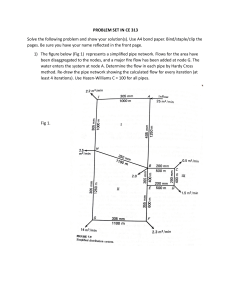

Design of Piping Systems Four types of pipe flow problem Type 2 problem or flow rate problem Assume Friction factor and start iteration procedure Work Last problem backward Type 3 or Sizing Problem Minor losses are local energy losses caused by the disruption of the flow due to the installation of appurtenances, such as valves, bends, and other fittings Minor head loss at the entrance of the pipe (flow leaving a tank) 0.05 Minor loss coefficient (down stream velocity) Gate Valve Ball Valve Problem 3: Water is pumped between two reservoirs at 0.0057 m^3/s through length 122 m of 5 cm diameter pipe and several minor losses, as shown in Fig. The roughness ratio is e/d 0.001. Compute the pump horsepower required. 1 hp = 736 Watts Flow in Noncircular Ducts But we should not necessarily expect the Moody chart to hold exactly in terms of this new length scale. And it is not, however, it is surprisingly accurate Pipes in parallel and Series Pipes in Series Pipes in parallel Problems Figure 1 Start solving by assuming fully rough flow. Assume that the same three pipes in previous problem are now in parallel with the same total head loss of 20.3 m. Compute the total flow rate Q, neglecting minor losses. Pipes in parallel 2. The head at inlet is 30 m over that at the outlet. A pipeline of 0.6 m in diameter is 1.5 km long transports water. A) Find the discharge. In order to augment the discharge, another parallel line of the same diameter is introduced in the second half of the length. Neglecting minor losses, B) find the increase in discharge if f = 0.04.