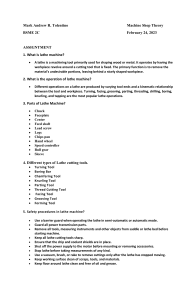

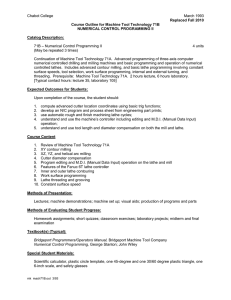

EMT 2231: WORKSHOP PROCESSES AND PRACTICE II Compiled By: Wawira Kyalo SEPTEMBER 2023 Students are reminded not to treat these lecture notes as comprehensive and solely sufficient for their studies. These notes are aimed at providing a quick reference and a brief guidance for the students NOT, a substitute for attending regular classes and reading recommended textbooks. Purpose of the course The aim of this course is to enable the student to • Understand the construction and the functions of the lathe • Understand the construction and the functions of the shaping machine • Understand primary forming processes, machines used and the various welding processes Expected Outcomes At the end of this course, the student should be able to; • Explain the different primary forming processes • Use and handle the lathe and shaper safely and effectively • Carry out and explain the various welding processes Course Outline SAFETY: Overview on work safety SHAPER: Safety; constructions and functions; attachments and cutting tools; setting up workpiece by use of parallels, angle plates, clamping plates, shims, wedges; selection of speeds, feeds and stroke adjustment; shaping of flat and tapered surfaces and slots. LATHE: safety; types; capstan, turret and NC lathes. Construction and functions. Attachments; 3- and 4-jaw chucks. Turning; facing, step turning, knurling, turning between centers, taper eccentric turning, screw thread cutting, boring, reaming; selection of feeds and speeds. i WELDING: safety; arc welding, gas welding, Metal Inert Gas (MIG) welding, Tungsten Inert Gas (TIG) welding, spot welding. PRIMARY FORMING PROCESSES: pressing, forging, piercing, drawing, rolling and extrusion. Workshop exercises involving lathe work, shaping and welding. Reference Textbooks 1. Singh, R., (2006), Introduction to basic manufacturing processes and workshop technology, New Age International 2. Pritchard, R. T., (1972), Workshop processes for mechanical technicians, Hodder and Stoughton 3. Bruce, J. B., (2004), Workshop processes, practices and materials, Elsevier 4. Chapman, W. A. J., Workshop Technology, Edward Arnold 5. Any book on workshop processes will be useful Teaching Methodology 2 hour lectures, 1 hour tutorial, 3 hour practicals per week please note that failing to complete practicals can lead to having to repeat the unit!! ii Examination Mode 2-hour written exam 50% Assignments 5% Continuous Assessment Tests 10% Practicals / Workshop 35% iii Contents Purpose i Expected Outcomes i Course Outline i Reference Textbooks ii Teaching Methodology ii Examination ii List of Figures vii List of Tables viii 1 SAFETY 1 1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1.2 Objectives of Industrial Safety . . . . . . . . . . . . . . . . . . 1 1.3 Causes of accidents . . . . . . . . . . . . . . . . . . . . . . . . 2 1.3.1 Human Causes . . . . . . . . . . . . . . . . . . . . . . 2 1.3.2 Environmental Causes . . . . . . . . . . . . . . . . . . 3 1.3.3 Machine Causes . . . . . . . . . . . . . . . . . . . . . . 3 General Precautions when working in a Machine Shop . . . . . 4 1.4 iv 2 LATHE MACHINE 5 2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 2.2 Lathe Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 2.3 Lathe Construction . . . . . . . . . . . . . . . . . . . . . . . . 6 2.3.1 Bed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 2.3.2 Head Stock . . . . . . . . . . . . . . . . . . . . . . . . 7 2.3.3 Tail Stock . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.3.4 Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.3.5 Feed Mechanism . . . . . . . . . . . . . . . . . . . . . 10 2.3.6 Thread Cutting Mechanism . . . . . . . . . . . . . . . 10 2.4 Types of Lathes . . . . . . . . . . . . . . . . . . . . . . . . . . 10 2.4.1 Speed Lathe . . . . . . . . . . . . . . . . . . . . . . . . 11 2.4.2 Center / Engine Lathe . . . . . . . . . . . . . . . . . . 11 2.4.3 Bench Lathe . . . . . . . . . . . . . . . . . . . . . . . . 11 2.4.4 Tool Room Lathe . . . . . . . . . . . . . . . . . . . . . 11 2.4.5 Capstan & Turret Lathe . . . . . . . . . . . . . . . . . 12 2.4.6 Special Purpose Lathe . . . . . . . . . . . . . . . . . . 16 2.4.7 Automatic Lathe . . . . . . . . . . . . . . . . . . . . . 16 2.4.8 CNC Lathe / Turning Center . . . . . . . . . . . . . . 16 2.5 Size and Specifications of a Lathe . . . . . . . . . . . . . . . . 17 2.6 Lathe Accessories . . . . . . . . . . . . . . . . . . . . . . . . . 19 2.7 Lathe Attachments . . . . . . . . . . . . . . . . . . . . . . . . 21 v 2.8 2.9 Lathe Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 2.8.1 Cutting Tools Materials . . . . . . . . . . . . . . . . . 25 2.8.2 Causes of Tool Chatter . . . . . . . . . . . . . . . . . . 26 Lathe Operations . . . . . . . . . . . . . . . . . . . . . . . . . 28 2.10 Tapers and Taper Turning . . . . . . . . . . . . . . . . . . . . 30 2.10.1 Taper turning by using a form tool . . . . . . . . . . . 32 2.10.2 Taper turning using double feeds . . . . . . . . . . . . 32 2.10.3 Taper turning by setting over tail stock center . . . . . 33 2.10.4 Taper turning attachment method . . . . . . . . . . . . 34 2.10.5 Taper turning by swiveling the compound rest . . . . . 34 2.11 Cutting feeds, speeds and material removal rate . . . . . . . . 37 2.11.1 Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . 39 2.11.2 Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . 39 vi List of Figures List of Tables vii 1 SAFETY 1.1 Introduction Industrial safety practices have been in force for decades and many manufacturing companies have entire departments dedicated to looking into matters of safety at the workplace. These are mainly called Safety, Health and Environment (SHE) or Occupational Health and Safety Administration (OHSA). Accidents take place unexpectedly causing injury or loss to men, machines or materials. Because of this, the main function of the safety department is to facilitate prevention of accidents and incidences in the workplace that could lead to death, permanent or temporary disablement of the industrial employee as well as avoid damage to the equipment and installations at the workplace. All industrial workers must be adequately trained on the safety aspects of man,machine and material and other infrastructural facilities available for avoiding any kind of minor or major accidents. Every worker must be taken through the safety precautions and measures before working on any machine. Safety begins right from the engineering design stage where the safety of man and machine during operation is concerned (think interlocks and redundancies). How the equipment is installed (think plant layout), how the production planning is concerned (material movement etc), how the material is handled (proper material handling practices) and how to correctly operate the equipment once installed. 1.2 Objectives of Industrial Safety 1. Industrial safety is needed to check all the possible chances of accidents for preventing loss of life and permanent disability of any industrial employee, any damage to machine and material as it leads to loss for the whole establishment. 1 2. It is needed to eliminate accidents causing work stoppage and production loss. 3. It is needed to prevent accidents in industry by reducing any hazard to a minimum. 4. It is needed to reduce workman’s compensation, insurance rate and all the costs associated with accidents. 5. It is required to educate all members regarding the safety principles in order to avoid accidents in industry 6. It is needed to boost employee morale 7. It is required to have better human relations within the company 8. It is needed to improve production outputs. 1.3 Causes of accidents Causes of accidents can broadly be categorized as human, machine or environment 1.3.1 Human Causes 1. Accidents may occur when working on dangerous or unsafe equipment or machines with rotating and reciprocating moving parts. 2. Operating machines without proper knowledge, safety precautions, authority or safety devices. 3. Operating or working at unsafe machine speeds. 4. Working for long hours, shift duty, especially without a break (shortstaffing & overtimes) 2 5. Working while distracted by worry, daydreaming, nervousness and anxiety, ignorance, carelessness 6. Improper handling of large or heavy items 7. Not using correct PPE (personal protective equipment) 8. Overconfidence when working with a machine 9. Not dressing appropriately for the work at hand 1.3.2 Environmental Causes 1. Accidents may occur because of working at improper/non-conducive temperatures, pressures and humidity, leading to faster bodily and mental fatigue 2. Presence of dust fumes and smoke 3. Poor housekeeping, congested work-spaces, blocked exits, blind corners, poor plant layout. 4. Inadequate illumination 5. Improper ventilation 1.3.3 Machine Causes 1. Accidents occur because of continued use of old, unsafe or poorlymaintained equipment 2. Use of unguarded or improperly guarded equipment 3. Unsafe processes, unsafe design and unsafe building construction 4. Improper materials handling system 3 1.4 General Precautions when working in a Machine Shop 1. Use the correct tools and work holding devices recommended for the process 2. Hold the workpiece and tool securely in the machine 3. Clamp the tool correctly, as an overhanging tool may cause catastrophic failure of the tool, workpiece or the machine tool 4. Do not try to remove chips from the machine with your hands 5. Do not blow away the chips; always use a brush. 6. Do not touch a job piece with un-gloved hands when doing inspection or removing the job from the machine 7. Operate the machine at the recommended operating conditions for the material, tool and other conditions specified. 8. Use recommended coolant depending on the work-tool combination. 9. Use chip guards and chip breakers when machining ductile materials. 10. Sharpen the tools immediately you notice chatter or rough surfaces on the workpiece. 11. Do not run machines at higher speed than recommended;it may produce chatter and vibrations that may damage the tool or workpiece or both. 12. Provide sufficient approach and other travel allowances necessary. 13. Hone your skills. The skill of the operator is the limiting factor in machining operation. 14. Stop the machine before attempting to clean or remove the tool or the workpiece. 