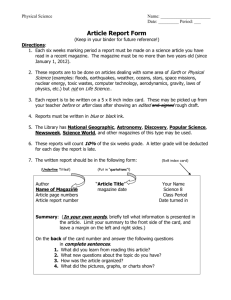

IConn High Performance Performance Wire W ire Bonder IConn J Boat Material Handling System Manual 98888-0000-JB3-01 Copyright © 2013 Kulicke & Soffa Industries Inc (www.kns.com (www.kns.com)) and all subsequent revision dates. All Rights Reserved. Original English language version. The information contained in this document is the property of Kulicke & Soffa Industries Inc and is subject to change without notice. This document may not be reproduced or transmitted in any form, nor stored in a retrieval system of any nature, without the express written authority from: Kulicke & Soffa Pte Ltd 6 Serangoon North Avenue 5, #03-16, Singapore 554 910 This page is left intentionally blank Material Handling System Manual Use of This Manual General Introduction The purpose of this manual is to provide technical information for application design on the K&S IConn High Performance Wire Bonder. The Table of Contents and the Index at the back of the manual should be used to quickly locate specific information within the manual. The following manuals should be referred to if additional information is required: • • IConn Operation Manual IConn Maintenance Manual Terms and Conventions used in this manual The following format is used in this publication: • Syst System em modes modes are cap capita italiz lized. ed. Example Example:: PROGRAM mode • Control Panel and keyboard keyboard buttons are in bracke brackets, ts, capital capitalized ized and and in bold. Example: [ENTER] • Graphic Graphical al Us User er Interfac Interface e (GUI) (GUI) buttons buttons are ca capital pitalized ized and in in bol bold d wit without hout brackets. Example: PROGRAM • Numeri Numeric c “hot keys” are in brackets brackets and and in bold, bold, followe followed d by the function function name. Example: [1] AUTO (Mode); [3] DELETE (Menu Option) • Moni Monitor tor me messa ssages ges are are in quotes. quotes. Example Example:: “Enable “Enable eye poi point nt ret reteac each” h” • Alphabe Alphabetic tic displays displays where any letter letter ma may y appear appear are represe represented nted by a capi capital tal letter (X). Numeric displays displays wh where ere any any number number ma may y appear appear are are represente represented d using using the pound symbol (#). • The following terminology is used in this manual: Term Explanation Ches Ch ess s Movin Moving g tthe he XY tab table le or bond bond head head us usin ing g tthe he mouse mouse or a arr rrow ow keys. keys. Sellect Se Sel Selection is is iin nitiated by by: 1) Place pointer on a button or menu item and press [b1](left mouse button). 2) If item is highlighted (box around item), press [Enter]. 3) Press menu item’s ‘hot key’. Click or Placing the pointer on a screen button or menu item. [b1] (left mouse button) Click On is pressed to initiate the selection. Drag Drag Repo Reposi sitio tioni ning ng or re resi sizi zing ng of an it item em on the di disp spla lay y. Th This is is done done by usin using g the mouse and [b1] (left mouse button) in a held state during the drag. Releasing [b1] terminates the drag function. Index ndex In Iniitiat atiing workholder moti motion on.. Scrol Scr olll Movin Moving g a te text xt fi fiel eld d iin n suc such h a way way a as s tto o hav have e tthe he da data ta move move up or down down within the field. Arrow keys or sliders are used to accomplish this function. Tar arget get Us Usin ing g chess chessin ing g hard hardwa ware re tto o plac place e the mon monit itor or cros crossh shai airr or s sca can n box a att a specific location in one of the display windows. 98888-0000-JB3-01 S-1 IConn High Performance Wire Bonder Record of Changes Change Description No S-2 00 Launch Release 01 Safety Safety In Info forma rmati tion on upd updat ated ed with with la lase serr safe safety ty dat data a and and warn warnin ing g Affected Pages Revised Date ALL 12/2009 Page S-1 1 Page S- 3/2013 98888-0000-JB3-01 Material Handling System Manual Safety Information S.1 General Kulicke & Soffa refer to the latest international health and safety standards, specifications and procedures during design and assembly of the the machine. The machine has an inh inherently erently safe design, however, incorrect maintenance or operation could cause injury to personnel or damage to the equipment. You must keep the machine in accordance with w ith the procedures included in this manual. During operation and maintenance, you must take all reasonable precautions to prevent injury to personnel and damage to the machine. Standard safety practices and local safety regulations apply. The machine is for use in the production of semiconductors. Do not use the machine for other functions. Unapproved mechanical or electrical modifications can have an unwanted effect on the safe and efficient operation of the machine. Kulicke & Soffa accept no responsibility for injury or damage (direct or indirect) caused if you use the machine for other tasks, make unapproved modifications, or if you use unapproved tools, materials, equipment or procedures. You must read and understand this safety chapter before you operate the bonder. S.2 Symbols a an nd M Me essages The symbols and messages used in this manual are shown below: S.2.1 Warning WARNING: The symbol and the word WARNING go before text that is safety related and show a potentially hazardous situation which, if not avoided, could result in death or serious injury. Warnings appear before the related task. Read the warnings before you do the task. All WARNINGs are printed in B old i talic li c letters. S.2.2 Caution CAUTION: The symbol and the word CAUTION go before text that is safety related and show a potentially hazardous situation, which, if not avoided, could result in minor or moderate injury. It is also used to alert against unsafe practices. Cautions appear before the related task. Read the cautions before you do the task. All CAUTIONs are printed in B old i talic li c letters. S.2.3 Note Note: The word Note goes after the text and gives additional data that can help you during a task, or gives you data about the machine.Notes are printed in B OLD ita italic lic letters. 98888-0000-JB3-01 Safety Information S-1 IConn High Performance Wire Bonder S.3 S. 3 Equi Equipm pmen entt-S Spe peci cifi fic c Wa Warn rnin ings gs WARNING: TYPE 4 ELECTRICAL HAZARD! THE POWER SUPPLY MODULE SUPPLIES A HAZARDOUS VOLTAGE OF 420 VDC. THIS POWER IS USED ON THE X AND Y MOTORS AND XY AMPLIFIER. BEFORE YOU GET ACCESS AND SERVICE THE POWER SUPPLY MODULE, THE XY AMPLIFIER MODULE OR THE X AND Y MOTORS OR THEIR RELATED CABLES, MAKE SURE THAT THE MACHINE POWER IS OFF. DISCONNECT THE POWER SUPPLY MODULE FROM THE AC MAINS AND MAKE SURE THAT THE RED SAFETY LED ADJACENT TO THE 420 VDC CONNECTOR ON THE POWER SUPPLY IS OFF (APPROXIMATELY AFTER FIVE MINUTES) BEFORE YOU GET ACCESS TO THE POWER SUPPLY MODULE, XY AMPLIFIER, AND THE X AND Y MOTORS. WARNING: TYPE 4 ELECTRICAL HAZARD! DO NOT TOUCH THE ELECTRONIC FLAMEOFF (EFO) WAND OR THE GOLD WIRE DURING OPERATION OR WHEN MANUALLY FIRING THE EFO. THE SYSTEM PRODUCES A SPARK BETWEEN THE EFO WAND AND WIRE WHICH CAN CAUSE AN ELECTRICAL SHOCK IF CONTACTED DURING EFO FIRING. THE POTENTIAL SHOCK HAZARD IS NOT USUALLY CONSIDERED LIFE THREATENING (AS GIVEN IN IEC PUBLICATION NO. 479). HOWEVER, K&S RECOMMENDS THAT PEOPLE WITH ABNORMAL HEART CONDITIONS OR ARTIFICIAL HEART STIMULATION DEVICES (E.G. PACEMAKERS) ATE OR SERVICE THE EQUIPMENT. MUST NOT BE PERMITTED TO OPERWARNING: TYPE 4 ELECTRICAL HAZARD! THE EFO PRODUCES UP TO 5 KV ON VARIOUS PARTS INSIDE OF THE EFO CONTROL BOX AND ON THE HIGH-VOLTAGE CABLE. DO NOT OPEN THE EFO BOX. IF IT BECOMES NECESSARY TO HANDLE THE HIGH-VOLTAGE CABLE OR REMOVE THE BOX, UNPLUG THE EFO BOX POWER CABLE AND WAIT AT LEAST FIVE MINUTES. USE HIGHVOLTAGE TECHNIQUES AND PRECAUTIONS AT ALL TIMES WHEN YOU HANDLE THIS UNIT. WARNING: ELECTROMAGNETIC FIELDS! SERVO MOTORS USED TO POSITION THE BOND HEAD AND OPTICS GENERATE STRONG MAGNETIC FIELDS. HEART STIMULATION DEVICES (E.G. PACEMAKERS) MAY BE ADVERSELY AFFECTED DURING BOND HEAD MOVEMENT. THEREFORE, PEOPLE WITH SUCH DEVICES MUST NOT BE NEAR THE EQUIPMENT WHILE IT IS IN OPERATION. WARNING: TYPE 4 ELECTRICAL HAZARD! DO NOT TOUCH THE CLAMP ASSEMBLY WHEN MACHINE POWER IS ON. THE CLAMP IS OPERATED BY AN ELECTRICAL POTENTIAL OF UP TO 500VDC. WHEN USED US ED WITH HEAVY WIRE OR COPPER KIT, IT CAN CAUSE AN ELECTRICAL SHOCK IF CONTACTED. THE POTENTIAL SHOCK HAZARD IS NOT CONSIDERED LIFE THREATENING. S-2 Safety Information 98888-0000-JB3-01 Material Handling System Manual WARNING: CLASS I LASER HAZARD! THE BOND HEAD Z-AXIS ENCODER HAS A CLASS I LASER (AND IN CERTAIN MODELS, THE X-AXIS AND Y-AXIS ENCODER). WHILE THE ENCODER SENSOR HEAD IS MOUNTED ON THE BOND HEAD OR X AND Y TABLE, THE LASER IS NOT DANGEROUS TO YOU OR MAINTENANCE TECHNICIAN. HOWEVER, WHEN THE SENSOR HEAD IS REMOVED AND THE MACHINE POWER IS ON, THE LASER LIGHT CAN CAUSE EYE DAMAGE IF VIEWED DIRECTLY ON AXIS. ALWAYS TURN OFF THE MACHINE POWER YOU REMOVE THE ENCODER SENSOR HEAD FROM THE BONDBEFORE HEAD OR X AND Y TABLE. WARNING: HAZARDOUS MATERIAL! THE BOND HEAD LINK IS MADE FROM A BERYLLIUM ALLOY THAT IS CONSIDERED A POTENTIAL CARCINOGEN. HAZARDOUS DUST IS PRODUCED WHEN THIS MATERIAL IS MACHINED, FILED, OR GROUND. DO NOT MACHINE OR OTHERWISE ATTEMPT TO REWORK THE BOND HEAD. DO NOT GOUGE THE LINK LI NK WHEN YOU WORK AROUND THE BOND HEAD AREA WITH SMALL, SHARP TOOLS AS THIS MAY PRODUCE CHIPS OR SPLINTERS THAT CAN PENETRATE SKIN. A MATERIAL SAFETY DATA SHEET FOR BERYLLIUM AND ITS SAFE USE IS AVAILABLE FROM K&S UPON REQUEST. WARNING: INJURY HAZARD! DURING OPERATION, PARTS OF THE MACHINE MOVE WITHOUT WARNING. KEEP HANDS, TOOLS, AND LOOSE ITEMS OF CLOTHING AWAY FROM THE MHS, XY X Y TABLE, AND BOND HEAD AREAS. WARNING: BURN HAZARD! HOT SURFACES CAN CAUSE BURNS. THE WORKHOLDER IS HOT DURING AND AFTER OPERATION. USE HEAT-RESISTANT PROTECTIVE GLOVES OR LET SURFACE TEMPERATURES DECREASE TO LESS THAN 60°C BEFORE YOU TOUCH THE WORKHOLDER. S.4 General Pre Precauti tio ons The general safety precautions that follow must be observed whenever you operate, adjust, or service this equipment: • • • • • • • • • • 98888-0000-JB3-01 Comp ompon onen ents ts of th thee work workho hold lder er ar aree ver very y ho hott Do not let your fingers, or any material with a low melting point to contact heated areas. Observ Observee all all WARNING ARNINGS S and and CAUTIO CAUTIONS NS noted noted in the tex texts ts of of tthe he techni technical cal pub public licati ations ons for the bonder Al Alwa ways ys disa disabl blee all all moto motors rs bef befor oree you you put put your your han hands ds nea nearr the the bond bond hea head, d, XY XY ta tabl ble, e, MHS MHS and other powered systems Keep Keep hand handss clea clearr o off the the bond bond ar area ea dur durin ing g mac machi hine ne oper operat atio ion n Oper Operat atee the the bond bonder er wi with th cove covers rs in inst stal alle led d at at all all time timess Discon Disconnec nectt the the elect electric rical al serv service ice to the bonder bonder before before you remove remove the rea rearr cover coverss or or open open the card rack door, unless machine power is required to do a specific maintenance task Standa Standard rd precau precautio tions ns rela related ted to liv livee elect electric rical al circuit circuitss must must be take taken n at at all all times times whe when n you you adjust or service the equipment Neve Neverr put put th thee tool toolss or mate materi rial alss on th thee MHS MHS or or bo bond nder er when when yo you u do do main mainte tena nanc ncee Obse Observ rvee the man manuf ufac actu ture rer' r'ss recom recomme mend nded ed safe safety ty prec precau auti tion onss when when you you use che chemi mica call substances Solv Solven ents ts and and aero aeroso sols ls,, if used used,, must must be be comp compat atib ible le with with the the bond bonder er ope opera rati tion onal al environment and the process Safety Information S-3 IConn High Performance Wire Bonder S.5 Trai rained ned Operat Operators ors and Servic Service eT Tech echnic nician ians s The users for operation and service maintenance must receive training in machine operation and maintenance given by Kulicke & Soffa. The Performance Based Equipment Training (P.B.E.T.) given by Kulicke & Soffa makes sure that the participants master job skills to meet measurable objectives. There are two levels of training: • • Level One Level One training includes basic machine operation and simple maintenance. Machine operators must successfully complete this training before you operate the machine. Level Two Level Two training covers advanced machine operation and maintenance. Service technicians must successfully complete both the Level One and Level Two training courses. Data on the training courses and locations can be found on the K&S website " www.kns.com". S.6 S. 6 Se Servi rvici cing ng El Elec ectri trica call Eq Equi uipm pmen entt CAUTION: Before you apply AC power to the machine, read through the items outlined in the safety checklist below. S.6. S.6.1 1 • Types pes of Electrical Electrical Hazards thoroughly Read through section S.6.1 Ty • • Servicing ng Power Power Supply thoroughly Read through section S.6.2 Servici Read through section S.6.3 Lockout Lockout/T /Tagout agout Procedu Procedure re thoroughly Typ ypes es of Elec Electr tric ical al Ha Haza zard rds s At times, it may be required to access certain areas of the machine in order to do setup procedures, calibrations or regular maintenance maintenance routines. If the work to be do done ne in these areas relate to components near exposed energized circuits; the steps to do the work, as outlined in the ATPremier Plus machine manuals, will define the type of electrical hazard. The types of electrical hazards are: • • • • • Typ ypee 1: 1: E Equ quip ipme ment nt is fully fully de de-e -ene nerg rgiz ized ed (ele (elect ctri rica call lly y col cold) d) Type 2: Eq Equipment iiss een nergized Live circuits are covered or insulated. Type 3: Eq Equipment iiss een nergized Live circuits are exposed and accidental contact is possible. Potential exposures are less than 30 volts RMS (42.2 volts peak). Type 4: Eq Equipment iiss een nergized Live circuits are exposed and accidental contact is possible. Potential exposures are greater than 30 volts RMS (42.2 volts peak) or radio frequency is present. Type 5: Eq Equipment iiss een nergized Measurements and/or adjustments require physical entry into the equipment or equipment configuration does not allow the use of clamp-on probes. N ot ote e: Wo Worr k i n e elect lectrr i cal ha haza zarr d typ type es 3 thr through ough 5 ar are e broug brought ht tto o the r ead ade er s at atte tenti ntion on iin n the ATPrr emier Plu ATP Pluss use userr m ma anua nuals. S-4 Safety Information 98888-0000-JB3-01 Material Handling System Manual S.6. S.6.2 2 Se Serv rvic icin ing gP Pow ower er Sup upp ply CAUTION: You may cause damage to the machine if you apply power that is i s below the specified voltage range. Do not connect the machine machi ne to source power unless the source power is within the rrange ange of 200 VAC to 240 VAC. If the source power is below this range, a step-up transformer is required (see NOTE below). N ot ote e: Iup f the custo custom mer sissource input vvo olta ltage ge withi within n the r ange of required 100 VA VAC C 200 to 120VA 120VAC , a ste stepptransformer required to raise theiissinput voltage to the to 240CVAC range. The step-up transformer is installed between the ATPremier Plus power supply and the sour source ce i nput vvolt oltage. age. C Cont ontac actt yo your ur loca locall K uli cke & S offa sale saless rre eprese presenta ntatitive ve forr m fo mo ore data about this fe fea ature ure.. DC power to all components on the ATPremier Plus are distributed by the power supply via the Power Distribution Unit (PDU) except the +420VDC to the XY Amp which is sourced directly from the power supply via an appropriately rated cable. CAUTION: There is a red safety LED adjacent to the 420 VDC connector on the power supply, which, when lit indicates the presence of voltage above 60 VDC. Make sure this safety LED is off before you disconnect the power supply, XY amp, or X and Y motors. See figure below for location. A A Safety LED Location Fi g ure S -1 S afet fetyy LE D on the P owe owerr S upp upply ly The power supply does not need to be configured to comply with the source AC line voltage as long as the source AC line voltage is within the range of 200 VAC to 240 VAC. Source input voltage frequency differences are also handled automatically. S.6. S.6.3 3 Lo Lock ckou out/ t/T Tag agou outt Pr Proc oced edur ure e Kulicke & Soffa strongly recommends that you use a power connector locking device. When you shut down power from the machine, implement user-supplied locking device on the power cable to prevent unintentional or accidental restoration of power to the machine during servicing. The attachment of a tagout device on the lockout device is also recommended. This gives a prominent warning to all personnel that the machine may not be operated until the tagout device and the lockout device are removed. Refer to OSHA Standard 29 CFR 1910.147 for detailed data on the control of hazardous energy with lockout/tagout procedures. 98888-0000-JB3-01 Safety Information S-5 IConn High Performance Wire Bonder S.7 S. 7 Safe Safe Use Use of H Hea eated ted Ma Mate teri rial al and and E Equ quip ipme ment nt The workholder heaters are typically heated to a temperature that will immediately burn unprotected skin if contact is made with the heaters, or with machine components close to the workholder. Precautions must be taken when you load/unload heated materials and parts or service equipment in the area around the workholder (work area) to avoid injury. S. S.7. 7.1 1 Us User er's 's R Res espo pons nsib ibili iliti ties es ffor or P Per erso sona nall Sa Safe fety ty It is your responsibility to operate and service the machine safely. You must know all the hazards and their related safety precautions. Examine all of the safety information given with the equipment and read the WARNING notices within the technical manuals that support the machine, and note the areas of the machine that are labeled as hazardous. S.8 S. 8 Po Pote tent ntia iall Er Ergo gono nomi mic c Ha Haza zard rd – M Mic icro rosc scop ope e Use Use There is a potential ergonomic hazard related with use of the microscope mounted on the machine. The eyepieces of the microscope are 1380 mm (54.3 inches) above floor level. For some machine users, this eyepiece height will be too low to use without bending; for others, the eyepiece height will be too high for them to view the work through the microscope. The height of the microscope is not adjustable. To prevent discomfort and the possibility of repetitive stress injuries, obey the precautions that follow when you use the microscope. WARNING: DO NOT STAND ON TIPTOE WHEN YOU LOOK THROUGH THE MICROSCOPE; THIS IS AN UNSTABLE POSITION THAT MAY RESULT RES ULT IN A LOSS OF BALANCE. A. If the eyepieces are too high: Stand on a portable step while you view the work area through the microscope. The portable step height should allow you to comfortably look through the eyepieces, but the portable step height should not exceed 100 mm (4 inches). B. If the eyepieces eyepieces are too low: Make sure that the time spen spentt to view through the microscope microscope in a bent position is no more than 20 seconds at a time. If the task requires more than 20 seconds to do, make sure that you stand up straight for approximately 10 seconds after each 20 second view session through the eyepieces. To prevent repetitive stress injury to the back, the number of sessions at the microscope in a stooped position should not exceed two per shift, with rest after each 20 second view session. S.8. S.8.1 1 Se Serv rvic icin ing g He Heat ated ed Eq Equi uipm pmen entt If you need to do maintenance in the work area, set the heaters to off and allow sufficient time for the workholder heaters to cool completely before you start the maintenance procedure. To make sure that the workholder heaters have cooled: A. In the Temperature Temperature Configuration dialog, set 1 TURN ALL ZONES to OFF. B. Monitor Monitor the heat zone temperature temperatures s shown on the monitor monitor screen. screen. C. When the shown temperatures equal the ambient temperature (approximately 25 °C), start the maintenance procedure. S-6 Safety Information 98888-0000-JB3-01 Material Handling System Manual S.9 Fire Safety This section gives the fire suppression equipment required for the ATPremier Plus P lus Stud Bumper and the storage of flammable supplies. S.9.1 Fire S Su uppression It is assumed that the machine will be operated in a clean room equipped with fire detection and fire suppression equipment. The only requirement for the wire bonding machine is that the fire extinguishing agent must be suitable for suppression of electrical fires. The machine contains no combustible liquids or gases, nor are any used in the process done by the machine. If there is no area fire suppression system in place where the machine operates, fire extinguishing equipment must be available close to the machine. Use an extinguishing device suitable for electrical and electronic equipment and compatible with the products used with the machine. Only personnel trained to fight fires must use fire extinguishers. In the event of a fire, the machine will produce only those substances that ordinarily result from the combustion of electrical or electronic equipment. Standard venting and clean-up methods must be used. S.9. S.9.2 2 Flam Fl amma mabl ble eM Mai aint nten enan ance ce Su Supp ppli lies es Some machine preventive maintenance procedures specify use us e of isopropyl alcohol and grain alcohol for cleaning and degreasing, which are flammable liquids. Large quantities of alcohol (more than 1 liter) must be stored in accordance with local regulations. At a minimum, the alcohol must be kept in approved containers that are clearly labeled, and the containers must be stored outside of the production area in fireproof lockers. When alcohol is required for machine maintenance, small amounts must be taken to the machine in labeled and tightly closed containers. When in use, keep the alcohol away from open flames or other sources of ignition. 98888-0000-JB3-01 Safety Information S-7 IConn High Performance Wire Bonder S.10 S.1 0 Emerge Emergency ncy Off Switch Switch The ATPremier Plus Emergency Off Switch is on the front right-hand side of the upper console (see Figure S-6). It is a latching switch with a large red knob surrounded by a yellow label. The switch is large, highly visible and conveniently in position to make sure that Trained Operators or Trained Service Personnel can easily find and use it, if an emergency power down of the system is required. Push the switch knob in to start an emergency power down process. This causes the main power supply contactor to open and to remove all AC power from the equipment. To power up the bonder after an emergency power power down, release the Emergency Off Switch, push the Machine Machine OFF Switch, and then push the Machine ON switch to power up the machine. CAUTION: When you push the Emergency Off Switch during bonding, operation may result in the loss of the process program and possibly cause damage to the product. Make sure that you clear all leadframes from the workholder before you restart the bonder after an emergency off condition. S.10.1 S.1 0.1 Eme Emerge rgency ncy Off S Switc witch h Sp Speci ecific ficati ations ons • • • Switc Switch h Loc Locat atio ion: n: Fron Front, t, righ rightt-ha hand nd co corn rner er of the the upp upper er co conso nsole le.. Switch Switch Descri Descripti ption: on: Latchin Latching g swit switch ch with with llar arge ge red knob, knob, surrou surrounde nded d by by a yel yellow low lab label el imprinted with the words "EMERGENCY OFF". When activated, the switch latches in the active position. The switch knob must be rotated clockwise to unlatch and de-activate the switch. Functions: • Emer Emerge genc ncy y Of Off- Pu Push sh th thee eeme merrge gen ncy off off sswi witc tch: h: When you push in the switch, it cuts off all A.C. power to the ssystem ystem by the release of the main power supply contactor. • When When th thee emer emerg gen ency cy off sw swit itch ch is pus pushe hed d: The emergency off switch remains in the latched position to prevent unauthorized use of the machine. If the “ON “ ON” switch button is pushed with the emergency off switch still latched down, the machine power will still remain off. Go to the next step to restart from emergency off. • Restart ffrrom em emergency of off: Turn the switch knob clockwise to release rele ase the switch and reset the emergency off switch. This and willthen release thethe switch to reset the “ button out” position. Push the machine. machine OFF switch push machine ON to switch to power up the N ot ote e: T he e equi quipm pme ent w wii ll not rrest estart art unl unless ess tthe he e em mer g ency off sswitch witch iiss rre eset to the “out “out"" position. si tion. S.10.2 S.1 0.2 Test E Emer mergen gency cy Of Offf Swit Switch ch Op Opera eratio tion n A test of Emergency Off Switch operation must be done regularly as part of the scheduled machine preventive maintenance. The test must also be done immediately after the machine is installed at your site, during initial power-up. In this test the trained service technician must operate the switch to make sure that power is immediately removed from the machine and make sure that the Main Power switch will not return power to the machine when the Emergency Off Switch is activated (latched down). S-8 Safety Information 98888-0000-JB3-01 Material Handling System Manual S.1 S. 11 Cove Coverr Pane Panels ls The MHS workholder cover, the input magazine handler and output magazine handler covers; the upper console cover panel; and lower console cover panel protect trained operators from many of the hazards presented by the movement of the mechanical parts, heating elements and electrical subsystems of the equipment. The covers must be in place and attached during all normal operations. They must be opened or removed by trained service personnel only. S.12 S. 12 Mach Machin ine e Em Emis issi sion ons s This section gives the various types of machine emissions for ATPremier Plus Stud Bumper. S.12.1 S.1 2.1 Ion Ionizi izing ng a and nd N Nonon-Ion Ionizi izing ng R Radi adiati ation on • • Ionizing Ra Radiation: There are no sources of ionizing radiation in the machine. Non-ionizing Radiation: The machine has been tested to show compliance with EN 61000-6-4, "Generic "Generic Emissions for Industrial Environments". Environments". S.12.2 Vibration If the machine is installed as given in the ATPremier Plus Stud Bumper Machine Installation Guide, with the machine on its leveling feet and with no contact between the machine and site walls or other equipment, the machine will not let out any appreciable vibration when in operation. Elastomer vibration isolators are used on the leveling feet to support the machine and prevent vibrations produced by the bonding and material handling equipment to transmit to the floor. S.12.3 Noise Continuous acoustical noise emitted by the machine will not be more than 85 dB(A), measured from the operator position as prescribed in ANSI S1.13 “Methods for the Measurement Measurement of Sound Pressure Levels." Levels." S. S.12 12.4 .4 Ga Gase ses, s, Vap apor or,, D Dus ustt The machine produces no gases, vapors, or dust as a result of its operations. 