Discussion Group: B

ME3200 Machine Design Project

Semester 5

Final Report

By

Index No.

180046U

Name

HRSKB Ariyarathne

Date of submission

Due date of submission

Marks

23/02/2022

23/02/2022

Discussion group advisors’ names and affiliations

Dr MMID Manthilake

Mr GPM

Ehelagasthenna

Mr HAP Bimsara

Department of Mechanical Engineering,

University of Moratuwa

Department of Mechanical Engineering,

University of Moratuwa

Department of Mechanical Engineering,

University of Moratuwa

Department of Mechanical Engineering

University of Moratuwa

Sri Lanka

1

Introduction

Gear are wheel with teeth used to transmit power and motion from one shaft to another

when constant velocity reduction is desired. Gear drives can multiply the torque while reducing

the rotational speeds and change the direction of shaft rotation. Compared to belt and chain

drives gear drives can transmit large powers with higher efficiency and they are compact in size.

also they can operate in high speeds as well.

Conveyor systems are used in most of the manufacturing processes to transport raw

material and end products. Since different loads needs different torques as well as specific tasks

need different speeds speed reduction method should be used. This speed reduction can be

achieved by using gearbox, pulley arrangement, variable speed motor or hydraulic operation.

Modern conveyor systems use VFD drives to control the speed of the conveyor belts. Main

problems with a VFD system are initial cost is relatively high, at some speeds resonance may

occur resulting increased noise and excessive vibrations and they have rather short lifespan. As a

low cost alternative gearboxes can be used.

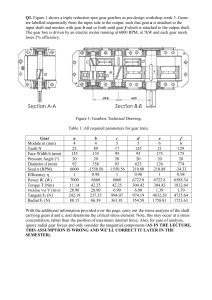

In this report 3 speed gearbox design for a conveyor belt in a canned fish manufacturing

plant is conducted. Gearbox will be needed to regulate the torque by selecting appropriate speed,

to control the speed of the drive and to reverse the drive. Gearbox should provide a speed

reduction from motor to driven pulley of the conveyor belt, should transmit the required amount

of power to the conveyor system, should provide smooth operation and should be easy to

manufacture.

Figure 1: Conveyor Gearbox [4 ]

2

Problem Description

2.1 Conveyors

Conveyors are used in almost every industry to move objects from one location to another.

There is a good chance that packaged products we get hands on has moved on a conveyor at

one stage. There are different types of conveyors such as screw type, gravity, pallet handling

and most commonly used type is the belt & chain.

Figure 2: Conveyor Belt [2]

Conveyor belts have make a great impact in food industry. They provide flexibility of

changing production volume according to the market and trends, save energy and labour cost,

improved productivity and competitiveness among the market and much higher production

capacity which lead to opportunity seizing in the market gaps. Gearbox is considered to be the

heart of a conveyor system. When it comes to conveyors the main role of the gearbox is the

speed reduction. In addition, it will multiply the torque and will help the longevity and improved

performance of the system.

2.2 Objective

Sri Lanka is an island surrounded by ocean which makes the fish industry very popular and

canned fish has a huge demand in Sri Lanka. Processed canned fish or cases of canned fish

needs to be transported from production line to storage facilities and then from storage facilities

to factory outlets. Large amount of canned tuna is manufactured daily making the manual

process of transporting highly inefficient. This is where conveyor belts are very useful.

Figure 12: Conveyor Belts Used for Canned Food [17]

Figure 3: Conveyor Belts Used for Canned Food [3]

Most of the large scale factories are using Variable Frequency Drives (VFD) in the conveyor

systems as they provide good control of the process. Main issues with a VFD system are initial

cost is relatively high, at some speeds resonance may occur resulting increased noise and excessive

vibrations and they have rather short lifespan. Therefore, use of a gearbox rather than a VFD is

more suited for a medium scale enterprise where initial cost and maintenance is a huge factor.

Most of the small scale factories use single speed reduction gearbox for the conveyors. This is not

only inefficient but also time consuming when designed for different loads.

Figure 5: Conveyor Belt with a Gearbox [4]

Figure 4: Variable Frequency Drive [1]

Canned fish comes in variety of sizes and most common are 125 g, 225g and 425g. Goal

of this project is to design a 3-speed gearbox to coop with the different sizes of canned fish

products. This will put less stress on prime mover due to torque multiplication from the gearbox

as well as ensure a long working life of the conveyor system. Further time consumed for the

process will be significantly less due to variable speeds. Canned fish comes in variety of sizes

and most common are 125 g, 225g and 425g and goal is to design a 3-speed gearbox to coop

with the different sizes of canned fish products. Filling the cans are mostly done by hand in the

industry and the time taken to fill a 125g can is less than time taken to fill 225g can. Therefore,

three sizes will have three different production rates which can be achieved by using a 3 speed

gearbox. Reverse gear will be essential for the quality control of the products.

2.3 Parameters

Table 1: Design Specifications [6]

Length

10 m

Width

0.3 m

Thickness

0.01 m

Material Used for Belt

Rubber Composite

Density

1.2 kg/m3

Linear Speed

0.35 m/s

Product Conveyor Carry

Canned Fish

Weight of an Empty Can

75 g

Weight of Different Sizes

425 g, 225 g, 125g

Production Rate

5000 per day

Maximum Loading Capacity

150 kg

Coefficient of Friction

0.64

Forward Gears

3

Reverse Gears

1

Cost of the Machine

Rs. 100,000

Cost of Maintenance

Rs. 30,000 per annum

Maintenance Intervals

3 months

Operator Skill

Advanced Beginner

2.4 Importance of the Parameters

Many make the mistake of designing the gearbox equivalent to the size of motor rather than

the equivalent to the load it’s working with. This will typically lead to a much bigger and

expensive prime mover which will be too much for the required load. Therefore, gearbox should

be designed keeping the load in mind in order to save money and energy in long run.

Weight of the conveyor belt and total weight of canned food on the conveyor belt is the

main parameter which determines the amount of torque needed for the operation of conveyor

belt. To find the weight of the belt, dimensions are needed. Here rubber composite is used as the

belt material and with the density weight of the belt can be determined. By knowing the weight

of a canned fish and the number of canned fish on the conveyor belt total weight of the canned

fish can be determined which will give the total load applied on the conveyor belt. With the total

weight and friction coefficient total pull needed for the operation can be found and with the

linear speed of the belt total required power can be determined. With the known gear ratios

finally prime mover for the application can be selected.

Figure 6: Conveyor Gearbox Sizing [5]

Additionally, assumed that conveyor operate in a flat surface and there is no incline

angle. Therefore, effect of the gravity can be neglected. Belt drive is used for the power

transmission as they are cost-effective, simple, low maintenance and they can absorb shock and

vibrations well. 3-phase induction motors are ideal for conveyor systems as it provides very high

starting torque. Typical motors used for conveyors generate the power around 1800 rpm, therefore

higher reduction ratios are desired. Input and output shaft diameters will be needed for torque and

speed calculations of the gearbox.

2.5 References

[1] - Variable Frequency Drives (VFD) Variable Frequency Drive. (n.d.).

[2] -Proymec. (2019). The conveyor belt market is ready to grow in 2019. Proymec.

https://proymec.es/en/el-mercado-de-las-bandas-transportadoras-esta-listo-para-crecer-en-2019/ ,

(accessed Oct. 29, 2021)

[3] -Aluminum cans for food processed in factory line conveyor machine at canned food

manufacturing, selective focus. (2020). https://www.dreamstime.com/aluminum-cans-foodprocessed-factory-line-conveyor-machine-canned-manufacturing-selective-focusimage202089575 , (accessed Oct. 20, 2021)

[4] - High-speed Solid-rotor Motors, Gearbox Motor Conveyor Manufacturers. (2021). NER

GROUP CO. LIMITED. https://www.guomaodrive.com/blog/gearbox-motor-conveyormanufacturers.html , (accessed Oct. 24, 2021)

[5] - Oriental Motor. (2021). Belt Conveyor Sizing Tool. Oriental Motor.

https://www.orientalmotor.com/motor-sizing/beltConveyor-sizing.html , (accessed Oct. 25,

2021)

[6] - Coefficient of Friction Equation and Table Chart. (2021). Engineers Egde.

https://www.engineersedge.com/coeffients_of_friction.htm , (accessed Oct. 20, 2021)

[7] - Allan Barber, G. I. O. M. T. C. (2020). The Key Role of Industrial Gearboxes. Lubrizol360.

https://www.youtube.com/watch?v=OlPht51R9k4&ab_channel=Lubrizol360, (accessed Oct. 17,

2021)

[8] - CASSANDRA. (2017). Conveyor belts and their role in the food industry. LOCKER.

http://locker.com.au/blog/general-industrial/conveyor-belts-and-their-role-in-the-food-industry/ ,

(accessed Oct. 20, 2021)

3

Background Study

3.1 What is Gearbox?

Gearbox is a mechanical method of transferring energy from one device to another while

increasing torque and reducing speed. Gearboxes are widely used in many industries such as

cement industry, sugar industry, paper industry, power generation etc. They are available in wide

range of different sizes depending on the application.

Figure 7: Simplified Gearbox [7]

3.2 Why We Need a Gearbox?

The purpose of a gearbox is mainly to increasing the torque while reducing the speed of the

prime mover output. Other than that they can be used to get the reverse movement as a prime

mover like IC engine only operate in one direction, to maximize the fuel efficiency by keeping the

prime mover in desired RPMs and to disconnect drive shaft and output shaft (Neutral) when

needed.

