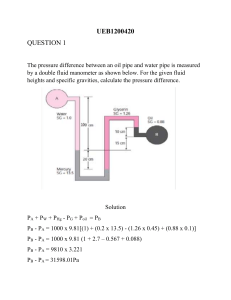

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/268811565 Fluid Hammer and Fatigue Analysis for Oil Transport Pipelines With Peak Points Conference Paper in American Society of Mechanical Engineers, Pressure Vessels and Piping Division (Publication) PVP · July 2014 DOI: 10.1115/PVP2014-28070 CITATIONS READS 3 1,098 3 authors: H. A. Warda Sherif Haddara Alexandria University Cairo University 37 PUBLICATIONS 498 CITATIONS 8 PUBLICATIONS 42 CITATIONS SEE PROFILE Essam Moustafa Wahba Alexandria University 63 PUBLICATIONS 869 CITATIONS SEE PROFILE All content following this page was uploaded by Essam Moustafa Wahba on 27 November 2014. The user has requested enhancement of the downloaded file. SEE PROFILE Proceedings of the ASME 2014 Pressure Vessels & Piping Conference PVP2014 July 20-24, 2014, Anaheim, California, USA PVP2014-28070 FLUID HAMMER AND FATIGUE ANALYSIS FOR OIL TRANSPORT PIPELINES WITH PEAK POINTS Hassan Warda Mechanical Engineering Department Alexandria University, Alexandria, Egypt Sherif Haddara Ministry of Petroleum and Mineral Resources Cairo, Egypt 1 Essam Wahba Mechanical Engineering Department American University of Sharjah, Sharjah, UAE ABSTRACT The SUMED pipeline is a major oil transport pipeline in the Middle East. It provides an important route for transporting oil from the Arabian Gulf region to Europe and North America. The pipeline was subjected to major damage in the 1990s, which required the replacement of several kilometers at its peak point. Fluid hammer simulations using the method of characteristics show that this damage was due to consecutive shutdown/startup events. Such events led to multiple formation and collapse of vapor cavities at the peak point. Low cycle fatigue analysis confirm the finite lifetime of the pipeline due to the high differential stress resulting from the cavity collapse. Moreover, a safe valve closure operational scheme is computed using fluid hammer analysis that would prevent further formation of cavities and hence ensure safe pipeline operation in the future. NOMENCLATURE A Pipe cross-sectional area D Pipe diameter Bulk modulus of compressibility for fluid Ef Young’s modulus of elasticity for pipe material Ep H Total head I Rotational inertia of pump system K Valve loss coefficient Stress concentration factor Kt N Rotational speed of pump system Fatigue crack initiation life for pipeline Ni T Pump torque V Average cross-sectional velocity a Wave speed 1. Mechanical Engineering Department, Alexandria University, Alexandria, Egypt (on leave) e f g s t z t S s eqv Pipe thickness Darcy-Weisbach friction factor Gravitational acceleration Axial location along the pipe Time Pipe elevation Time step size Nominal stress range Spatial step size along pipe axis Equivalent stress range p Poisson’s ratio for pipe material Fluid density Cavity volume INTRODUCTION Over-land transportation of large quantities of oil is generally carried out using pipelines. With the rapid growth in the oil industry over the past century, a number of major crosscountry pipelines were constructed worldwide, such as the Trans-Alaska Pipeline (TAPS) in North America, the Druzhba (Comecon) pipeline in Eastern Europe and the Yanbu (EastWest) pipeline in Saudi Arabia, to name a few. The present study is concerned with one of these major transport pipelines, namely the SUMED (Suez-Mediterranean) pipeline in Egypt. The SUMED pipeline is a major oil transport pipeline in the Middle East, running from Ain-Sukhna terminal on the Red Sea to Sidi-Kerir terminal on the Mediterranean Sea. It provides an important route for transporting oil from the Arabian Gulf region to Europe and North America. The API 5L X60 SUMED pipeline consists of two parallel lines, each with 1 Copyright © 2014 by ASME a diameter of 42 inches and a length of 320 km. Figs. 1 and 2 show a schematic of the pipeline and its profile, respectively. The pipeline was first operated in 1977 with an annual capacity of 40 million tons, which was extended during its second phase to 60 million tons with the operation of the booster pump station. Successful operation of the pipeline continued until the 1990s, when results from electronic pigs indicated severe damage