4 2 LATHE MACHINE 2.1 Introduction The lathe machine is the most commonly used and versatile machine found in a machine shop. It is used to shape and form rotating workpieces by material removal. The workpiece is held securely between centers or in a chuck on the lathe and it is turned or rotated against a cutting or shaping tool. Single point cutting tools are the most commonly used; these remove material from the workpiece in the form of chips. The basic principle of operation of the lathe is shown in figure 2.1. Operations that can be carried out using the lathe are drilling, reaming, boring, turning, knurling, facing, thread cutting, grinding, etc. Figure 2.1: Basic operating principle of a lathe machine 2.2 Lathe Safety Some of the basic safety precautions when operating a lathe machine include 1. Do not wear gloves,rings, watches or have loose clothing. sleeves should be rolled up to the elbow to prevent being caught in the rotating parts. 5 2. Do not lean on the machine while it is in operation. 3. Wear protective eye gear or keep your face away from flying chips 4. Do not make ANY adjustments while the machine is in operation; wait until it has stopped and then make the adjustments 5. Never leave the chuck key in the chuck 6. If the lathe has guards,ensure that the guards are securely in place 7. Do not leave the lathe unattended while it is running 8. Do not make deep cuts on slender workpieces, as they can bend or fly off during operation 9. Only use the recommended feed and speed for the workpiece and tool material combination. 2.3 Lathe Construction The figure 2.2 shows the various parts of an engine lathe machine The major components of any lathe machine are i. Bed ii. Head stock iii. Tail stock iv. Carriage v. Feed mechanism vi. Thread cutting mechanism 6 Figure 2.2: Detailed drawing of an engine lathe 2.3.1 Bed The bed is the base on which all other parts of the lathe are mounted. It’s a massive, single piece of casting made to support all other active parts of the lathe. It’s generally manufactured from cast iron alloyed with nickel and chromium. It sits on legs made of cast iron, which are firmly bolted to the floor. The bed and leg materials have a high shock absorbency, compressive strength and wear resistance capacity and they absorb vibrations from the machine during operation and transfer them to the floor. Below the bed is the chips span or tray, which is used to capture hot chips during machining. On the top of the bed are guideways (innerways and outerways), which allow for movement of the tail stock and carriage. 2.3.2 Head Stock It is permanently fastened on the left hand side of the bed and transmits power to the different parts of the lathe as well as supporting the spindle. 7 This power transmission may be through gears, pulleys or motor. The power and most motion control devices are on the head stock. The head stock and spindle are hollow inside to allow for holding of long workpieces or workholding devices. The main spindle holds the live centre to which the work can be attached. 2.3.3 Tail Stock The tail stock works primarily to give and outer bearing and support to the circular job being turned on centers. It can easily be set for alignment or non-alignment w.r.t. the spindle center, and carries a center called a dead center for supporting one end of the work. Figure 2.3: Tail stock 2.3.4 Carriage The carriage, shown in figure 2.4, controls and supports the cutting tool and has these 5 major parts (a) Saddle — Has a H-shaped casting fitted over the bed and moves along the guideways. 8 (b) Cross-slide — It carries the compound rest and tool post and can be moved by power or manually by hand. (c) Compound rest — It’s marked in degrees and is used during taper turning to set the tool for angular cuts. (d) Tool post — This is where the tool is clamped as shown in figure 2.5. Figure 2.4: Tool carriage Figure 2.5: Tool post (e) Apron — this is attached to the saddle and hangs in front of the bed. It has gears, levers and clutches for moving the carriage with the lead screw for thread cutting. 9 2.3.5 Feed Mechanism The feed mechanism is the combination of different units through which motion of the headstock spindle is transmitted to the carriage of the lathe machine. It is employed for imparting various feeds (longitudinal, cross and angular) to the cutting tool. The most important parts are end of bed gearing, feed gear box, lead screw and feed rod and apron mechanisms. The gearing at the end of bed transmits the rotary motion of the headstock spindle to the feed gearbox. Through the feed gearbox, the motion is further transmitted to the lead screw or the feed rod, depending on the operation. The feed gearbox contains different sized gears which provide a means to alter the feed rate by changing the speed of rotation of the lead screw or feed rod. The apron is fitted to the saddle and contains gears and clutches to transmit motion from the feed rod to the carriage, and the half-nut which engages the lead screw during thread cutting. 2.3.6 Thread Cutting Mechanism The half nut or split nut is used for thread cutting on a lathe. It engages or disengages the lead screw so that the rotation of the lead screw is used to traverse the tool along the workpiece to cut screw threads. The direction in which the carriage moves is dependent on the position of the feed reverse lever on the headstock. 