3.3 Advantages of a Gearbox

Due to no slip exact velocity ratio can be obtained

Able to transmit larger powers than belt drives and chain drives

Gears are more efficient in transmitting power

They are much compact compared to belt and chain drives

Power can be transmitted in very low velocities which cannot be done with belt drives

3.4 Limitations of a Gearbox

Special tools and machines are required to manufacture gears

Manufacturing and maintenance cost are comparatively high

Cutting of gear teeth should be precise otherwise vibrations will induce

3.5 Gearbox Applications

Industrial applications

Cranes

Conveyers

Machine tools (Lathe, Drilling, Milling)

Crushers

Power generation (Wind Turbines)

Figure 8: Gearbox used in a Conveyor [6]

Automobiles

Manual Transmissions

Automatic Transmissions

Home appliances

Dishwashers

Washing machines

Lawn mowers

3.6 Gearbox Components and Features

Input Shaft - Takes power from the engine to the gearbox. It uses a clutch to engage and

disengage the input shaft to gearbox.

Lay Shaft - Connects with the clutch shaft directly. Engine power is transferred to output

shaft by continuous meshing.

Output Shaft - It is the shaft that runs at the wheel speed. It carries power from the counter

shaft by use of gears and it runs at different speeds and torque compared to the counter

shaft.

Gears – Circles with teeth that rotate and meshes with another gear on different shaft. They

are used to transmit power from one shaft to another. The amount of torque transmitted

through gears depends on the number of teeth and size of the gear.

Figure 9: Shafts in a Gearbox [5]

Synchromesh Devices – Used to synchronize the speeds between collar and the gear.

Sometimes the speeds could end up being different, so you need the synchronizers to

prevent that from happening.

Collar – Locks the selected gear in place and allows power to transmit.

Bearings – Used to reduce the friction in rotating parts.

Gear Lever – Used to shift gears and it is controlled by our hand.

Figure 10: Synchronisers [9]

Figure 11: Bearings [10]

3.7 Types of Gearboxes

Industrial

Helical Gearbox

Coaxial Helical Inline Gearbox

Bevel Helical Gearbox

Skew Bevel Helical Gearbox

Worm Reduction Gearbox

Planetary (Epicyclic) Gearbox

Figure 12: Helical Gearbox [8]

Manual Transmission

Sliding Mesh Gearbox

Constant Mesh Gearbox

Synchromesh Gearbox

Automatic Transmission

Torque Converter

Automated Manual Transmission (AMT)

Continuously Variable Transmission (CVT)

Dual Clutch Transmission (DCT)

Figure 14: Torque Converter [11]

Figure 13: CVT Transmission [12]

3.8 Materials Used in Gearboxes

Table 2: Materials Used in Gearboxes

Part

Materials used

Casings

Cast Iron, Cast Aluminium, Composites

Shafts

Steel, Cast Iron, Stainless Steel, Hardened Steel

Bearings

High Carbon Chromium Steel, High Carbon Stainless Steel

Gears

Case Hardening Steel, Cast Iron, Plastic, Wood, Aluminium,

Brass, Magnetic Alloys

Collars

Aluminium, Steel, Stainless Steel, or Alloyed Steel and Coated

with Zinc, Chromium

Synchromesh Devices

Steel, Brass

Gear Lever

Medium Carbon, Steel, Polymer

Figure 15: Gearbox Components [8]

3.9 Lubrication of Gearboxes

3.10 Purpose of Lubrication in a Gearbox

Reduce the friction in moving parts

Cools the surfaces by carrying heat away

Absorb shocks between bearings and other parts

Reduce the noise of the moving parts

Cleaning the surface by carrying away small debris

Grease Lubrication [13]

Suitable for low speed applications.

No cooling effect

Should not be used for continuous operation or high load gear drives

Splash lubrication [13]

Typically used for Spur, Helical, and Bevel gears

Gears are dip into an oil bath

Oil will be splashed once rotation starts

Spray Lubrications [13]

Suitable for high speed applications

Spray using a nozzle with a circulation pressure

3.11 Alternatives for Gearboxes

Electric Drives

Hydraulic Drives

Belt Drives

Chain Drives

Magnetic Gears [14]

Diesel-Electric Transmission (Used in Locomotives)

Figure 9: Hydraulic drives [15]

Figure 17: Hydraulic drives [15]

Figure 16: Magnetic gears [14]

3.12 Gearbox Type & Layout

3.13 Sliding Mesh Gearbox

Sliding mesh gearbox is selected because it is simple to design and cheap to manufacture.

Main issue with the sliding mesh gearbox is the fact that speeds of the input and output shafts

should matched when changing gears. Otherwise gearwheels do not align and crash into one

another. This will not be a problem as our application does not require to change gears will in the

move. Shifting of the gears is done by meshing of the gears on the main shaft with the gears on

the lay shaft by moving right or left direction on main shaft. Here first gear provides the maximum

torque with low speed and final gear provides lowest torque with a higher speed.

Figure 18: Sliding Mesh Gearbox

3.14 Gear Types

3.15 Spur Gears

Spur gears are the simplest and widely used type of gears. They are cylindrical gears with radial

straight teeth and shafts are parallel and coplanar. Often pressure angle of a spur gear is considered

to be 200. They have an involute profile and mesh one tooth at a time. Involute profile means spur

gears only produce radial forces (no axial forces). Spur gears are good for low and moderate speed

applications and at high speed operation will be noisy.

Pros

Ease of assembly

Ease of maintenance

Straight teeth are easy to align

Minimal power loss

Axial loads are non-existent (Therefore no need of locking mechanisms in axial direction)

Cons

Not strong as other gears (Helical gears have a better stress distribution)

Power only can be transmitted in parallel direction (Cannot transmit power in

perpendicular directions like worm gears)

Meshing is difficult while in operation

Noisy in high speed operation

For our application power is only transmitted in parallel directions and meshing is not done while

conveyor is under operation. Therefore, spur gears will be the best selection.

Figure 19:Spur Gears [9]

3.16 Environmental and Operational Conditions

Gearbox should be dust and waterproof in order to maximize the lifetime. Also anti

corrosive treatments will be needed if the humidity in air is very high. Optimum working

temperature range is preferred as overheating will lead to premature gearbox failure. Proper

lubrication is required to minimize the friction in gear wheels and to absorb the heat generated.

Splash lubrication is frequently used in small to medium gearboxes. Operation of the gearbox

should be user-friendly as well should not be harmful to the user. There will be no large shocks or

vibrations involved with the operation but loading and unloading can impact the drive. System will

run for around 8 hours per day with intervals in between. Gearbox can be mounted right angled to

the shaft in order to save space and it can be operated by a person with only basic knowledge on

operating a conveyor.

Figure 20: Gearbox Lubrication [19]

Further gearbox should be water and dust proof for a longer operation life. Specially in

food industry conveyors may expose to the water in operation or by accidents. Therefore, IP44

water and dust resistance rating is suggested. IP44 means the gearbox is protected against objects

bigger than 1mm and water splashing from all directions. IP44 is enough for our applications as

going with higher IP rating will drastically increase the manufacturing effort and cost.

Figure 21: IP44 Water Resistance [14]

Working temperature is another crucial factor for smooth operation of a gearbox as at high

temperatures viscosity of lubricants becomes lower and at low temperatures viscosity becomes

higher which will change the flow characteristics of the lubricants as well as lubrication may not

be as effective as operating under the ideal conditions.

3.17 References

[1] - Stokes, Alec. (1992). Manual gearbox design. Butterworth-Heinemann.

[2] – Operations, M. (2007). CONVEYOR DESIGN REVIEW Prepared for ABC MINING

CONVEYOR NUMBER CV202.

[3] - Bebic, M. Z., & Ristic, L. B. (2018). Speed controlled belt conveyors: Drives and

mechanical considerations. Advances in Electrical and Computer Engineering, 18(1), 51–60.

https://doi.org/10.4316/AECE.2018.01007

[4] - Krushna Sawant. (2021). What is Gearbox: Types of Gearbox, Parts & Working.

https://www.automobileinformer.com/gearbox/, (accessed Oct. 20, 2021)

[5] - ANAA LAVAA. (2021). Gearbox Components and Parts: Everything You Need to Know.

Linquip. https://www.linquip.com/blog/gearbox-components-and-parts/, (accessed Oct. 25,

2021)

[6] - Supplier Homepage. (2021). Mining Industry Quarry Use Belt Conveyor Gearbox Drive.

https://cntruemax.en.made-in-china.com/product/HZrmBdDPbnWL/China-Mining-IndustryQuarry-Use-Belt-Conveyor-Gearbox-Drive.html. (accessed Oct. 25, 2021)

[7] - Variable Frequency Drives (VFD) Variable Frequency Drive. (n.d.).

[8] - Gear box. (2021). SlideShare. https://www.slideshare.net/deep388/gear-box-79440028,

(accessed Oct. 20, 2021)

[9] - Gear 1/2 Synchroniser Original Jumper Boxer Ducato 2323E5 9467633588. (2021).

Eurofrance24.Com. https://eurofrance24.com/gear-1-2-synchroniser-original-jumper-boxerducato-2323e5-9467633588.html, (accessed Oct. 25, 2021)

[10] - Gearbox Bearing. (2021). Indiamart.Com. https://www.indiamart.com/proddetail/gearboxbearing-20160074597.html, (accessed Oct. 24, 2021)

[11] - AAMCO. (2019). AAMCO Blog | What is a Torque Converter. AAMCO Transmissions

Total Car Care Blog. https://www.aamcoblog.com/Article/What-is-a-Torque-Converter-andHow-Does-it-Function, (accessed Oct. 22, 2021)

[12] - Jessica Shea Choksey. (2021). What is a CVT, or Continuously Variable Transmission?