in the pipeline near its peak point. This required the replacement of several kilometers of the pipeline in this region. The objective of the present study is to identify the main cause of failure for the pipeline near its peak point, a region of supposedly low pressure and hence minimal stresses in the pipe. With the pipeline operating under start-and-stop conditions and the failure happening after many years, two fundamental causes of failure come to attention; fluid hammer and pipeline fatigue. The present study aims to couple fluid hammer computations with low cycle fatigue analysis in order to identify the main cause behind the pipeline failure. FLUID HAMMER ANALYSIS ‘Fluid hammer’ commonly refers to the generation and propagation of fluid transients in pipes, as a result of abrupt changes in flow conditions. Such changes could occur due to the sudden closure of a valve or shutdown of a pump. The study of such transients is of great practical importance and may well provide the design condition for the piping system as a whole. Severe fluid transients could lead to large fluctuations in pressure, distributed cavitation along the pipeline, structural vibrations, and column separation [1]. Fluid Hammer Model and Numerical Methods One-dimensional (1-D) fluid hammer models are based on conservation of mass and axial momentum principles. The model equations are given as follows 1 dp V a2 0 dt s dV 1 p dz f g VV 0 dt s ds 2D (1) (2) Using order of magnitude analysis, Wahba [2] and Ghidaoui et al [3] showed that the nonlinear convective terms could be neglected from the continuity and axial momentum equations, since the wave speed is several orders of magnitude larger than the flow velocity, resulting in Interior Valve Supply Pump Booster Pump Downstream valve Fig. 1 SUMED Pipeline Schematic 1 p V a2 0 s t dz f V 1 p g VV 0 ds 2D t s (3) (4) Pipe elasticity and fluid compressibility are included in the model through the expression of the wave speed a 500 Ef a2 E D 1 f eE p Elevation (m) 400 300 200 100 0 0 50 100 150 200 Distance (km) 250 Fig. 2 SUMED Pipeline Profile 300 (5) Here, is the fluid density, Ef is the bulk modulus of compressibility for the fluid, Ep is the Young’s modulus of elasticity for the pipe material, e is the pipe thickness and D is the pipe diameter. The hyperbolic system of equations could be efficiently solved using the method of characteristics [4]. Other methods of solution include Runge-Kutta methods [2], implicit methods [5], Godunov methods [6] and finite element methods [7]. In the present study, the method of characteristics is applied to numerically solve equations (3) and (4) resulting in the left and right running characteristic equations 2 Copyright © 2014 by ASME dV g dH f VV 0 dt a dt 2D dV g dH f VV 0 dt a dt 2D ds a dt ds for a dt (6) for (7) Here, H is the total head at a pipe section. Applying a standard finite difference discretization procedure along the characteristic lines would result in V V ga H g V H a n 1 Vin1 i n 1 i n i 1 f2Dt V V ft H V V 2D n 1 H in1 i n 1 i n i 1 n i 1 n i 1 n i 1 n i 1 0 0 (8) (9) The time step t is taken equal to s/a, where s is the spatial grid size along the pipe axis. Solving equations (8) and (9) simultaneously would provide the velocity and total head at each pipe section at the new time level (n+1). Supply Pump Boundary Condition The boundary condition at the supply pump is formulated using the right running characteristic equation (9), together with the quasi-steady energy equation (10) and the pump performance curve (11) n 1 H in 1 H os H sp n 1 H sp f Q in 1 f Vin 1 (10) (11) where Hos is the time-invariant total head at the upstream terminal and Hsp is the supply pump head. The three equations are solved simultaneously to compute the velocity Vin 1 , the details about the supply pump boundary condition could be found in [4]. Booster Pump Boundary Condition The boundary condition at the booster pump is formulated similar to the supply pump. However, in case of the booster pumps, we have four equations instead of three, with the addition of the left running characteristic equation (8). The four equations are solved simultaneously to compute the velocity Vin 1 , the total head at the pump suction H