98888-0000-JB3-01 Safety Information S-9 IConn High Performance Wire Bonder S.13 S.1 3 Warn arning ing and Safety Safety L Labe abels ls This section gives the safety and identification labels on the ATPremier Plus Stud Bumper. The safety labels inform trained operators and trained service personnel that a hazardous condition may exist in the general area of each of those labels. This requires caution if actions must be done in those areas. The identification labels are informative and intended to help trained operators and trained service personnel to do their duties safely. A: S.13.2 Burn Hazard Hazard Warning Warning B: S.13.3 Pinch Point Point Hazard Warning Warning C: S.13.4 Electri Electrical cal Hazard Warning Warning S.13.1 Emerge Emergency ncy Off D: S.13.5 Genera Generall Hazard Warning Warning A B C D S.13.3 Pin S.13.3 Pinch ch Point Hazard Warning S.13.3 Pinch Point Hazard Warning S.13.8 Operat Operator or ESD Connection Point Label Fi g ure S-2 Ma Machi chine ne Fr ont and MHS S afet fetyy Label Label Ta Tagg s S-10 Safety Information 98888-0000-JB3-01 Material Handling System Manual S.13.4 Electr Electrical ical Hazard Warning Machine Rear View With Covers S.13.4 Electr Electrical ical Hazard Hazard Warning S.13.5 .5 Gen Genera erall S.13 Hazard Warning S.13.7 Equi S.13.7 Equipme pment nt Grounding IEC Lower Console Rear View Without Cover Fi g ure S-3 Ma Machine chine R ea earr S afet fetyy Label Label Ta Tag s 98888-0000-JB3-01 Safety Information S-11 IConn High Performance Wire Bonder S.14.3 FDA Explana Explanatory/ tory/ Certification Label S.1 S.14.2 4.2 Equi Equipmen pmentt Identification/Manufacturer’s Identification Label S.13.6 Discon Disconnect nect Power Power Label S.13.4 Electri Electrical cal Hazard Hazard Warning Lower Console Front View (without cover) Electrical ical Hazard Hazard S.13.4 Electr Warning Card Cage Front View (when cage door is opened) Clamp Driver Board Zoom-in Card Cage Front View Fig ure S-4 Lower Cons ol ole e Fr ont S afet fetyy Label Label Ta Tagg s S-12 Safety Information 98888-0000-JB3-01 Material Handling System Manual S.14.1 EFO Box Ordering Ordering Notice Label Label S.13.4 Electri Electrical cal Hazard Warning Warning S.13.3 Pinch Point Hazard Hazard Warning Warning Upper Console Rear View (without rear cover) S.13.9 Berylli Beryllium um Product Warning Warning Bond Head Link Bottom View Fig ure S -5 B ond Hea Head, d, E FO, and and MHS S afet fetyy Label Labelss 98888-0000-JB3-01 Safety Information S-13 IConn High Performance Wire Bonder S.13 S.13.1 .1 Em Emer erge genc ncy y Of Offf Fig ure S -6 E mergency Off Off Labe Labell • • • Label: Emergency Off Label Description: The label further identifies and increases the visibility of the Emergency Off Switch to make sure that the Trained Operators and Service Personnel are fully aware of its location and function. Color: Bl Black on on Yel elllow Ba Background S. S.13 13.2 .2 Bu Burn rn Ha Haza zard rd Warni arning ng Haza ard Wa Warning rning L abel Fi g ure S -7 B urn Haz WARNING: HOT TEMPERATURES CAN EXCEED 200°C. • • • Label: Bu Burn Ha Hazard Wa Warning Description: Trained Operators and Service Personnel are warned of hot surfaces in the t he workholder area and on the bond head and optics assembly. Color: Bl Black on on Yel elllow Ba Background S. S.13 13.3 .3 Pi Pinc nch h Poi Point nt Ha Haza zard rd W War arni ning ng Warning rning L abe bell Fig ure S -8 Pi nch Point Wa • • • S-14 Label: Pi Pinch Point Ha Hazard Label Description: Trained Operators and Service Personnel are warned to keep hands and fingers clear c lear of the area. This applies to the front areas of the input and output magazine handlers, rear cover area of the input and output magazine handlers, and on the front of the workholder area. Color: Bl Black on on Yel elllow Ba Background Safety Information 98888-0000-JB3-01 Material Handling System Manual S. S.13 13.4 .4 El Elec ectr tric ical al Haz Hazar ard d Wa Warn rnin ing g Fi g ure S -9 E le lectrical ctrical Haza Hazard rd Warning Warning Labe Labell • • • Lab abel el:: El Elec ectr tric ical al Haz Hazar ard d Warn arnin ing g Lab abel el Descri Descripti ption: on: This This label label alerts alerts Tr Train ained ed Serv Service ice Personn Personnel el to to th thee pres presenc encee of high high volt voltage age in the area Color: Black on Yellow Ba Background S. S.13 13.5 .5 Ge Gene nera rall Ha Haza zard rd W War arni ning ng eneral ral Haz Haza ard Warning Warning Labe Labell Fi g ure S-10 G ene • • • Label: Wa Warning, Ge General Ha Hazard La Label Description: This label alerts Trained Service Personnel (TSP) to the presence of danger at the workholder area, Upper and lower console areas when covers are taken out The TSP is required to follow-up on the related labels (next to the General Hazard Label) and read the safety information before you try to service s ervice the equipment. Color: Black on Yellow Ba Background S. S.13 13.6 .6 Di Disc scon onne nect ct P Pow ower er La Labe bell • • • 98888-0000-JB3-01 -11 1 Dis conn connect ect Powe Powerr B ef efore ore S ervicing L abe bell Fig ure S -1 La Labe bel: l: Di Disc scon onne nect ct Po Powe werr Befo Before re Se Serv rvic icin ing g La Labe bell Description: The label notifies Trained Service Personnels that the input power cord of the power supply assembly must be disconnected before you service the t he equipment within the lower console of the machine. Color: Wh White on on Bl Blue Ba Background Safety Information S-15 IConn High Performance Wire Bonder S. S.13 13.7 .7 Eq Equi uipm pmen entt Gr Grou ound ndin ing g IE IEC C Fig ure S -1 -12 2 E quip quipm men entt G roun rounding ding IE C Label Label • • • Label: Eq Equipment G Grroundin ing g IE IEC La Label Description: • Labe Label: l: Iden Identi tifi fies es th thee con conne nect ctio ion n poi point nt for for inpu inputt pow power er gr grou ound nd Color: Bla lacck on White Background S.13.8 S.1 3.8 Ope Operat rator or E ESD SD Co Conne nnecti ction on P Poin ointt Lab Label el Operato torr E S D C onne onnection ction Point Labe Labell Fi g ure S -13 Opera • • • La Labe bel: l: Oper Operat ato or ESD ESD Con onn nec ecti tio on Po Poin intt Lab Label el Description: Label identifies the connection point to attach the ESD wrist strap. This is to avoid equipment damage from electrostatic discharge. Color: Bla lacck on White Background S. S.13 13.9 .9 Be Bery ryll lliu ium m Pro Produ duct ct W War arni ning ng eryllium ium P roduct Wa Warning rning L abe bell Fig ure S -14 B eryll • • • S-16 Labe Label: l: Bery Beryll lliu ium m Produ Product ct War Warni ning ng Labe Label. l. “BER “BERYL YLLI LIUM UM PR PROD ODUC UCT T. HAZAR HAZARDOU DOUS S DUST PRODUCED WHEN MACHINED, FILED, OR GROUND”. Description: Trained Service Personnel are directed to Manual for safety information with parts made from Beryllium alloy, which can represent a health hazard under certain conditions. During normal machine operations and maintenance actions, the Beryllium alloy does not represent a hazard to machine users or service technicians. Refer to ATPremier Plus Stud Bumper Maintenance Manual, chapter 5: bond head, for more data. Color: Bl Black on on Yel elllow Ba Background Safety Information 98888-0000-JB3-01 Material Handling System Manual S.13.10 S.13.1 0 Hard Stop Cauti Caution on A A Hard Stop Limit Line Fi g ure S -15 Hard S to top p C aut ution ion • • Labe Label: l: Hard Hard Sto Stop p Caut Cautio ion n Labe Label. l. “HAR “HARD D STOP STOP CAU CAUTI TION ON.. Do n not ot ffor orce ce bey beyon ond d the the hard hard stop”. Description: Trained operators and service personnel are alerted to not rotate the work light beyond the hard stop as rotation beyond the hard stop will cause damage to the joint on the goose • neck. The hard stop location is denoted on the caution label. Colo Color: r: Blac Black k and and whit whitee ttex extt o on n yel yello low w, red red,, and and gr gray ay ba back ckgr grou ound nd 98888-0000-JB3-01 Safety Information S-17 IConn High Performance Wire Bonder S.14 Ident Identifica ification tion Label Descri Description ptions s The sections below give descriptions of each identification label that includes label location, color(s) and purpose, meaning, additional instructions, etc. S.14.1 S.1 4.1 EFO Box Ord Orderi ering ng Not Notice ice Lab Label el -16 6 E FO B ox Ordering Ordering Notice Notice Lab Label el Fig ure S -1 • • • Label: EFO EFO Box Or Ord dering No Notice La Label Description: This label tells the trained service personnel to take note of the full part number that includes the last two digits when ordering a new or replacement EFO Box. It also instructs them to consult the customer service representative if required. Color: Bl Black on beige ca card stock S.14.2 S.14. 2 Equip Equipment ment Ident Identifica ification/M tion/Manufa anufacture cturer’s r’s Ident Identificat ification ion L Label abel quipment nt Identificat Identification ion Label Fi g ure S -17 E quipme • • • S-18 Labe Label: l: Equ Equip ipme ment nt Ide Ident ntif ific icat atio ion/ n/Ma Manu nufa fact ctur urer er's 's Ide Ident ntif ific icat atio ion n Labe Labell Description: The label specifies the Equipment and Manufacturer's Identification Numbers (model number, serial number, series and date manufactured), identifies the country of origin, and indicates CE compliance. It also shows data on the AC power configuration of the system on the date shipped and informs the customers and trained maintenance personnel of the expected maximum power consumption of the bonder at listed nominal voltages. It also directs trained maintenance personnel to consult the Machine Manuals before you try to reconfigure the system. Color: Black on gray Safety Information 98888-0000-JB3-01 Material Handling System Manual S.14.3 S.1 4.3 FDA E Expl xplana anator tory/C y/Cert ertific ificati ation on La Label bel Fi g ure S-18 FD A E xpla xplana nattory/ ory/C C ert ertificat ification ion Label Label • • • 98888-0000-JB3-01 Lab abel el:: F FDA DA Ex Expl plan anat ator ory/ y/Ce Cert rtif ific icat atio ion nL Lab abel el Description: This label specifies that, with the use of Class 1 lasers within, the equipment is considered a Class 1 Laser Product as classified per international standard EN/IEC 60825-1:2007. It also specifies that the equipment complies with the US Food and Drug Administration/ Center for Devices and Radiological Health (FDA/CDRH) performance standards for laser products except for deviations as documented in FDA/CDRH Laser Notice Number 50 published on June 24, 2007. This label, in conjunction with the Equipment Identification Label (FDA/CDRH Manufacturer's Identification Label), comprise the required US FDA/CDRH label requirement for Class 1 Laser Products. Color: Black on white Safety Information S-19 IConn High Performance Wire Bonder S.15 S. 15 Lase Laserr Saf Safet ety y N ote te:: T he da datta below ap app plie li es to to K & S m ma achi chine ness w wii th se serr i al num numb ber s @@ @@E E @-@@ @- @@X X X XX X whe herr e @ i s alp alpha ha cco onfi g ura ur ation iinfor nform mati ati on a and nd X i s num nume er i c. LASER SAFETY INFORMATION: Mercury & ChipEncoder These encoders contain an infrared laser diode or diodes. Emitted invisible laser radiation levels have been measured to be within the CDRH Class 1 range, which is not considered hazardous; however, to minimize exposure to the diverging beam, the encoder sensor should be installed in its operational configuration in close proximity to the encoder scale before power is applied. • • • • • In Inv vis isib ible le la lase serr rrad adia iati tion on;; wav wavel elen engt gth: h: 85 850 0 nm nm Max Max po power wer 2. 2.4 mC mC CW CW (4 (4.8 mW CW CW fo for Mer Mercu cury ry II™ II™) All mainte maintenan nance ce proc procedu edures res such such as cleani cleaning ng must must be be p perf erform ormed ed with with the Micr MicroE oE enc encode oderr turned off. Do not not ins inser ertt any any refl reflec ectiv tivee surf surfac acee into into the the bea beam m path path whe when n enco encode derr is pow power ered ed.. Do no not aatttempt tto o se service tth he een ncoder. MicroE Systems 125 Middlesex Turnpike, Bedford, MA 01730 Serial # XXXXX Model # Mercury II 1900XY/ZCRS Manufactured Date: October 201 2011 1 A. Caution - use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure. B. This laser product product is designated designated as Class 1 during all procedures procedures of operat operation. ion. • Non-accessi ssible Laser Parameters: • Wavelength: 850 nm • Laser Power: <4.8 mWatts C. The bond head Z-axis encoder and the XY table X and Y encoders contain a Class 1 laser. While the encoders are mounted in the bonder, the laser poses no danger to the user or maintenance technician. However, when the encoder heads are removed and machine power p ower is on, the laser light can cause eye damage if viewed directly on axis. Always turn off/lock-out machine power before you remove the sensor heads from the bond head or the XY table. D. Under normal usage, there is no user maintenance required or any scheduled maintenance necessary to the laser encoders. The laser encoders should not be opened and no repair, service or modification shall be done by customer. Only trained K&S service personnel or K&S trained customer service engineers are able to service the encoders. S-20 Safety Information 98888-0000-JB3-01 Material Handling System Manual E. Due to the complex complexity ity and special tools tools required for the rep repair air,, setup and recalibration, in the event that the X or Y encoder becomes faulty, the repair and/or replacement is to be done with the return of the complete X/Y table assembly to the factory. In some instances, and subject to the fault finding results, a trained K&S service engineer may make the repairs on-site. The repair or replacement of the Z-axis encoder can be done at a customer site but only by a trained K&S service engineer or K&S trained customer service engineer. F. A bonder with a faul faulty ty laser enc encoder oder should should be taken out of service service for rep repair air by a qualified qualified service engineer as mentioned above. G. For customer performed service functions, only K&S trained customer service engineers, supplemented by K&S supplied calibration tools and maintenance procedures contained within the equipment's Maintenance Manual, are permitted. N ot ote e: T he da data ta below app pplilie es to to K & S m mac achi hine ness wi wi th se serr i al num numb ber s @@ @@H H @-@@ @- @@X X XX XX wherr e @ i s alp whe alpha ha confi confi g ura ur ation iinfor nform mati ati on a and nd X iiss num nume er i c. H. Caution - use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure. I. This llaser aser product product is designated designated as Class Class 1 during during al alll procedures procedures of of operation. operation. • Non-accessib sible Lase serr Par Parameters: • Wavelength: 850 nm • Laser Power: <1.5 mWatts J. The bond head ZZ-axis axis encoder encoder contains contains a class 1 laser. laser. While the encoder encoder is mounted mounted in the bonder, the laser poses no danger to the user or maintenance technician. However, when the encoder head is removed and machine power is on, the laser light can cause eye damage if viewed directly on axis. Always turn off/lock-out machine power before you remove the sensor head from the bond head. K. Under norm normal al usage, there is no user maintenance maintenance required required or any scheduled scheduled maintenan maintenance ce necessary to the laser encoders. The laser encoders should not be opened and no repair, service or modification shall be performed by customer. Only trained K&S service personnel or K&S trained customer service engineers are allowed to service the encoders. L. The repai repairr or replacement replacement of the Z-axis Z-axis encoder can be done done at a customer site site but only by a trained K&S service engineer or K&S trained customer service engineer. M. A bonder with a faulty laser encoder should be ttaken aken out of service for repair by a qualified service engineer as mentioned above. N. For customer performed service functions, only K&S trained customer service engineers, supplemented by K&S supplied calibration and maintenance procedures contained within the equipment's Maintenance Manual, are permitted. 98888-0000-JB3-01 Safety Information S-21 IConn High Performance Wire Bonder S.16 S.1 6 Declar Declarati ation on o off Ex Exemp emptio tion n Kulicke & Soffa Pte Ltd declares that our products, i.e. ball bonders, wedge bonders, die bonders and similar industrial equipment are exempt from the European RoHS (Restriction of Use of Certain Hazardous Substances) and WEEE (Waste of Electrical and Electronics Equipment) directives based on the equipment under the not applicable category of “Large-scale, stationary industrial tools” as referenced in EU Directive 2011/65/EU (RoHS) Article 2§4(d) and Article 3§(3). Examples of this type of equipment have previously been reviewed by third party evaluators (see Note 1) who determined that the equipment equipment reviewed meet the aabove bove criteria (see Note 2) and, as such, are deemed to be outside the scope of both European Union (EU) RoHS and WEEE. N ote te:: 1) T TUV UV R hei hei nla nland nd of N No or th A mer i ca ca,, R oH S & WE E E – Offi Official cial le lettter of exe exem mpti on, K uli ulicke cke & Soffa; Sep Septe tem mber 26, 2005 N ote te:: 2) T TUV UV R hei hei nla nland nd of N No or th A Am mer i ca ca,, WE E E and R oH S D i r ecti cti ve A pplica licab bi lity tto o I ndust ndustrr i al M Mac achi hine nerr y; Sep Septe tem mbe berr 27, 2005 S-22 Safety Information 98888-0000-JB3-01 Material Handling System Manual S.17 Shut Shutdown down and Start-up Start-up Procedures Procedures In the event of a plant shutdown, bonders must be shut down appropriately. The machine shutdown and start-up procedures are given below: S.17.1 S.1 7.1 Mac Machin hine e Shu Shutd tdown own Pro Proced cedure ure A. Turn “OFF” all heaters (pre-heat, bond site & post-heat) from the GUI. B. Remove all materials, units, magazines, wires, P-parts, etc from the bonder bonder.. C. Re-ini Re-initiali tialize ze the workhol workholder der.. D. Save Bond Process Programs Programs (if needed). needed). E. Sav Save e MD MDP P to C:\ C:\ drive drive.. F. Push the ma machine chine off off button to shut shut down the machine machine.. G. Disconnect clean dry ai airr (CDA) supply line and AC power cord from the AC mains. H. Wait for machine to cool down to room temperature. Place desiccants on the X/Y motors, lower console (inside and outside) and heat block. Position the bond headbond head above the heat block. I. Place a plastic plastic sheet sheet ove overr the machine machine to prevent prevent dust dust acc accumulat umulation. ion. J. At this junc juncture, ture, inform inform the personnel personnel in-charge in-charge of the site to shut down down the HV HVAC AC (heating, (heating, ventilating and air conditioning) system. S.17.2 S.1 7.2 Mac Machin hine e St Start art-up -up Pro Proced cedure ure N ot ote e: C oo oorr dinati dination on w wii th faci facililititie es is is e exxtre tremely iim mpo porr tant tant tto o make sur sure e tha thatt there there iiss smo smoot oth h transition of the bonders into production. A. Wait for the production environment to stabilize to the these conditions: • • • Temperature ~77°F (25°C) or below low Relative hu humidity of of 4 40 0-60% Baro Barome metr tric ic pr pres essu sure re of 540 540 to to 810 810 mm Hg (2 (21. 1.2 2 to to 3 31. 