J.D.Power. https://www.jdpower.com/cars/shopping-guides/what-is-a-cvt-or-continuouslyvariable-transmission, (accessed Oct. 22, 2021)

[13] - 3 Common Methods of Gearbox Lubrication. (2017). Amarillogearservice.

https://www.amarillogearservice.com/3-common-methods-gearbox-lubrication/, (accessed Oct.

22, 2021)

[14] - Paul Boughton. (2013). Magnets offer alternative to mechanical gears. ENGINEERLIVE.

https://www.engineerlive.com/content/magnets-offer-alternative-mechanical-gears, (accessed

Oct. 22, 2021)

[15] - KEN KORANE. (2020). New hydraulic drives for excavators. Mobilehydraulictips.

https://www.mobilehydraulictips.com/ifpe-download-new-hydraulic-drives-for-excavators/,

(accessed Oct. 20, 2021)

[16] -Markus Ihmsen. (n.d.). How to Cut Gearbox Lubrication Development from Days to

Hours. AVL. Retrieved October 30, 2021, from https://www.avl.com/-/how-to-cut-gearboxlubrication-development-from-days-to-hours , (accessed Oct. 20, 2021)

4

Design Calculations and Materials Selection

4.1 Components of the Conveyor Design

Figure 22 : Components in the Gearbox Design

Prime Mover

(3 Phase Induction

Motor)

Coupler

(Sleeve Coupler)

Input Shaft

(Keys and Gears)

Lay Shaft

(Keys and Gears)

Output Shaft

(Splines and

Gears)

Belt Drive

(Keys Pulleys and

V-Belt)

Conveyor Belt

(Drive Roller)

Figure 23 : Power Flow

Table 3:Conveyor Specifications

Length

10 m

Width

0.3 m

Thickness

0.01 m

Material Used for Belt

Rubber Composite

Density

1200 kg/m3

Linear Speed

0.35 m/s

Product Conveyor Carry

Canned Fish

Weight of a Empty Can

75 g

Weight of Different Sizes

425 g, 225 g, 125g

Production Rate

5000 per day

Maximum Loading Capacity

150 kg

Coefficient of Friction

0.64

Forward Gears

3

Reverse Gears

1

Power Calculation

30cm

(3 cans)

9cm

1000cm

(100 cans)

Figure 24: Dimensions of Conveyor Belt and Cans

There are 3 x 100 = 300 of maximum cans on the conveyor belt at any given time.

• Weight of

Belt

• Weight of

Product

the

the

Belt Pull

• Total Weight

• Friction

Coefficient

• Belt Pull

• Constant Speed

• Power Losses

Power

Required

Total Weight

Figure 25- Power Calculations

Weight of the conveyor belt

= Length x Width x Thickness x Density

= 10m x 0.3m x 0.01m x 1200kg/m3

= 36kg

Considering the first gear with 425g fish cans,

= Weight of a Can × No. of Cans

Weight of products

= 425g x 100 x 3

= 127.5kg

= Weight of the conveyor belt + Weight of the products

Total Weight

= 36kg + 127.5kg

= 163.5kg

Assumed that conveyor operate in a flat surface and there is no incline angle. Therefore, effect

of the gravity can be neglected.

Required belt pull

= Friction Coefficient x Total Weight x Gravitational Acceleration

= 0.64 x 163.5kg x 9.81ms-2

= 1026.5184N

Required Power

= Force x Linear Speed

= 1026.5184N x 0.2ms-1

= 205.30368Nms-1

1 Watt = 1 Nms-1

Therefore, Required Power

= 205.30368W

= 0.205kW

Figure 26: 425g Jack Mackerel [22]

Considering the second gear with 225g fish cans

= Weight of a Can × No. of Cans

Weight of products

= 225g x 100 x 3

= 67.5kg

= Weight of the conveyor belt + Weight of the products

Total Weight

= 36kg + 67.5kg

= 103.5kg

Required belt pull

= Friction Coefficient x Total Weight x Gravitational Acceleration

= 0.64 x 103.5kg x 9.81ms-2

= 649.8144N

Required Power

= Force x Linear Speed

= 649.8144N x 0.35ms-1

= 227.435Nms-1

Therefore, Required Power

= 227.435W

= 0.227kW

Figure 27:225g Canned Fish [22]

Considering the third gear with 125g fish cans

= Weight of a Can × No. of Cans

Weight of products

= 125g x 100 x 3

= 37.5kg

= Weight of the conveyor belt + Weight of the products

Total Weight

= 36kg + 37.5kg

= 73.5kg

Required belt pull

= Friction Coefficient x Total Weight x Gravitational Acceleration

= 0.64 x 73.5kg x 9.81ms-2

= 461.4624N

Required Power

= Force x Linear Speed

= 461.4624N x 0.5ms-1

= 230.7312Nms-1

Therefore, Required Power

= 230.7312W

= 0.23kW

Figure 28: 125g Canned Fish [22]

Table 4: Power Calculation

Load (kg)

Gear

Linear Speed

Torque Required

Power Required

(ms-1)

(Nm)

(kW)

163.5

1

0.2

102.65

0.205

103.5

2

0.35

64.98

0.227

73.5

3

0.5

46.15

0.23

Power losses occur due to gears, bearings, seals and auxiliaries. By using 1.4 power loss factor

for the drive train,

Required power from prime mover

= 1.4 x 0.23kW

= 0.322kW

= 0.432 HP

Y2 Series 3 Phase Induction Motor

ATO Y2 series 3 phase induction motor was selected as the prime mover

Table 5: Prime Mover Selected [23]

ATO Y2 series 3 phase induction motor

kW

0.37

HP

0.5

RPM

900

Input Current

1.23 Amp

Efficiency

62%

Power Factor

0.70

Rated Torque

3.93N/m

Max Torque/Rated Torque

2.0

Noise

54 dB

Weight

15.5 kg

4.2 Gear Calculations

Table 6 : Gear Ratios

Gear Ratios

Input and Lay shaft

3.75

1st Gear

3.14

2nd Gear

1.79

3rd Gear

1.25

Reverse Gear

3.14

Belt Drive

2

4.2.1 Assumptions

200 full depth involute system is assumed

Face width of the gear teeth is equal to 9 x module

Gears are assumed to be carefully cut

Power loss is neglected in the spur gears

4.2.2 Standard Proportions of a Gear System

Figure 29 : Detailed Geometry of a Gear Teeth [1]

d = P.C.D. of a gear

T = number of teeth

Circumference of the pitch circle = π d = p T

m = (p / π) = module of the gear

P.C.D. of the gear = d = (p T / π) = (p / π) T = m T

According to AGMA (American Gear Manufacturers Association) following is the standard values

for the module of a gear teeth and two meshing gears should be equal for a proper mesh between

them.

Set I: 1.0, 1.25, 1.5, 2.0, 2.5, 3.0, 4.0, 5.0, 6.0, 8.0, 10.0, 32.0, 40.0 [1]

Table 7 : Standard Proportions [1]

20o full depth Involute

Particulars

Value for this case (mm)

system

Addendum

1m

2

Dedendum

1.25m

2.5

Working depth

2m

4

Minimum total depth

2.25m

4.5

Tooth thickness

1.5708m

3.1416

Minimum clearance

0.25m

0.5

Fillet radius at root

0.4m

0.8

4.2.3 Calculation of Gear teeth for input and lay shaft gears (Gears 1 and 2)

4.2.3.1 Data

Power = 370 W

RPM = 900 rpm

Gear Reduction = 3.75

4.2.3.2 Formulas [1]

𝑟𝑝𝑚 𝑜𝑓 𝑡ℎ𝑒 𝑝𝑖𝑛𝑖𝑜𝑛

𝑁𝑜.𝑜𝑓 𝑡𝑒𝑒𝑡ℎ 𝑖𝑛 𝑤ℎ𝑒𝑒𝑙

G = Gear Ratio = 𝑟𝑝𝑚 𝑜𝑓 𝑡ℎ𝑒 𝑔𝑒𝑎𝑟 𝑤ℎ𝑒𝑒𝑙 = 𝑁𝑜.𝑜𝑓 𝑡𝑒𝑒𝑡ℎ 𝑖𝑛 𝑝𝑖𝑛𝑖𝑜𝑛

Tp ≥ 2 / {[G2 + Sin2(ψ) (1+2G)] ½ - G}

P.C.D. of the gear = d = m T

0.154 – 0.912 / T, for 200 full depth system

Strength of the teeth = ( σo y) b m π Cv

The pitch line velocity (v) = ω d / 2

Velocity factor (Cv) = 3 / (3+v)

4.2.3.3 Determining the no. of Teeth in Pinion

T1 ≥ 2 / {[G2 + Sin2(ψ) (1+2G)] ½ - G} = 15.45 = 16

Calculated minimum no. of teeth for interference is 16. Taking the no. of teeth close to

the minimum requirement will be beneficial in manufacturing process. But taking 16 as

the input pinion no. of teeth clearance for the reverse pinion and gear will be not

sufficient. Therefore no. of teeth of the input pinion is selected to be 20. Center distance

should be calculated using input and lay shaft gears and center distance calculated can be

carried out to the rest of the gears as well.

4.2.3.4 Determining the Center Distance

Module is assumed to be 3mm in the first iteration and after some iterations comparing

dynamic loads and wear loads module is selected to be 2mm.