2.4 Types of Lathes There are several types and sizes of lathes that may be found in a machine shop, but all operate on the same basic principle. The lathes are mostly defined by their use and by their construction. We shall consider the 7 most common ones here. 10 2.4.1 Speed Lathe The simplest of all types of lathes in both construction and operation. The important parts are the bed, headstock, tailstock and tool post mounted on an adjustable slide. It has no feedbox, leadscrew or conventional carriage. Tool is fed into the work manually. The headstock spindle rotates at a very high speed and so this lathe finds application where low cutting forces are needed, e.g. wood working, spinning, centering, polishing, winding, buffing, deburring 2.4.2 Center / Engine Lathe This is the most widely used lathe. In earlier days, the lathe used to be run by a steam engine, and hence the name Engine Lathe. Engine lathes are classified according to the method of transmitting power to the machine and can be motor-driven, gear-head type or belt-driven. This has all the lathe parts discussed above, as well as additional mechanism for driving the lathe spindle at multiple speeds. The cutting tool can also be fed in both cross and longitudinal directions with reference to the lathe axis, with the help of a carriage, feed rod and lead screw. Basic parts of a center lathe are shown in figure 2.6 2.4.3 Bench Lathe This is a small lathe that is usually mounted on a bench. It is commonly used for small and precision machining work. 2.4.4 Tool Room Lathe This lathe has features similar to the engine lathe, but is much more accurately built and possesses high rigidity to produce accurate and precise parts. 11 Figure 2.6: Main components of a centre lathe It has a wide range of spindle speeds, from very low to high. It’s used for precision work on tools, dies, gauges and machining work where high accuracy is needed 2.4.5 Capstan & Turret Lathe Developed from the engine lathe, capstan and turret lathes are semi-automatic lathes that are designed to facilitate mass production of work. In place of a tail stock, this lathe has a hexagonal turret, on which multiple tools may be fitted and fed into the work in proper sequence. This enables several different operations to be done on a job without resetting the work ot the tools. A number of identical parts can be produced in minimum time. Some of the differences in construction and operation of the capstan and turret lathes are captured in figures 2.7, 2.8 and 2.9 12 CAPSTAN LATHE Lightweight machine Turret tool head is mounted over the ram which is mounted over the saddle To provide feed to the tool, the ram is moved Since there is no saddle movement, movement of the turret tool head over the longitudinal direction of the bed is small Used for shorter workpieces because of limited ram movement Working operations are fast because of lighter construction Heavy cuts cannot be given to the workpiece because of the lighter construction Turret head cannot be moved in the lateral direction of the bed Collet is used to grip the job Can machine work up to 60mm diameter Usually horizontal lathes TURRET LATHE Heavyweight machine The turret tool head is mounted over the saddle as a single unit To prove feed to the tool, the saddle is moved Turret tool head moves along with the saddle over the entire bed in the longitudinal direction Used for longer workpieces, facilitated by saddle movement along the bed Working operations are slower because of heavier construction Heavy cuts can be given to the workpiece because of the rigid construction of the machine. Turret head can be moved cross-wise, i.e. in the lateral direction of the bed Power jaw chuck is used ot grip the job Can machine work up to 200mm diameter Available in horizontal and vertical lathes Table 2.1: Differences between capstan and turret lathes 13 Figure 2.7: Capstan and Turret Lathe comparison 14 Figure 2.8: Capstan Lathe Schematic Figure 2.9: Turret Lathe Schematic 15 2.4.6 Special Purpose Lathe As the name suggests, these lathes are designed specifically for jobs that cannot be accommodated on the conventional lathe machines. These are (a) Wheel lathe — made for finishing the journals and turning the thread on railroad car and locomotive wheels. (b) Gap bed lathe — a section of the bed adjacent to the headstock is removable in order to swing extra-large diameter workpieces. (c) T-Lathe — this lathe’s bed has a T-shape and is used for machining of rotors for jet engines (d) Duplicating lathe — duplicates the shape of a flat or round template onto the job. 2.4.7 Automatic Lathe High-speed, heavy duty, mass production lathes with complete automatic control: all the working and job handling movements of the complete manufacturing process are done automatically. It should be noted that this automatic lathe nomenclature does not conventionally include NC and CNC lathes, but the mechanically automated lathes. 2.4.8 CNC Lathe / Turning Center Computer controlled lathe machines whose operation is fully automated. 16 ASSIGNMENT 1 Assignment is due by the 12/10/2023. Late assignments will NOT be accepted. Early assignment submissions are welcome. 1. With the aid of a suitable diagram, briefly describe the construction of a CNC lathe machine and identify the different CNC lathe configurations. 2. Identify the advantages, disadvantages/limitations and areas of application of CNC lathe machines. 3. Using a diagram, describe the different number axis CNC lathes and where they find use. 4. Describe the ways in which you would program a CNC lathe to carry out a turning operation to reduce the diameter of a part from 50mm to 45mm. 2.5 Size and Specifications of a Lathe The size of a lathe may be defined using any of the following main specifications, also illustrated in figure 2.10 1. The height of the centers measured from the lathe bed 2. The swing diameter over the bed: This is the largest diameter of work that will revolve without touching the bed and is twice the height of the centre measured from the bed of the lathe. 