1.9” 9” Hg) Hg) B. Remov Remove e all desiccants desiccants from from the bonder bonder.. C. Purge the CDA supply (incoming facilities) before you you connect the CDA supply line to the bonder. D. Check the supply (incoming) voltage with a multimeter. multimeter. This is dependent on the AC voltage requirement on the machine. E. Connec Connectt the AC power power cord cord to the AC mains. mains. F. Push the machine machine on button button to power power up the the machi machine. ne. G. Load Bond Process Process Program. Program. H. Inst Install all the h heat eat block block & clamp clamp insert. insert. I. Do the bon bonder der dry cycle cycle mode with with pre-heat, pre-heat, bond site site and post-heat post-heat te temperat mperature ure set-points set-points turned “OFF”. J. Turn “ON “ON”” pre-heat, pre-heat, bond site and post-heat post-heat heaters after suc successfu cessfull completi completion on of dry cycle. K. Do the machine setup for producti production on qualific qualification ation based on customer’s customer’s standard proce procedure. dure. 98888-0000-JB3-01 Safety Information S-23 IConn High Performance Wire Bonder This pa pagg e is le left ft inte intentiona ntionall llyy bla blank nk S-24 Safety Information 98888-0000-JB3-01 Material Handling System Manual Table Of Contents Use of This Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -S-1 General Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -S-1 Terms and Conventions used in this this manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-1 Record of Changes Changes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -S-2 Safety Information Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-1 S.1 General General - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -S-1 S.2 Symbols Symbols and and Messages Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-1 S.2.1 Warni Warning ng - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-1 S.2.2 Cauti Caution on - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-1 S.2.3 Note - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-1 S.3 Equipment Equipment-Spec -Specific ific Warnin Warnings gs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-2 S.4 General General Precaution Precautionss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-3 S.5 Trained Trained Operato Operators rs and and Service Service T Techni echnicians cians - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -S-4 S.6 Servicing Servicing Electri Electrical cal Equipm Equipment ent - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -S-4 - S-4 S.6.1 Types o off Electrical Electrical Haza Hazards rds - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-4 S.6.2 Servic Servicing ing Po Power wer Sup Supply ply - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-5 S.6.3 Locko Lockout/Ta ut/Tagout gout Pr Procedu ocedure re - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-5 S.7 S.7.1 Safe Use UUser' se ofs Heated He atedsibilities Materi Material al and E Equip quipment ment User's Respon Responsibilit ies for Pe Personal rsonal Safety Safety - - -- -- -- -- ------- -- -- -- -- -- -- -- ------- -- -- -- -- -- -- ----- -- -- -- -- -- -- --S-6 S-6 S.8 Potential Potential Ergono Ergonomic mic Hazard Hazard – Microsc Microscope ope Use Use - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -S-6 S.8.1 Servic Servicing ing He Heated ated E Equipm quipment ent - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-6 S.9 Fire Safety Safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-7 S.9.1 Fire Su Suppress ppression ion - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-7 S.9.2 Flamm Flammable able M Mainte aintenance nance Supplie Suppliess - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-7 S.10 Emergency Off Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -S-8 S.10.1 Emergency Off Switch Specifications Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-8 S.10.2 Test Emergency Off Switch Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-8 S.11 Cover Panels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-9 S.12 Machine Emissions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -S-9 S.12.1 Ionizing and Non-Ionizing Radiation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-9 S.12.2 Vibration Vibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-9 S.12.3 Noise - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-9 S.12.4 Gases, Vapor, Dust - - - - -- -- -- -- -- -- ------- -- -- -- -- -- -- -- ----- -- -- -- -- -- -- -- -- -- ------- -- -- -- -- -- -- ------- -- -- -- -- S-10 - S-9 S.13 Warning and Safety Safety Labels S.13.1 Emergency Off - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-14 S.13.2 Burn Hazard Warning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-14 S.13.3 Pinch Point Hazard Warning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-14 S.13.4 Electrical Hazard Warning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-15 S.13.5 General Hazard Warning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-15 S.13.6 Disconnect Power Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-15 S.13.7 Equipment Grounding IEC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-16 S.13.8 Operator ESD Connection Point Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-16 S.13.9 Beryllium Product Warning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-16 S.13.10Hard Stop Caution - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-17 S.14 Identification Label Descriptions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-18 S.14.1 EFO Box Ordering Notice Notice Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-18 S.14.2 Equipment Identification/Manufacturer’s Identification Label - - - - - - - - - - - - - - - - - - - - - - - S-18 S.14.3 FDA Explanatory/Certification Label Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-19 S.15 Laser Safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-20 S.16 Declaration of Exemption Exemption - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-22 S.17 Shutdown and and Start-up Procedures Procedures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-23 98888-0000-JB3-01 Table Of Contents TOC-1 IConn High Performance Wire Bonder S.17.1 Machine Shutdown Procedure Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-23 S.17.2 Machine Machine Start-up Start-up P Proced rocedure ure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-23 Table Of Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - TOC-1 List of Figures- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - LOF-1 List Of Tables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - LOT-1 1 Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1 1.1 General General Informa Information tion - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1 1.1.1 1.1.2 1.1.3 1.1.4 Scope - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1 MHS Manual Manual Co Content ntentss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1 MHS Informati Information on in Ot Other her Man Manuals uals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2 Safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2 1.2 Descriptio Descriptions ns - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3 1.2.1 1.2.2 1.2.3 1.2.4 General General - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3 Workholder Workholder - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4 Device Device Indexing Indexing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5 Magazine Magazine Handlers Handlers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5 1.3 Specificat Specifications ions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6 1.3.1 Carrier Carrier Dime Dimension nsionss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6 1.3. 1.3.1. 1.1 1 J Bo Boat at C Carr arrie ierr Dime Dimens nsion ionss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6 1.3.2 Magazine Magazine Dimensi Dimensions ons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6 1.3.3 Other Specif Specificati ications ons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6 1.4 Operator Operator Contro Controls ls - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6 1.4.1 1.4.2 1.4.3 1.4.4 EMERGENCY EMERGENCY OF OFF F Switch Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6 Operator Operator Control Control Panel Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6 Video Monitor Monitor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9 Signal Light and Audible Audible Alarm - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9 1.5 Video and Graph Graphics ics Display Displayss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-1-10 10 1.6 MHS Softw Software are Function Functionss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-1 -1-12 2 1.6.1 1.6.2 1.6.3 1.6.4 1.6.5 MHS Configura Configuration tion - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-12 MHS Calibrat Calibration ion - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-12 MHS Utilities Utilities - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-13 MHS Magazine Magazine Utiliti Utilities es (Wit (Without hout Sa Safety fety C Covers) overs) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-14 MHS Workholde Workholderr Util Utilities ities - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-15 1.6.6 MHS Auto Auto Run Run Con Configura figuration tion ((Index Indexing ing Type) Type) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-16 1.6.7 MHS Diagnos Diagnostics tics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-17 1.7 Operating Operating Procedures Procedures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-1 -1-18 8 1.7.1 1.7.2 1.7.3 1.7.4 1.7.5 1.7.6 Initial Initial Start–up Start–up - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-18 Load/Unload Load/Unload Magaz Magazines ines Du During ring Bo Bonding nding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-20 Stop Auto Auto Bo Bonding nding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-20 Clear Leadframes Leadframes ffrom rom Ind Indexer exer - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-20 Remove Remove Magazine Magaziness From Ma Magazin gazinee Han Handlers dlers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-20 Bonder/Workh Bonder/Workholder older Sy System stem Sh Shutdow utdown n - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-21 1.8 1.8 Pr Prod oduc uctt Co Conv nver ersi sion on (Figure 1-17) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-22 1.8.1 Tools/Parts Tools/Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-23 1.8.2 Replace Replace Hea Heatt Bloc Block k Inser Inserts ts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-23 1.8.3 Load Existing Existing Proce Process ss Program Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-24 1.8.4 MHS Material Material Dimen Dimension/P sion/Paramet arameter er File File Handling Handling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-24 1.8.4.1 1.8.4. 1 Edit Work Workholder holder Config Configuration uration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-24 1.8.4.2 1.8.4. 2 Edit Ma Magazine gazine Handle Handlerr Parameters Parameters:: - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-25 1.8.5 MHS Operatio Operation n Che Check ck - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-25 2 Workholde Work holderr - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1 TOC-2 Table Of Contents 98888-0000-JB3-01 Material Handling System Manual 2.1 Abou Aboutt this this section section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1 2.2 Desc Descripti ription on - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2 2.2.1 Major Compone Components nts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2 2.2.2 Workholder Workholder Su Subsyste bsystems ms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5 2.2.2.1 2.2.2 .1 Puller Assem Assembly bly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5 2.2.2.2 2.2.2 .2 Front/R Front/Rear ear R Rail ail Assembl Assemblies ies - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6 2.2.2.3 2.2.2 .3 Prehea Preheatt Heat Bloc Block k Assem Assembly bly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6 2.2.2.4 2.2.2 .4 Bond Site H Heat eat B Block lock Assemb Assembly ly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7 2.2.2.5 2.2.2 .5 Index/ Index/Tucke Tuckerr Assem Assembly bly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7 2.2.2.6 J Boat MHS Pne 2.2.2.6 Pneumati umaticc Syste System m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-8 2.2.2.7 2.2.2 .7 Indexe Indexerr Inte Intermedi rmediate ate B Board oard - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-8 2.2.3 Boat Injecti Injection on Seq Sequence uence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-9 2.2.4 Boat Transfe Transferr Sequence Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-11 2.2.5 Boat Indexin Indexing g and Ej Ejectio ection n Sequ Sequence ence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-11 2.3 Setu Setups ps and Adjustmen Adjustments ts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-13 2.3.1 Set-Up Seque Sequence nce - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-13 2.3.2 Pulle Pullerr Pin Se Setup tup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-15 2.3.2.1 2.3.2 .1 Workho Workholder lder G Gauge auge - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-15 2.3.2.2 2.3.2 .2 Puller Pin Se Setup tup Sequen Sequence ce - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-16 2.3.3 Index Pin/Tuc Pin/Tucker ker Eje Eject ct Set Setup up - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-20 2.3.3.1 2.3.3 .1 Index Pin Se Setup tup Sequenc Sequencee - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-20 2.3.3.2 2.3.3 .2 Tucke Tuckerr Ejec Ejectt Set Setup up Seq Sequenc uencee - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-22 2.3.4 Bond Site Site Heat Heat Block Block Ali Alignmen gnmentt - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-24 2.3.5 Rail Paralle Parallelism lism Ad Adjustme justment nt - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-27 2.3.6 Preheat Preheat Heat Heat Block/B Block/Bond ond S Site ite Alignme Alignment nt - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-32 2.3.7 Puller Rack Backlash Backlash A Adjustm djustment ent - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-36 2.3.8 Heat Block Block V Vacuu acuum m Senso Sensorr Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-38 2.4 Work Workhold holder er Calibrat Calibration ion Pro Procedu cedures res - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-40 2.4.1 Workholder Workholder C Calibra alibration tion - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-40 2.4.1.1 2.4.1 .1 Introd Introductio uction n - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-40 2.4.1.2 2.4.1 .2 Do the Workho Workholder lder Calib Calibration ration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-40 2.4.2 Heat Block Calib Calibratio ration n - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-51 2.4.2.1 2.4.2 .1 Introd Introductio uction n - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-51 2.4.2.2 2.4.2 .2 Do the Heat Block Block Cal Calibrati ibration on - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-51 2.4.3 Tucker Tucker Eject Calibratio Calibration n - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-52 2.4.3.1 2.4.3 .1 Introd Introductio uction n - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-52 2.4.3.2 2.4.3 .2 Do the Tucke Tuckerr Ejec Ejectt Cal Calibrati ibration on - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-52 2.4.4 Workholder Workholder C Calibra alibrations tions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-53 2.5 Work Workhold holder er Configu Configuratio ration n - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-54 2.5.1 Boat/Devic Boat/Devicee Dime Dimensions nsions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-55 2.5.1.1 2.5.1 .1 Boat Dimen Dimensions sions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-55 2.5.1.2 2.5.1 .2 Devic Devicee Dime Dimensions nsions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-56 2.5.1.3 2.5.1 .3 Bond P Plane lane O Offset ffset - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-57 2.5.2 Indexing Indexing Paramete Parameters rs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-57 2.5.3 Indexing Indexing Options Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-59 2.5.4 Workholder Workholder C Configu onfiguratio ration n - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-59 2.6 2.7 2.8 2.9 J Boat Indexer Indexer Assembly Assembly Removal Removal and Installat Installation ion - - - - - - - - - - - - - - - - - - - - - - - - - - 2-61 J Boat Slider Slider Ass Assembl embly y Rem Removal oval and and Insta Installatio llation n - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-66 Preve Preventive ntive Mainte Maintenanc nancee - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-69 Parts Replacemen Replacementt Procedures Procedures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-71 2.9.1 Bond Site/Pr Site/Preheat eheat Heat Block Assemb Assembly ly Part Partss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-71 2.9.1.1 2.9.1 .1 Compre Compression ssion Spring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-71 2.9.1.2 2.9.1 .2 Prehea Preheatt Heater Heater Assembl Assembly y - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-73 2.9.1.3 2.9.1 .3 Prehea Preheatt Thermocou Thermocouple ple As Assembly sembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-75 2.9.1.4 2.9.1.4 2.9.1.5 2.9.1 .5 2.9.1.6 2.9.1 .6 2.9.1.7 2.9.1 .7 98888-0000-JB3-01 Bond Site H Heate eaterr Asse Assembly mbly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-76 Bond S Site ite Th Thermoc ermocouple ouple Assemb Assembly ly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-78 Prehea Preheatt Heat Bloc Block k Assem Assembly bly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-79 Bond Site H Heat eat B Block lock Assemb Assembly ly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-80 Table Of Contents TOC-3 IConn High Performance Wire Bonder 2.9.1.8 2.9.1 .8 Preheat Preheat Motor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-82 2.9.1.9 Bond Site Mo 2.9.1.9 Motor tor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-85 2.9.1.10 2.9.1 .10 Preheat Preheat Lin Linear ear Sl Slide ide Assembly Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-86 2.9.2 Puller Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-88 2.9.2.1 2.9.2 .1 Pulle Pullerr Fing Finger er - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-88 2.9.2.2 2.9.2 .2 Pulle Pullerr Rac Rack k - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-89 2.9.2.3 2.9.2 .3 Pulle Pullerr Moto Motorr - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-90 2.9.2.4 2.9.2 .4 Pulle Pullerr Sole Solenoid noid - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-93 2.9.3 Index/Tucke Index/ Tucker r Part Parts s - an - -d- Pin - - - -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- 2-95 2-95 2.9.3.1 2.9.3 .1 Index Arm and 2.9.3.2 2.9.3 .2 Tucke Tuckerr - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-98 2.9.3.3 2.9.3 .3 Tucke Tuckerr Soie Soienoid noid - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-99 2.9.4 Rail Parts Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-101 -2-101 2.9.4.1 2.9.4 .1 Index Indexer er Mo Motor tor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-101 2.9.4.2 2.9.4 .2 X Axi Axiss Lea Leadscrew dscrew Assem Assembly bly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-103 -2-103 2.9.4.3 2.9.4 .3 Leads Leadscrew crew B Bearin earing g - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-105 -2-105 2.9.5 Sensor Assemb Assemblies lies - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-106 2.9.5.1 2.9.5 .1 X Reg Registrat istration ion Sensor Sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-106 2.9.5.2 2.9.5 .2 Optic Optical al Swi Switch tch As Assembli semblies es - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-107 2.9.5.3 2.9.5 .3 J Boa Boatt Pres Present ent Sensor Sensor Amplif Amplifier ier - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-109 2.9.6 Indexer Indexer Flex Cable Cable A Assembl ssembly y - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-111 2.9.6.1 2.9.6 .1 Pulle Pullerr Flex C Cable able A Assemb ssembly ly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-111 2.9.6.2 2.9.6 .2 Gripp Gripper er Fle Flex x Cable Cable Asse Assembly mbly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-113 2.9.7 Heat B Block lock V Vacuum acuum Solen Solenoid oid Va Valve lve - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-116 3 Magazine Maga zine Handle Handlersrs- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1 3.1 About About This Section Section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1 3.2 Descriptio Description n - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2 3.2.1 General General - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2 3.2.2 Major Compone Components nts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2 3.2.3 Magazine Magazine Handler Handler Positions Positions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3 3.2.3.1 3.2.3 .1 Input and O Output utput Pickup Position Position - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3 3.2.3.2 3.2.3 .2 Input and Ou Output tput S Slot lot Posi Positions tions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6 3.2.3.3 3.2.3 .3 Input Stagin Staging g Posit Position ion - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6 3.2.3.4 3.2.3 .4 Depo Deposit sit Position Position - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6 3.2.4 Optional Optional Equ Equipmen ipmentt - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6 3.2.4.1 3.2.4 .1 Safety Covers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6 3.2.4.2 3.2.4 .2 Bar Code Code Re Readers aders (Option (Optional) al) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6 3.3 Setup Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6 3.4 Magazine Magazine Handle Handlerr Calibrat Calibration ion - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7 3.4.1 Input/Output Input/Output Trays Calibr Calibration ation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7 3.4.2 Input/Output Input/Output Slot Calibr Calibration ation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-9 3.5 Magazine Magazine Handler Handler Config Configurati uration on - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3 -3-13 -13 3.6 Magazine Magazine Handler Handler Adjus Adjustmen tments ts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-13 3.6.1 Set-up the Belt Belt Tension Tension - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-13 3.6.2 Tray Adjustme Adjustment nt - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-15 3.7 Magazine Magazine Handler Handler Remov Removal al and Insta Installatio llation n - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-1 -3-15 5 3.7.1 Input Magaz Magazine ine Handler Handler - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-15 3.7.2 Output Magazine Magazine Handle Handlerr - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-21 3.8 Preventive Preventive Maint Maintenanc enancee - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-2 -3-24 4 3.9 Part Replac Replacement ement Procedures Procedures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-26 3.9.1 Replace Replace Sen Sensor sor Asse Assemblie mbliess - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-26 3.9.2 Replace Replace Ca Cable ble Assembl Assemblies ies - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-29 3.9.2.1 3.9.2 .1 Magaz Magazine ine G Gripper ripper Assem Assembly bly Motor Motor Ca Cable ble - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-29 3.9.2.2 3.9.2 .2 Y Axi Axiss Moto Motorr Cab Cable le - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-30 3.9.2.3 3.9.2 .3 Z Axi Axiss Moto Motorr Cab Cable le - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-30 3.9.3 Replace Replace Maga Magazine zine H Handle andlerr Circ Circuit uit Board Board Assem Assembly bly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-31 TOC-4 Table Of Contents 98888-0000-JB3-01 Material Handling System Manual 3.9.4 Repla Replace ce Loa Load d Tray Timing Belt Belt - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-31 3.9.4.1 3.9.4. 1 Repla Replace ce Dr Driven iven Timing Belt - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-31 3.9.4.2 3.9.4 .2 Repla Replace ce Dr Drive ive Tim Timing ing Be Belt lt - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-32 3.9.5 Repla Replace ce Loa Load d Tray Motor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-35 3.9.6 Repla Replace ce Ma Magazin gazinee Gri Gripper pper P Parts arts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-36 3.9.6.1 3.9.6. 1 Repla Replace ce Ma Magazine gazine Grippe Gripperr Paw Paw/Paw /Paw Return Return Springs Springs - - - - - - - - - - - - - - - - - - - - - 3-36 3.9.6.2 3.9.6 .2 Repla Replace ce Ma Magazin gazinee Stop Stop Butt Buttons ons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-40 3.9.7 Repla Replace ce Br Brake ake Assembl Assembly y - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-41 3.9.8 Repla Replace ce Stepper Mo tors -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- 3-44 3-44 3.9.8.1 3.9.8 .1 Ste Zpper AxisMotors Motor 3.9.8.2 3.9.8 .2 Y Axis Motor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-46 3.9.8.3 3.9.8 .3 Magaz Magazine ine G Gripper ripper Assemb Assembly ly Mot Motor or - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-48 4 Electronics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1 4.1 Abou Aboutt This This Section Section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1 4.2 Overa Overall ll Descripti Description on - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - --4-2 4-2 4.2.1 4.2.2 4.2.3 4.2.4 System System Organizat Organization ion - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2 Stepper Stepper Drive Drive - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4 Sensor Sensor Hand Handling ling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-5 DMHS Backpl Backplane ane A Assembl ssembly y - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-7 4.3 Subsyste Subsystem/Boa m/Board rd Descript Descriptions ions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-8 4.3.1 Circuit Circuit Boa Board rd Loc Locations ations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-8 4.3.2 Circuit Circuit Boa Board rd Asse Assemblie mbliess - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-14 4.3.2.1 4.3.2 .1 DMHS In Indexer dexer/Sole /Solenoid noid Dri Driver ver Boa Board rd - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-14 4.3.2.2 DMHS He 4.3.2.2 Hex x Half Steppe Stepperr Driver Driver Circuit Circuit Boards Boards - - - - - - - - - - - - - - - - - - - - - - - - - 4-15 4.3.2.3 4.3.2 .3 DMHS St Stepper epper Contr Controller oller B Board oard - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-17 4.3.2.4 4.3.2 .4 DMHS Mi Micro/Tri cro/Tri Half Steppe Stepperr Drive Driverr Board Board - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-18 4.3.2.5 4.3.2 .5 Magaz Magazine ine Ha Handler ndler IInterme ntermediate diate Board ((08888 08888-4116-4116-000-xx 000-xx)) - - - - - - - - - - - - - - - - 4-20 4.3.2.6 4.3.2 .6 Indexe Indexerr Inte Intermedia rmediate te Boa Board rd (08 (08888-42 888-4226-000 26-000-xx) -xx) - - - - - - - - - - - - - - - - - - - - - - - 4-21 4.3.2.7 4.3.2 .7 Magaz Magazine ine Ha Handler ndler Connection Connectionss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-22 4.3.3 Repla Replace ce DMH DMHS S Card Rack Circuit Circuit Boar Boards ds - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-23 4.3.4 Replacing Replacing tthe he Inpu Input/Outp t/Output ut Mag Magazine azine Handl Handler er Intermedia Intermediate te Boa Board rd - - - - - - - - - - - - - - - - - - - 4-24 4.3.5 Repla Replace ce Ind Indexer exer IInterme ntermediate diate Board - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-26 4.4 MHS S Senso ensors rs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-28 4.4.1 4.4.2 4.4.3 4.4.4 Sensor Sensor Type Typess - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-28 Workholder Workholder Se Sensor nsor Loc Location ationss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-29 Magazine Magazine Handler Handler Sensor Locat Locations ions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-30 Reflective Reflective Sensor A Amplifi mplifier er Setup Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-33 4.4.4.1 4.4.4 .1 J Boa Boatt Pres Present ent Sensor Sensor S Setup etup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-34 4.4.5 Sensor Sensor Statu Statuss Displ Display ay - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-34 4.5 Cab Cable le Assembli Assemblies es - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-35 5 Main Maintena tenance nce - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1 5.1 5.2 5.3 5.4 Abou Aboutt This This Section Section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1 Preve Preventive ntive Mainte Maintenanc nancee Schedule Schedule - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - --5-2 5-2 Spec Special ial Too Tools ls and Gauges Gauges - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-5 Trou Troublesh bleshootin ooting g - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-5 5.4.1 MHS Workholde Workholderr and Mo Motor tor Cy Cycling cling D Diagno iagnostics stics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-5 5.4.1.1 5.4.1. 