Table 8 : Input and Lay Shaft Gear Calculation

Pinion

Gear

No. of Teeth

20

75

P.C.D (mm)

40

150

Addendum (mm)

2

2

Dedendum (mm)

2.5

2.5

Face Width (mm)

15

15

Therefore center distance between shafts =

𝐃𝟏 + 𝐃𝟐

𝟐

= 95 mm

Using gear ratio and center distance, P.C.D. of other gears can be calculated

For pinion and gear wheel of 1st gear,

Let x be the P.C.D. of the pinion,

Then P.C.D. of the gear = G x x = 3.14x

Since center distance should be the same

x + 3.14x = 190

x = 45.87mm

Therefore, P.C.D. of the pinion = 45.87mm and P.C.D. of the gear = 144.13mm

Teeth in pinion = d / m = 45.87 / 2 = 22.938

Teeth in gear = D / m = 144.13 / 2 = 72.06

By rounding off the teeth values exact number of teeth can be calculated and by using module

rounded off pitch circle diameter of the gears can be calculated. These final diameters should align

with the center distance calculated previously.

Likewise calculating for other gears,

Table 9 : Gear Dimensions

Gear

D_Pinion

D_Gear

Teeth_Pinion

Teeth_Gear

Input and Lay shaft

40

150

20

75

1st

46

144

23

72

2nd

68

122

34

61

3rd

84

106

42

53

Reverse

38

122

19

61

4.2.3.5 Determining the teeth strength using Lewis equation

Table 10 : Commonly used Gear Materials [1]

First Grade 20 cast iron was selected and loads were compared and the material strength was not

sufficient. Therefore, next material was selected in repeated iterations and finally settled with the

Grade 35 Grey Cast Iron.

Service factor is considered to be in class II with operation time of up to 8-10 hours per day with

light shocks.

Table 11 : Service Factor for Spur Gears [1]

Cs = 1.25

Transmitted Power = Pt = 370 W

Design Power = Pd = Cs x Pt = 1.25 x 370 = 462.5 W

Design Power = Pd = Wt x (d1/2) x ω1

Therefore, tangential tooth load = Wt = 245.36 N

Table 12 : Allowable Static Stress [2]

Allowable static stress of pinion (Cast Iron) = ( σo )p = 105 MPa

Lewis Form Factor of the pinion (yp)

= 0.154 – 0.912 / T1

= 0.1084

The pitch line velocity (v)

= ω1 d1 / 2

= 94.25 x 0.02

= 1.885 m/s

Therefore, velocity factor (Cv)

= 3 / (3+v)

= 3 / 4.885

= 0.614

Using Lewis Equation,

Strength of the pinion teeth

= ( σo y)p b m π Cv

= 11.382 x 106 x 7.5 x (3 x 10-3)2 x π x 0.614

= 988.2 N

4.2.3.6 Determining the Dynamic Load

WD = WT + W I = W T +

21𝑣(𝑏𝐶+𝑊𝑇 )

21𝑣+ √𝑏𝐶+𝑊𝑇

WD = Total dynamic load

WT = Steady load due to transmitted torque

WI = Increment load due to dynamic action

v = Pitch line velocity

b = Face width of gears

C = A deformation or dynamic factor

Deformation factor can be determined using the following table,

Table 13 : Deformation factor [1]

For cast iron pinion and gear with 200 full depth involute teeth with module 2mm deformation

factor would be 114.

21 𝑥 1.885 𝑥 (7.5 𝑥 2 𝑥 114 + 245.36)

WI = 21 𝑥 1.885 +

√7.5 𝑥 2 𝑥 114 + 245.36

= 176.3 N

WD = WT + WI = 245.36 + 180 = 421.7 N

Load on gear teeth = Wt = 421.7 N < {σo y b m π Cv }p = 988.2 N = Strength of the gear teeth

Therefore, the teeth of this spur gear with a module of 2 mm will have sufficient strength to

transmit the specified power required in this conveyor belt system.

4.2.3.7 Determining Limiting Load for Wear

WW = DP x b x Q x K

Ww = Maximum or limiting load for wear

DP = Pitch circle diameter of the pinion

b = Face width of the pinion

Q = Ratio factor = 𝑇 +𝐺𝑇

V.R. = Velocity ratio = TG / TP

K = Load-stress factor where,

2𝑇

𝐺

K=

(σ𝑒𝑠)2 sin φ

1.4

𝑃

1

1

𝑃

𝐺

(𝐸 + 𝐸 )

σes = Surface endurance limit

φ = Pressure angle

EP = Young's modulus for the material of the pinion

EG = Young's modulus for the material of the gear

K=

(630 x 10^6)2 sin 20

1.4

1

1

(110 𝑥 10^9 + 110 𝑥 10^9) = 1.76

2 𝑥 75

WW = 40 x 7.5 x 2 x 75 + 20 x 1.76 = 1669.87 N

Load on gear teeth = Wt = 425.36 N < WW = 1669.87 N = Limiting load for wear. Therefore, the

teeth of this spur gear with a module of 2 mm will have sufficient limiting load for wear to transmit

the specified power required in this conveyor belt system.

Figure 30 : Gearbox Layout

Figure 31 : Idler Gear Configuration

Final results for each gear is shown below,

Table 14 : Loads acting on the Gears

Gear

Total dynamic

Strength of

Limiting load for

load (N) [Wd]

the gear (N)

wear (N) [Ww]

Gear 1

421.694

988.192

1669.868

Gear 2

421.694

1293.037

30057.640

Gear 3

663.524

1162.046

35684.430

Gear 4

776.849

1273.392

2770.646

Gear 5

1040.168

1328.283

30971.392

Gear 6

1204.360

1357.403

18084.680

Gear 7

661.441

1200.325

35684.430

Gear 8

777.195

1392.456

36018.404

Gear 9

1042.977

1642.694

30971.392

Gear 10

1184.230

1775.271

27579.137

Gear 11

1204.360

1357.403

27579.137

4.2.4 Conclusion

Table 15 : Conclusion of Gear Calculations

Gear

Gear 1

Gear 2

Gear 3

Gear 4

Gear 5

Gear 6

Gear 7

Gear 8

Gear 9

Gear 10

Gear 11

Number of

Teeth (T)

20

75

42

34

23

19

53

61

72

61

19

P.C.D. (mm)

[d]

40

150

84

68

46

38

106

122

144

122

38

Module

(mm) [m]

2

2

2

2

2

2

2

2

2

2

2

Face Width

(mm) [b]

15

15

12

13

14

15

12

13

14

15

15

Material

ASTM Class 35 gray iron

ASTM Class 35 gray iron

ASTM Class 35 gray iron

ASTM Class 35 gray iron

ASTM Class 35 gray iron

ASTM Class 35 gray iron

ASTM Class 35 gray iron

ASTM Class 35 gray iron

ASTM Class 35 gray iron

ASTM Class 35 gray iron

ASTM Class 35 gray iron

4.3 Belt Drive Calculations

Belt drive connects to the output shaft of the gearbox. Need to find the tensions of the belt in order

to do the shaft calculations.

4.3.1 Data

RPM of the output shaft

Power transmitted = 370W

V-belt is selected because it can transmit more power without slip due to increased

friction

4.3.2 Assumptions

Slip between belt and pulley is neglected

4.3.3 Formulas [1]

2.3 log (T1 / T2) = μ θ cosec β

sin α = (d2 – d1) / 2x

θ = 1800 - 2α

B = 1.25b where B = Face width of the pulley and b = face width of the V-belt

4.3.4 Calculating Dimensions

Table 16 : Type of Belt [1]

Figure 32 : V-Belt Dimensions [1]

Since power requirement for this case is limited to 370W Type A belt will be sufficient. Friction

coefficient can be taken from standard tables once pulley and belt materials are known.

Table 17 : Coefficient of Friction for Different Materials [1]

Table 18 : Belt Drive Materials

Belt

Pulley

Friction Coefficient

Materials

Rubber

Cast Iron

0.3

Table 19 : V-belt face width [21]

According to the table,

b = ½ inches = 12.7 mm

Taking b as 13 mm,

B = 1.25 b

B = 1.25 × 12.7

B = 15.875 mm

By the standard width values for pulleys, 16 mm face width can be obtained.

Table 20 : Belt Dimensions [1]

Gear

Type of Belt

First Gear

Second Gear

Third Gear

Reverse Gear

A

A

A

A

Minimum

pitch diameter

of the pulley

(D) [mm]

75

75

75

75

Top Width

(mm) [b]

Thickness (t)

[mm]

Groove angle

(2β)

13

13

13

13

8

8

8

8

32

32

32

32

4.3.5 Calculate Tensions for First Gear

Figure 33 : Belt Drive System

After some iterations diameter of the smaller and larger pulley and centre distance was selected in

order to minimize the tension of the belt.

