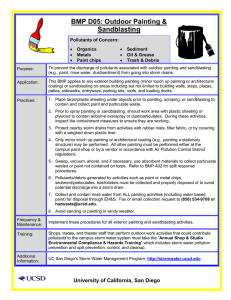

TYPES OF SANDBLASTING TECHNIQUES: PROS AND CONS Euroblast Middle East LLC Sandblasting - Introduction Sandblasting is a mechanical process that involves propelling abrasive materials (such as sand, glass beads, or other particles) at high speeds against a surface to clean, smooth, or shape it. This technique is commonly used for various applications, including surface preparation before painting, removing rust and old coatings, and achieving specific finishes on materials. Sandblasting is widely utilized in industries such as construction, automotive, and manufacturing. How to Select Right Sandblasting Technique Selecting the right sandblasting technique is crucial for several reasons, including surface compatibility, cleaning effectiveness, and achieving the desired finish. Different surfaces require specific methods to avoid damage, while the effectiveness of contaminant removal varies by technique, impacting the preparation for subsequent processes like painting or coating. Additionally, the right choice can enhance time efficiency and cost-effectiveness by optimizing resources and reducing project costs. Health and safety considerations are also important, as some methods generate more dust and debris, posing risks to workers. Furthermore, selecting an eco-friendly technique can minimize waste and align with environmental regulations. Ultimately, understanding the project requirements ensures that the appropriate tools and materials are used, leading to efficient and high-quality sandblasting outcomes. Different Types Of Sandblasting Techniques Technique Description Pros Cons Dry Sandblasting Uses compressed air to - Versatile for propel abrasive various surfaces material. - Can create dust; may require cleanup Wet Sandblasting Mixes water with abrasives to reduce dust. - Less airborne dust; safer for health - Equipment may be bulkier; slower process Micro Sandblasting Uses fine abrasives for detailed work. - Precise control; ideal for delicate items - Slower; may require multiple passes Abrasive Blasting Utilizes different abrasives (e.g., glass beads). - Customized finish; versatile materials - Requires expertise; potential for surface damage Soda Blasting Uses sodium bicarbonate as an abrasive. - Non-toxic; safe for delicate surfaces - Not suitable for heavy-duty Conclusion In conclusion, each sandblasting technique offers unique advantages and limitations, making it essential to select the appropriate method based on the specific cleaning or finishing requirements. Understanding these pros and cons will help optimize efficiency and effectiveness in various applications. Thanks • Any questions? • You can find me at: • Euroblast Middle East LLC • Email: info@euroblastme.com • Contact number: +971 42824400 • Website: https://www.euroblastme.com • Address: P.O Box 31230, National Industries Park, Jebel Ali, Dubai, United Arab Emirates