1 Indexer Indexer Diagn Diagnostics ostics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6 5.4.1.2 5.4.1 .2 Puller Diagn Diagnostic osticss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6 5.4.1.3 5.4.1 .3 Heat Block Diagn Diagnostics ostics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-7 5.4.1.4 5.4.1 .4 Magaz Magazine ine H Handle andlerr Diagnostic Diagnosticss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-7 5.4.2 Temperature Temperature Contr Controller oller D Diagno iagnostics stics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-8 5.4.2.1 5.4.2 .1 System Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-8 5.4.2.2 Any Zon 5.4.2.2 Zonee Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-9 5.4.2.3 5.4.2 .3 Zone Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-9 5.4.3 Re–Initiali Re–Initialize ze MH MHS S - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10 98888-0000-JB3-01 Table Of Contents TOC-5 IConn High Performance Wire Bonder 5.4.4 Maintenance Maintenance Diagnostics Diagnostics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10 5.4.5 MHS Toolbar Toolbar U Utility tility Menus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-14 5.4.5.1 5.4.5 .1 MHS Wo Workhol rkholder der U Utilitie tilitiess - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-14 5.4.5.2 5.4.5 .2 MHS Ma Magazine gazine Utiliti Utilities es - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-16 5.4.6 MHS Manual Manual Mod Modee Utili Utilities ties - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-16 5.4.6.1 5.4.6 .1 Index Utiliti Utilities es - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-16 5.4.6.2 5.4.6 .2 Heat Block Utiliti Utilities es - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-18 5.4.6.3 5.4.6 .3 Prehe Preheat at Blo Block ck Util Utilities ities - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-18 5.4.6.4 .4 Pin U 5-19 5.5 MHS Errors E5.4.6 rrors - - - -Utilitie -tilities - - -s- -- -- ----- ---- -- -- -- -- -- -- --------- -- -- -- -- -- -- ------- -- -- -- -- -- -- -- --------- -- -- -- -- -- -- ------5-21 5.5.1 Error Indicat Indications ions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-21 5.5.1.1 5.5.1 .1 Error Recov Recovery ery O Options ptions Dialo Dialog g Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-21 5.5.1.2 5.5.1 .2 Signa Signall Ligh Lights ts and Audible Audible Ala Alarm rm - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-21 5.5.2 Error and and Sta Status tus Mess Messages ages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-22 5.5.2.1 5.5.2 .1 ”Home Not Fo Found” und” or ”N ”Not ot Out of Ho Home” me” Errors Errors - - - - - - - - - - - - - - - - - - - - - - - 5-22 5.5.2.2 5.5.2 .2 Materi Material al Co Conditio ndition n Error Errorss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-22 5.5.2.3 5.5.2 .3 Statu Statuss Messa Messages ges - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-23 5.5.2.4 5.5.2 .4 Calib Calibratio ration n Messages Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-23 5.5.2.5 5.5.2 .5 Magaz Magazine ine H Handli andling ng Err Errors ors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-23 5.5.2.6 5.5.2 .6 Injec Injection, tion, Index Indexing, ing, aand nd Eje Ejection ction Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-26 5.5.2.7 5.5.2 .7 Initia Initializat lization ion Errors Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-28 5.5.2.8 5.5.2 .8 Program Execut Execution ion Err Errors ors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-29 5.6 MHS–Relat MHS–Related ed Bondin Bonding g Problems Problems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-3 -5-30 0 5.6.1 Eye Point Point Find Find Fail Failures ures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-31 5.6.2 Non–Stick Non–Stick o on n Pad (NSOP) Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-32 5.6.3 Non–Stick Non–Stick on Lead (NSOL) (NSOL) Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-33 A Glossary of Terms Terms & Abbreviations Abbreviations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1 B IConn J Boat Boat Wire Bonder MHS MHS Wiring Diagrams Diagrams - - - - - - - - - - - - - - - - - - - - - - - - B-1 Index - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - INDEX-1 TOC-6 Table Of Contents 98888-0000-JB3-01 Material Handling System Manual List of Figures Figure S-1 Safety LED on the Power Supply - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -S-5 Figure S-2 Machine Front and MHS Safety Label Tags - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-10 Figure S-3 Machine Rear Safety Label Tags - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-11 Figure S-4 Lower Console Front Safety Label Tags - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-12 Figure S-5 Bond Head, EFO, and MHS Safety Labels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-13 Figure S-6 Emergency Off Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-14 Figure S-7 Burn Hazard Warning Warning Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-14 Figure S-8 Pinch Point Warning Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-14 Figure S-9 Electrical Hazard Warning Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-15 Figure S-10 General Hazard Warning Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-15 Figure S-11 Disconnect Power Before Servicing Servicing Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-15 Figure S-12 Equipment Grounding IEC Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-16 Figure S-13 Operator ESD Connection Point Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-16 Figure S-14 Beryllium Product Warning Warning Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-16 Figure S-15 Hard Stop Caution - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-17 Figure S-16 EFO Box Ordering Notice Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-18 Figure S-17 Equipment Identification Label Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-18 Figure S-18 FDA Explanatory/Certification Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - S-19 Figure 1-1 The IConn J Boat Boat Material Handling System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3 Figure 1-2 “C” Style Magazine Handling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5 Figure - - - -(MMI) - - - - - -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- 1-7 Figure 1-3 1-4 Operator Operator Controls Control Panel 1-8 Figure 1-5 Video Monitor Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10 Figure 1-6 MHS Configuration (Workholder (Workholder and Magazine Handler) - - - - - - - - - - - - - - - - - - - - - 1-12 Figure 1-7 MHS Calibration Menus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-13 Figure 1-8 Access to MHS Utilities (Manual Mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-14 Figure 1-9 Standard Mag Handler Utilities Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-14 Figure 1-10 Workholder Utilities Dialog Box Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-15 Figure 1-11 Boat Inject Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-15 Figure 1-12 Clamp Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-16 Figure 1-13 Heat Block Vacuum Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-16 Figure 1-14 Access to Auto Run Configuration Dialog B Box ox - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-17 Figure 1-15 Access to MHS Diagnostics Menus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-18 Figure 1-16 Load Magazines on Magazine Handler (Input Magazine Handler Shown) - - - - - - - - - - 1-19 Figure 1-17 Product Conversion Sequence Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-22 Figure 2-1 Slider Assembly: Major Components Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2 Figure 2-2 Indexer Assembly: Major Components (Front View) - - - - - - - - - - - - - - - - - - - - - - - - - -2-4 - 2-4 Figure 2-3 Indexer Assembly: Major Components (Rear View) - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5 Figure 2-4 MHS Boat Injection Sequence (Top View) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-10 Figure 2-5 MHS Boat Transfer Sequence (Top View) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-11 Figure 2-6 MHS Boat Indexing Indexing and Ejection Ejection Sequence (Top View) - - - - - - - - - - - - - - - - - - - - - - 2-12 Figure 2-7 Workholder Setup Sequence, Sequence, Sheet 1 of 2 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-13 Figure 2-8 Workholder Setup Sequence, Sequence, Sheet 2 of 2 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-14 Figure 2-9 Workholder Gauge Funtionality for Puller Pin Setup - - - - - - - - - - - - - - - - - - - - - - - - - 2-15 Figure 2-10 2-10 Install the Workholder Setup and Calibration Gauge Assembly Position - - - - - - - - - - 2-17 Figure 2-11 Install the Workholder Workholder Setup and Calibration Gauge Assembly at 45o angle - - - - - - - - 2-17 Figure 2-12 Puller Pin Y axis Adjustment Adjustment (Top View) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-18 Figure 2-13 Puller Pin Level 1 Adjustment Adjustment (Right Side View) - - - - - - - - - - - - - - - - - - - - - - - - - - 2-18 Figure 2-14 Puller Pin Level 2 and Level 3 Adjustment (Rear View) - - - - - - - - - - - - - - - - - - - - - - 2-19 Figure 2-15 Puller Pin Level 4 Adjustment (Side View) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-19 Figure 2-16 Index Pin Alignment Groove - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-20 Figure 2-17 Index Pin - Y axis Adjustment and Up/Down Adjustment - - - - - - - - - - - - - - - - - - - - - 2-21 Figure 2-18 Tucker Eject Alignment Surfaces Surfaces - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-22 98888-0000-JB3-01 List of Figures LOF-1 IConn High Performance Wire Bonder Figure 2-19 Tucker “Raised Position” Adjustment Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-23 Figure 2-20 Tucker Pin Lower Travel Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-23 Figure 2-21 Install the Workholder Setup Gauge Position (Right Side View) - - - - - - - - - - - - - - - - -2-24 Figure 2-22 Bond Site Heat Block Alignment (Top View) - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-25 Figure 2-23 Y Value At The Top Right Corner of the GUI Display - - - - - - - - - - - - - - - - - - - - - - -2-25 Figure 2-24 Rear Rail Assembly (Rear View) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-28 Figure 2-25 Front Rail Assembly (Front View) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-28 Figure 2-26 Install the Rail Width Gauge Position - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-29 Figure 2-27 Install the Rail Width Gauge and Gauge Pins - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-30 Figure 2-28 Rail Parallelism - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-31 Figure 2-29 Install the Rail Width Gauge - 3.6” Position - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-33 Figure 2-30 Install the Rail Width Gauge at 45o angle (Right Side View) - - - - - - - - - - - - - - - - - - -2-33 Figure 2-31 Install the Preheat Setup Gauge and the Gauge Pins - - - - - - - - - - - - - - - - - - - - - - - - -2-34 Figure 2-32 Preheat Heat Block Alignment (Top View) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-35 Figure 2-33 Puller Rack Backlash - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-36 Figure 2-34 Vacuum Sensor Controller - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-38 Figure 2-35 Workholder Calibration Menu - Remove Material - - - - - - - - - - - - - - - - - - - - - - - - - -2-41 Figure 2-36 Workholder Calibration - Install Bond Site Heat Block Gauges/Inserts - - - - - - - - - - - -2-41 Figure 2-37 Workholder Calibration - Heat Block Focus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-41 Figure 2-38 Workholder Calibration - Heat Block Crosshair Crosshair Alignment (Left - Rear Corner) - - - - - -2-42 Figure 2-39 Heat Block Crosshair Alignment (Right - Front Corner) - - - - - - - - - - - - - - - - - - - - - -2-42 Figure 2-40 Workholder Calibration - Remove Heat Bloc Block k Gauge/Insert - - - - - - - - - - - - - - - - - - -2-42 Figure 2-41 Workholder Calibration - Install Rail Width Gauge - - - - - - - - - - - - - - - - - - - - - - - - -2-43 Figure 2-42 Workholder Calibration - Install the Rail Width Gauge Position - - - - - - - - - - - - - - - - -2-43 Figure 2-43 Workholder Calibration - Install the Rail Width Gauge at 45o angle - - - - - - - - - - - - - -2-44 Figure 2-44 Workholder Calibration - Teach Heat Block Block Assembly - - - - - - - - - - - - - - - - - - - - - - -2-44 Figure 2-45 Workholder Calibration Calibration - Pin Touches Bond Site Heat Block Assembly - - - - - - - - - - -2-44 Figure 2-46 Workholder Calibration - Remove Rail Rail Width Gauge - - - - - - - - - - - - - - - - - - - - - - - -2-45 Figure 2-47 Workholder Calibration - Install Bond Site Heat Block Gauge/Insert - - - - - - - - - - - - - -2-45 Figure 2-48 Workholder Calibration - Teach Bond Bond Height Position - - - - - - - - - - - - - - - - - - - - - - -2-45 Figure 2-49 Workholder Calibration - Remove Heat Bloc Block k Gauge/Insert - - - - - - - - - - - - - - - - - - -2-45 Figure 2-50 Workholder Calibration - Install the Workholder Setup an and d Calibration Gauge Assembly Position 2-46 Figure 2-51 Workholder Calibration - Install the Workholder Workholder Setup and Calibration Gauge Assembly at 45o angle - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-46 Figure 2-52 Workholder Calibration - Install the Gauge Pede Pedestal stal - - - - - - - - - - - - - - - - - - - - - - - - -2-47 Figure 2-53 Workholder Calibration Pedestal Crosshair Focus - -Alignment - - - - - - -t -(Right - - - - -Side) - - - - -- -- -- -- -- -- -- -2-48 -2-4 -2-47 7 Figure 2-54 Workholder Calibration -- Gauge Gauge Pedestal Alignmen Figure 2-55 Workholder Calibration - Gauge Pedestal Crosshair Alignment Alignment (Left Side) - - - - - - - - -2-4 -2-48 8 Figure 2-56 Workholder Calibration - Remove the Gau Gauge ge Pedestal - - - - - - - - - - - - - - - - - - - - - - -2-48 Figure 2-57 Workholder Calibration - Puller move into Input Magazine Handler Area - - - - - - - - - -2-49 Figure 2-58 Workholder Calibration - Remove Remove the Workholder Setup and Calibration Gauge Assembly 2-49 Figure 2-59 Workholder Calibration - Teach Preheat Heat B Block lock Assembly - - - - - - - - - - - - - - - - -2-49 Figure 2-60 Workholder Calibration - Pin Touches Preheat Heat Block Assembly - - - - - - - - - - - - -2-50 Figure 2-61 Workholder Calibration - Remove the Rail Width Gauge - - - - - - - - - - - - - - - - - - - - -2-50 Figure 2-62 Workholder Calibration - Remove Remove All Calibration Gauges - - - - - - - - - - - - - - - - - - - - -2-50 Figure 2-63 Workholder Calibration - Install Heat Block IInserts nserts - - - - - - - - - - - - - - - - - - - - - - - - -2-50 -2-50 Figure 2-64 Workholder Calibration - Complete Complete - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-50 Figure 2-65 Heat Block Calibration - Install Bond Site Heat Block Gauges/I Gauges/Inserts nserts - - - - - - - - - - - - -2-51 -2-51 Figure 2-66 Heat Block Calibration - Move Bond Head - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-51 Figure 2-67 Heat Block Calibration - Remove the Heat Block Gauge - - - - - - - - - - - - - - - - - - - - - -2-52 Figure 2-68 Heat Block Calibration - Complete - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-52 Figure 2-69 Tucker Eject Calibration - Warning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-52 Figure 2-70 Tucker Eject Calibration - Align the Tucker - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-53 LOF-2 List of Figures 98888-0000-JB3-01 Material Handling System Manual Figure 2-71 Tucker Eject Calibration - Tucker Tip Extends Extends 1/16 inches - - - - - - - - - - - - - - - - - - - - 2-53 Figure 2-72 Workholder Configuration Configuration Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-54 Figure 2-73 Boat/Device Parameters Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-55 Figure 2-74 Boat Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-56 Figure 2-75 Hole On Boat End Conditions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-56 Figure 2-76 Device Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-57 Figure 2-77 Index Parameters Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-57 Figure 2-78 Indexing Options Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-59 Figure 2-79 Workholder Configuration Configuration Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-59 Figure 2-80 Remove/Replace J Boat Indexer Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-63 Figure 2-81 Remove/Replace J Boat Indexer Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-64 Figure 2-82 Remove/Replace J Boat Slider Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-68 Figure 2-83 Compression Spring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-72 Figure 2-84 Preheat Heater and Thermocouple Thermocouple Assemblies - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-74 Figure 2-85 Bond Site Heater and Thermocouple Assemblies - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-77 Figure 2-86 Replace Preheat Heat Block Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-80 Figure 2-87 Replace Bond Site Heat Block Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-81 Figure 2-88 Remove Preheat Assembly (Front View) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-83 Figure 2-89 Replace Preheat Motor - Exploded Rear View - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-84 Figure 2-90 Replace Bond Site Motor - Exploded Rear Rear View - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-86 Figure 2-91 Replace Preheat Linear Slide Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-87 Figure 2-92 Puller Finger (Front Wall Assembly - Rear View) - - - - - - - - - - - - - - - - - - - - - - - - - - 2-88 Figure 2-93 Puller Rack - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-89 Figure 2-94 Puller Motor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-92 Figure 2-95 Puller Solenoid - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-94 Figure 2-96 Index Arm and Pin - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-97 Figure 2-97 Tucker - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-99 Figure 2-98 Tucker Solenoid - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-100 Figure 2-99 Indexer Motor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-102 Figure 2-100 X Axis Leadscrew Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-104 Figure 2-101 X Registration Sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-107 Figure 2-102 J Boat Present Sensor Amplifier Controls/Indicators - - - - - - - - - - - - - - - - - - - - - - 2-109 Figure 2-103 Puller Flex Cable Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-112 Figure 2-104 Gripper Flex Cable Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-114 Figure 2-105 Heat Block Vacuum Solenoid Valve (XY Table Assembly - Right View) - - - - - - - - 2-116 Figure 3-1 Magazine Handlers Major Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4 Figure 3-3 3-2 Tray Assembly (Load andns Unload Trays) Trays) -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- 3-5 Figure Touching Benching Buttons Butto (Side View) 3-8 Figure 3-4 Magazine-Sized Gauge and Workholder Workholder Setup & Calibration Gauge - - - - - - - - - - - - - - - 3-9 Figure 3-5 3-5 Install the Workholder Setup & Calibration Gauge Assembly Position - - - - - - - - - - - - 3-10 Figure 3-6 Install the Workholder Workholder Setup & Calibration Gauge Assembly at 45o angle - - - - - - - - - - 3-11 Figure 3-7 Install the Workholder Setup & Calibration Gauge - - - - - - - - - - - - - - - - - - - - - - - - - - 3-12 Figure 3-8 Magazine Handler Configuration Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-13 Figure 3-9 Load Tray, Belt Tension Components Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-14 Figure 3-10 Remove/Install Magazine Handler Handler (Input Magazine Handler Shown) - - - - - - - - - - - - - 3-17 Figure 3-11 Input Tray Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-19 Figure 3-12 Cable Routing & Sensors (Input Magazine Handler Handler Shown - Detail A) - - - - - - - - - - - - 3-27 Figure 3-13 Cable Routing & Sensors (Input Magazine Handler Handler Shown - Detail B) B) - - - - - - - - - - - - 3-28 Figure 3-14 Load Tray Assembly (Exploded (Exploded View - Bottom of Tray) - - - - - - - - - - - - - - - - - - - - - 3-34 Figure 3-15 Bottom Paw/Spring Replacement (Lower (Lower Jaw Gripper Assembly) - - - - - - - - - - - - - - - 3-37 Figure 3-16 Top Paw/Spring Replacement (Upper Jaw Magazine Gripper Assembly Shown) - - - - - 3-39 Figure 3-17 Brake Assembly Replacement - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-43 Figure 3-18 Remove/Replace Z Axis Motor Motor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-45 Figure 3-19 Remove/Replace Y Axis Motor Motor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-47 98888-0000-JB3-01 List of Figures LOF-3 IConn High Performance Wire Bonder Figure 4-1 Model 3131 Control Control System Organization - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3 Figure 4-2 Typical Stepper Motor Control Path - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4 Figure 4-3 Sensor Data Input to Control System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-6 Figure 4-4 DMHS Backplane Board P/N 08888-4000-000-xx, 08888-4000-000-xx, Major Compon Components ents - - - - - - - - - - - - - 4-7 Figure 4-5 Sensor Data Input to Control System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-8 Figure 4-6 Serial Communications Path - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-9 Figure 4-7 Card Rack Circuit Circuit Board Assembly Locations - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-11 Figure 4-8 MHS Interface Locations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-12 Figure 4-9 Power Supply Locations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-13 Figure 4-10 DMHS Indexer/Solenoid Driver Board, Board, P/N 08888-4032-000-xx, 08888-4032-000-xx, Major Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-14 Figure 4-11 DMHS Hex Half-Stepper Drivers, P/N 08888-4166-000-xx, 08888-4166-000-xx, Major Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-16 Figure 4-12 DMHS Stepper Controller Board, P/N 08888-4300-000 08888-4300-000-xx, -xx, Major Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-17 Figure 4-13 DMHS Micro/Tri Half Stepper Driver Board, Major Components - - - - - - - - - - - - - - -4-19 Figure 4-14 Magazine Handler Intermediate Board Layout, Majo Majorr Components - - - - - - - - - - - - - - -4-20 Figure 4-15 Indexer Intermediate Board Board Connection Points - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-21 Figure 4-16 Input or Output Interconnect Boards, Boards, Cable and Sensor Connections - - - - - - - - - - - - - -4-22 Figure 4-17 Replace Input or Output Magazine Handler Intermediate Intermediate Board (Input Side) - - - - - - - -4-25 Figure 4-18 Replace Indexer Intermediate Board Board (Front View of J Boat Indexer Assembly) - - - - - -4-27 Figure 4-19 Workholder Sensor Locations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-29 Figure 4-20 Magazine Handler Sensors - Detail A (Input Magazine Handler Shown) - - - - - - - - - - -4-30 Figure 4-21 Magazine Handler Sensors - Detail B (Input Magazine Handler Shown) - - - - - - - - - - -4-31 Figure 4-22 Tray Assembly Sensors - Detail C (Output Tray Assembly Shown) - - - - - - - - - - - - - -4-32 Figure 4-23 Reflective Sensor Amplifier Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-33 Figure 5-1 Access to Workholder and Magazine Handler Cycling Menus - - - - - - - - - - - - - - - - - - - 5-5 Figure 5-2 Indexer Motor Diagnostics Diagnostics Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6 Figure 5-3 Puller Diagnostics Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6 Figure 5-4 Heat Block Diagnostics Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-7 Figure 5-5 Magazine Handler Motor Diagnostics Diagnostics Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-8 Figure 5-6 Temperature Controller Diagnostics Diagnostics Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-9 Figure 5-7 Maintenance Diagnostics Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-10 Figure 5-8 Sensor Diagnostics Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-11 Figure 5-9 Access to Workholder and Mag Handler Utilities (without safety cover) - - - - - - - - - - - -5-14 Figure 5-10 Boat Inject Dialog Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-15 Figure 5-12 5-11 Heat Heat Block Block Vacuum Dialog Box - - -Box - - - -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -5-15 Figure Dialog -5-15 -5-15 Figure 5-13 Access to MHS Utilities (Manual Mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-16 Figure 5-14 Index Utilities Dialog Box (Manual Mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-17 Figure 5-15 Heat Block Utilities Dialog Box (Manual Mode) - - - - - - - - - - - - - - - - - - - - - - - - - - -5-18 Figure 5-16 Preheat Block Utilities Dialog Box (Manual Mode) - - - - - - - - - - - - - - - - - - - - - - - - -5-19 Figure 5-17 Pin Utilities Dialog Box (Manual Mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-20 Figure 5-18 Error Recovery Options Dialog Boxes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-22 LOF-4 List of Figures 98888-0000-JB3-01 Material Handling System Manual List Of Tables Table 2-1 Boat Injection - Puller Pin and Boat Present Sensor Conditions - - - - - - - - - - - - - - - - - - - 2-9 Table 2-2 Workholder Preventive Maintenance Schedule - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-69 Table 3-1 Magazine Handler Preventive Maintenance Maintenance Schedule - - - - - - - - - - - - - - - - - - - - - - - - - 3-24 Table 4-1 DMHS Circuit Boards, 3U Circuit Board (Top (Top Level) - - - - - - - - - - - - - - - - - - - - - - - - - 4-10 Table 4-2 DMHS Indexer/Solenoid Driver Board, P/N 08888-4032-000-xx 08888-4032-000-xx - - - - - - - - - - - - - - - - - 4-14 Table 4-3 DMHS Hex Half-Stepper Drivers, P/N 08888-4166-000-x 08888-4166-000-xx x - - - - - - - - - - - - - - - - - - - - - 4-15 Table 4-4 DMHS Stepper Controller Board, P/N 08888-4300-000-xx 08888-4300-000-xx - - - - - - - - - - - - - - - - - - - - - 4-17 Table 4-5 DMHS Micro/Tri Half Stepper Board, Board, P/N 08888-4214-000-xx 08888-4214-000-xx - - - - - - - - - - - - - - - - - - 4-18 Table 4-6 Magazine Handler Intermediate Intermediate Board, P/N 08888-4116-000-xx 08888-4116-000-xx - - - - - - - - - - - - - - - - - 4-20 Table 4-7 Indexer Intermediate Board, Board, P/N 08888-42 08888-4226-000-xx 26-000-xx - - - - - - - - - - - - - - - - - - - - - - - - - 4-21 Table 4-8 Recommended Signal values for output output signal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-34 Table 4-9 MHS Cable Assemblies - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-35 Table 5-1 MHS Preventive Maintenance Schedule - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2 Table 5-2 Special Tools and Gauges - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-5 98888-0000-JB3-01 List Of Tables LOT-1 IConn High Performance Wire Bonder Thiss pa Thi pagg e is le left ft inte intentiona ntionall llyy bla blank nk LOT-2 List Of Tables 98888-0000-JB3-01 Material Handling System Manual 1 Introduction 1.1 General Informati tio on 1.1.1 Scope This manual contains information for operation, maintenance, setup, and troubleshooting of the J Boat Material Handling System (MHS) used on the IConn High Performance Wire Bonder. It is the Material Handling System Manual Manua l of the IConn Manual Set. 1. 