be installed on both sides. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 32 OF 36 Confidential External 10.3 • The adjacent cable markers should be in line of sight of each other. Maximum distance between adjacent cable markers shall not exceed 50 m • at any change in cable route direction, including the cable route deviation f rom straight line route. • at the cable termination. • Where cables have been laid at a reduced depth. • Situations where cables are laid at a reduced depth. Reinstatement The Contractor shall ensure that a warning tape is installed 200 mm above the protection tape or protection tile as illustrated in Appendix A. The cable trench must be backfilled immediately af ter installation, to avoid the chance of damage to the cable. Trenches shall be backf illed, reinstated, and compacted to their original level or in accordance with required by local authorities of NEOM. Backf ill material shall be compacted to the same density as the surrounding soil. 11 Requirements for Crossings 11.1 Road Crossing Cables that cross under paved roads, concrete slabs, railroads, or other areas that would require extensive or impractical excavations. It shall be run in concrete encased duct banks in accordance with Section 8.3 11.2 Highway Crossings It is highly unlikely that excavations of highways are not allowed, therefore, it is necessary to provide provision of cable duct during the construction of highways. Alternatively, crossing highway can be achieved using HDD which is specif ied in section 8.7 of this document. 11.3 Pipelines and other Cables Crossing Where work is required close to a gas pipeline, the contractor must contact the pipeline owner bef ore commencing the work. In addition, when excavation within 15m of highpressure pipeline, the owner of the pipeline must be contacted to observe the job. The minimum crossing or parallel clearance between direct buried cables or conduits and underground piping, shall be 300 mm. For directly buried cables, the 300 mm clearance can be reduced to 80 mm if the cable is installed in a HDPE conduit at the crossing. Direct buried cables, conduits, or duct banks shall not be installed directly above or below parallel underground piping. Electrical cables that cross a pipeline corridor shall be installed at least 1 meter under the pipelines in duct banks. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 33 OF 36 Confidential External 12 Cable Duct Sealing Systems It is a mandatory requirement to prevent danger due to the influx of water, or any noxious or explosive liquid or gas f rom the surrounding ground into substations, street pillars and buildings. These entries shall be sealed with or without cables installed. The Contractor shall ensure the cable duct remains f ree of contamination and debris during and af ter the cable installation. The mouth of the ducts shall be cleaned as per Section 8 and the space between the cable and the duct shall be filled using an approved sealing compound or other approved alternative to a depth of 150mm. Care must be taken to ensure that the cable is supported from the bottom of the duct and the compound is in intimate contact with the cable to make a good seal with the duct. The Contractor shall ensure spare ducts are f itted with a plug and then sealed around the duct edge or alternatively an approved end cap and the edge sealed with anti-corrosion tape where necessary. To f urther reduce the possibility of gas entering a building, sub-station, street pillar etc. where continuous ducting is laid, a break shall be provided in the duct run, if possible, immediately outside the building or equipment. All cable ducts entering substations or buildings shall be sealed by products assessed by ENOWA DSO and installed in accordance with the manuf acturer’s instructions to prevent the ingress of gas and water. A range of duct ends for a range of applications across a variety of suppliers is included in Figure 9 Examples of Duct Sealing Systems. The list of suppliers included is indicative only and any alternatives proposed by the Contractor shall be subject to review and acceptance by ENOWA DSO. The Contractor must refer to NEOM-NDS-SPC-023 for more guidance on the specif ication requirements f or a cable duct sealing system. Figure 9 Examples of Duct Sealing Systems Supplier and Application Sealing Type Application Hauff Technik HSD Duct Seals Mechanical Duct. Used to seal ducts within wall sleeves or core drillings. Hauff Technik GKD MODULAR Duct Seal. Duct Seals Used to seal ducts within wall sleeves or core drillings. Can be placed around existing duct. Hauff Technik HRD UNIVERSAL Cable Seals Used to seal cables within duct, wall sleeves or core drillings. Can be placed around existing cables Image Mechanical Cable Seal D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 34 OF 36 Confidential External Supplier and Application Sealing Type Application Hauff Technik HRD Cable Seals Used to seal cables within duct, wall sleeves or core drillings. Can BESPOKE Mechanical Cable Seal. be placed around existing cables Emtelle Cable Seal Universal Press Seal Hauff Technik FZR Fibre Cement Wall Wall Sleeves Used as a cast-in wall sleeve. Concrete coated with smooth inner bore to accommodate Sleeve Hauff Technik FZRG SPLIT Fibre Cement Wall Sleeve Image seals. Wall Sleeves Used as a cast-in wall sleeve. Can be placed around existing cables. Concrete coated with smooth inner bore to accommodate seals Hauff Technik Segmento MODULAR Entry Seals Building Entry Systems Cable sealing - for use with wall entry systems Hauff Technik Wall Entry System DUCT SOCKET Building Entry Systems For setting in concrete walls single opening to accept sealing attachments Hauff Technik Wall Entry Building Entry For setting in concrete walls single opening to accept sealing System Systems attachments Building Entry Systems For setting in concrete walls single opening to accept sealing attachments SINGLE Hauff Technik Wall Entry System DOUBLE D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 35 OF 36 Confidential External Supplier and Application Application Hauff Technik HSI XXX-D Building Entry Cable sealing - for use with wall entry systems. Variants: Cable Sea Systems Heatshrink and Coldshrink. ROXTEC Building Entry Systems Range taking single cable seal (fire rated, dust tight, watertight and rodent resistant). ROXTEC Building Entry Range taking single cable seal (fire rated, dust tight, watertight Systems and rodent resistant). Building Entry Rise spacers plus removable sealant (flood protection, Systems prevents gas and rodent ingress) Building Entry System Duct sealing system for all sizes. CSD Filoform UK 13 Sealing Type Image