3. The length between centers: This is the maximum length of work that can be mounted between the lathe centers. 4. The swing diameter over carriage: this is the largest diameter of work that will rotate over the lathe saddle and is always less than the swing diameter over bed. 17 5. The maximum bar diameter: this is the maximum diameter of bar stock that will pass through the hole of the headstock spindle. 6. The length of the bed: This indicates the approximate floor space that will be occupied by the lathe. Figure 2.10: Lathe specification Other specifications that contribute to specifying a common lathe are; • Length, width and depth of bed • Depth and width of the gap in case of a gap lathe • Swing over gap • Number and range of spindle speeds • Number of feeds • Lead screw diameter • Number and range of metric threads that can be cut • Tail stock spindle travel and set-over 18 • Back gear ratio • Power rating of the electric motor 2.6 Lathe Accessories These are devices used for handing and supporting the work and tool on the lathe. Some are shown in figure 2.11 and include Figure 2.11: Lathe accessories 1. Chucks Provide a very efficient and true device for holding work on the lathe dur- ing the operation. Commonly used chucks include three-jaw universal chucks, four-jaw independent chucks, combination chucks, magnetic chuck, air or hydraulic chucks and collet. 19 2. Face plate Usually a circular cast iron disc, having a threaded hole at its center to be screwed to the threaded nose of the spindle. Consists of a number of holes and slots to secure the work. Bolts, nuts, washers, clamping plates etc are required for holding the work properly on a face plate. 3. Angle plate Used for holding work in conjunction with a face plate. When size or shape of work is not possible to mount directly on face plate, angle plate is secured to face plate and work mounted on it. 4. Driving plate It is a circular disc having a projected boss at its rear. The boss carries internal threads to be screwed onto the spindle work. It also carries a hole to accommodate a pin which engages with the tail of a lathe dog/carrier. 5. Lathe carriers or dogs Are used in conjunction with the driving plate. Have two forms: straight tail or bent tail. Work to be secured using set screws. 6. Lathe centres Act as solid bearings to support the work during the operation. Commonly made of cast iron or high grade tool steel. Are the hardened and ground to correct angle. For very high speeds to be used, their tips are made of cemented carbides or high speed steels fitted into the usual types of shanks. 7. Lathe mandrels or arbors A mandrel is a solid steel shaft or spindle used for holding bored parts for machining their outside surfaces on a lathe. Common types of mandrels are: solid or plain, collar, stepped, expanding and double cone mandrels. 8. Rests When a very long job is to be turned between centers on a lathe, due to 20 its own weight it provides a springing action and carries a lot of bending moment and thus turning tool is spoiled very soon and may even break. To avoid these, such jobs are always supported on an attachment called steady rest or center rest. 9. Jigs and fixtures Are used in conjunction with face plate for supporting and holding odd shaped and eccentric jobs. Specifically for mass production of identical parts. 2.7 Lathe Attachments Attachments increase production and efficiency and widen the scope of use since such works are normally not carried on lathes and include: 1. Steadies If unsupported, long slender work may tend to be pushed aside by the forces of cutting. To overcome this, a two-point travelling steady is used which provides support to the workpiece opposite the tool as cutting is carried out along the length of the work, figure 2.12. Work of a larger diameter than can be accepted through the machine spindle and yet requiring work to be carried out at one end can be supported using a three-point fixed steady. This steady is clamped to the machine bed and the points are adjusted so that the workpiece is running true to the spindle centre line before the machining operation is carried out. 2. Centres Components having a number of diameters which are required to be concentric can be machined between centres. A centre is inserted in the spindle nose, using a reducing bush supplied for this purpose. This centre rotates with the spindle and workpiece and is referred to as a live centre. A centre inserted in the tailstock is fixed, does not rotate and is 21 Figure 2.12: Steadies referred to as a dead centre. Great care must be taken to prevent overheating of dead centres due to lack of lubrication or too high a pressure. Keep the centre well lubricated with grease, and do not overtighten the tailstock. In order to drive the workpiece, a work-driver plate must be mounted on the spindle nose and the drive is completed by attaching a work carrier to the workpiece, figure 2.13. Where the size of workpiece requires greater pressure and where considerable time is required for the operation, dead centres will burn out, i.e. overheat and the point wear out. To overcome this, live or rotating tailstock centres are available, the centres of which run in bearings which will withstand high pressures without overheating. Tailstock centres are often required for long work which is held in the chuck but requires support owing to its length. 