1.1. 1.2 2 MH MHS S Ma Manu nual al Co Cont nten entts The J Boat MHS manual is divided into five (5) sections: • Sect Sectio ion n 1: 1: IInt ntro rodu duct ctio ion n Contains descriptions of the J-Boat MHS equipment, controls/indicators used in MHS operations, and machine software functions involved in MHS setup and use. It also includes simple daily MHS operating procedures, and product conversion procedures. • Sect Sectio ion n 2: Work Workho hold lder er Covers the workholder subsystem of the J-Boat MHS, MHS , which transports, heats, and clamps leadframe or or other device carriers for bonding. Contains detailed descriptions of the workholder and provides procedures for setup, calibration, workholder removal/installation, and parts replacement. • Sec Secti tion on 3: Magazi Magazine ne Hand Handle lers rs Covers the two MHS subsystems that handle carrier storage magazines: the input magazine handler (at workholder input end) and output magazine handler (at workholder output end). Although there are some physical difference between the subsystems, they are functionally identical. This section contains descriptions of the magazine handlers and provides procedures for setup, calibration, magazine handler removal/installation, and parts replacement. • Sect Sectio ion n 4: El Elec ectr tron onic ics s Contains a general description of the J Boat MHS electronic control system and more specific information concerning circuit board locations within the machine, functions of individual circuit boards in the system, and location/identification of cables, motors, and sensors. Also includes procedures for circuit board replacement, sensor replacement, and sensor setup. • Sect Sectio ion n 5: Main Mainte tena nanc nce e Specifies preventive maintenance requirements for the J Boat MHS and provides error recovery/troubleshooting information. This includes coverage of IConn software functions that may be helpful when determining the cause of machine errors. 98888-0000-JB3-01 Introduction 1-1 IConn High Performance Wire Bonder 1. 1.1. 1.3 3 MH MHS S In Info form rmat atio ion n in Ot Othe herr M Man anua uals ls The IConn manual set consists of six volumes. In addition to this volume (described in the previous paragraph), five other publications are shipped with the machine. • IConn Operation Manual This volume covers machine operation, programming, and use of the many machine software functions, including calibrations, control parameter definitions, and programming procedures for the MHS. • IConn Maintenance Manual Provides maintenance information for the machine as a system and for all major components individually with the exception of the MHS, which is covered in this volume. • IC ICon onn n Oper Operat ator’ or’s s Hand Handbo book ok Provides operating, maintenance, and troubleshooting information useful to machine operators. Printed in a smaller format than the other manuals and on clean-room paper for use at a machine in the production area. • IC ICon onn n Inst Instal alla lati tion on Gui Guide de Identifies machine operating site requirements and provides procedures for unpacking, machine installation, and power-up tests. Also includes instructions for repacking a IConn machine for return shipment. 1.1.4 Safety The IConn High Performance Wire Bonder with Model 3035 J Boat MHS has been designed and manufactured manu factured to operate safely. However, However, as with any production machine, certain specific and general safety precautions should always be observed. These are listed in the “Safety Information” section, which immediately follows the title page of this manual. Other WARNINGS and CAUTIONS have also been added where appropriate throughout the text of this manual and in the other volumes of the IConn manual set. 1-2 Introduction 98888-0000-JB3-01 Material Handling System Manual 1.2 Descriptions 1.2.1 General 1-1)) is designed for use on The J Boat Material Handling System (MHS) (Figure ( Figure 1-1 the IConn High Performance Wire Bonder. The MHS performs all functions necessary to move and position carriers and their magazines (automatically or under user control) during the wire bonding process. The MHS consists of three major subsystems: • Inpu Inputt Magaz Magazine ine Handle Handlerr (handl (handles es inpu inputt magaz magazines ines)) • Workholder • Outp Output ut Magaz Magazine ine Hand Handler ler (han (handle dles s output output m maga agazin zines) es) Input Magazine Handler Output Magazine Handler Z Tower Assembly Z Tower Assembly Input Tray Assembly Output Tray Assembly MHS Electronic Control System (DMHS Backplane Board and other control system located in card rack, behind door J Boat Workholder (behind cover) Fi g ure 1-1 1-1 The IC onn J B oa oatt Ma Matterial Han Handl dling ing S ys te tem m 98888-0000-JB3-01 Introduction 1-3 IConn High Performance Wire Bonder The input magazine handler stages several multi–slot magazines that contain carriers holding die–bonded devices. Multiple magazines are used to provide sufficient storage capacity of these devices to minimize material replacement time. Each magazine has a fixed pitch (distance) between carrier slots, but the number of magazine pitches between adjacent carriers stored in the magazine may vary. Magazine dimensions and slot pitches must be constant within the same process batch or lot. The workholder extracts a carrier from the input magazine and provides the necessary incremental movement and registration into and out of the location where wires are bonded to devices (bond site). The workholder is capable of locating each device of the carrier at the bond site with a high degree of repeatability while providing a high transfer rate to maintain high throughputs. The center section of the workholder has two heated blocks capable of independent vertical motion: one preheats the device to the temperature required for wire bond formation; the other maintains device temperature during bonding. The heat h eat block lifts devices upwards away from the boat after each index operation. The bond site heat block holds the device with vacuum during bonding. After the device at the bond site has been bonded, the heat blocks moves downward to return the devices to the boat, boat , the bond site vacuum is switched off, then the heat blocks continue to move downward to a position where they will not interfere with the boat or its devices during the carrier index. Independently programmable heaters are located: • Pri Prior or to th the e bon bond d sit site e ((Pre Prehe heat) at) • At the the bond bond site site (Bo (Bond nd site site)) Each heater location has an independent thermocouple and temperature controller circuit to program, measure, and control heater performance. The temperature controller circuits are all part of a circuit board assembly housed in the lower console card rack. The output magazine handler stages multiple–slot magazines for ejection of processed carriers. Output magazines are initially empty and accept carriers into the magazine slots as they are removed from the workholder. Multiple magazines are used to provide sufficient storage capacity. 1.2.2 Workholder The workholder consist of the indexer and slider assemblies that provides carrier handling capabilities for the purpose of wire bonding. The following functions are available for carrier handling: 1-4 • Carrie Carrierr e extra xtracti ction on from an input input magazin magazine e • Devi Device ce index ndexin ing g • Device Device vacuum vacuum clam clampin ping g and positio positionin ning g functio functions ns • Independent Independent heat block block functionality functionality (raises and lowers lowers the preheat preheat or bo bond nd site heat block without affecting the rest of the workholder) • Multipl Multiple ep prog rogramm rammabl able e bond bond plane plane levels levels • Carrie Carrierr ejec ejectio tion n into into an output output magazi magazine ne • Carrie Carrierr jjam am detecti detection on during during ejecti ejection. on. Introduction 98888-0000-JB3-01 Material Handling System Manual 1.2.3 .2.3 Dev evic ice e In Inde dexi xing ng Indexing operations take place whether the bonder is configured to run in an Auto Run operation (normal operating mode where wires are bonded) or a Dry Cycle operation (wires are not bonded). Both operations include a Normal Index (automatic) mode and a Manual Index mode. Normal indexing automatically moves a device via the boat to and from the bond site. Manual indexing requires the user to select “Index” from the function bar or the MMI to move a device to and from the bond site. A Dry Cycle operation also includes a Dry Index Mode that allows the bonder exercises all parts of the MHS without using magazines and boats. 1.2.4 .2.4 Ma Maga gazi zine ne H Ha and ndle lers rs The magazine handlers provide the MHS workholder with input (raw material supply) and output (finished material storage) functions. They stage magazines of unbonded material for carrier extraction, and magazines with empty slots for insertion of carriers after bonding. The magazine mag azine handlers operate under machine control with no attention required from the user other than to load unprocessed magazines and unload processed magazines. The user can, however, initiate the following magazine handling functions: • Jo Jog gm mag agaz azin ine e up up one one slot slot • Jo Jog gm mag agaz azin ine e dow down no one ne slot slot • Pic Pick k up up mag magaz azin ine e ffro rom m loa load d ttray ray • • Pla Place ce maga magazi zine ne on un unlo load ad tray tray Mov Move e ma maga gazi zine ne to to first first sl slot ot pos positi ition on • Ent Entry ry of maga magazi zine ne hand handli ling ng para parame mete ters rs • Mag Magaz azin ine e ha hand ndle lerr cal calib ibrat ratio ion n Magazines are manipulated within the magazine handlers by a method referred to as the "C" style, which reflects the path that the magazine takes from the load tray to the unload tray (see Figure 1-2 1-2). ). Note that the direction in which the magazines travel is reversed for the output magazine handler versus the direction they travel on the input magazine handler. handler. At the input side, full magazines are placed on the lower tray (load tray), and when emptied are placed on the upper tray (unload tray). At the output side, side, empty magazines are placed on the upper tray (load tray) and, when filled, are placed on the lower tray (unload tray). Gripper Gripper Magazine Magazine (empty) (empty) Load Tray Unload Tray s s e c o r P s s e c o r P Gripper Gripper Magazine Magazine (contains boats with unbonded devices) (contains boats with bonded devices) Unload Tray Load Tray InputSide MagView Handler Side View Output Mag Handler Fi g ure 1-2 1-2 “C ” S tyl tyle e Ma Magg azine Handling Handling 98888-0000-JB3-01 Introduction 1-5 IConn High Performance Wire Bonder 1.3 Specifications 1. 1.3. 3.1 1 Ca Carr rrie ierr Di Dime mens nsio ions ns 1.3 .3.1 .1.1 .1 J Bo Boat Car Carri rie er Dim Dimen ensi sion ons s Package Lengt Length h Width Width Th Thic ickn knes ess s Devi De vice ce Pit Pitch ch 1. 1.3. 3.2 2 J Boat 21 215. 5.9 9 tto o 304. 304.8 8 mm mm (8. (8.5 5 to 12 in in.) .) 78 78.74 .74 to 109 109.2 .22 2 mm (3. (3.1 1 to 4.3 4.3 in in.) .) 9. 9.62 62 mm (0 (0.3 .38 8 iin. n.)) 6. 6.4 4 to 152 mm ( 0. 0.25 25 tto o 6.0 6.0 in.) in.) Boatt Index Boa Index Hole Hole P Pitc itch h 12.7 12.7 mm to 38 38.1 .1 mm mm (0. (0.5 5 to 1.5 in) First First H Hole ole to End End Minimu Minimum: m: n none; one; Maximu Maximum: m: 1 1.6 .6 iin. n. Ma Maga gazi zine ne Di Dime mens nsio ions ns Magazine Width Wid th 83.82 83.82 mm mm to to 119.3 119.38 8 mm mm (3.3 (3.3 in to 4.7 in) Length Len gth 215. 215.9 9 mm to 3 305 05 mm mm (8.5 (8.5 in in to 12.0 12.0 iin) n) Heig He ight ht 50 mm mm to 178m 178mm m (2.00 (2.00 in to to 7. 7.00 00 in) in) Slot Pitch5 Maximu Max imum m Ma Magaz gazine ine 1. 1.3. 3.3 3 Dimension Minimum 10.16 mm (0.4 in) Max Maximu imum m 5. 5.5 5 kg (12.125 (12.1254 4 Ibs) Ibs) load loaded ed Ot Othe herr S Spe peci cifi fica cati tion ons s For other machine/MHS specifications, refer to IConn Operation Manual and IConn Maintenance Manual. 1.4 Operator C Co ontrols 1. 1.4. 4.1 1 EM EMER ERGE GENC NCY Y OF OFF F Sw Swit itch ch Emergency OFF switch (Figure (Figure 1-3) 1-3) is located on the front face of the upper console assembly (red mushroom switch). The switch removes all power from the bonder and MHS when pressed (electrically identical to the Main Power switch on the front of the computer console). However, if latched down it will prevent operation of the main main power power switch. switch. 1. 1.4. 4.2 2 Op Oper erat ator or C Con ontr trol ol P Pan anel el NOTE: The operator control panel panel is sometimes referred to as the ’Man– Machine Interface’ or ’MMI’ in IConn manuals. The Operator Control Panel (Figure (Figure 1-4) 1-4) is the primary operator interface for both teaching and operating the machine. The three-button mouse and various key switches have multiple functions depending on mode, current procedure, machine status sta tus,, etc. etc. 1-6 Introduction 98888-0000-JB3-01 Material Handling System Manual Signal Light Tower (Hidden) Main Power Switch Video Monitor EMERGENCY OFF (EOFF) Switch Control Panel Mouse Fi g ure 1-3 Operat Operator or C ont ontrols rols • Thre Three– e–Bu Butt tton on Mous Mouse e Moves table in the X and Y axes. Also moves screen cursor to select items on the graphics display. Three push button switches (part of the mouse) have functions defined in the graphics display (identified as B1, B2, and B3 in display). • [MOTOR STOP] Disables all servo motors and stepper motors when activated by simultaneously pressing both of the two (2) switch actuators. Stops machine and workholder operation. The bonder will drop out of the current mode and enter Standby Mode when this control is latched. The [MOTOR STOP] button does not remove power from the PC boards boar ds or power supply. • [SHIFT] Used in conjunction with other keys to provide additional functions. • [INDEX] This momentary button commands the MHS to perform one index cycle. The function is valid under conditions determined by the bonder status. 98888-0000-JB3-01 Introduction 1-7 IConn High Performance Wire Bonder Wire Feed Control/Indicator Air Guide Control/ Indicator Mouse Buttons B1, B2, B3 Function Keys Motor Stop Run/Stop Index Mouse Auto Index Alpha Keypad Numeric Keypad (with Shift Enter, Escape, and Arrow keys) Tensioner Control/Indicator 1-4 Operat Operator or Control P ane anell (MMI) Fi g ure 1-4 • [AUTO INDEX] When pressed, commands the MHS to index after bonding of every device. Key lamp lights when auto index has been selected. Active in Auto mode only. • [ENTER] A momentary push button pressed to enter reference points, bond positions, and other program information into memory. • [ESCAPE] A momentary button pressed to exit the menu displayed on screen and return to the previous menu. • [RUN/STOP] Pressed to start bonding in auto mode. Key lamp is ON while the machine is bonding. When key lamp is lit, pressing key stops Auto mode operation and enables Sequence Stop mode. Sequence Stop mode provides many of the same operator options as Manual mode. Active in Auto mode only only.. • [ARROW KE KEYS] Press to move an axis of motion or screen feature (cursor, PRS box sides, etc.) Active only during some calibrations or teaching procedures, as defined on the graphics display. display. • Fu Func ncti tion on Key Keys s ([F1 ([F1]] - [F1 [F10] 0])) The function keys are referenced to the virtual buttons displayed at the bottom of the monitor display. Functions change with machine status. Pressing [SHIFT] while pressing a function key selects the tool bar function f unction immediately above the virtual button that defines defines that function key. key. • Al Alph pha a Key Keys s ((A A tthr hrou ough gh Z) Used to enter alpha characters char acters (for program file name entry, etc.) • Air Guid Guide e Contr Control ol// Indic Indicato atorr Pressing button turns air pressure to air guide ON and OFF OFF.. LED lights when air guide is ON. • Wi Wirre Fe Feed Co Control Wire spool rotates to feed wire when button is pressed. • Tensi ension oner er Con Contr trol/ ol/ In Indi dica cato torr Pressing button turns vacuum to wire tensioner ON and OFF. OFF. LED lights when vacuum to wire tensioner is ON. 1-8 Introduction 98888-0000-JB3-01 Material Handling System Manual 1.4.3 Vid ide eo M Mo onit ito or The video monitor provides a magnified view of various areas of the device in the display video window and displays messages, option menus and other program information. A second window shows a graphical representation of the taught device, that indicates the locations of reference points, bond pads, leads, wires, and other device characteristics. Device images are acquired by a solid–state camera head mounted on the optics housing. Lenses and a system of mirrors complete the optical system (standard configuration). Electronic crosshairs in the video window and graphics window on the monitor screen are used to teach or target reference points and bond positions. 1.4. 1.4.4 4 Si Sign gnal al Li Ligh ghtt a and nd Au Audi dibl ble eA Ala larm rm This unit can be programmed to indicate various operating conditions. Two–, three–, or four–light units may be fitted depending on machine specification. Green, red, and yellow lights (standard implementation) will light under the following conditions if signal light programming has not been performed: • GREEN: Normal operation in Auto mode. • • RED: • [MOTOR STOP] active • Critic Critical al system system error error (logi (logic–a c–acti ctivate vated d emer emergen gency cy off) off) YELLOW: • PRS eye point point or VLL VLL lead lead non–r non–reco ecogni gnitio tion n • Miss Missin ing g ba ball ll de dete tect cted ed • BITS er error • No maga magazi zine ne in el elev evat ator or • MHS MHS or or el elev evat ator or ja jam m • Mach Machin ine e mot motio ion n err error or • RAM parit rity er error • Logic– Logic–act activa ivated ted emerge emergency ncy off off cond conditi ition on • Heat Heat bl bloc ock k te tempe mpera ratu ture re al alar arm m An audible alarm is part of the signal light assembly. The alarm can be programmed to sound and alert the operator under some or all of the conditions listed above. Several sounds are available to indicate different events. Refer to IConn Operation Manual for information concerning signal light and alarm programming. 98888-0000-JB3-01 Introduction 1-9 IConn High Performance Wire Bonder 1. 1.5 5 Vide deo oa and nd Gr Grap aphi hics cs Dis Displ play ays s The monitor display (Figure (Figure 1-5) 1-5) is the primary source of machine and program information. Display content varies depending on mode, current operation and machine status. Fi g ure 1-5 Video Mon Monitor itor S creen Unless specific operating routines have been initiated, the information on the screen will be organized as follows: • MODE Current mode is highlighted on the bar at the top of the screen. Modes are Auto, Manual, Program, Configure, Calibration, Utilities, Diagnostic, and Sys(tem) Admin(istration). • LIVE LIV E VIDE VIDEO O AND DEV DEVICE ICE GRA GRAPHI PHIC C WIND WINDOWS OWS Two views of the device are present on the monitor screen. One shows video from the bond site, either live or digitized by the PRS. The other is a graphic representation of the taught device which shows the lead and die reference systems, wires, operator points, and eyepoints. The views may be exchanged between the larger and smaller windows in the display by pressing the [F1] key. • MENU ME NUS S AND AND DI DIAL ALOG OG BO BOXE XES S Provide most optional operations when teaching and operating the bonder. Click on desired functions within menu to begin them. Dialog boxes appear during operations to allow the user to set parameters, select operating conditions, and perform specific actions. 1-10 Introduction 98888-0000-JB3-01 Material Handling System Manual • CROSSHAIR The crosshair is an electronic image in both the live video window and device graphics window that has two purposes. It is used to target reference points to positively locate reference systems and, secondly, it is used to target bond locations. In the second function the crosshair represents the position of the bond tool over the device. Since the objective lens and the capillary are not in line above the device, the distance between them (Crosshair Offset) must be taught to achieve achiev e this alignment. alignment. • AXIS AX IS POS POSIT ITIO ION N INDI INDICA CATO TORS RS • PRS BOX At the top–right of the screen, X, Y and Z indicators give g ive the position of the X-Y table (X and Y axes) and bond head capillary (Z axis) from their ‘zero’ points (established during machine initialization). The distances are expressed in mils or millimeters, depending upon the unit of measure selected by the user during machine configuration. Active in the live video window when eye eye points are being taught and during PRS calibration, the PRS box is a green, outline box centered on the crosshair. The area enclosed by the box is the scene which the PRS learns so that it can locate the eye point during operation. The eye point itself is at the geometrical center of the eye point scene. The size of the box can be changed to suit the scene. • OPER OP ERAT ATIN ING G INF INFOR ORMA MATI TION ON Several types of operating information informa tion are present in the display. The name of the current process program is above the larger device image window. Operator prompts andworkholder instructionsheat appear below process program name. Temperatures of the three zones are the below the th e window. • TOO OOL L BAR BAR AN AND D FUN FUNCT CTIO ION N KEY KEYS S The tool bar is the upper of two rows of virtual buttons in the lower part of the display.. Function keys ([F1] - [F10]) are defined in the lower of the two rows of virtual play buttons. These keys will have different functions depending upon the machine operating mode. Selecting a tool bar button will display a menu, enable a function, or start a procedure. The purpose of the tool bar is to provide easy access to functions that are performed often during machine operation (bond–site illumination adjustment, MHS operations, relearn bond height, etc.) The tool bar buttons are active during most machine functions. Tool bar functions can also be selected by b y holding down the [SHIFT] key on the control panel and pressing the function key designated by the virtual button directly below the tool bar button. To initiate function key options, the user can either press the indicated control panel function key or select the appropriate appropriat e virtual button in the display to activate the desired function. • ERR ER ROR MESSAGES When operating, error detection will generate an appropriate message on the monitor that describes the nature of the problem, and may provide access to software options that will help when correcting the error. Error messages may describe an MHS malfunction, a defect in the program or device (such as PRS/ VLL teach or find failure), the entry of unacceptable information, a missing wire, missing ball, or other machine malfunction. 