Diameter of the smaller pulley (mm) [d1] = 80 mm

Diameter of the larger pulley (mm) [d2] = 2 x 80 = 160 mm

Centre Distance (mm) [x] = 1.2 x D = 192 mm

sin α = (d2 – d1) / 2x = (160 – 80) / (2 x 192) = 0.208

α = 12.0240

θ = 1800 - 2α = 1800 – 2 x 12.0240 = 155.950 = 2.72 radians

2.3 log (T1 / T2) = μ θ cosec β

2.3 log (T1 / T2) = 0.3 x 2.72 x cosec (160)

log (T1 / T2) = 1.287

T1 / T2 = 19.36

Belt Velocity = 0.04 x 4 = 0.16 m/s

T1 - T2 = Power / Belt Velocity = 481 / 0.16 = 3006.25 N

T2 = 163.74 N

T1 = 3169.99 N

Similarly tensions for other gear positions can be calculated as well,

Table 21 : Tension of Belt Drive for Different Gear Positions

Gear

First Gear

Second Gear

Third Gear

Reverse Gear

T1 (N)

3169.55

1811.17

1267.82

3169.55

T2 (N)

163.3

93.31

65.32

163.3

4.3.6 Conclusions

Diameter of the smaller

pulley (mm)

Diameter of the larger

pulley (mm)

Centre Distance (mm)

Pulley Face

Width (mm)

80

160

192

16

Figure 34 : Belt Drive Dimensions

4.3.7 Shaft Calculations

4.4 Determining Input Shaft Diameter

4.4.1 Data

RPM of input shaft = 900

Power transmitted = 370W

4.4.2 Assumptions

Neglect the weight of the shafts

Neglect the weight of the gears

Plain shafts are assumed for calculations

4.4.3 Formulas

16

τmax = π∗d3 √(K m M)2 + (K t T)2

Input torque = 𝜔

Tangential load (Wt) = 𝑅𝑎𝑑𝑖𝑢𝑠 𝑜𝑓 𝑔𝑒𝑎𝑟

Radial load (Wr) = Wt × tan(200)

𝑃

𝐼𝑛𝑝𝑢𝑡 𝑡𝑜𝑟𝑞𝑢𝑒

3

D =

16

√1.52 × 8.6162 + 12 × 5.882

𝜋

420×106

1.8

4.4.4 Calculations

Table 22 : Commonly used Shaft Material [1]

Shaft material was selected to be 50 C 12 Steel (AISI 1065) due to its balance between cost

effectiveness and shear strength.

Table 23 : 50C12 Steel Properties [3]

50 C 12 Steel (AISI 1065)

Density

Ultimate tensile strength

Modulus of Rigidity

Allowable Shear Stress

7.85

700

80

224.389

g/cm3

MPa

GPa

MPa

For steel shear strength = 0.577 x UTS = 0.577 x 700 = 224.389 MPa [4]

Km = Combined shock and fatigue factor for bending

Kt = Combined shock and fatigue factor for torsion

Table 24 : Recommended values for Km and Kt. [1]

Since AC induction motors gradually increase the torque,

𝐾𝑚 = 1.5 , 𝐾𝑡 = 1

Safety factor for shear stress = 1.5

Since steel is a ductile material maximum shear stress theory (Guest's theory) can be used to

account for the elastic failure.

According to maximum shear stress criteria,

16

τmax = π∗d3 √(K m M)2 + (K t T)2

𝑃

370

Input torque = 𝜔 = 94.25 = 5.88 Nm

𝐼𝑛𝑝𝑢𝑡 𝑡𝑜𝑟𝑞𝑢𝑒

5.88

Tangential load (Wt) = 𝑅𝑎𝑑𝑖𝑢𝑠 𝑜𝑓 𝑔𝑒𝑎𝑟 = 0.02 = 294.44 N

Radial load (Wr) = Wt × tan(200) = 294.44 × tan(200) = 107.14 N

Figure 35 : Input Shaft

4.4.5 Bending moment Diagrams

Figure 36 : Tangential Bending Moment for Input Shaft [5]

Figure 37 : Radial Bending Moment for Input Shaft [5]

Mt = 8.097 Nm

Mr = 2.946 Nm

Therefore maximum bending moment = √Mt 2 + Mr 2 = 8.616 Nm

Equivalent twisting moment = Te = √(𝐾𝑚 x M)2 + (𝐾𝑡 x T)2

By maximum shear stress criteria,

3

D =

16

√1.52 × 8.6162 + 12 × 5.882

𝜋

420×106

1.8

D = 6.76 mm

Table 25 : Input Shaft Diameter Calculations

Gear 1

Torqu

e

(Nm)

5.888

Tangenti

al force

(N)

294.436

Radial

load (N)

107.144

Tangenti

Radial

al BM BM (Nm)

(Nm)

8.097

2.946

BM

(Nm)

Equivalent

TM (Nm)

8.616

14.202

Shaft

Diameter

(mm)

6.767

4.4.6 Conclusions

Table 26 : Input Shafts Conclusions

Input shaft diameter

10 mm (Standard diameter for calculated value)

Input shaft material

50C12 Steel (AISI 1065)

4.5 Determining Lay Shaft Diameter

4.5.1 Data

RPM of lay shaft = 240

Power transmitted = 370W

4.5.2 Calculations

When taking the forces in the lay shaft need to consider 1st, 2nd, 3rd and reverse gears separately as

forces vary with the gear position.

Figure 38 : Lay Shaft

Table 27 : Lay Shaft Forces

Gear 2

Gear 3

Gear 4

Gear 5

Gear 6

Transmitted Torque

(Nm) [Tt]

22.082

22.082

22.082

22.082

22.082

Tangential force on

gear (N) [Ft]

294.436

525.779

649.492

960.119

1162.249

Radial load on the

tooth (N) [Fr]

107.144

191.328

236.347

349.383

422.937

4.5.3 Bending Moment Diagrams

Figure 39 : Tangential Bending Moment for Lay Shaft in First Gear [5]

Figure 40 : Radial Bending Moment for Lay Shaft in First Gear [5]

Figure 41 : Tangential Bending Moment for Lay Shaft in Second Gear [5]

Figure 42 : Radial Bending Moment for Lay Shaft in Second Gear [5]

Figure 43 : Tangential Bending Moment for Lay Shaft in Third Gear [5]

Figure 44 : Radial Bending Moment for Lay Shaft in Third Gear [5]

Figure 45 : Tangential Bending Moment for Lay Shaft in Reverse Gear [5]

Figure 46 : Radial Bending Moment for Lay Shaft in Reverse Gear [5]

Calculated maximum bending moments using the bending moment diagrams were as follows,

Table 28 : Bending Moments in Lay Shaft [5]

Gear

Position

Maximum bending

moment in

tangential direction

(Mt) [Nm]

59.256

42.709

28.707

29.204

First gear

Second gear

Third Gear

Reverse

Maximum bending

moment in radial

direction (Mr) [Nm]

Maximum

bending moment

(M) [Nm]

21.562

15.541

10.446

10.627

63.057

45.449

30.549

31.077

By maximum shear stress criteria,

16

D3 = 𝜋

√(𝐾𝑚 x M)2 +(𝐾𝑡 x T)2

τ

Table 29 : Shaft Diameter of Lay Shaft

Gear Position

First gear

Second gear

Third Gear

Reverse

Equivalent twisting

moment (Te) (Nm)

97.129

71.661

50.867

51.582

Shaft Diameter

(mm)

13.015

11.760

10.491

10.539

4.5.4 Conclusions

Table 30 : Lay Shaft Conclusions

Lay shaft diameter

15 mm (Standard diameter for calculated value)

Lay shaft material

50C12 Steel (AISI 1065)

4.6 Determining Output Shaft Diameter

4.6.1 Data

RPM of lay shaft = 38.2, 66.8, 95.5, 38.2

Power transmitted = 370W

4.6.2 Calculations

Same as the lay shaft need to consider 1st, 2nd, 3rd and reverse gears separately as forces and torque

transmitted vary with the gear position.

Figure 47 : Output Shaft

Using the formulas found the torque and forces for each gear as follows,

Table 31 : Output Shaft Forces

Gear 7

Gear 8

Gear 9

Gear 10

Transmitted Torque

(Nm) [Tt}

55.5

79.285

138.75

138.75

Tangential force on

gear (N) [Ft]

1047.169

1299.766

1927.083

2274.590

Radial load on the

tooth (N) [Fr]

381.060

472.979

701.257

827.713

4.6.3 Bending Moment Diagrams

Figure 48 : Tangential Bending Moment for Output Shaft in First Gear [6]

Figure 49 : Radial Bending Moment for Output Shaft in First Gear [6]

Figure 50 : Tangential Bending Moment for Output Shaft in Second Gear [6]

Figure 51 : Radial Bending Moment for Output Shaft in Second Gear [6]

Figure 52 : Tangential Bending Moment for Output Shaft in Third Gear [6]

Figure 53 : Radial Bending Moment for Output Shaft in Third Gear [6]

Figure 54 : Tangential Bending Moment for Output Shaft in Reverse Gear [6]

Figure 55 : Tangential Bending Moment for Output Shaft in Reverse Gear [6]

Calculated maximum bending moments using the bending moment diagrams were as follows,

Table 32 : Bending Moment in Output Shaft

Gear Position

Maximum bending

moment in

tangential direction

(Mt) [Nm]

194.635

155.322

190.585

62.551

First gear

Second gear

Third Gear

Reverse

Maximum bending

moment in radial

direction (Mr) [Nm]

Maximum bending

moment (M) [Nm]

70.827

56.521

69.353

22.762

207.122

165.286

202.811

66.564

By maximum shear stress criteria,

16

D3 = 𝜋

√(𝐾𝑚 x M)2 +(𝐾𝑡 x T)2

τ

Table 33 : Output Shaft Diameter

Gear Position

First gear

Second gear

Third Gear

Reverse

Equivalent twisting

moment (Te) (Nm)

404.269

338.847

309.283

295.034

Shaft Diameter

(mm)

20.935

19.739

19.147

18.848

4.6.4 Conclusions

Table 34 : Output Shaft Conclusion

Output shaft diameter

25 mm (Standard diameter for calculated value)

Output shaft material

50C12 Steel (AISI 1065)

4.7 Determining Idler Shaft Diameter

4.7.1 Data

RPM of lay shaft = 38.2

Power transmitted = 370W

Table 35 : Idler Shaft Diameter Calculations

Gear 1

Torque

(Nm)

Tangential Radial Tangential

force (N) load (N) BM (Nm)

Radial

BM

(Nm)

BM

(Nm)

22.083

1162.250

11.630

34.012

422.937

31.962

Equivalent

Shaft

TM (Nm) Diameter

(mm)

55.592

10.806

4.7.2 Conclusion

Table 36 : Idler Shaft Conclusion

Idler shaft diameter

15 mm (Standard diameter for calculated value)

Idler shaft material

50C12 Steel (AISI 1065)

4.8 Summary of the Shaft Calculations

Table 37 : Shaft Calculations Summary

Input Shaft

Lay Shaft

Output Shaft

Idler Shaft

Maximum Bending

Moment (Nm)

8.616449153

63.05748413

253.1417982

34.01229929

Material

50C12 Steel (AISI 1065)

50C12 Steel (AISI 1065)

50C12 Steel (AISI 1065)

50C12 Steel (AISI 1065)

Shaft Diameter

(mm)

10

15

25

15

4.9 Design of Keys

Keys need to be design for both crushing and shearing and also need to consider the effect of the

keyways when doing shaft calculations.