isn 1 , the total head n 1 , at the pump discharge H id Interior Valve Boundary Condition The boundary condition at the interior valve is formulated using the left and right running characteristic equations (8) and (9), together with the quasi-steady energy equation n 1 n 1 H iu H id K Percent Open 100 90 80 70 60 50 40 30 20 10 0 (12) Here, I is the rotational inertia of the supply pump system. Based on equation (12), the new rotational speed N could be evaluated as follows 60 n T t 2I (13) The supply pump performance curve is constructed at each time level from the steady-state performance curve using the affinity laws [4]. The non-return valve on the discharge side of the pump is simulated by checking the direction of flow velocity; if the velocity is negative then it is set to zero. More (14) 2g Table 1 Loss Coefficient for Through-Conduit Gate Valve governed by N n 1 N n n 1 2 i n 1 n 1 and H id , at the valve. In case of a negative heads, H iu velocity at the interior valve, the quasi-steady energy equation is reformulated based on flow in the reverse direction, and the system of equations is re-solved. It should be noted here that the interior valve is a through-conduit gate valve and its valve loss coefficient K is provided in table (1) as a function of the percentage valve opening. n 1 H sp . Pump acceleration/deceleration due to restart/failure is 2 dN I 60 dt V The three equations are solved simultaneously to compute the velocity Vin 1 and the upstream and downstream total total head at the pump discharge H in 1 and the pump head T and the booster pump head n 1 H bp . 1/K 5.27 2.5 1.25 0.625 0.333 0.179 0.1 0.0556 0.0313 0.0167 0 Downstream Valve Boundary Condition The boundary condition at the downstream valve is formulated using the left running characteristic equation (8) and the quasi-steady energy equation 3 Copyright © 2014 by ASME H in 1 H od K 2 Vin 1 (15) 2g Here, Hod is the head at the downstream terminal which is equal to 50 m. The two equations are solved simultaneously to compute the velocity Vin 1 and the total head H in 1 at the valve. In case of a negative velocity at the downstream valve, the quasi-steady energy equation is re-written based on the reverse flow direction and the two equations are re-solved simultaneously. Similar to the interior valve, the downstream valve is also a through-conduit gate valve and its valve loss coefficient is given in table (1). Discrete Vapor Cavity Model (DVCM) Column separation occurs during a fluid transient when the pressure drops to the vapor pressure at specific locations along the pipe, such as peak points and dead ends. As a result, a vapor cavity starts to develop at this specific location, which would split the liquid column in the pipeline. The collapse of this vapor cavity and the re-joining of the liquid column would result in an abrupt rise in pressure, which could present a significant threat to the structural integrity of the pipeline. Several incidents are documented in the literature regarding catastrophic failure of piping systems due to column separation [8], [9]. The discrete vapor cavity model (DVCM) [10]-[13] allows the formation of cavities at any of the pipe cross sections whenever the computed pressure at this section becomes equal to or lower than the vapor pressure. Under such condition, the pressure head at this section is set equal to the vapor pressure head as follows Hi H v (16) The upstream and downstream velocities, Viun 1 and Vidn 1 , for the cavity are computed from the left and right running characteristic equations, respectively. The growth/collapse of the cavity is then computed from principles of mass conservation as follows V V Adt t t0 id (17) iu Here, represents the cavity volume and t0 is the time at which the cavity starts to form. Trapezoidal rule is used to numerically integrate equation (17) as follows n 1 n 0.5 Vidn 1 Viun 1 0.5 Vidn Viun At (18) If the cavity volume becomes zero or negative, the cavity disappears and the numerical procedure reverts back to the standard method of characteristics. LOW CYCLE FATIGUE ANALYSIS Fatigue represents the main failure mode for mechanical structures subjected to variable loading. Starting with the pioneering work of Wohler (1860), high