98888-0000-JB3-01 Introduction 1-11 IConn High Performance Wire Bonder 1. 1.6 6 MHS So Sofftw twar are e Fu Fun ncti ction ons s The following MHS functions are programmed or can be accessed through machine software, using the control panel and graphics displays presented on the monitor. 1. 1.6 6.1 MH MHS S Co Conf nfig igur urat atio ion n Dimensions and settings related to the carriers, devices, and magazines used during the bonding operation entered through the MHS configuration menus. Workholder configuration canare be accessed by making the following selections: 1-6.) Magazine handler configuraCONFIGURE and [6] WORKHOLDER (See Figure 1-6.) tion can be accessed by selecting CONFIGURE and [7] MAG HANDLER. Refer to IConn Operation Manual, Section 5, for descriptions of workholder and magazine handler configuration menus, dialog boxes, and parameters. Select #7 Select #6 Press ESCAPE (or click on menu title) Fi g ure 1-6 MHS C onfig urat uration ion (Workholder (Workholder and and Mag Mag azine Handl Handler) er) 1. 1.6 6.2 MH MHS S Ca Cali libr brat atio ion n The MHS Workholder Calibration functions can be found in the CALIBRATION mode > [4] WORKHOLDER (See Figure 1-7.) 1-7.) The following is a brief description of each function. • WORKHOLDER: This function contains several workholder calibrations: pedes- tal insert focus height calibration, bond height calibration, location of the diagonal center of the bonding area, rail calibration, preheat block height calibration. • HEAT BLOCK: Teaches the pedestal bond height position. This calibration is also part of the Workholder Calibration function. It has been made available as a separate function so that the user can avoid running the entire workholder calibration after replacing the pedestal insert. • 1-12 TUCKER EJ EJECT: Determines the distance from the index gripper home position to the index gripper position where the working end of the tucker is aligned with the outer surface of the output magazine handler side wall. Introduction 98888-0000-JB3-01 Material Handling System Manual Select #5 Select #4 Press [DONE] Fi g ure 1-7 1-7 MHS C alibra librattion Menu Menuss • WORKHOLDER CALIBRATION: Displays a dialog box containing the results of all the workholder calibrations. of the items in user. the dialog box are for viewing purposes only and cannot beAllchanged by the The MHS Magazine Handler Calibration functions can be found in the CALIBRATION mode > (5) MAG HANDLER (See Figure 1-7.) 1-7.) These functions are: • INPUT TRAYS: Establishes locations of the input side magazine trays. • OUTPUT TRAYS: Establishes locations of the output side magazine trays. • INPUT SLOT: Establishes location of the workholder rails in the Y and Z axes with regard to the input magazine handler gripper. • OUTPUT SLOT: Establishes location of the workholder rails in the Y and Z axes with regard to the output magazine handler gripper. • CALIBRATION RESULTS: Displays a dialog box containing the results of all the magazine handler calibrations. All of the items in the dialog box are for viewing purposes only and cannot be changed by the user. See Section 2: Workholder, for more information concerning workholder calibrations. See Section 3: Magazine Handlers, Handlers , for information concerning magazine handler calibrations. 1.6.3 MHS U Uttili litties ies The MHS Utilities are accessed by selecting MANUAL and then [3] MHS UTILITIES. (See Figure 1-8.) 1-8.) These utilities allow manual control of MHS subsystems. Refer to Section 5 for more information. Utilities available are: • IND IN DEX UT UTIL ILIITIES Allow the operator to adjust the number of index cycles, reset the index count, verify correction, inhibit strip injection, select or stop an indexing mode, park the index gripper at a safe safe location, and home the index gripper. • HEA HE AT BLO BLOCK UT UTIL ILIT ITIE IES S Allow the operator to position the bond site heat block at an entered offset value from its raised position and to raise the heat block to bond plane height, lower tthe he heat block to carrier clearance height, or home the heat block. • PREH PR EHEA EAT T BLO BLOCK CK UT UTIL ILIT ITIE IES S Allow the operator to move the preheat block at its raised position, carrier clearnace position, or home position 98888-0000-JB3-01 Introduction 1-13 IConn High Performance Wire Bonder • PIN UTILITIES Allow the operator to raise /lower/home the puller pin, raise or lower the indexer pin, and raise or lower the tucker. Select #3 Press [DONE] 1-8 A cces s to MHS MHS Ut Utilit ilities ies (Manua (Manual Mod Mode) e) Fi g ure 1-8 1.6.4 1.6 .4 MHS Mag Magazi azine ne U Util tilitie ities s (W (With ithout out Saf Safety ety Cov Covers ers)) The standard Mag Handler Utilities dialog box appears when MAG OPER is selected from the upper function bar (see Figure 1-9 1-9). ). The functions listed in this dialog box allow the user to send a command to either magazine handler to perform a single action. Select #8 Fig ure 1-9 1-9 S ta tanda ndard rd Mag Mag Han Handl dler er Utilit Utilities ies Dial Dialog og B ox NOTE: If the magazine handlers are enclosed within safety covers, the Mag Handler Utilities dialog box contains ‘Latch’ and ‘Unlatch’ commands in addition to those shown in Figure 1-9. output 1-9. These magazine commandshandler are used to manipulate the locks on the input and access doors. Safety covers are optional equipment and will not be present on all IConn machines. The Mag Handler Utilities dialog box selections and their function are defined as follows: • [1]] [1 JOG JO G INP INPUT UT// OUTP OUTPUT UT MA MAG G Causes the supply magazine to step to the next slot. • REVERS ERSE E JOG JOG INPUT INPUT// OUTPU OUTPUT T MAG MAG Causes the supply magazine to step [2] REV backward to the previous slot. • [3] [3] EJEC EJ ECT T INPU INPUT/ T/ OUT OUTPU PUT T MAG MAG Causes the supply magazine currently in use to be placed on the Unload tray. • 1-14 [8]] [8 MAG MA G SE SELE LECT CTIO ION N Toggles INPUT mode or OUTPUT mode. Introduction 98888-0000-JB3-01 Material Handling System Manual 1. 1.6. 6.5 5 MH MHS S Wo Work rkho hold lder er U Uti tili liti ties es The Workholder Utilities menu appears when W/H OPER is selected from the tool bar. (See Figure 1-10) 1-10) The functions listed in this menu allow the operator to send a command to the workholder to perform a single action or call up a dialog box listing additional commands. Select DONE to exit dialog Fi g ure 1-10 Workhold Workholder er Ut Utilit ilities ies Di alo logg B ox The workholder utilities are defined as follows: • • [1]] [1 STO TOP P IND INDEX EXIN ING: G: Halts the indexing of carriers through the workholder. [2 [2]] PUL ULL L BO BOAT IN IN:: Causes the workholder to pull a carrier from the input (left– side) magazine. • [3 [3]] • [4 [4]] • BOAT INJ INJEC ECT T: Opens another dialog box. That dialog box, shown in Figure 1-11, 1-11, allows the operator to set the ON or OFF status of the puller for pulling carriers from the input (supply) magazine into the workholder. Once the desired setting is made, the user selects DONE which causes the Workholder Utilities dialog box to appear. EJE JECT CT BO BOAT AT:: Causes the workholder to push a carrier into the output (right–side) magazine. CLEA CL EAR R WOR WORKH KHOL OLDE DER: R: Causes the workholder to remove all carriers. [5 [5]] • [1] BOAT INJECT OFF: Halts carrier injection. No additional carriers are pulled into the workholder. Those carriers already in the workholder are processed normally (unless Stop Stop Indexing is activated) and then ejected into the output magazine. • [2] BOAT INJECT ON: Restores normal operation. Fi g ure 1-1 1-11 1 B oa oatt Inject Dial Dialog og B ox • HEA EAT T BLO BLOC CK: Allows the user to perform heat block related functions. Pressing [6] causes the Heat Block dialog box to appear as shown in Figure 112 . Once the desired setting is made, the t he user selects DONE which causes the Workholder Utilities dialog box to appear. [6]] [6 • [1] LOWER HEAT BLOCK: Causes the heat block to be lowered to the index- ing height (i.e., the position below the boat, so as to clear the boat during the indexing of a device). • [2] RAISE HEAT BLOCK: Causes the heat block to be raised to the bonding height. 98888-0000-JB3-01 Introduction 1-15 IConn High Performance Wire Bonder • [3] HOME HEAT BLOCK: Causes the heat block to be lowered to the home position. Fi g ure 1-12 C lamp Di alo logg B ox • HEAT HE AT BLO BLOCK CK VAC VACUU UUM: M: Opens the dialog box shown in Figure 1-13 1-13.. The user may then set the vacuum to On or Off. Once the desired setting is made, the user selects DONE which causes the Workholder Utilities dialog box to appear. [7 [7]] • [1] HEAT BLOCK VACUUM ON: Applies heat block vacuum. • [2] HEAT BLOCK VACUUM OFF: Removes heat block vacuum. Fi g ure 1-13 1-13 Hea Heatt B lo lock ck Vacuum Dial Dialog og B ox 1.6.6 1.6 .6 MHS Aut Auto o Ru Run n Co Confi nfigur gurati ation on ((Ind Indexi exing ng T Type ype)) The type of MHS indexing to be used while the bonder is operating in Auto mode is selected in the AUTO RUN CONFIGURATION dialog box. This dialog box is key, (6) CONFIGURE AUTO, and (2) AUTO accessed by selecting the AUTO mode key, 1-14)) The (6) INDEXING option is selected to change indexing RUN. (See Figure 1-14 type. NORMAL Indexing should be selected for normal production operations. Refer to IConn Operation Manual for more information concerning Auto Run configuration. 1-16 Introduction 98888-0000-JB3-01 Material Handling System Manual Select #2 Select #6 Select Done Select Done Fig ure 11-14 14 A ccess to Auto Auto Run Config ura urattion Dial Dialog B ox 1.6.7 .6.7 MH MHS S Diag Diagno nost stic ics s Diagnostic routines related to the material handling system may be accessed in 1-15)) Refer to Section 5 for more information conDiagnostic mode. (See Figure 1-15 cerning diagnostic routines. • WORKHOLDER CYCLING: Allows the operator to verify workholder motor opera- tions. • MAG HANDLER CYCLING: Allows the operator to verify magazine handler motor operations. • TEMPERATURE CONTROLLER: Diagnostic display for workholder temperature control system. Useful when diagnosing problems with preheat, bond site, and • post–heat heaters. RE-INITIALIZE MHS: Starts an MHS initialization sequence in which all axes of motion of the workholder and magazine handlers are moved to home positions. • MAINTENANCE DIAGNOSTICS: Diagnostic display that shows status of sensors. Useful when diagnosing problems with workholder or magazine handler hand ler sensor sensors. s. • 98888-0000-JB3-01 BAR CODE DIAGNOSTICS: Diagnostic display that allows the user to test operation of bar code reader (optional) that may be mounted on the input and output magazine handlers. This option is active only if bar code reader are present on the machine. Introduction 1-17 IConn High Performance Wire Bonder #1 SelectSelect #1 Select Select #2#2 Select#3 #3 Select Select #5 Select #5 Select #1 Select #1 Sensor Diagnostics (See Section 5) Sensor Diagnostics (See Section 5) Fig ure 11-15 15 A ccess to MHS Diagnos tics Menus Menus 1.7 Operatin ting P Prrocedures res The following procedures are those commonly performed when bonding with the J Boat MHS Model 3035 MHS and IConn Bonder. 1. 1.7 7.1 Init Initia iall S Sttart rt– –up NOTE: This procedure assumes that the machine has been previously set up and calibrated, and that a process program is avaliable on the hard disk drive or on a floppy disk for the device and carrier that will be processed. It is also assumed that the correct P–parts (bond site heat block insert and preheat heat block insert) for the carrier and device being processed have been installed. If necessary ne cessary,, install the heat blocks following instructions in paragraph 1.8.4 1.8.4.. Refer to the appropriate kit installation instruction if it is necessary to install equipment for a different type of carrier. CAUTION: Remove all P-parts when prompt to avoid damaging the rails. A. Perform bonder power–up sequence (refer to IConn Operation Manual). Manual). B. Make sure all system pneu pneumatic matic gaug gauges es indicate adequate adequate press pressure. ure. (Refer to IConn Maintenance Manual for pneumatic pneumatic settin settings.) gs.) C. Make sure wi wire re feed system system is correctly correctly configured. configured. 1-18 Introduction 98888-0000-JB3-01 Material Handling System Manual D. Load desir desired ed process program. program. The input magazine magazine handle handler, r, workholder, and output magazine handler are automatically converted to correct positions for selected carrier, device, and magazine. Temperature Temperature controller states (on or off) and set points will be loaded as part of the program. Allow at least 30 minutes for the workholder heaters to stabilize at set–point temperatures. E. Enter “H.B. (heat (heat block) Operator Operator Point”. Point”. Follow instruct instructions ions in the display display. F. Se Sele lect ct AUTO at top of graphics display. G. Place magazines containing containing carriers with with unbonded devices onto the load tray of the input magazine handler. Place empty magazines onto the load tray of the output magazine handler. Make sure that the magazines are correctly oriented to feed carriers into or receive carriers from the workholder and that they are benched against the magazine handler side plate. (See Figure 1-16). 1-16). H. Make sure co correct rrect process process program program name is displayed. displayed. (See Figure 1-5 for location.) I. Ve Verif rify y mast master er bond bond para paramet meters ers.. Z Tower Assembly Input Tray Unload Tray Note: When placing magazine on load tray tray,, make sure magazine is parallel to front edge of motorised tray and benched against input side plate Input Magazines Wall Magazines Magazine guide should be set approximately 1/1 in. (1.5mm) from end of magazine Place magazine on load tray belts. Belts move magazine to pickup position. Load Tray Fi g ure 1-16 Load Magazines Magazines on Mag Mag azine Handle Handlerr (Input (I nput Ma Magg azine Handle Handlerr S hown) NOTE: If Bond Position was not previously taught, the machine will require that the user teach the position before it will perform an index. Refer to Section 2 for information concerning MHS Teach. J. Press [INDEX] to initiate carrier indexing. The input magazine handler picks up a magazine from the load tray and align the first boat in that magazine with the workholder. The boat is then pulled from the magazine onto the workholder rails and indexed to where the bond site heat block raises the first device to bond height. 98888-0000-JB3-01 Introduction 1-19 IConn High Performance Wire Bonder K. Pr Pre ess [RUN/STOP] key on control panel to start automatic bonding. Press [AUTO INDEX] for automatic indexing (if desired). 1.7.2 1.7 .2 Loa Load/U d/Unlo nload ad Mag Magazi azines nes Dur During ing Bon Bondin ding g NOTE: If Safety Covers are installed on the magazine handlers, the magazine handler access doors must be unlatched and opened in order to load/ unload magazines. The door latches are controlled through options on the Mag Handler Operations menu that can be called up by a tool bar button. A. Select MAG OPER. B. Load additi additional onal magazines magazines of carriers carriers onto the load tray of the input magazine magazine handler and empty magazines onto the load tray of the output magazine handler, as finished magazines are placed on the unload trays (See Figure 1-16 1-16). ). C. Do not allow the magazi magazine ne handler load trays trays to become empty or operati operation on will be halted. D. Remove mag magazines azines from unload unload trays. Do not allow the unload unload trays to remain full or operation will be halted. 1. 1.7 7.3 Sto top pA Au uto Bon ondi ding ng NOTE: This procedure assumes that the operator wishes to halt the auto bonding operation before all carriers in the input magazines are bonded. A. Select W/H OPER button on tool bar (see Figure 1-10 1-10). ). B. Set [5] BOAT INJECT. The Boat Inject dialog box appears (see Figure 1-1 1- 11). C. Sele Select ct [1] BOAT INJECT OFF . Select DONE to exit the Boat Inject dialog box. Select DONE to exit the Workholder Utilities dialog box. D. Bonding wil willl continue until until all remaining carriers carriers in the workholde workholderr are bonded and ejected into an output magazine. No new carrier will be pulled into the workholder from the input magazine. 1. 1.7. 7.4 4 Cl Clea earr L Lea eadfr dfram ames es fr from om In Inde dexe xerr NOTE: Use the procedure that follows if bonding has been halted with carriers in the workholder, and bonding will not be continued. A. Select W/H OPER button on the tool bar (see Figure 1-10). 1-10). B. Sel Select ect [3] EJECT BOAT from Workholder Utilities dialog box. Carriers in workholder are moved into the output magazine. C. Sele Select ct DONE to exit the Workholder Utilities dialog box. 1.7.5 1.7 .5 Rem Remove ove Mag Magazi azines nes Fro From mM Maga agazin zine eH Hand andler lers s NOTE: This procedure assumes that bonding is halted and that there are magazines in the magazine handler grippers. A. Select MAG OPER button on the tool bar (see Figure 1-9 1-9). ). B. Sel Select ect [3] EJECT INPUT MAG. and [7] EJECT OUTPUT MAG. from the Mag Handler Utilities dialog box. 1-20 Introduction 98888-0000-JB3-01 Material Handling System Manual NOTE: If Safety Covers are installed on the magazine handlers, the magazine handler access doors must be unlatched and opened in order to load/ unload magazines. The door latches are controlled through options on the Mag Handler Operations menu that can be called up by a tool bar button. C. Remov Remove e magazines from from the load tray and unload tray of the input magaz magazine ine handler. D. Remov Remove e magazines magazines from the load tray and and unload tray of the output output magazi magazine ne handler. E. Se Sele lect ct DONE to exit the Mag Handler Utilities dialog box. 1.7.6 1.7 .6 Bon Bonder der/Wo /Workh rkhold older er Sys System tem Shu Shutd tdown own NOTE: This procedure secures the bonder/workholder at the end of a shift/day shift/day.. A. On wire feed system, press the [AIR GUIDE] and [TENSIONER] buttons on the MMI to turn off air pressure. (AIR GUIDE and TENSIONER LED indicators OFF.) B. Make sure sure carriers carriers are removed removed from workholde workholder. r. C. Make sure mag magazines azines are are removed from from magazine magazine handlers handlers.. NOTE: The [MOTOR STOP] key has two (2) actuators, and is comprised of two (2) key switches. Both actuators must be pressed at the same time to activate the Motor Stop function. This arrangement prevents accidental activation of Motor Stop. D. Pr Pres ess s [MOTOR STOP] (key lamp in [MOTOR STOP] key goes ON.) The bonder enters Standby Mode. E. Machine Machine power may may be turned off off at the Main Main Power circuit circuit breaker breaker if desired. desired. 98888-0000-JB3-01 Introduction 1-21 IConn High Performance Wire Bonder 1.8 Product Conversi rsion (Figure 1-17) START Heat block inserts right type for boat?* NO Install new heat block inserts. Perform heat block calibration. YES Load process program from disk. disk. NOTE: If process program program has not been taught, refer to IConn Operation Manual. MHS Configuration file for boat on disk? NO Enter boat/device/magazine dimensions and parameters as needed. YES Check MHS operatio operation n. Check/edit MHS parameters and dimensions. NO MHS operation OK? YES DONE Fi g ure 1-1 1-17 7 Pr oduct C onve onvers rs ion S eq equen uence ce 1-22 Introduction 98888-0000-JB3-01 Material Handling System Manual 1.8.1 1.8. 1.8.2 2 Tools/Pa /Parts • Pr Preh ehea eatt B Blo lock ck In Inse sert rt • Bond Bond Si Site te Heat Heat Blo Block ck In Inse sert rt • M4 x 1 1 1/2 /2”” Sock Socket et Hea Head d Cap Cap Scre Screw w (SHC (SHCS) S) Re Repl plac ace e He Heat at Bl Bloc ock k In Inse sert rts s The following steps show the replacement of the preheat block insert and bond site heat block insert. This procedure assumes that the workholder has been cleared of all material, the temperature controllers are on, and the workholder heating zones are at their operating temperature WARNING: DO NOT TOUCH THE HEAT BLOCK, THE INSERT INSE RT OR OTHER PARTS WITHIN THE WORKHOLDER RAILS IF THE TEMPERATURE CONTROLLERS ARE ON. THESE ITEMS ARE EXTREMEL EX TREMELY Y HOT AND WILL INSTANTL INSTAN TLY Y BURN UNPROTECTED SKIN. controllers NOTE: In the following procedure, it is assumed that the temperature controllers are on and the workholder heating zones are at operating temperatures. A. Turn the temperature controllers off: 1. Se Sellect [4] CONFIGURE from the mode bar. b ar. 2. Se Sellect [4] TEMPERATURE from the Configure mode menu. 3. Sele Select ct th the e TURN ALL ZONES OFF button in the Temperature Set Points dialog box. While the heat block cools, observe its temperature reported in the temperature status display on the monitor (see IConn Operation Manual for location). WARNING: DO NOT CONTINUE WITH THIS PROCEDURE OR ATTEMPT TO TOUCH EITHER HEAT BLOCK OR ITS INSERT UNTIL THEY HAVE COOLED. B. Remove Remove the heat block inserts inserts on the preheat preheat and/or and/or bond site. 1. Install Install a M4 x 38 mm screw screw into the tapped tapped hole hole at the rear edge edge of the insert. 2. Use a small small amount of pressure pressure to pull pull the insert insert to th the e front rai rail. l. This action lift up the rear edge of the insert out of the heat block. 3. Remove the insert insert from the the heat heat blo block. ck. C. Insta Installll the heat block block insert on the preheat preheat and/or and/or bond site. 1. Hold the insert insert at 45 degrees degrees angle, angle, with with the fron frontt side points points dow down. n. 2. Install Install the insert to the heat heat block unti untill the notch at it its s front-bo front-bottom ttom edge engage to the pin on the heat block. 3. Use a small small amount of pressure pressure to to push the insert insert down until until it moves moves quickly into the heat block. D. Remove the screw screw from from the insert. insert. E. Refer to section section 2 to calibrate calibrate the the workholder workholder.. 98888-0000-JB3-01 Introduction 1-23 IConn High Performance Wire Bonder 1. 1.8. 8.3 3 Lo Load ad E Exi xist stin ing gP Pro roce cess ss Pr Prog ogra ram m A. Click on PROGRAM at the mode bar. Select [1] LOAD/SAVE/CLEAR from the Program Mode menu to clear the current process program. B. Cl Cliick on [3] LOAD PROCESS PROGRAM. A dialog box appears listing the available process programs. C. Scroll thro through ugh the list on the display to find the process process program file for the device that will be processed. Click on the process program file name. Click on LOAD to load the program. D. A message appe appears ars in the displaying displaying stating stating that the setu setup p procedure procedure must be performed. Click on OK, then perform setup. Refer to Section 2 of this manual for Teach Teach Bond Position P osition procedure. E. Press [ESCAPE] key as needed to exit Program Mode. 1.8.4 MHS Mater Material ial D Dimens imension/P ion/Parame arameter ter File Hand Handling ling When performing product conversion, the user can change MHS configuration to fit the new product by either using the K&S prepackaged software supplied with the machine or by editing configuration parameters in Configuration mode. The prepackaged software eliminates the task of entering each parameter and dimension separately via the GUI software. It can only be used when the process program uses a 3.1 inch to 4.3 inch wide boat. If the prepackaged MHS software does not conform with the boat that will be used, the user must manually enter MHS dimensions and parameters through Configure mode. The following paragraphs overview the procedures required to do this. The dimensions and parameters that reside under the Workholder configuration menu are defined in Section 2 and those that reside under the Mag Handler configuration menu are defined in Section 3. 1. 1.8. 8.4. 4.1 1 Edit Edit Wor Workh khol olde derr Conf Config igur urat atio ion n To edit the configuration of the workholder (see Section Sectio n 2.5 2.5,, Figure 2-72 2-72): ): A. Select [4] CONFIGURE from the mode bar. B. Sel Select ect [5] WORKHOLDER from the Configure mode menu . C. Do the fol following lowing from from the Workhold Workholder er menu: 1. Sel Select ect [1] DEVICE PARAMETERS. Enter the boat/device dimensions and, as required, set the index hole at the end of the boat to TRUE or FALSE. Select APPLY, and then DONE after all changes have been made. 2. Select [2] INDEXING PARAMETERS. Enter the index parameter values. Select DONE after all changes have been made. 3. Select [3] INDEXING OPTIONS. As required, set the indexing options to yes or no. Select DONE after all changes have been made. 4. Sel Select ect [4] WORKHOLDER CONFIGURATION. As required, set CHECK DEVICE OVERHEAT and CHECK HEAT BLOCK VACUUM to ON or OFF. Enter the workholder configuration parameters. Select APPLY, and then DONE after all changes have been made.. NOTE: All parameters accessed through the Workholder menu selection [5] RESERVED PARAMETERS cannot be configured by b y the user. 5. Press [ESCAPE] as needed to exit the Configure mode. 1-24 Introduction 98888-0000-JB3-01 98888 0000 JB3 01 Material Handling System Manual 1. 