4.9.1 Data

Proportions of standard parallel, tapered and Gib head keys

4.9.2 Assumptions

Sunk keys are used

4.9.3 Formulas

𝒅

𝑻 = 𝒍 × 𝒘 × 𝝉𝒎𝒂𝒙 × 𝟐

𝑻 = 𝒍 × 𝟐 × 𝝈𝒄 × 𝟐

𝒆 = 𝟏 − 𝟎. 𝟐(𝒘/𝒅) − 𝟏. 𝟏(𝒉/𝒅)

𝒕

𝒅

Key length for shear stress

Key length for crushing stress

Effect of the keyway

4.9.4 Design the key on input shaft

Figure 56 : Sunk Key [7]

Since shaft diameter is known key width and thickness can be taken from the standard tables.

Table 38 : Proportions of standard parallel, tapered and Gib head keys [1]

Figure 57 : Key and Keyway Dimensions [1]

Shaft diameter d = 10mm

Therefore, w = 4 mm and t = 4 mm

Calculating key length for shearing strength,

𝑻 = 𝒍 × 𝒘 × 𝝉𝒎𝒂𝒙 ×

𝒅

𝟐

462.5 x

1

2𝜋

900 ∗ 60

= 4 ∗ 10−3 ∗ 𝑙 ∗

420

∗ 0.577 ∗ 106 ∗ 0.005

1.8

𝑙 = 1.822 𝑚𝑚

Calculating key length for crushing strength,

𝑻=𝒍×

462.5 x

𝒕

𝒅

× 𝝈𝒄 ×

𝟐

𝟐

1

2𝜋

900 ∗ 60

= 2 ∗ 10−3 ∗ 𝑙 ∗

250

∗ 0.577 ∗ 106 ∗ 0.005

1.8

𝑙 = 6.123 𝑚𝑚

Since 1.822 mm < 6.123 mm < 15 mm (Face width) key is safe for shearing stress and crushing

stress.

Effect of the keyway,

𝒆 = 𝟏 − 𝟎. 𝟐(𝒘/𝒅) − 𝟏. 𝟏(𝒉/𝒅)

e = 1 – 0.2 ( 4 / 10 ) – 1.1 ( 2 / 10 )

e = 0.7

strength of the shaft with keyway

Effect of the keyway (e) =

strength of the shaft without keyway

Therefore, allowable strength of the shaft with the keyway

= 0.7 x 224.389

= 157.072 MPa

Shaft Diameter with the keyway by maximum shear stress criteria,

3

D =

16

√1.52 × 8.6162 + 12 × 5.882

𝜋

420×106

x 0.7

1.8

D = 7.72 mm

Same procedure was used to ensure lay shaft keys and Pulley keys are safe against shearing and

crushing and key dimensions for each gear is as follows,

Table 39 : Key Dimensions

Gear

Width (mm)

Thickness

(mm)

Gear 1

Gear 2

Gear 3

Gear 4

Gear 5

Gear 6

Gear 11

Smaller Pulley

Larger Pulley

4

6

6

6

6

6

6

10

10

4

6

6

6

6

6

6

5

5

Length for

shear stress

(mm)

Length for

crushing

stress (mm)

Effect of

keyway (e)

2.391

3.986

3.986

3.986

3.986

3.986

3.986

0.45

0.901

3.533

5.888

5.888

5.888

5.888

5.888

5.888

1.332

2.664

0.7

0.7

0.7

0.7

0.7

0.7

0.7

0.981

0.981

4.9.5 Shaft diameters after the effect of the keyway

Table 40 : Final Shaft Diameters

Effect of the

keyway

Input Shaft

Lay Shaft

Output Shaft

Idler Shaft

Pulley Shaft

0.7

0.7

0.7

0.7

0.981

Shaft

Diameter

(mm)

7.722

14.658

20.935

12.17

21.069

Standard Shaft

Diameter

(mm)

10

15

25

15

25

4.10 Bearing Selection for Shafts

4.10.1 Data

NTN Bearing catalogue [19]

Bearing loads obtained in shaft calculations

4.10.2 Assumptions

Bearings are mounted at the ends of each shaft

Bearing life is expected to be 3 years, working 8-10 hours a day

Deep grove ball bearings are chosen since they have low friction, less noise and

vibrations.

4.10.3 Formulas

For ball bearings L10 = (C/P)3, where L10 is the bearing life with 90% reliability, under a given

load and speed.

Figure 58 : Deep Groove Ball Bearing [8]

4.10.4 Calculation

Average L10 life time of a bearing used for conveyors is measured to be about 8000 hours which

roughly converts to about 3 years with 8 hours per day operation.

Table 41 : Bearing Selection

Shaft

Input

Lay

Output

Idler

Left End Bearing

Number

6000

6202

6305

6302

Right End Bearing

Number

6000

6202

6305

6302

L10 life calculated

in hours

25812.10756

10135.17587

8588.153929

25013.56713

Dimensions of the selected bearings according to the catalogue is shown below,

Table 42 : Dimensions of the Selected Bearings

Bearing

Number

6000

6202

6305

6302

Nominal bore

diameter (d)

[mm]

10

15

25

15

Nominal outside

diameter (D)

[mm]

26

35

62

42

Nominal

width (B)

[mm]

8

11

17

13

Ring chamfer

dimension (r)

[mm]

0.5

1

2

1.5

4.11 Spline Design

4.11.1 Assumptions

The shaft and the splines are made out of the same material

Number of teeth of the spline is 16

The pressure angle of spline is 37.50, considering the torque transmitting and by literature

review

Shaft diameter is considered as the minor diameter of the pitch

4.11.2 Data

Diameter of the output shaft = 25mm

4.11.3 Formulas [20]

Torque allowed for the spline =

Allowable shaft torque =

𝜋𝑑3 𝜏

𝜋𝑑𝑝 𝑑𝑟 𝐿𝜏𝑑

16

𝑑

16

Figure 59 : Spline Design Parameters [9]

4.11.4 Calculations

Minor diameter external = Shaft diameter = 25 =

16 − 1.3

𝑃

P = 0.588

Pitch diameter = 16 / 0.588 = 27.21 mm

Major external diameter = 0.588 = 28.91 mm

16+1

The torque allowed for the spline should be more than or equal to allowable shaft torque,

π × 27.21 × 25 × Lτ𝑑

16

=

𝜋 x 253 x 𝜏𝑑

16

L = 22.97 mm

16 − 1.3

Minor diameter internal = 0.588 = 25 mm

16 + 1.6

Major diameter internal = 0.588 = 29.93 mm

4.11.5 Conclusions

Table 43 : Spline Dimensions

Gear

Gear 7

Gear 8

Gear 9

Gear 10

No. of Splines

Minimum

Length of the

spline (mm)

Minor

diameter

internal (mm)

Major

diameter

internal (mm)

Major diameter

internal rounded

(mm)

16

16

16

16

22.96875

22.96875

22.96875

22.96875

25

25

25

25

29.93197279

29.93197279

29.93197279

29.93197279

30

30

30

30

4.12 Coupling Design

4.12.1 Data

Shaft diameter is calculated to be 10mm

Output power of the prime mover is 370W

4.12.2 Assumptions

Sleeve coupling is used since input shaft does not transmit large amount of torque

4.12.3 Formulas

Figure 60 : Sleeve Coupling

𝒅

𝑻 = 𝒍 × 𝒘 × 𝝉𝒎𝒂𝒙 × 𝟐

𝑻 = 𝒍 × 𝟐 × 𝝈𝒄 × 𝟐

𝑻 = 𝟏𝟔 𝐱 𝝉𝑪 (

𝒕

𝝅

𝒅

𝑫𝟒 − 𝒅𝟒

𝑫

Key length for shear stress

Key length for crushing stress

)

For Sleeve Design

4.12.4 Design for Sleeve

Sleeve is designed by considering it as a hollow shaft

𝑇=

𝜋

𝐷4 − 𝑑4

x 𝜏𝐶 (

)

16

𝐷

T = Torque to be transmitted

𝜏𝐶 = Permissible shear stress for the material of the sleeve

𝜋

𝐷4 − 0.014

6

4.9 =

x 14 x 10 x (

)

16

𝐷

Dmin = 13.6 mm

D = 2d + 13mm = 2 x 10 +13 = 33 mm

Since Dmin = 13.6mm < 33mm = D sleeve is safe against shearing

4.12.5 Design for Key

Shaft diameter d = 10mm

Therefore, w = 4 mm and t = 4 mm according to the standard tables

Calculating key length for shearing strength,

𝑻 = 𝒍 × 𝒘 × 𝝉𝒎𝒂𝒙 ×

4.9 = 4 ∗ 10−3 ∗ 𝑙 ∗

320

∗ 0.577 ∗ 106 ∗ 0.005

1.8

𝑙 = 2.39 𝑚𝑚

Calculating key length for crushing strength,

𝒅

𝟐

𝑻=𝒍×

4.9 = 2 ∗ 10−3 ∗ 𝑙 ∗

𝒕

𝒅

× 𝝈𝒄 ×

𝟐

𝟐

250

∗ 0.577 ∗ 106 ∗ 0.005

1.8

𝑙 = 3.53 𝑚𝑚

Length of the sleeve, L = 3.5d = 3.5 x 10 = 35mm

Since 𝑙 = 2.39 𝑚𝑚 < l =3.53mm < L = 35mm key is safe from shearing and crushing. Therefore,

both sleeve and key design is safe.