cycle fatigue (HCF) was studied by numerous researchers in order to determine the fatigue limit for metallic materials. This was mainly done through establishing S-N curves, which represent the relation between the load and the number of cycles to failure. In the 1960s, researchers developed special interest in studying low cycle fatigue (LCF). Instead of the stress-based approach used in HCF, Manson [14], [15] and Coffin [16], [17] independently proposed a strain-based approach for LCF. The strain-based model is known as the Manson-Coffin relation p 2 'f 2 N f c (19) where p and Nf are the plastic strain range and the number of cycles to failure, respectively. Moreover, 'f and c are the fatigue ductility coefficient and the fatigue ductility exponent, respectively. Most pipelines operating under start-and-stop conditions are subjected to low-cycle fatigue [18]-[20]. With the aid of experimental tests performed on X60 pipeline steel specimens with single edge notches, Zheng et al [21], [22] developed a modified Manson-Coffin relation using an energetic approach. The modified relation for X60 pipeline steel is expressed as follows N i 1.96 1015 eqv 2 / 1 n 4412 / 1 n 2 (20) Here, Ni is the fatigue crack initiation life, n is the hardening exponent and eqv is the equivalent stress range which is calculated from 1 eqv 1 n 1 n 1 R 2 1/ 2 K t S (21) in which Kt is the stress concentration factor, S is the nominal stress range and R is the stress ratio, which is evaluated from the minimum and maximum internal pressures as follows R 4 Pmin Pmax (22) Copyright © 2014 by ASME cracks do not initiate and the fatigue life is infinite. In the present study, the equivalent stress range eqv is evaluated as 1260 MPa from the fluid hammer analysis, while the given by Zheng [22] to be 441 MPa. Hence, as a result of cavity collapse during pipeline startup, fatigue cracks would initiate and the pipeline would have a finite fatigue life. The fatigue crack initiation life is estimated from equation (20) to be 7.7x103 cycles. 1800 Pipe profile Steady−state total head (t=0) Maximum total head Minimum total head 1600 1400 1200 Head (m) Fluid Hammer and Fatigue Analysis Results Fluid hammer analysis is carried out to simulate a pipeline shutdown event. In this simulation, the interior and downstream valves are closed in 200 s and both the supply and booster pumps are shutdown. The flow rate through the pipe corresponds to an annual capacity of 60 million tons and the density and kinematic viscosity of crude oil are 870 kg/m3 and 20 cSt, respectively. Grid-independent results are obtained with the use of 100 parts along the pipe axis. Fig (3) shows the resulting maximum and minimum total heads generated along the pipeline during the transient event. Fig (3) clearly indicates that with such shutdown scenario, the maximum heads generated at the pipeline peak points are not high enough to cause failure in this region. Hence, one would argue that the pressure transient generated during the pipeline shutdown process is not the main cause for the pipeline failure at its peak point. Further investigation is carried out by plotting the total head along the pipe after 1000 s from the initiation of the transient in fig (4). This would provide the static head in the pipe after the transient has been damped out considerably. As can be seen from fig (4), column separation occurs at the peak point, and a large cavity is formed in this region. The collapse of such cavity during the startup of the pipeline could cause abrupt and significant rise in pressure. To evaluate the possible pressure rise as a result of the cavity collapse, a second fluid hammer simulation is performed to model pipeline startup. Results from the simulations show that at the instant of cavity collapse, the pressure head at the pipe peak point reaches 950 m. In its design, SUMED pipeline was designed with telescopic thickness, where the pipeline thickness varies from 17.48 mm in regions of high pressure to 9.52 mm in regions of low pressure. At the peak points, pressures are supposedly low and the thickness is 9.52 mm. With the high pressure rise due to cavity collapse and the low thickness at the peak point, significant stresses are developed in