3. Stops Stops are used in conjunction with both the carriage and cross-slide to enable a quick and accurate positioning of carriage and cross-slide. 22 Figure 2.13: Centres When similar operation is to be repeatedly done, stops effect considerable saving in time and give more accuracy. 4. Grinding Attachment It is also known as tool post grinder. Generally, it consists of a bracket, grinding wheel and a separate motor. The job is held as usual in a chuck or between centers and the rotating grinding wheel fed against the job. 5. Milling Attachment Consists of a vertical pillar and the job is held stationery between the centers. Dividing head is fitted in front of the pillar for indexing the work. 6. Copying Attachment Used for repetition work. 7. Relieving attachment Relieving is usually done on most of multi-point tools e.g. milling cutters. taps and reamers. 8. Taper turning attachment Facilitates accurate tapering operations 23 2.8 Lathe Tools For general purpose work, a single point tool is sufficient, but for special operations, multi-point tools are used. Some of the most common tools are shown in figure 2.14. Common material used in tool-making are high carbon steel, high speed steel, cemented carbides, diamond and ceramics. Figure 2.14: Common lathe tools Lathe cutting tools should possess the following properties 1. They should be hard. 2. They should be wear resistant 24 3. They should be capable of maintaining red hardness during operation. 4. They should be able to withstand shock during operation. 5. They should be shaped so that the edge penetrates the work. 2.8.1 Cutting Tools Materials The main types of materials used for single-point lathe cutting tools are: 1. High speed steels — tool most commonly used in school machine shops. HSS tools may contain combinations of tungsten, chromium, vanadium, molybdenum and cobalt. They are capable of taking heavy cuts, withstand shock and maintain a sharp cutting edge under red heat. There are many different grades of HSS cutting tools, one should refer to the manufacturer’s recommendations for a cutting tool for a specific job. 2. Cast alloy steels — cast alloy (stellite) tools contain chromium, tungsten, carbon and cobalt. They have high hardness, high wear resistance, excellent red hardness, capable of high speeds (2X HSS) and feeds on deep, uninterrupted cuts. However, because they are cast, they’re relatively weak and brittle. 3. Cemented carbides — consists mostly of tungsten carbide sintered in a cobalt matrix. Used to machine cast iron and non-ferrous materials. These possess high hardness, excellent red hardness, capable of high cutting speeds (3-4X HSS) but low toughness. 4. Ceramics — ceramics are heat-resistant materials produced without a metallic bonding agent such as cobalt. Aluminium oxide is the most popular material. Titanium oxide or titanium carbide may be used as additives. They permit higher cutting speeds,increased tool life, better surface finish than carbide tools. However, they can only be used in no-shock or low-shock operations. 25 5. Cermets — these are cutting tool inserts composed of ceramics and metal. Most are made from aluminium oxide, titanium carbide and zirconium oxide, compacted and compressed under intense heat. They can be used to machine hard materials, machine at hogh temperatures, give an improved surface finish and extended tool life as compared to coated and uncoated carbides. 6. Diamond (PCD) — these tools consist of tiny manufactured diamonds, fused together and bonded to a suitable carbide substrate. Compared to carbide tools, PCD tools offer greater wear and shock resistance, increased cutting speeds, better surface finish, better partsize control, increased productivity and greater tool life (up to 100X). 7. Borazon (PCBN) — cubic boron nitride is next to diamond on the hardness scale. Polycrystalline CBN is bonded to a cemented crabide substrate, which improves shock resistance. They have very high wear resistance and edge life and may be used to machine high-temperature alloys and hardened ferrous metals. 2.8.2 Causes of Tool Chatter Chatter in machining is the vibration of the tool or the workpiece during the cutting process. The most common type of chatter is tool chatter. The most common causes of tool chatter are: 1. Looseness or wear of machine slides 2. Excessive overhang of the tool 3. The use of too large a radius on round-nose tools 4. Insufficient rigidity of the workpiece, or excessive overhang of the workpiece 26 5. Having an excessively long cutting edge in engagement with the workpiece (chatter from this cause can be eliminated by reducing the approach angle to the point where it ceases) 6. Incorrect speeds and feeds 7. Incorrect tool angles relative to the type of material being machined, e.g. hard, soft, tough etc. Some consequences of chatter in machining are 1. On a workpiece, it will unfavorably affect surface finish quality and geometric tolerance of parts. In some cases, it may cause possible deformation of geometric shape. 2. At times it may put extra demand on workholding structures like fixtures by having to incorporate an extra degree of rigidity to withstand additional forces caused by vibration. 