4.12.6 Conclusions

Table 44 : Coupling Dimensions

Shaft

Diameter

(mm) [d]

10

Outside

diameter of

the sleeve

(mm) [D]

33

Length of the

sleeve (mm)

[L]

Width of the

key (mm)

Thickness of

the key (mm)

Actual Length

of the key

(mm)

35

4

4

35

4.13 Lubrication

4.13.1 Selection of Suitable Lubricant

Table 45 : Pitch Line Velocities of the Gears

Gear

Gear 1

Gear 2

Gear 3

Gear 4

Gear 5

Gear 6

Gear 7

Gear 8

Gear 9

Gear 10

Gear 11

Pitch line velocity

(m/s) [V]

1.885

1.885

1.055

0.854

0.578

0.477

1.06

0.854

0.576

0.488

0.477

Tangential velocity in this case does not exceed 5 m/s. With low tangential speed splash lubrication

will not be able to splash the lubricants properly to other gears. Therefore, grease lubrication was

selected.

Table 46 : Ranges of Tangential Speeds and Lubrication Method for Spur Gears [10]

When selecting the type of lubricant for the gear system, most crucial factor is the viscosity of the

lubricant. Therefore, commercial lubricants are classified according to their viscosity. Following

table guides shows which grade of viscosity should be used based on the application.

Figure 61 : Grease Lubrication

Table 47 : Recommended Viscosity for Enclosed Gears [10]

Since in this case,

Maximum RPM

= 900 rpm

Horsepower

= 0.5 HP

Maximum Reduction Ratio

= 3.75

ISO Viscosity Grade Range = 100-150

Therefore, selected Viscosity Grade = ISO VG 150

From what is available in market to match this grade, Rheolube 374A gear grease was chosen.

[11]

4.14 References

[1] - Khurmi, R. S., & Gupta, J. K. (n.d.). [A Textbook for the Students of A TEXTBOOK OF

MACHINE DESIGN Top. In Engg. Services.

[2] - Permissible Working Stress for Gear Teeth in the Lewis Equation. (2021). Faadooengineers.

http://www.faadooengineers.com/online-study/post/me/machine-design-ii/455/permissibleworking-stress-for-gear-teeth-in-the-lewis-equation , (accessed Dec 1, 2021)

[3] - AZO Materials. (2021). AISI 1065 Carbon Steel (UNS G10650). AZO Materials.

https://www.azom.com/article.aspx?ArticleID=6575 , (accessed Nov 28, 2021)

[4] - wikipedia. (2021). Shear strength. Wikipedia. https://en.wikipedia.org/wiki/Shear_strength ,

(accessed Nov 29, 2021)

[5] - Beamguru. (2021). Beam Calculator. https://beamguru.com/online/beam-calculator/ ,

(accessed Dec 02, 2021)

[6] - SkyCiv. (2021). Beams. https://platform.skyciv.com/beam , (accessed Dec 02, 2021)

[7] - Jignesh Sabhadiya. (2021). haft Key: Definition, Type, And Application. Engineering

Choice. https://www.engineeringchoice.com/shaft-key/ , (accessed Dec 04, 2021)

[8] - Mohd Sufian Othman, M. Z. N. R. M. (2016). Nomenclature of a deep groove ball bearing.

ResearchGate. https://www.researchgate.net/figure/Nomenclature-of-a-deep-groove-ballbearing-5_fig1_283021626 , (accessed Dec 03, 2021)

[9] - Engineersedge. (2021). Involute Spline ANSI B92.1 Equations and Design. Engineersedge.

https://www.engineersedge.com/gears/involute_spline_13649.htm , (accessed Dec 05, 2021)

[10] - KHKgears. (2021). LUBRICATION OF GEARS. KHKgears.

https://khkgears.net/new/gear_knowledge/gear_technical_reference/lubrication-of-gears.html ,

(accessed Dec 07, 2021)

[11] - Nye Lubricants. (2021). Design Engineer’s Guide - Selecting a Gear Box Grease. Nye

Lubricants. https://www.nyelubricants.com/gearbox-grease-guide , (accessed Dec 07, 2021)

[12] - FG Machine. (2021). What’s the Process for Creating a Spur Gear? FG Machine.

https://fg-machine.com/blog/whats-the-process-for-creating-a-spur-gear/ , (accessed Dec 08,

2021)

[13] - SCRIET. (2020). MACHINE DESIGN (UNIT 2ND, SHAFT LECTURE 3). CCS

University. https://ccsuniversity.ac.in/bridge-library/pdf/Engg-0605-AG-LECTUREMACHINE-DESIGN-UNIT-2ND-LECTURE-3.pdf , (accessed Dec 08, 2021)

[14] - FreeASEStudyGuides. (2021). Shift Forks. FreeASEStudyGuides.

https://www.freeasestudyguides.com/manual-transmission-shift-fork.html , (accessed Dec 08,

2021)

[15] - indiamart. (2021). Gear Shifter Fork. Indiamart.

https://www.indiamart.com/proddetail/gear-shifter-fork-21565313155.html , (accessed Dec 08,

2021)

[16] - LADA World. (2021). Gearbox: Output shaft: Circlip. LADA World.

https://ladaworld.com/en/gearboxes/910-input-shaft-2105-1701026.html , (accessed Dec 08,

2021)

[17] - Minispares. (2021). GEARBOX GASKET SET. Minispares Logo.

http://www.minispares.com/product/Classic/AJM804B.aspx , (accessed Dec 08, 2021)

[18] - IndiaMart. (2021). Gearbox Oil Seal. IndiaMart.

https://www.indiamart.com/proddetail/gearbox-oil-seal-13440926812.html , (accessed Dec 08,

2021)

[19] - Ball Bearing Catalogue Page small bearings. (n.d.).

[20] - Jack A. Collins, Henry R. Busby, George H. Staab - Mechanical Design of Machine

Elements and Machines_ A Failure Prevention Perspective-Wiley (2009). (n.d.).

[21] - V-Belt Size Chart - Belt Sizes, Dimensions, & Lengths, MDS,

https://www.mdsofmi.com/v-belt-size-chart/ , (accessed Dec 08, 2021)

[22] - Classic Mackerel Canned Fish 425 g. (2021). Clicksri.Com.

[23] - 3-phase-induction-motor-catalog. (n.d.).

4.15 Annexes

4.16 Detailed Calculation Excel File

https://docs.google.com/spreadsheets/d/19EWngxntyevmTLgk9dbaSu1ss5HzYy1v/edit?usp=sha

ring&ouid=107028206207364628641&rtpof=true&sd=true

4.17 Motor Catalogue

https://drive.google.com/file/d/1yQI8e2A6kN_hp071LKrEyy-XTsCh1ceZ/view?usp=sharing

4.18 Bearings Catalogue

https://drive.google.com/file/d/1uddkn2s8lF30Rb49vSuiYZTZ_Z7b7HHH/view?usp=sharing

4.19 Tables Used

https://drive.google.com/file/d/1P3m3o0bsUyjEommeB0jjil_rsgt7i_Wv/view?usp=sharing

5

Final Design

This design uses a sliding mesh gearbox with spur gears which is one of the most simplistic

gearbox to design and manufacture. Sliding mesh gearbox consists of various sets of gears and

shafts that are arranged together in an organised order and meshing of different gears is done by

the sliding the output gears right or left along a splined output shaft with the help of the gear lever

operated by the operator. Main issue with the sliding mesh gearbox is the fact that speeds of the

input and output shafts should matched when changing gears. Otherwise gearwheels do not align

and crash into one another. In our application gear meshing is done while the system is at rest as

our application does not require to change gears will in the move.

Figure 62: Gearbox Without Casing

Figure 63: Final Gearbox Design

Figure 64: Exploded View

5.1 Operation of the Gearbox

Layout of the gearbox is as follows,

Figure 65: Gearbox Layout

1 – Input Pinion

2 – Input Gear

3 – 3rd Pinion

4 - 2nd Pinion

5 - 1st Pinion

6 – Reverse Pinion

7,8 – 2nd and 3rd Gear Assembly

9,10 – 1st and Reverse Gear Assembly

11 – Idler Gear

This is a 3 forward 1 reverse sliding mesh gearbox layout. Input, Output and Lay shafts are

parallel to each other and input and output shafts lie on the same line as well. 11 gears are used in

total including clutch gear and idler gear. Meshing is done by sliding the gearwheel 7, 8, 9 and 10

along the output shaft.

5.1.1 Neutral Position

Figure 66: Neutral Position

Initially gearbox is at neutral position. Input shaft pinion is meshed with the input gear in lay shaft

as well as reverse pinion in lay shaft is meshed with the idler gear. These gears will be meshed

together throughout the gearbox operation. Output shaft is disconnected from the lay shaft.

Therefore, power is not transmitted to the conveyor system. Speed ratios are obtained by moving

output gears left or right with other gears in the same position as in the neutral position.