this region. Using equation (21) in conjunction with the ASME B31.4 thin pressure vessel design formula for pipelines transporting liquid hydrocarbons [23], the equivalent stress range is calculated to be 1260 MPa. Zheng [22] showed that when eqv eqv th , fatigue equivalent endurance limit eqv th for X60 pipeline steel is 1000 800 600 400 200 0 0 50 100 150 200 Distance (km) 250 300 Fig. 3 Maximum and minimum total heads along the pipe (Scheme 1) 1800 Pipe profile Steady−state total head (t=0) Transient total head (t=1000 s) 1600 1400 1200 Head (m) RESULTS AND DISCUSSION In the present section, results from the fluid hammer/low cycle fatigue analysis are presented and used to identify the main cause of failure for the SUMED pipeline at its peak point. Moreover, after identifying the main cause of failure, fluid hammer simulations are performed to identify a safe valve closure scheme that would prevent further damage to the pipeline in the future. 1000 800 600 400 200 0 0 50 100 150 200 Distance (km) 250 300 Fig. 4 Transient total head at time t=1000 s (Scheme 1) Safe Valve Closure Scheme In the previous section, both the interior and downstream valves were closed in 200 s. This resulted in a relatively low static head in the pipeline after shutdown, which led to column separation and cavity formation at the peak point. The objective 5 Copyright © 2014 by ASME 1800 1400 1200 200 Downstream Valve (s) 200 30 200 Although scheme 2 provides high static head after shutdown as can be seen from fig (6), however, fig (5) shows that the scheme also results in excessive pressures along the pipeline due to the relatively fast valve closure time, 30 s, for both valves. On the other hand, figs (7) and (8) show that scheme 3 provides enough static head to prevent cavity formation after the pipe shutdown while limiting the maximum pressures to some extent, as compared to scheme 2. Hence, the implementation of valve closure scheme 3 would result in the elimination of cavity formation at the peak point after pipe shutdown, which would prevent the subsequent events of cavity collapse and the high stress levels which could lead to eventual failure due to low cycle fatigue. 800 400 0 0 50 100 150 200 Distance (km) 250 300 Fig. 6 Transient total head at time t=1000 s (Scheme 2) 1800 Pipe profile Steady−state total head (t=0) Maximum total head Minimum total head 1600 1400 1200 Head (m) Interior Valve (s) 200 30 50 1000 600 Table 2 Closure Time for the Different Valve Closure Schemes Scheme No. 1 2 3 Pipe profile Steady−state total head (t=0) Transient total head (t=1000 s) 1600 Head (m) of the present section is to use fluid hammer simulations to identify a safe valve closure scheme that would result in a higher static head in the pipeline after shutdown. This would prevent cavity formation at the peak point, and hence eliminate the large stresses that arise due to cavity collapse at startup. Besides the valve closure scheme discussed in the previous section, two other schemes are considered herein. A summary of all three valve closure schemes is provided in table (2). Results for scheme 2 are given in figs (5) and (6), while results for scheme 3 are given in figs (7) and (8). 1000 800 600 400 200 1800 1400 50 100 150 200 Distance (km) 250 300 Fig. 7 Maximum and minimum total heads along the pipe (Scheme 3) 1200 Head (m) 0 0 Pipe profile Steady−state total head (t=0) Maximum total head Minimum total head 1600 1000 800 600 400 200 0 0 50 100 150 200 Distance (km) 250 300 Fig. 5 Maximum and minimum total heads along the pipe (Scheme 2) CONCLUDING REMARKS A coupled fluid hammer\low cycle fatigue analysis is used in the present study to identify the main cause of failure for the SUMED pipeline at its peak point. The analysis shows that the consecutive shutdown/startup events for the pipeline resulted in the formation and subsequent collapse of cavities at the peak point of the line. The cavity collapse would lead to high pressure rise, which under low cycle fatigue conditions, would result in the failure of the pipeline in this region. Moreover, fluid hammer simulations are used to identify a safe valve closure scheme for the pipeline that would prevent column separation events at the peak point and hence ensure safe operation of the pipeline in the future. 