3. It may cause excessive or uneven wear on cutting tools which may lead to premature breakages and thus compromising process security. Going further such breakages may jeopardize future reconditioning possibilities or usability of remaining cutting edges resulting in higher consumable cost. 4. Persistent vibrations may cause damage to dynamically moving parts of a machine including the gears, bearings, guide ways and spindle assembly, leading to their higher wear and tear. Chatter may eventually affect long term geometric and/or positioning accuracy of a machine tool contributing to additional repair cost. 5. Machinists most commonly respond to chatter by cutting back on speeds, feeds, depth of cut or by reprogramming a tool path. This impacts the optimum metal removal rate, leads to loss of productivity, and compromises overall efficiency. In cases like high speed machining, it restricts the fullest exploitation of the machine and cutting tool capability. 27 2.9 Lathe Operations Some of the common operations performed on a lathe are shown in figure 2.17 and are discussed briefly below. 1. Facing Facing is the machining of the ends of a workpiece, to produce a flat surface. It is also used to cut the work to the required size. Tool feed is perpendicular to the axis of rotation of the workpiece. It is done in 2 steps; rough facing with a deep feed, followed by a finer cross-feed for a smaller dept of cut and a smoother finish. 2. Plain turning This is an operation of removing excess material from the surface of the cylindrical workpiece. In this operation, the work is held either in the chuck or between centers; the longitudinal feed is given to the tool either by hand or powered. 3. Step turning Thus us an operation of producing various steps of different diameters in the workpiece. The operation is carried out in a similar manner to plain turning. 4. Taper turning Taper turning means to produce a conical surface by gradual reduction or increase in the diameter of a cylindrical workpiece. This tapering operation had a wide range of use in construction of machines. Almost all machine spindles have taper holes which receive taper shanks of various tools and work holding devices. We shall look at tapering in depth later on. 5. Drilling It is an operation of making a hole in a workpiece with the help of a drill. The drill is mounted on the sleeve or barrel of the tail stock and 28 fed normally into the rotating workpiece by rotating the tail stock hand wheel. 6. Reaming This is a finishing operation on a previously drilled hole. It is used to achieve a high grade of surface finish and dimensional accuracy of internal holes. The work is rotated at low speed to achieve a good finish. The reamer is held in the tail stock and fed into the workpiece just like in drilling operation. 7. Boring This is enlarging and truing of a hole by removing material from the internal surface with a single point cutting tool. 8. Undercutting / grooving This is the process of cutting a narrow channel or passsageway into the outside diameter of a cylindrical workpiece. It is often done at the end of a thread or adjacent to a shoulder to leave a small margin. 9. Threading This is cutting a long, spiraling groove of a specific shape into a workpiece with a single point cutting tool. Both internal and external threads can be cut on a lathe. Threading processes are essential to the creation of fasteners. 10. Knurling This is embossing a diamond-shaped pattern on the surface of a workpiece, either for cosmetic purposes or (mostly) for better handling by providing an effective gripping surface. 11. Forming This is an operation that produces a convex, concave or any irregular profile on a workpiece as shown in figure 2.16. 29 Figure 2.15: Lathe threading operations Figure 2.16: Forming operations 2.10 Tapers and Taper Turning A taper is defined as a uniform increase or decrease in diameter of a workpiece, measured along its length. Taper turning means producing a conical surface by gradually reducing the diameter in a cylindrical job. When machining a taper, you set the tool in such a way that the angle formed by the rotational axis of the workpiece and the axis of the cutting tool corresponds to half of the taper angle. This means that if I want a 60o taper, I’ll set my cutting tool to 30o . 30 Figure 2.17: Common lathe operations Tapers are used in machines because of their capacity to align and hold machine parts, and to realign them when they are repeatedly assembled and disassembled. This repeatability assures that tools such as centers in lathes, 31 taper shank drills in drill presses, and arbors in milling machines will run in perfect alignment when placed in the machine. Tapers are very suitable in self aligning and locating and widely applied in all assembly of static or dynamic components in engineering. The main methods for use in taper turning are • Using a form tool • Using double feeds (longitudinal and cross) • Setting over the tail stock center • Using a taper turning attachment • Swiveling the compound rest 2.10.1 Taper turning by using a form tool This is one of the simplest taper turning methods in lathe machine used to produce short tapers as seen in figure 2.18. The tool is ground to the required taper angle. The tool cutting edge length must be greater than the taper length. Since the entire cutting edge removes the metal, it will produce a lot of vibration and hence a large cutting force is required. It is done on slow speed. 