1.8. 8.4. 4.2 2 Edit Edit Maga Magazi zine ne Hand Handle lerr Para Parame mete ters rs:: To edit the configuration of the magazine handler (see Figure 1-6). 1-6). 1. Se Sellect [4] CONFIGURE from the mode bar. b ar. 2. Se Sellect [7] MAG HANDLER from the menu. 3. Se Sellect [1] MAGAZINE PARAMETERS from the Mag Handler configuration menu. In the dialog box, select INPUT to enter dimensions for the input only, or BOTH for both magmagazines only, only, OUTPUT for output magazines only, azines. Enter values for the magazine dimensions. Select DONE after all changes have been made to the dialog box. 4. If INPUT or OUTPUT was selected in step 1, open the Magazine Dimensions dialog box again and select the remaining magazine type (Input or Output). Enter dimensions for that magazine, then select DONE. 5. Se Sellect [2] MAG INDEX PARAMETERS. Enter magazine index parameter values. Select DONE after all changes have been made to dialog box. 6. Se Sellect [3] MAGAZINE SLOT ORDER. Select and define a sequential slot order, or enter a user–defined slot order, for input and/or output magazines. 7. Se Sellect [4] MAGAZINE ALIGNMENT. Enter magazine alignment parameter values. Select DONE after all changes have been made to dialog box. 8. Se Sellect [5] MAG CONFIGURATIO CONFIGURATION N. Enter magazine index parameter values. Select DONE after all changes have been made to dialog box. 9. Se Sellect [6] MAGAZINE EJECT OPTIONS. Enter magazine index parameter values. Select DONE after all changes have been made to dialog box. 10.Select [7] TEACH INPUT MAG SLOT . Enter magazine index parameter values. Select DONE after all changes have been made to dialog box. 11. Select [8] TEACH OUTPUT MAG SLOT. Enter magazine index parameter values. Select DONE after all changes have been made to dialog box. 12.Press [ESCAPE] as needed to dismiss all menus. 13.Select SAVE BND button from the tool bar to save the MHS information as part of the current process program. 1. 1.8. 8.5 5 MH MHS S Op Oper erat atio ion n Ch Chec eck k A. Place a magazine filled with sample carriers (same type that will be used in production) on the input magazine handler load tray. B. Place an empty empty magazine magazine on the output magazine magazine handl handler er load tray tray.. C. Make sure there is no material in the workholder. workholder. If there is, click on the W/H OPER button on the tool to ol bar. Select [3] EJECT LEADFRAME. The carrier will be ejected from the workholder output. Select DONE to remove dialog box from display. D. Se Sele lect ct MANUAL mode. Select [4] MHS UTILITIES from the Manual mode menu. Select [1] INDEX UTILITIES. CONTINUOUSLY SLY. Select APPLY. MHS operations begin: E. Se Sele lect ct NORMAL INDEX CONTINUOU 1. The input magazine magazine handler handler will grasp grasp the magazine magazine on the load plat platform form and position the first slot level with the workholder. The output magazine handler grasps the empty magazine on the load platform and positions its first slot to receive a carrier from the workholder. 2. The leadframe leadframe in the first first slot is pulled pulled by the pull puller er into the wo workhold rkholder er and moved to a position where it can be picked up by the index gripper. 3. The index index gripper moves moves the first first devi device ce on the ca carrier rrier to the b bondsit ondsite e where it is aligned, positioned, and clamped. The device is unclamped and the next device is moved to and clamped at the bond site. This continues until all devices devices of the carrier have been clamped. clamped. Introduction 98888 0000 JB3 01 Introduction 1 25 IConn High Performance Wire Bonder 4. After the last last device is unclampe unclamped d the tucker on the index index gripper pus pushes hes the carrier into a slot in the magazine held by the output magazine handler gripper. 5. The indexing indexing cycle continues continues until until stopped stopped by the user or until th the e input magazine runs out of carriers. F. Observe Observe the magazine handlers handlers and wo workholde rkholderr as they operate. If an error error is indicated, note the information given in the error dialog box on screen, then click on CONTINUE . If the MHS will not continue to operate and the error dialog box is displayed again, click on ABORT, then refer to the troubleshooting information in Section 5 of this manual. G. When satisfied satisfied that the MHS is operating operating properly or that all opera operational tional pro probblems have been identified, select the WH OPER button on the GUI tool bar. Select [1] STOP INDEXING from the Workholder Utilities menu. Click on CANCEL to exit the menu. Select DONE to exit the menu. H. Sele Select ct MAG OPER from the tool bar (see Figure 1-10 ). Select [3] EJECT INPUT MAG and [7] EJECT OUTPUT MAG to eject the input and output magazines. Select DONE to exit the Mag Handler Utilities menu. Select W/H OPER from the tool bar and select [4] CLEAR WORKHOLDER. Use tweezers to remove leadframes from the workholder. Select DONE to exit the Workholder Utilities menu. I. Adjust magazin magazine e dimensions, dimensions, leadfra leadframe me dimensions, dimensions, and MHS p paramete arameters rs as needed to correct problems noted while the MHS was operating. Save MHS configuration when done. Refer to Section 2 for more information. 1 26 Introduction 98888 0000 JB3 01 Material Handling System Manual 2 Workholder 2.1 About tth his s se ection Here is what you will find in this section: • Section 2.2 2.2,, Description Description,, gives an overview of the J boat workholder and how it functions with the IConn High Perfromance Wire Bonder. There is also a brief description of all the major components of the J boat workholder. • Each Each se sect ctio ion n from from Sect Sectio ion n 2.3 through 2.9 details the calibration, operating instructions and maintenance procedures for the workholder: • Section 2.3, 2.3, Setups and Adjustments, details the initial hardware setup of the workholder. • Procedures. Section 2.4, 2.4, Workholder Calibration Procedures. • Section 2.5, 2.5, Workholder configuration. • Section 2.6, 2.6, Workholder Removal and Installation • Section 2.7, 2.7, J Boat Slider Assembly Removal and Installation • Section 2.8, 2.8, Preventive Maintenance. • Section 2.9, 2.9, Parts Installation Procedures. Workholder 98888-0000-JB3-01 21 IConn High Performance Wire Bonder 2.2 Description The J boat workholder contains the mechanisms and assemblies to index boats from the input magazine handler, to the bond site, then onto the Output Magazine Handler. It also supplies heat to the device, lifts the device from the boat for bonding, and holds the device during bonding at the bond site. 2. 2.2 2.1 Ma Majo jorr C Com omp pon one ent nts s The major components of the workholder are: • Sl Sliider As Ass sembly This assembly contains the heat block assembly that holds and heat up each device on the carrier during bonding operation. • Bo Bond nd Sit Site As Asse semb mbly ly The bond site assembly contains heat block that heats the device to the temperature necessary for bonding. It lifts up the device to the bond height and hold down the device during the bonding operation. Bond Site Heat Block Assembly Bond Site Heat Block Motor Bond Site Assembly Fi g ure 2-1 S lider As s em embl bly: y: Major Major Compone Component ntss 22 Workholder 98888-0000-JB3-01 Material Handling System Manual • In Inde dexe xerr Asse Assemb mbly ly The indexer assembly contains the mechanisms to move the carrier for extraction, indexing and ejection. • Puller As Ass sembly The puller pin pulls a boat within the input magazine and pulls it into the workholder. • X Regi Regist stra rati tion on Se Sensor nsor Finds the leading edge of the boat when is injected into the workholder. • Fron Frontt and and Rear Rear Rail Rails s Support the boat as it is indexed in dexed through the workholder in the X axis direction and in the Y axis direction to the correct boat width. • Prehea heat Ass Asse embl mbly The preheat assembly contains heat block that increases the temperature of the device before bonding that is necessary for bond formation (hot processes). • In Inde dex/ x/T Tuc ucke kerr Asse Assemb mbly ly Indexes the boat through the workholder in the X axis for device bonding and, once all devices have been bonded, tucks (pushes) the boat into the output magazine. • Air Ma Manifold Distributes air pressure from the bonder main manifold to pneumatic devices on the workholder. • Moto Motorr Ass Assembl embliies. es. Move the workholder assemblies (i.e, puller, heat blocks and index/tucker) via leadscrew or rack and pinion drive. Workholder 98888-0000-JB3-01 2-3 IConn High Performance Wire Bonder J Boat Present Sensor (Input) X Registration Sensor Preheat Heat Block Assembly Puller Assembly Index/Tucker Assembly Rear Rail J Boat Present Sensor (Output) Puller Motor Indexer Motor Front Rail Rail Height Spac Spacer er X Axis Leadscrew Assembly PCB Cover Indexer Intermediate Board (Hidden) Rail Height Spac Spacer er Fi g ure 2-2 2-2 Indexer As s em embl bly: y: Major Major Compone Component ntss (F ront View) 2-4 Workholder 98888-0000-JB3-01 Material Handling System Manual Index/Tucker Assembly Boat Present Sensor Amplifier (Output) Rear Rail Front Rail Boat Present Sensor Amplifier (Input) Puller Assembly Preheat Assembly Preheat Motor Fi g ure 2-3 2-3 Indexer A s s em embl bly: y: Major Major Component Componentss ( R ea earr View) Refer to Section 4 of this volume for information concerning the stepper motor control system. 2. 2.2. 2.2 2 Wo Work rkho hold lder er Sub Subsy syst stem ems s The position and the function of each workholder subsystem are specified in this section. The subsystems are: 2.2.2.1 • Pu Pulller Assem ssemb bly • Fr Fron ont/ t/Re Rear ar Ra Rail il Ass Assem embl blie ies s • Preh Prehea eatt Heat Heat Blo Block ck Ass Assem embl bly y • Bon Bond d Sit Site e Hea Heatt Blo Block ck As Asse semb mbly ly • In Inde dex/ x/T Tuc ucke kerr Ass Assem embl bly y • J Bo Boat at MHS MHS Pneu Pneuma mati tic c Sys Syste tem m • In Inde dexe xerr Inte Inteme medi diat ate e Boar Board d Puller As Assembly During the operation, when a boat is sensed by the th e sensor at the input magazine, the motor operates the rack and pinion to move the puller assembly in the X axis direction to the pick-up position in the magazine. At this point, the puller solenoid de-energizes and the puller pin moves to the up position. The puller assembly pulls a boat from the input magazine to the preheat site of the indexer assembly for indexing. Workholder 98888-0000-JB3-01 2-5 IConn High Performance Wire Bonder It contains the following parts: • Puller Finger Operates in three positions: pin up, pin down and pin trigger position. (The pin is at up position when pulling a boat from the magazine). • Pul Puller So Solenoid Controls the pin up/down position of the puller pin. (The solenoid is de-energized when the puller pin moves up.) • Pulle Pullerr Pin Pin Se Sens nsor or and and Fig Figer er Flag Flag Used to determine the sensor triggering position of the puller pin. • Motor Moves the puller assembly along the indexer assembly in the X axis direction by the rack and pinion drive. • Home Sensor Detects the home positioin of the puller assembly on the inde indexer xer assembly. 2. 2.2. 2.2. 2.2 2 Fr Fron ont/ t/Re Rear ar Ra Rail il Asse Assemb mbli lies es The front/rear rail assemblies support and guide the boat as it moves through the indexer assembly. The width of the front/rear rail is set manually according to the width of the boat. Each contains the following subassemblies: • Fron Frontt a and nd Rear ear R Rai ails ls Support and guide the boat as it moves through the indexer assembly in the X axis direction movement. 2. 2.2. 2.2. 2.3 3 Preh Prehea eatt Heat Heat Bl Bloc ock k Asse Assemb mbly ly The preheat block assembly increases the temperature of the device before it is at the bond site position. During operation, the preheat motor operates the preheat block in the vertical movement along the linear slider. Before the boat is indexed, the preheat block is lowered. When a device is at the preheat site, the preheat block moves up to the "pick up" position to move the device up above the top surface of the boat for heating. After the device is heated, the preheat block is lowered and the device is placed on the top surface of the boat. The preheat block then moved to the home position as detected by the home sensor, and the device is indexed to the bond site. Each contains the following subassemblies: • Preh Prehea eatt Hea Heatt B Blo lock ck Mo Moto torr Moves the preheat block vertically. • Linear Sliders Allows the heat block to move smoothly in the vertical (V) axis based on the programmed boat and device dimensions. • Base Block Supports the heat block. • Heater Ca Cartrid ridge Heats the heat block site to the temperature set during configuration. (Heat is provided by a 250 watt element fitted inside the cartridge that operates under control of a temperature controller circuit.) • Thermocouple Monitors the temperature of the heater cartridge. (The thermocouple is seated inside the cartridge.) • Home Sensor Detects the home position of the preheat heat block. 2-6 Workholder 98888-0000-JB3-01 Material Handling System Manual 2. 2.2. 2.2. 2.4 4 Bond Bond Site Site Heat Heat Bl Bloc ock kA Ass ssem embl bly y At the bond site, the bond site motor transfers drive to the heat block via the leadscrew allowing it to move vertically along the linear slider. Before the boat is indexed , the heat block is lowered. Once a device reaches the bond site, the heat block is raised to heat the device and to lift it to bond height. While the device is out of the boat, vacuum secures it to the heat block for bonding. Once the device is bonded, the heat block to the heat block to move to its lower position via the linear slider; vacuum is turned OFF releasing the device onto the boat; and heat block is moved to the home position as detected by the home sensor. 2.2 .2.2 .2.5 .5 In Inde dex/ x/T Tuc ucke kerr Ass Assem emb bly In operation, the indexer/tucker assembly is positioned in relation to the boat so that the indexer pin is above an index index hole. The air cylinder then activates causing the indexer pin to move, via the cross roller way slider, to its down position and pin the boat. Once pinned, the indexer motor provides drive via the leadscrew to move the indexer along the X axis linear slide. In this way the boat is moved from left to right until the all devices are bonded. After the last device is bonded, the tucker solenoid energizes and the tucker moves to its down position. As the indexer/tucker assembly moves to the right, the tucker pushes the boat into the output magazine. If greater than normal resistance to boat motion is detected during boat indexing or ejection, the index overload sensor will stop the operation. operat ion. At this point, the user will be instructed to clear the jam and restart the operation. • Indexer Motor Transfers drive to the indexer/tucker assembly as sembly via the leadscrew. • Li Lin near Sl Sliiders X Axis - allows the index/tucker assembly to move in the X axis. Cross Roller Way - allows the index pin to move in the Y axis. • Coupling Couples the indexer motor to the leadscrew. Reduces any misalignment between the motor and the leadscrew while minimizing backlash. • Index Pin Holds the boat during indexing. • Ind Index ex Pin Pin Pos Posit itio ion n Sens Sensor ors s and and Fl Flag ag Two sensors detect the current vertical position of o f the pin: raised position, lowered position with pin engaged in a boat indexing hole, or lowered position with no boat under the index arm. • In Inde dex x Over Overlo load ad Sens Sensor or Detects greater than normal resistance to boat motion during boat indexing and ejection operations. Too much resistance to boat motion mot ion indicates the boat is jammed. • A ir C Cy ylinder Causes the indexer pin to move to its down position and pin the boat. • Tuc ucke kerr Sole Soleno noid id (1 (12 2 vol volt) t) Controls the up and down position of the tucker. • Tucker Pushes the boat into the output magazine once the last device on the boat is bonded. Workholder 98888-0000-JB3-01 2-7 IConn High Performance Wire Bonder 2. 2.2. 2.2. 2.6 6 J Boat Boat MHS MHS Pneu Pneuma mati tic c Syst System em The J Boat MHS pneumatic system supply vacuum to the bond site heat block and supply air pressure to t o the air cylinder of the index/tucker assembly. Its components are on the workholder and at other position on the machine. Components of the system are: • 33-Wa Way yV Vac acuu uum m Sole Soleno noid id Val Valve ve Controls the air pressure supply to the air cylinder that moves the index pin to its up or down position. It is at the rear of the front wall assembly of the indexer assembly. • Vac acuu uum m Val Valve ve Asse Assemb mbly ly Controls the vacuum that holds the device to the bond site heat block. It is on the right side of the t he XY table assembly.. • Vacuu acuum m Ge Gene nera rato torr Supply the vacuum used at the bond site from an air pressure input. It is on the upper console assembly. assembly. • Ai Airr Regulator Regulates the air pressure input to the J Boat MHS pneumatic system components. It is on the upper console assembly. • Heat Heat Bl Bloc ock k Vac Vacuu uum m Sens Sensor or Monitors the vacuum that holds the devices at the bond site heat block. If no vacuum or low vacuum is sensed after a device is positioned for bonding, an error is indicated and machine auto operation is stopped. It is on the interface panel. 2. 2.2. 2.2. 2.7 7 In Inde dexe xerr Inte Interm rmed edia iate te Boar Board d The indexer intermediate board has the following functions: • An interface interface between between the IConn card rack rack and and the Workh Workholder older electrical electrical comcomponents. • Supplies Supplies operatin operating g voltage voltages s to the motors, motors, solenoids solenoids and sensors. sensors. The indexer intermediate board is at the front right side of the t he indexer assembly to minimize cable routing within the workholder (see Section 4). 2-8 Workholder 98888-0000-JB3-01 Material Handling System Manual 2. 2.2. 2.3 3 Bo Boat at IInj njec ecti tion on S Seq eque uenc nce e During the boat injection sequence, the workholder extracts a boat from the input magazine and delivers it to the preheat zone through combined motions of the puller assembly and the input magazine handler. The puller engages a boat within the input magazine, pulls it out of its slot, and presents it to the X registration sensor. The puller then moves the boat and position the first device in the boat at the hand-off location (preheat block)(see Figure 2-4). 2-4). Depending on the conditions of the puller pin and boat present sensors, certain types of boat injection injection results can occur from the boat injection injection sequence. Such results are defined in Table 2-1 2-1.. Table 2-1 Boat Injection - Puller Pin Pin and Boat Boat Present Sensor Conditions Conditions Puller Pull er Pin Pin Sen Sensor sor Puller Puller Pin Sens Sensor or Boat Present Sensor Condition Condition Boat Injection Result Boat Detected Pin Up Blocked Move boat to X Registration Sensor Boat Detected Pin Not Up Blocked Stop or retry the same slot Boat Detected Pin Not Up Unblocked Stop or retry the same slot Boat Not Detected Pin Always Up Unblocked Move to the next slot or stop and report error (Optional) Workholder 98888-0000-JB3-01 2-9 IConn High Performance Wire Bonder Magazine Boat Present Sensor Boat X Registration Sensor Rear Rail 1. The boat is ready for injection Puller 2. The puller motor moves the puller finger into the magazine. The puller solenoid deactivates and the puller pin moves to the up position. 3. The puller assembly moves to the workholder. The pin engages one of the hole in the boat. As the puller pulls the boat from the magazine, the boat present sensor detects the boat. 4. The puller moves to the right to the X registration sensor. This cycle is repeated until the sensor is blocked or the software is in the time out mode. Registration finds the leading edge of the boat. 5. The puller moves the boat to the preheat block. The pin stays in the up position until control is transferred to the index. The preheat block lift up the device. Fi g ure 2-4 2-4 MHS B oa oatt Injection S eq equen uence ce (Top (Top View) View) Preheat Block 2-10 Workholder 98888-0000-JB3-01 Material Handling System Manual 2.2. 2.2.4 4 Bo Boat at Trans ransfe ferr Se Sequ quen ence ce During the boat transfer sequence, control of the boat on the workholder rails is transferred from the puller assembly to the indexer assembly (see Figure 2-5). 2-5). Bond Site Heat Block Index/Tucker 1. The workholder prepares to begin the transfer sequence. 2. The puller solenoid activates and puller pin moves to the down position. The puller moves left to make room for the index. 3. The index moves left and then pins the boat at the preheat block. Fi g ure 2-5 2-5 MHS B oa oatt Tra Trans ns fer Sequence Sequence (Top View) 2.2. 2.2.5 5 Bo Boat at In Inde dexi xing ng a and nd E Eje ject ctio ion n Se Sequ quen ence ce During the indexing sequence, the boat is positioned in the workholder where the first device can be picked up from the boat and lifted lifted to bond height by the bond site heat block. At the same time, the temperature of the next device in the boat is raised by the preheat block at the same time). Once the bonding operation is complete for the first device, the boat indexes to the right and presents the next device device for bonding. This sequence continues, and when the last device on the boat is bonded, the boat is ejected into the output magazine (see Figure 2-6 2-6). ). The bonder will stop the indexing or ejection operation if the index overload sensor detects a greater than normal resistance resistance to boat motion. The software, which translates this action to be a boat jam at the workholder output, will display an error dialog box on the monitor. If this occurs, the user should clear the jam and restart the operation 98888-0000-JB3-01 Workholder 2-11 IConn High Performance Wire Bonder FIRST DEVICE First Device 1. With the boat held by the index assembly at the end of the Transfer Sequence, the heat blocks are lowered. The indexer moves the first device on the boat to the bond site. The heat blocks lift up the devices. NEXT DEVICE ON BOAT 1. When the first device has been bonded, the heat blocks are lowered. The index assembly moves the next device on the boat to the bond site. The heat blocks moves up to lift up the devices. 2. The index assembly moves its pin out of the boat index hole. The index assembly moves to the left to the next index position and holds the boat. This position is at the bond site unless there is no hole to hold. Next Device Preheat Block NEXT BOAT Bond Site Heat Block 1.The index assembly moves the completed boat to the right, away from the bond site. 2.The index assembly lifts up its pin, moves to the transfer position, and do the transfer sequence. 3.The index assembly moves the next boat to the bond site position and do the sequence for "First Device". First Device 4.The index assembly lifts up its pin, releases the boat at the bond site. The index assembly moves to the right and lowers the tucker. The tucker ejects the boat into the output magazine. The tucker moves up and the index assembly moves to the left to the bond site and holds the boat. The process continues with the "Next Device on Boat". Fi g ure 2-6 2-6 MHS B oa oatt Indexing and Ejection S eq equen uence ce (Top (Top View) 2-12 Workholder 98888-0000-JB3-01 Material Handling System Manual 2.3 2.3 Se Setu tup ps an and d Adjus djustm tmen entts 2.3.1 .3.1 Se Sett-Up Up Seq eque uen nce The flowchart in Figure 2-7 and Figure 2-8 shows a suggested set–up sequence for the workholder that should be followed after the machine is first installed. Note that the area within the dash–line box contains operations that should be performed whenever the type of carrier or device used in production is changed. The rest of the operations on the flowchart should only be necessary after disassemble/assemble the workholder or after the machine is moved to a different location. START Puller Pin engage correctly? NO Do the Puller Pin setup. See paragraph 2.3.2 NO Do the Index Pin setup. See paragraph 2.3.3.1 NO Do the Bond Site Heat Block Alignment. See paragraph 2.3.4 NO Do the Rail Parallelism Adjustment. See paragraph 2.3.5 YES Index Pin engage correctly? YES Teach Tucker Eject Position. See paragraph 2.3.3.2. Bond Site Heat Block aligned with optical crosshair? YES Is the Rails parallel? YES A Fi g ure 2-7 2-7 Workhold Workholder er S et etup up Sequence, Sequence, S hee heett 1 of 2 Workholder 98888-0000-JB3-01 2-13 IConn High Performance Wire Bonder A Preheat Heat Block aligned with Rails and Bond Site? NO Do the Preheat Heat Block/ Bond Site Alignment. See paragraph 2.3.6 YES Do the Workholder Calibrations. See paragraph 2.4. Correct Heat Block Inserts installed? NO Install new Heat Block Inserts. YES Enter MHS configuration parameter values and select MHS options. See paragraph 2.5 Carrier/Device Carrier/ Device S pecific repeat each time carrier or device type is changed. Teach carrier bonding position. DONE Fi g ure 2-8 2-8 Work hold holder er Setup S eque equence, nce, Shee S heett 2 of of 2 2-14 Workholder 98888-0000-JB3-01 Material Handling System Manual 2.3.2 .3.2 Pul ulle lerr Pin Setup etup 2.3 .3..2.1 Workholder Gauge The puller pin setup procedure uses the workholder setup and calibration gauge assembly K&S P/N: 03035-0501-000-XX. The part of the gauge used to set up the puller pin is divided into four levels. Each level is individually referenced during this procedure as to where the top to p surface of the puller pin must be on that level. The holes in the gauge are used to engage the tip of the puller pin as it travels through in the gauge. Figure 2-9 shows the part of the gauge used and identifies itsthe fourslot levels. Rear Rail Workholder Gauge (T (Top op View) Vie w) Puller Pin (Beneath Gauge in Slot) Front Rail Top View Level 1 Puller Pin Up Level 4 Level 3 Level 2 Puller Pin Down Puller Pin Puller Pin Sensior ON Sensor OFF Level 1 Puller Pin Up Level 2 Puller Pin Sensior ON Level 3 Puller Pin Sensor OFF Level 4 Puller Pin Down 2-9 Workhold Workholder er Ga G aug e Funtiona Funtionalit lityy for Puller Puller Pi n S et etup up Fi g ure 2-9 Workholder 98888-0000-JB3-01 2-15 IConn High Performance Wire Bonder 2. 