6 Copyright © 2014 by ASME 1800 Pipe profile Steady−state total head (t=0) Transient total head (t=1000 s) 1600 1400 10. Head (m) 1200 1000 11. 800 600 400 12. 200 13. 0 0 50 100 150 200 Distance (km) 250 300 Fig. 8 Transient total head at time t=1000 s (Scheme 3) REFERENCES 1. 2. 3. 4. 5. 6. 7. 8. 9. Bergant, A., Simpson, A.R., and Tijsseling, AS, 2006, “Water Hammer with Column Separation: A Historical Review”, Journal of Fluids and Structures, 22, pp. 135171. Wahba, E.M., 2006, “Runge-Kutta Time-Stepping Schemes with TVD Central Differencing for the Water Hammer Equations” International Journal for Numerical Methods in Fluids, 52(5), pp. 571-590. Ghidaoui, M.S., Zhao, M., McInnis, DA, and Axworthy, D.H., 2005, “A Review of Water Hammer Theory and Practice”, ASME Applied Mechanics Reviews, 58(1), pp. 49-76. Watters, G.Z., 1984, Analysis and Control of Unsteady Flow in Pipelines, Butterworth. Tan, J.K., Ng, K.C., and Nathan, G.K., 1987, “Application of the Centre Implicit Method for Investigation of Pressure Transients in Pipelines” , International Journal for Numerical Methods in Fluids, 7(4), pp. 395-406. Hwang, Y., and Chung, N., 2002, “A Fast Godunov Method for the Water-Hammer Problem”, International Journal for Numerical Methods in Fluids, 40(6), pp. 799819. Szymkiewicz, R., and Mitosek, M., 2005, “Analysis of Unsteady Pipe Flow Using the Modified Finite Element Method”, Communications in Numerical Methods in Engineering, 21(4), pp. 183-199. Bonin, C.C., 1960, “Water-Hammer Damage to Oigawa Power Station”, ASME Journal of Engineering for Power, 82, pp. 111-119. List, E.J., Burnam, J., Solbrig, R., and Hogatt, J., 1999, 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 7 View publication stats “Vapor Cavity Formation and Collapse: Field Evidence for Major Pipeline Damage”, Proceedings of the Third ASME-JSME Joint Fluids Engineering Conference, Symposium S-290 Water Hammer, San Francisco, USA, ASME-FED 248, Paper FEDSM99-6886. Thibessard, G., 1961, “The Simulation of Water Hammer on a Numerical Calculator”, Proceedings of the Ninth IAHR Convention, Dubrovnik, Yugoslavia, pp. 881–890. Vreugdenhil, C.B., 1964, “Digital Computations of Water-Hammer”, Delft Hydraulics Laboratory, Report S 103-I, Delft, The Netherlands. Streeter, V.L., 1969, “Water Hammer Analysis”, ASCE Journal of the Hydraulics Division 95, pp. 1959–1972. Tanahashi, T., and Kasahara, E., 1969, “Analysis of the Waterhammer with Water Column Separation”, Bulletin of the JSME 12(50), pp. 206–214. Manson, S.S., 1953, “Behavior of Materials under Conditions of Thermal Stress”, TN 2933: NACA. Manson, S.S., 1962, “Discussion: Experimental Support for Generalized Equation Predicting Low Cycle Fatigue”, Journal of Basic Engineering, 84 pp. 537. Coffin Jr, L.F., 1954, “A Study of the Effects of Cyclic Thermal Stresses on a Ductile Metal”, Trans. ASME, 76, pp. 931-950. Tavernelli, J.F., and Coffin Jr, L.F., 1962, “Experimental Support for Generalized Equation Predicting Low Cycle Fatigue”, Journal of Basic Engineering, 84, pp. 533. Kannan, K., and Hirth, J.P., 1998, “Mixed Mode Fracture Toughness and Low Cycle Fatigue Behavior in an HSLA80 Steel”, Scripta Materialia, 39(6), pp. 743-748. Zhong, Y., Shan, Y., Xiao, F, and Yang, K, 2005, “Effect of Toughness on Low Cycle Fatigue Behavior of Pipeline Steels”, Materials Letters, 59, pp. 1708-1784. Cunha, D.J.S., Benjamin, A.C., Silva, R.C.C., Guerreiro, J.N.C., Drach, P.R.C., 2014, “Fatigue analysis of corroded pipelines subjected to pressure and temperature loadings”, International Journal of Pressure Vessels and Piping, 113, pp. 15-24. Zheng, M., Niemi, E., Zheng, X., 1997, “An Energetic Approach for Predict Fatigue Crack Initiation Life of LY 12 CZ Aluminum and 16 Mn Steel”, Theoretical and Applied Fracture Mechanics, 26(1), pp. 23–28. Zheng, M., Luo, J.H., Zhao, X.W., Bai, Z.Q., and Wang, R., 2005, “Effect of Pre-deformation on the Fatigue Crack Initiation Life of X60 Pipeline Steel”, International Journal of Pressure Vessels and Piping, 82(7), pp. 546552. ASME B31.4, 2003, “Liquid Transportation System for Hydrocarbons, Liquid Petroleum Gas, Anhydrous Ammonia and Alcohols”, ASME, New York. Copyright © 2014 by ASME