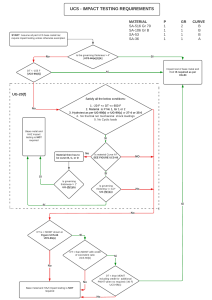

ASME Part UCS: Carbon & Low Alloy Steel Pressure Vessel Requirements

advertisement