2.10.2 Taper turning using double feeds In certain lathes, both longitudinal and cross feeds may be engaged simultaneously causing the tool to follow a diagonal point which is the resultant of the magnitude of the two feeds, see figure 2.19. The direction of resultant feed may be changed by varying the rate of feeds by change of gears provided inside the apron of the lathe. 32 Figure 2.18: Form tool taper turning Figure 2.19: Double feed taper turning 2.10.3 Taper turning by setting over tail stock center Figure 2.20 shows how a tail-stock set over is done. The job is inclined to the required taper angle. When the workpiece rotates the tool is moved parallel to the lathe axis, so that the taper will be generated on the workpiece. This method is basically employed for turning small tapers on longer jobs and is 33 confined to external tapers only. Figure 2.20: Tail stock set over taper 2.10.4 Taper turning attachment method This method is commonly employed for generating external tapers only. In this method, the taper turning attachment is bolted back of the lathe machine as shown in figure 2.21. It has a guide bar that may be set at any desired angle. As the carriage moves along the bed length, the tool moves according to the setting of the bar, duplicating the taper setting on the bar. 2.10.5 Taper turning by swiveling the compound rest In this method the workpiece is rotated on the lathe axis and the tool is fed at an angle to the axis of rotation of the workpiece. The tool is mounted on the compound rest which is attached to a circular base, graduated in degrees. The compound rest can easily be swiveled or rotated and clamped at any desired angle as shown in figure 2.22. Once the compound rest is set at the desired half taper angle, rotation of the compound slide screw will cause the tool to be fed at that angle and generate a corresponding taper. This method is limited to turn a short but steep tapers because of the limited movement of the cross-slide. The compound rest can be swiveled at 45Âř on either side of the lathe axis enabling it to turn a steep taper. The movement of the single point cutting tool in this method is controlled purely by hand, thus it provides a low production capacity and 34 Figure 2.21: Taper turning attachment poor surface finish. If the diameter of the small and large end and length of taper are known, the half taper angle can be calculated. The complete setup for producing a taper by swiveling the compound rest is given in figure 2.23 35 Figure 2.22: Compound rest swivel taper turning Figure 2.23: Swivel taper turning set-up 36 2.11 Cutting feeds, speeds and material removal rate Cutting speed in a lathe for turning operation is the peripheral speed of the workpiece past the cutting tool given by equation 2.11.1 where U is the cutting/peripheral speed in m/min, D is the job diameter in mm and N is the job or spindle speed in rpm. V = π×D×N 1000 (2.11.1) Main factors in selection of proper cutting speed include • material of the cutting tool • hardness and machinability of metal being machined • use or absence of coolant • rigidity of the tool and work • tool shape • depth of cut • feed • rigidity of the machine. Feed is the distance that a tool advances into the work during one revolution of the headstock spindle. Feed is expressed in mm/rev. The smaller the feed, the better the surface finish. Larger feed reduces machining time but reduces tool life. Feed f is given by equation 2.11.2 where L is the length of cut in mm N is rpm and Tm is the machining/cutting time in min. f= L N × Tm 37 (2.11.2) Depth of cut d is the perpendicular distance measured from the machined surface to the uncut (or previous cut) surface of the workpiece. For turning operations, depth of cut is given by equation 2.11.3 where Di , is the initial/original diameter of the workpiece in mm, Df is the final diameter of the workpiece in mm. d= Di − Df 2 (2.11.3) For rough cutting, depth of cut should be as large as possible, consistent with the size or capacity of the lathe and material being machined. The values of speed, feed and depth of cut generally depend on type of workpiece material, type of tool material and type of surface finish required. Material removal material MRR is the volume of material removed per unit time. Its a function of speed, feed and depth of cut. Material removed per revolution is the volume of chip whose length is πDi ; Since the job is making N rpm, the MRR in mm3 is given as M RR = πDi × d × f × N (2.11.4) In terms of cutting speed V from equation 2.11.1 we have M RR = 1000 × V × d × f (2.11.5) Machining time Tm , per pass or per cut is given by Tm = L fN (2.11.6) Rewriting this using equations 2.11.2 and 2.11.1, we have Tm = L πDL = 1000V 1000V f f × ( πD ) 38 (2.11.7) Number of passes or cuts np equals total machining allowance divided by material removed per cut. Material removed per cut = depth of cut. Total manufacturing time = machining time + set-up time + moving and waiting time + inspection time. Power required at the spindle for turning depends on: cutting speed, depth of cut, feed rate, hardness and machinability of workpiece material. 2.11.1 Example 1 Calculate the time taken to face a workpiece of 80 mm diameter. The spindle speed is 90 rpm and cross-feed is 0.3mm/rev 2.11.2 Example 2 Calculate the time taken to turn a brass component 60 mm diameter by 84 mm long if the cutting speed is 50 m/min and the feed is 0.4 mm/rev. Only one cut is to be considered. Neglect tool approach and tool travel 39