5.1.2 First Gear

Figure 67: First Gear Position

When 1st and reverse gear assembly is moved to left side using the shifter fork first gear will be

engaged and power will start to transmit. First gear will give the minimum speed output while

giving the maximum output torque. First gear will be used when carrying the heaviest load which

in this case is the 425g canned fish.

5.1.3 Second Gear

Figure 68: 2nd Gear Position

Before engaging to second gear first gear should be disengaged. For that 1st and reverse gear

assembly should move back to the initial position. Then 2nd and 3rd gear assembly should move to

the right side to engage the 2nd gear. Second gear will have intermediate speed while transmitting

intermediate output torque. It will be useful to carry the medium amount of load which in this case

is the 225g canned fish.

5.1.4 Third Gear

Figure 69: Third Gear Position

Before engaging to third gear second gear should be disengaged. For that 2nd and 3rd gear assembly

should move back to the initial position. Then 2nd and 3rd gear assembly should move to the left

side to engage the 3rd gear. Third gear will have the highest speed while transmitting the lowest

output torque. It will be useful to carry the light weight loads which in this case is the 125g canned

fish.

5.1.5 Reverse Gear

Figure 70: Reverse Gear Position

Before engaging the reverse gear other gears should be disengaged. For that 2nd and 3rd gear

assembly and 1st and reverse gear assemblies should move back to the initial position. Then 2nd

and 3rd gear assembly should move to the left side to engage the 3rd gear. Third gear will have the

highest speed while transmitting the lowest output torque. It will be useful to carry the light weight

loads which in this case is the 125g canned fish.

5.1.6 Shifting Mechanism

Figure 71: Shifting Mechanism

Shifting mechanism is designed to be as simple as possible and easy to manufacture. It consists of

two shift forks which are connected to 1st and reverse assembly and 2nd and 3rd assembly. Shift

forks can be slide along the shift rails which are connected to the gearbox casing. By sliding the

shift fork different gear positions can be achieved.

Figure 72: Shift Rails connecting to the Casing

End of the shift rail is threaded and using a nut, rail can be assembled to the casing. Then one side

of the rail will be fixed with the nut and other side will be fixed to the casing by a step in the rail.

Assembly and disassembly of the shifter mechanism is rather easy too. Top of the shifter fork is

threaded and shift knob is connected by rotating into the fork. First of all, shift knob can be

removed. Then top part of the casing can be removed. Finally, the shift rails can be disassembling

by the nut and shift fork will also can be removed with the shift rail.

Figure 73: Exploded View of the Shifter Mechanism

5.1.7 Lubrication

Grease lubrication is used in the gearbox design as gear wheel tangential speeds are not sufficient

to use splash lubrication. Top casing is removable and it can be used for regular lubrication of the

gearbox.

Figure 74: Disassembled for Lubrication

5.2 Gearbox Components

5.2.1 Input Shaft

Figure 75: Input Shaft

Figure 76: Input Shaft Assembly

Input shaft is connected to the prime mover of the system which is 3 phase AC motor. Step shaft

is used to hold the input gear and bearings in place. If only one bearing is used it has to be fixed in

both directions by casing in order to prevent axial movements. Then it is impossible to disassemble

the bearing from the casing. Therefore, two deep grove ball bearings are used to fix the shaft to

the casing axially. Use of two bearings will help with the bending moments and stress distribution

of the shaft as well.

Figure 77: Stepped Input Shaft

Figure 78: Input Shaft Bearing Assembly

Circlips are used to keep the gears and bearings axially fixed to the shaft. Circlips can be removed

if needed. This allows for ease of disassemble of the gear wheels and bearing when needed.

Gear is connected to the shaft using a key.

Figure 79: Input Key and Keyway

Keyway is cut by milling operations. Therefore, circular part at the end of keyway is inevitable.

This can interfere with the circlips used. To compensate that key and keyway length is reduced

than the face width of the gears from the side where circlip is situated. This will not affect the

design as minimum length of the key required to avoid a failure is way below the actual key length.

Keyway and key has 0.25mm clearance for a tighter fit.

5.2.2 Lay Shaft

Figure 80: Lay shaft

Lay shaft is meshed with the input shaft and transmit power from the input shaft to the output

shaft. Step shaft is used to hold the gears in place. Two deep groove ball bearings are connected at

the end of both sides of the lay shaft. Circlips are used to keep the gears and bearings axially fixed

to the shaft and keys are used to connect gears to the shaft.

Figure 81: Stepped Lay Shaft

Centre of the shaft has the highest diameter and diameter gradually decrease from centre to both

ends. Input and 3rd gears are connected from the left side of the shaft while 1st and 2nd gear assembly

and reverse gear are connected from the right side of the shaft. Here also keys are used to connect

the gears with the lay shaft.

Figure 82: Exploded View of Lay Shaft Assembly

5.2.3 Output Shaft

Figure 83: Output Shaft

Output shaft is meshed with the Lay shaft and transmit power from the Lay shaft to the conveyor

system. Two deep groove ball bearings are used to fix the output shaft to the casing. Circlips are

used to keep the gears and bearings axially fixed to the shaft and splines are used to connect gears

to the shaft.

Figure 84: Splined Output Shaft

Splined shaft is used since gear assemblies needs to be moved axially along the shaft which can’t

be done with the use of keys. 3rd and 2nd assembly is connected from the left side of the shaft while

1st and reverse gear assembly is connected from the right side of the shaft. There is a step in middle

of the shaft in order to prevent moving gears axially more than required. Splines are cut with the

same procedure as cutting spur gears.

Figure 85: Exploded View of the Output Shaft

5.2.4 Idler Shaft

Figure 86: Idler Shaft Assembly

Idler shaft acts as an intermediate shaft between Lay and Output shaft reversing the rotational

direction. Two deep groove ball bearings are used to fix the idler shaft to the casing. Circlips are

used to keep the gears and bearings axially fixed to the shaft and keys are used to connect gears to

the shaft. Size of the pinion and Assembly is identical to the input shaft.

Figure 87: Exploded View of Idler Shaft

Figure 88: Idler Shaft

5.2.5 Casing

Figure 89: Gearbox Casing

Gearbox casing will hold all the mechanical components in the gearbox. Bearings will be fixed to

the casing and shafts are fixed to the casing through bearings. It provides the mechanical support

to parts which rotate in it. In this design casing can be disassembled into main three parts which

can be removed from top and left side. Top part will be used for greasing which will carried out in

regular intervals and left side casing can be removed and used to exit all the parts inside the

gearshift.

5.2.6 Bearings

Figure 90: Bearing

Bearings are used in almost every rotational motions. They will support and guide the shafts

rotational motion while connecting them to the casing. Using bearings will reduce the friction

between shafts and casing.

Figure 91: Bearing Shaft and Casing Connection

Deep groove ball bearings are chosen since spur gears does not produce axial force but only radial

forces. Bearing is fixed to the step of the shaft from one side while other side is fixed by a circlip.

To disassemble the bearing circlip needs to be removed first and then bearing will slide out of the

shaft. By fixing the bearing from both sides will ensure that there will be not any axial movement

of shaft with respect to the bearing. Once bearing is fixed to the casing shaft will be axially fixed

with respective to the shaft.

Figure 92: Bearing fixed to a Shaft using Circlip and Step of the Shaft

5.2.7 Circlips

Circlips are used to prevent the axial movement of gears and bearings with respective to the shaft.

They are used as retaining rings and are manufactured using semi-flexible metal rings.

Figure 93: Circlips

Figure 94: Inserting Circlip to a Shaft

Circlip will sit in a groove cut in the shaft and only the lower half of the ring will be under the

shaft groove and other half will be above the shaft. This upper part will hold the gear or bearing in

place. Circlips can be removed by using circlip pilers.

Figure 95: Circlip Pilers

https://www.wonkeedonkeetools.co.uk/circlip-pliers/how-to-use-circlip-pliers

5.2.8 Oil Seals

Figure 96: Oil Seal

Oil seals are used to protect shafts and bearings from dirt and foreign matter. Also oil seal will

prevent grease or oil going out of the gearbox which is essential in food industry. An oil seal

generally consists of an outer circular metal part and an inner flexible member that does the actual

sealing and is bonded to the metal part by chemical adhesive agents.

5.2.9 Gaskets

A gasket is a seal that is manufactured to fit between two or more surfaces. The gasket is designed

prevent leakage whilst being subjected to varying levels of compression. Gasket will be useful in

removing parts of the gearbox casing in order to keep the IP44 water and dust resistant.

Figure 97: Gaskets

5.2.10 End Caps and End Caps with Shaft Outlets

Figure 98: End Caps

Figure 99: End Cap with Shaft Opening

End caps are used to seal gearbox housings where the shaft does not protrude through the outer

casing. Comprising of a steel cap with a rubber covering they can be used to seal any round bore.

For output and input shafts end caps have a shaft hole as input and output shafts protrude out of

the casing. Idler and lay shaft have end caps without any holes since they both don’t protrude

outside of the gearbox casing. Assembly is done by press fitting and then tighten with nuts and

bolts.

Figure 100: End Cap Assemble

5.3 Manufacturing Process

In this case sliding mesh gearbox with spur gears has been designed. It includes spur gears,

cylindrical shafts with keyways, cylindrical shafts with splines, keys, ball bearings, couplings, belt

drive and selector fork. There are few techniques used in manufacturing process,

Machining (Milling, Turning, Gear Cutting, Thread Cutting)

Heat Treatment (Hardening)

Grinding (Finishing)

Assembling

5.3.1 Manufacturing of Spur Gears