Appendices Appendix A Details of Cable Trenches Appendix B Details of Cable Marker Post Appendix C Traditional and Non-Traditional Cable Backfill Material D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External PA GE 36 OF 36 Confidential External Appendix A Details of Cable Trenches D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External A.1 Appendix A Details of Cable Trenches The Contractor may request the following cable trench drawings from ENOWA DSO in a pdf f ormat. A.1.1 LV Cable Trenches Drawing No: NEOM-NDS-DRG-001 Drawing No: NEOM-NDS-DRG-002 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External Drawing No: NEOM-NDS-DRG-003 Drawing No: NEOM-NDS-DRG-004 Drawing No: NEOM-NDS-DRG-005 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External A.1.2 13.8 kV Cable Trenches Drawing No: NEOM-NDS-DRG-022 Drawing No: NEOM-NDS-DRG-023 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External Drawing No: NEOM-NDS-DRG-024 Drawing No: NEOM-NDS-DRG-025 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External Drawing No: NEOM-NDS-DRG-026 Drawing No: NEOM-NDS-DRG-027 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External Drawing No: NEOM-NDS-DRG-028 Drawing No: NEOM-NDS-DRG-029 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External A.1.3 33 kV Cable Trenches Drawing No: NEOM-NDS-DRG-006 Drawing No: NEOM-NDS-DRG-007 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External Drawing No: NEOM-NDS-DRG-008 Drawing No: NEOM-NDS-DRG-009 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External Drawing No: NEOM-NDS-DRG-010 Drawing No: NEOM-NDS-DRG-011 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External Drawing No: NEOM-NDS-DRG-013 Drawing No: NEOM-NDS-DRG-012 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External Drawing No: NEOM-NDS-DRG-014 Drawing No: NEOM-NDS-DRG-015 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External Drawing No: NEOM-NDS-DRG-016 Drawing No: NEOM-NDS-DRG-017 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External Drawing No: NEOM-NDS-DRG-018 Drawing No: NEOM-NDS-DRG-019 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External Drawing No: NEOM-NDS-DRG-020 Drawing No: NEOM-NDS-DRG-021 D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX A Confidential External Appendix B Details of Cable Marker Post B.1 Concrete Marker Post B.2 Details of Warning Sign D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX B Confidential External D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX B Confidential External Appendix C Traditional and Non-Traditional Cable Backfill Material C.1 General Requirements The cable backf ill material must not contain materials that could damage the cable oversheath or any part of the cable during installation and subsequent operation of the cable throughout its service lif e. The backfill material shall be of consistent composition and must not contain f oreign matter or readily visible organic debris as organic materials have poor TR value. All cable backfills shall have the ability to f acilitate ef f icient installation and subsequent removal of the backfill without damage to cables, ducts or the environment f or f uture cable repairs or diversions. The composition of the cable backf ill must be that it can be removed by non-mechanical means f or cable and/or duct repairs without damaging the cable or the duct. The mechanical performance of backfill must be compatible with its intended environment, and must provide structural support and resist settlement, erosion, impact and f rost heave. The composition of the backfill material shall not constitute a danger to the environment and water courses. The backfill material must not impair or be harmf ul to crop growth. It must not contain any hazardous waste material. The composition of the backfill material shall not constitute a hazard to the health and safety of workers involved in the cable installation. Where risks are identified the Contractor shall provide instructions to enable the risk to be properly managed. The backf ill material shall not contain any dangerous substances. Where there is the possibility of risk to public health and safety during cable installation, e.g., dust clouds from offloading backfill material in vicinity to public areas, then steps shall be taken to prevent exposure of the public to that risk. The measures to be taken shall be agreed between ENOWA DSO and the Contractor. C.2 Traditional Stabilized Backfill Traditional cable backfill material must have thermal resistivities in the dried-out state which do not exceed the TR value assigned in the design of the cable system. The stabilized cable backfill shall not have any chemical additives beyond water, concrete and sands. The Contractor must provide evidence that the stabilized cable backf ill to be installed in capable of maintaining the TR values f or the design lif e of the cable system. Table 12 def ines the Maximum Dried-Out TR baseline requirements of the Stabilized cable backf ill material within the 50°C isotherm. Power cables rated at 33 kV and their associated f iber cables shall be installed in a stabilized backfill material that meets the TR Dry-Out rating of 1.2 K.m/W (or less) except where the cable rating calculations prove that either a stabilized backf ill material is not required or selected sand with the TR value def ined in Table 12 may be suitable f or the design of the cable system. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX C Confidential External Table 12 Traditional and Non-Traditional Cable Backfill; Maximum Dried-Out Thermal Resistivity (TR) Cable Backfill TR (K.m/W) Cable Installation Method Stabilized Backfill Winter (Dec to Feb) Normal Cold (March, April, November) Normal Hot Summer (May to August) (September, October) 1.05 1.05 2.70 2.70 1.05 1.05 1.20 1.20 1.05 1.05 1.20 1.20 - Selected Sand Stabilized Backfill - Gravel/Sand - CBS Non-Traditional - Alternative Backfill C.3 Non- Traditional Stabilized Backfill The inclusion of the traditional backf ill materials in this document does not prevent Contractors to of f er alternative backf ill materials. Non-Traditional cable backfill must offer the same baseline TR of the traditional stabilized backf ills detailed in Table 12 or alternatives that provide enhanced thermal properties. These must satisf y the f undamental requirements of this guidance. Any Non-Traditional cable backfill material shall be subject to f ield trials f or removal using the above or other of f ered means of saf e removal as part of the type test process. D OC U M EN T C OD E: N EOM - N D S- ST D - 202 R EVISION : 01.00 ©NEOM [2023]. All rights reserved. Confidential External A PPEN D IX C