2.3. 3.2. 2.2 2 Pull Puller er Pi Pin n Setu Setup p Sequ Sequen ence ce The purpose of this adjustment is to make sure that the puller pin is engaged to the correct hole in the gauge. The adjustment is necessary, only when the machine is first installed or if the puller pin is disassembled. It is not necessary to do this adjustment at any other time. Tools/ Materials/ Parts • • Workholder Workholder setup and calibration calibration gauge assembl assembly y (P/ (P/N: N: 0 03035-05 3035-0501-000 01-000-XX) -XX) Hand Tools Procedure A. Turn temperature controllers OFF: 1. Sel Select ect [4] CONFIGURE from the mode bar. 2. Select [4] TEMPERATURE from the Configure mode menu. 3. Sele Select ct th the e TURN ALL ZONES OFF button from the "Temperature Set Points" dialog box. While the heat blocks cool down, observe their temperature at the temperature status display on the monitor. 4. Sel Select ect DONE when the heat blocks cool down to close the dialog box. 5. Pu Push sh th the e [ESCAPE] button to exit the Configure mode. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. B. Move the puller puller to home home position: position: 1. Sel Select ect [2] MANUAL from the mode bar. 2. Sel Select ect [3] MHS UTILITIES from the Manual menu. 3. Sel Select ect [4] PIN UTILITIES from the MHS Utilities menu. 4. Sel Select ect HOME PULLER from the Pin Utilities menu. 5. Select APPLY to move the puller to home position. 6. Sel Select ect DONE to close the dialog box. C. Displ Display ay the the sensor sensor panel: panel: 1. Sel Select ect [7] DIAGNOSTIC from the mode bar. 2. Sel Select ect [5] MAINTENANCE DIAGNOSTICS from the Diagnostic mode menu. 3. Sel Select ect [1] SENSOR from the Maintenance Diagnostics menu. 4. Moni Monito torr tthe he PULLER PIN sensor on the Sensor Diagnostics panel while doing the puller pin adjustments. D. Put workhol workholder der setup and calibration calibration gauge gauge assembly between between the rails (se (see e 2-12). ). Figure 2-10 and Figure 2-12 WARNING: DO NOT DAMAGE THE REAR RAIL BOAT BIAS SPRING WHEN YOU PUT THE WORKHOLDER SETUP AND CALIBRATION GAUGE ASSEMBLY BETWEEN THE RAILS. 1. Make sure sure that the index index slot of the the gauge is o on n the right right side, point point towards the Output Magazine Handler Assembly (see Figure 2-10). 2-10). 2-16 Workholder 98888-0000-JB3-01 Material Handling System Manual Rear Rail Output Magazine Handler Assembly Front Rail Index slot on the right side. Fi g ure 2-10 2-10 Ins ta tall ll th the e Workholde Workholderr S et etup up and and Calibrat Calibration ion G aug e As s em embl blyy P os osition ition 2. Hold Hold the the gau gauge ge at at 45o angle (rear edge down) and put the rear edge of the gauge on the rear rail (see Figure 2-1 2- 11). 3. Without Without moving the gauge gauge forward, forward, slowly slowly lower the the gauge until until it is on the front rail (see Figure 2-11). 2-11). 4. Make sure that that the gauge gauge can move move along the rrails ails with with small resista resistance. nce. Gauge at 45o angle Front Rail Rear Rail Fi g ure 2-11 2-11 Ins ta tall ll the Work hold holder er S et etup up and and Calibration Calibration G aug e As s em embly bly at at 45o angle E. Move the gauge gauge to the left and let the puller puller pin move in the oval slot slot on the left front side of the gauge. As the puller pin moves in the slot, make sure that it is in center position. If not: 1. Loosen the the two M2 screws screws at the left left sid side e of the pull puller er solenoid solenoid (see Figure 2-12). 2-12 ). 2. Adjust the puller puller pin in the Y-axis Y-axis direction direction (front (front and back) until until the pin is in the center position when it moves in the slot of the gauge. 3. Tig ight hten en the the screw screws. s. Workholder 98888-0000-JB3-01 2-17 IConn High Performance Wire Bonder . Puller Pin 2x M2 Screws Puller Pin Solenoid Fi g ure 2-12 Pulle Pullerr Pi n Y axis axis A djus djustm tment ent (Top View) F. Disconnect Disconnect the pull puller er pin solenoid solenoid cable at connector connector J2 on the puller puller assemassembly circuit board. NOTE: If necessary, necessary, refer to Figure 2-9 while doing the following “LEVEL” adjustments. 2-13). G. Do the LEVEL LEVEL 1 (Puller (Puller Pin UP) UP) adjustment adjustment (see Figure 2-13). 1. Set the position position of the the puller pin pin tip below below level 1 of of the gauge. gauge. 2. Turn the the M3 set screw screw above the the pulle pullerr pin solen solenoid oid to adjust adjust the tip of of the puller pin until it touches level 1. M3 Set Screw Puller Pin Solenoid Fi g ure 2-13 P ul ulle lerr Pi n Level Level 1 Adjus tm tment ent (R ig ht S ide View) 2-18 Workholder 98888-0000-JB3-01 Material Handling System Manual H. Do the LEVEL 2 (Pu (Puller ller Pin Sensor Sensor ON) adj adjustment ustment (see (see Figure 214). 14 ). 1. Move the gauge gauge until the the tip of the puller puller pi pin n touches level level 2. 2. Look Look fo forr th the e PULLER PIN sensor display on the Sensor Diagnostic dialog box, loosen the sensor flag mounting screw and adjust the puller pin sensor flag until the sensor turns ON. 3. Tighten Tighten the sensor flag mountin mounting g screw. screw. Puller Pin Sensor Flag Puller Pin Sensor Sensor Flag Mounting Screw 2-14 P ull uller er Pi n Level 2 and and Level 3 Adjus tm tment ent (R ea earr View) Fi g ure 2-14 I. Do the LEVEL LEVEL 3 (Pulle (Pullerr Pin Sensor Sensor OF OFF) F) adj adjustm ustment ent (s (see ee Figure 2-14 2-14). ). 1. Move the gauge gauge until the the tip of the puller puller pi pin n touches level level 3. 2. Manually Manually push th the e puller pin pin down to get get into this position position.. 3. Make Make sur sure e that that the the PULLER PIN sensor display in the Sensor Diagnostic dialog box is OFF. If not, adjust the sensor flag until the sensor turns OFF. H.)) and Level 3 (step I. I.)) adjustments. Make 4. Do a check check for for Level Level 2 (step (step H. sure that the adjustments are adjusted correctly. 5. Connect Connect the puller so soleniod leniod cable cable to connect connector or J2 on the puller ass assembly embly circuit board. 2-15). ). J. Do the LEVEL 4 (Puller Pin DOWN) DOWN) adjustment adjustment (see Figure 2-15 1. Move the gauge gauge until the the tip of the puller puller pi pin n touches level level 4. 2. Look Look fo forr tthe he PULLER PIN sensor display in the Sensor Diagnostic dialog box, turn the top M3 set screw on the flag mounting arm to adjust the tip of the puller pin until it touches level 4. M3 Set Screw 2-15 P ul ulle lerr Pin P in Level 4 Adjus tm tment ent (S ide View) View) Fi g ure 2-15 Workholder 98888-0000-JB3-01 2-19 IConn High Performance Wire Bonder K. Sel Select ect DONE to exit the Sensor Diagnostic dialog box. L. Sel Select DONE to exit the Maintenance Diagnostics menu. M. Pu Push sh the the [ESCAPE] button if necessary to exit the Diagnostics mode. N. Remove the workh workholder older setup and calibration calibration gauge assembly assembly.. 2. 2.3. 3.3 3 Inde Index x Pi Pin/ n/T Tuc ucke kerr E Eje ject ct S Set etup up 2.3 .3.3 .3.1 .1 In Ind dex Pi Pin Se Setup tup Seq Sequ uenc ence The purpose of this adjustment is to make sure that the index pin is engaged to the correct groove in the th e gauge. The adjustment is necessary, only when the machine is first installed or if the index pin is disassembled. It is not necessary to do this adjustment at any other time. Tools/ Materials/ Parts • Workholder Workholder setup and calibration calibration gauge assembl assembly y (P/ (P/N: N: 0 03035-05 3035-0501-000 01-000-XX) -XX) • Hand Tools Procedure A. Turn temperature controllers OFF: 1. Sel Select ect [4] CONFIGURE from the mode bar. 2. Select [4] TEMPERATURE from the Configure mode menu. 3. Sele Select ct th the e TURN ALL ZONES OFF button from the "Temperature Set Points" dialog box. While the heat blocks cool down, observe their temperature at the temperature status display on the monitor. 4. Sel Select ect DONE when the heat blocks cool down to close the dialog box. 5. Pu Push sh th the e [ESCAPE] button to exit the Configure mode. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. B. Put workhol workholder der setup and calibration calibration gauge gauge assembly between between the rails (se (see e section 2.3.2.2, 2.3.2.2, step D. C. Disconnect the tubing from the fitting in the index mount. This tubing supplies air to the index pin air cylinder. D. Manual Manually ly lift the index index pin and move the gauge gauge under it. E. Set the pin posit position ion until it moves moves smoothly smoothly to the lower she shelf lf of the groove at 2-16). ). the right front portion of the gauge (see Figure 2-16 Upper Shelf Lower Shelf Groove 2-16 16 Inde Indexx P in Alig nm nmen entt G roove Fig ure 2- 2-20 Workholder 98888-0000-JB3-01 Material Handling System Manual F. Make sure that that the pin pin aligns correctl correctly y in the groove. groove. If not: not: 1. Loosen the the two M3 screws screws that attach attach the pi pin n to the asse assembly mbly (see Figure 2-17). 2-17). 2. Adjust the the pin until until it is is aligned aligned directly directly on the groo groove. ve. 3. Tig ight hten en the the screw screws. s. 2x M3 Screws Sensor Flag Mounting Screw Indexer Pin Sensor Flag Fi g ure 2-17 2-17 Index Pi n - Y axis A djus tm tment ent and Up/ Up/Down A djus djusttme ment nt G. Display Display the sensor panel: panel: 1. Se Sellect [7] DIAGNOSTIC from the mode bar. 2. Se Sellect [5] MAINTENANCE DIAGNOSTICS from the Diagnostic mode menu. 3. Se Sellect [1] SENSOR from the Maintenance Diagnostics menu. 4. Monitor Monitor the sensors on the Sensor Sensor Diagnostics Diagnostics panel panel while doi doing ng the index pin UP and pin DOWN adjustments. NOTE: Before doing the following steps, make sure sure that there is no interference between the work light and the operation of the index sensor. H. Put the index pin pin in the lower lower shelf of the groove groove on the gauge gauge and do a index pin DOWN position check. I. Lo Look ok for the INDEXER PIN RIGHT and INDEXER PIN LEFT sensors display in the Sensor Diagnostic dialog box. Make sure that the INDEXER PIN RIGHT sensor is ON and INDEXER PIN LEFT sensor is OFF. If not (see Figure 2-17 2-17): ): 1. Loosen the sensor sensor flag mountin mounting g screw screw.. 2. Adjust Adjust the s sens ensor or flag flag until until the the INDEXER PIN RIGHT sensor is ON and INDEXER PIN LEFT sensor is OFF. 3. Tighten Tighten the sensor flag mountin mounting g screw. screw. J. Put the index index pin in the upper upper shelf shelf of the groove groove on the gauge gauge and do a index index pin UP position check. K. Make sure sure tthat hat the INDEXER PIN RIGHT sensor and INDEXER PIN LEFT sensor are OFF. If not: 1. Loosen the sensor sensor flag mountin mounting g screw screw.. Workholder 98888-0000-JB3-01 2-21 IConn High Performance Wire Bonder 2. Adjust Adjust th the e sensor sensor flag flag until until the the INDEXER PIN RIGHT sensor and INDEXER PIN LEFT sensor are OFF. 3. Tighten Tighten the sensor flag mounting mounting screw. screw. L. Sel Select DONE to exit the Sensor Diagnostic panel. M. Sele Select ct DONE to exit the Maintenance Diagnostic menu. N. Push Push th the e [ESCAPE] button if necessary to exit the Diagnostics mode. O. Remove the workholder workholder setup and calibration gauge assembly. assembly. P. Connect the tubing that supplies air to the index pin air cylinder cylinder.. 2. 2.3. 3.3. 3.2 2 Tucke uckerr Eje Eject ct Setu Setup p Sequ Sequen ence ce The purpose of this setup is to make sure the tucker eject is positioned correctly cor rectly.. This is done to avoid interference between the tucker tip and other indexer parts during carrier ejection. Tools/ Materials/ Parts • Workholder Workholder setup and calibration calibration gauge assembl assembly y (P/ (P/N: N: 0 03035-05 3035-0501-000 01-000-XX) -XX) • Hand Tools Procedure A. Turn temperature controllers OFF: 1. Sel Select ect [4] CONFIGURE from the mode bar. 2. Select [4] TEMPERATURE from the Configure mode menu. 3. Sele Select ct th the e TURN ALL ZONES OFF button from the "Temperature Set Points" dialog box. While the heat blocks cool down, observe their temperature at the temperature status display on the monitor. 4. Sel Select ect DONE when the heat blocks cool down to close the dialog box. 5. Pu Push sh th the e [ESCAPE] button to exit the Configure mode. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. B. Put workhol workholder der setup and calibration calibration gauge gauge assembly between between the rails (se (see e section 2.3.2.2, 2.3.2.2, step D.. D.. C. Move the gaug gauge e to the right and put the tucker tucker tip over the upper upper shelf at the front, right side of the gauge (see Figure 2-18). 2-18). Upper Shelf Lower Shelf 2-18 8 Tucker Eject Ej ect A lig nm nment ent S urfa urfaces ces Fi g ure 2-1 D. Make sure tha thatt the tucker tip touches touches the upper upper shelf. If not (see (see Figure 2-19 2-19): ): 1. Find the set set screw below below the tucker tucker solenoid solenoid and loosen loosen it. 2. Adjust the the set screw until the tucker tucker top top touches tthe he upper sh shelf. elf. 2-22 Workholder 98888-0000-JB3-01 Material Handling System Manual 3. Ti Tight ghten en the the set screw screw.. .. Tucker Solenoid Set Screw Fi g ure 2-1 2-19 9 Tucker “R “R ais ed P os osition” ition” A djus djustm tment ent E. Move the gauge gauge to the right until the the tucker tip is above above the lower sh shelf elf at the front, right side of the gauge. F. Move the the tucker tucker down to the the lower lower shelf shelf of the guage: guage: 1. Select [2] MANUAL from the mode bar. 2. Se Sellect [3] MHS UTILITIES from the Manual menu. 3. Se Sellect [4] PIN UTILITIES from the MHS Utilities menu. 4. Sele Select ct th the e LOWER TUCKER option from the Pin Utilities dialog box. 5. Select APPLY. G. Make sure that that the tucker tip touches touches the lower lower shelf. If not (see ): 1. Loosen the the M3 set screw screw at the left left side of the ttucker ucker so solenoid lenoid (see Figure 2-20 2-20). ). 2. Use a wrench wrench tool to turn turn the M3 hex hex screw until until the tucker tucker tip ttouches ouches the the lower shelf on the gauge. 3. Ti Tight ghten en the the M3 set set screw screw.. 4. Sele Select ct th the e LIFT TUCKER option from the Pin Utilities dialog box. 5. Se Sellect APPLY. 6. Pr Pre ess th the e [ESCAPE] button if necessary to exit the Manual mode. Tucker Solenoid M3 Set Screw M3 Hex Screw Fi g ure 2-20 2-20 Tucker Pi n Lower Lower Travel Travel A djus djustm tment ent H. Remove the workho workholder lder setup and calibration calibration gauge assembly assembly. Workholder 98888-0000-JB3-01 2-23 IConn High Performance Wire Bonder 2. 2.3. 3.4 4 Bo Bond nd Si Site te He Heat at Bl Bloc ock kA Alig lignm nmen entt The purpose of this adjustment is to align the heat block with the X axis of the Bond Head. The adjustment is necessary, only when the machine is first installed or if the bond site heat block assembly is disassembled. It is not necessary to do this alignment frequently. Specification • Y val value ue is +/- 0. 0.02 0254 54 mm (1 mi mil) l).. Tools/ Materials/ Parts • Workho Workholde lderr Setup Setup Gaug Gauge e (P/N: (P/N: 0303 03035-0 5-0908 908-001 -001-XX) -XX) • Tor orque que Wre Wrenc nch, h, 13 lb. lb.in in.. (1.4 (1.47 7 Nm) Nm) • Hand Tools Procedure A. Turn temperature controllers OFF: 1. Sel Select ect [4] CONFIGURE from the mode bar. 2. Select [4] TEMPERATURE from the Configure mode menu. 3. Sele Select ct th the e TURN ALL ZONES OFF button from the "Temperature Set Points" dialog box. While the heat blocks cool down, observe their temperature at the temperature status display on the monitor. 4. Sel Select ect DONE when the heat blocks cool down to close the dialog box. 5. Press [ESCAPE] to exit the Configure mode. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. B. Insta Installll the workholder workholder setup gauge on the bond site heat bloc block k assembly. assembly. 2-21): ): When you install the gauge, make sure that (see Figure 2-21 1. The engrave engrave part number number on the top top surface of of the gauge points points to you. you. 2. The notch at at the front edge edge of the gauge gauge engages engages to the pin on the the bond site heat block assembly. assembly. Engraved Part Number Workholder Setup Gauge Notch Notch engages to the pin Fi g ure 2-21 2-21 Ins ta tall ll th the e Workholde Workholderr S et etup up G aug e Position Pos ition (R ig ht S ide View) 2-24 Workholder 98888-0000-JB3-01 Material Handling System Manual C. Align the the horizontal horizontal line of the the cross crosshair hair to the lef leftt rear edge edge of the gauge (see Figure 2-22). 2-22). If necessary, select the F10 button on the function bar to adjust the illumination until the edge can see clearly. Align the crosshair horizontal horizontal line to the rear edge to the left side as shown. M3 Screws Align the crosshair horizontal horizontal line to the rear edge to the right side as shown. 03035-0908-001 Workholder Setup Gauge Fi g ure 2-22 2-22 B ond S ite Hea Heatt B lo lock ck A lig nm nment ent (Top View) D. Make a note of the Y value at th the e top right corner corner of the graphical graphical user interinterface (GUI) display for left rear edge position of the gauge (see Figure 2-23 2-23). ). At the same time, take note of the X value. Align the crosshair horizontal horizontal line to the rear edge to the left side as shown. Y Value Fi g ure 2-23 2-23 Y Value Value A t The To Top p R ig ht C orner of of the the G UI Dis pl pla ay E. Chess the horizont horizontal al line of the crosshair crosshair to the right right rear edge of the gaug gauge. e. F. Make a note of the the Y value for this this position. position. At th the e same time time,, take note of of the X value G. ference Compare the be measured Y position for to thestep rightH.and left edges. The difmust 0.0254 mm (1 mi).values If not, go 98888-0000-JB3-01 Workholder 2-25 IConn High Performance Wire Bonder H. If the value is gre greater ater than 0.0254 0.0254 mm (1 mil), do the bond bond site heat bloc block k 2-22): ): alignment (see Figure 2-22 1. Hold the heat heat block assembly assembly,, then loose loosen n the four M3 screws th that at attach the heat block to the heat block slider assembly slowly to 1/4 turn. 2. Rotate Rotate the heat block assembly assembly and and chess the hori horizonta zontall line of the crosscrosshair to the rear edge of the heat block gauge. 3. Chess the horizont horizontal al line of the crosshair crosshair from left left to right edges edges (the approximate X values in step D. and F.) of the gauge. 4. Make sure sure that the rear rear edge of the gauge gauge is straight. straight. Us Use e the Y value o on n the display to do the check (refer to step G.). 5. Tighten Tighten each each of the four M3 screws screws on the the bond site heat heat block block assembl assembly y with a 1/4 turn in diagonal sequence, to set the assembly position. 6. Use a torque torque wrench wrench to apply a torque torque of 13 lb.in. lb.in. (1.47 Nm) Nm) to the four M3 M3 screws in diagonal sequence. 7. Make sure sure that the heat heat block assembly assembly does does not mov move e when the sc screws rews are tightened. I. Do a check check on on the bond bond site site heat heat block block align alignmen ment. t. 1. Align the horizont horizontal al line of the crosshair crosshair to the left left rear edge, then to right right rear edge of the gauge. 2. Make note note of the Y value on on the display display and and comp compare. are. 3. Do the the alignm alignment ent again again (see (see step step H.) H.) if the value is greater than 0.0254 mm. J. Rem Remove ove the the work workhold holder er gaug gauge. e. K. Continu Continue e the rail parallelis parallelism m adjustment adjustment (see par paragraph agraph 2.3.5 2.3.5). ). 2-26 Workholder 98888-0000-JB3-01 Material Handling System Manual 2.3. 2.3.5 5 Ra Rail il Pa Para rall llel elis ism m Ad Adju just stme ment nt The purpose of this adjustment is to adjust the the front and rear workholder rails until the rails are parallel to each other and the heat block is parallel to the rails. This adjustment will continue after the bond bon d site heat block alignment is done (see 2.3.4). ). paragraph 2.3.4 NOTE: Do the bond site head block alignment first before you do the rail parallelism adjustment. Specification • Parallel Parallelism ism be between tween the front front and and rear rail is +/- 0.1 mm over tthe he len length gth of the rails. Tools/ Materials/ Parts • Wor Workho kholde lderr Setup Setup Gaug Gauge e (P/N: (P/N: 03035 03035-09 -090808-001001-XX) XX) • Ga Gauge uge Pin (P (P/N /N:: 0303 030355-09 0908 08-00 -0055-XX) XX) • Rails Width Gauge (Example: (Example: 3.6” (stan (standard), dard), P/N: 03035-0 03035-0908-003 908-003-XX) -XX) • Hand Tools Procedure A. Turn temperature controllers OFF: 1. Se Sellect [4] CONFIGURE from the mode bar. b ar. 2. Select [4] TEMPERATURE from the Configure mode menu. "Temperature Set Points" 3. Sele Select ct th the e TURN ALL ZONES OFF button from the "Temperature dialog box. While the heat blocks cool down, observe their temperature at the temperature status display on the monitor. 4. Se Sellect DONE when the heat blocks cool down to close the dialog box. 5. Press [ESCAPE] to exit the Configure mode. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. B. Make sure that that the heat block is at the home home position. position. If not, move the he heat at block to its home position: 1. Se Sellect [4] MANUAL from the mode bar. 2. Select [3] MHS UTILITIES from the Manual menu. 3. Se Sellect [2] HEAT BLOCK UTILITIES from the MHS utilities menu. 4. Se Sellect [4] HOME HEAT BLOCK. The bond site heat block moves to its home position. 5. Se Sellect DONE. C. Loosen the four M5 scre screws ws at the two ends of the rear rail assembly, assembly, that 2-24). ). attach the rear rail to the input and output base supports (see Figure 2-24 D. Manuall Manually y move the rear rail a sma smallll distance distance to the back Workholder 98888-0000-JB3-01 2-27 IConn High Performance Wire Bonder . Front Rail Assembly Rear Rail Assembly M5 Screw M5 Screws M5 Screws (one screw is not shown) earr R ail A s s em embl blyy (Rear View) Fi g ure 2-24 R ea E. Loosen the fou fourr M5 screws at the two ends ends of the front rail assembly assembly,, that attach the front rail to the input and output base supports (see Figure 2-24 and Figure 2-25 2-25). ). F. Manually Manually move the the front rail rail a small distance distance to to the fron front. t. M5 Screw Front Rail Assembly M5 shown) Screw (not Fi g ure 2-25 Fr Front ont R ail A s s em embl blyy (Front View) 2-28 Workholder 98888-0000-JB3-01 Material Handling System Manual G. Install Install the workholder workholder setup gauge on the bond site heat block block assembly. When you install the gauge, make sure that (see Figure 2-21 2-21): ): 1. The engrave engrave part number number on the top top surfac surface e of the gaug gauge e points to you. 2. The groove groove at the front front edge of the gauge gauge touches touches the pin on the bond bond site heat block assembly. H. Instal Installl the rail width width gauge on the workholder workholder se setup tup gauge. WARNING: DO NOT DAMAGE THE REAR RAIL BOAT BIAS SPRING WHEN YOU PUT THE RAIL WIDTH GAUGE BETWEEN THE RAILS. 1. Make sure that that the cut-out cut-out of the gauge gauge is on th the e right side, side, point towards towards the Output Magazine Handler Assembly (see Figure 2-26). 2-26). Output Magazine Handler Assembly Cut-out on the right side Fi g ure 2-26 2-26 Ins ta tall ll th the e R ail Width Width Ga G aug e P os osition ition 2. Put the rail rail width width gauge on the workhold workholder er gauge. gauge. 2-27): ): I. In Inst stall all th the e gaug gauge e pins pins (se (see e Figure 2-27 1. Align the the first hole hole of the rail width width gauge gauge with the fi first rst hole of the the workholder setup gauge. 2. Continue Continue to align align the remaini remaining ng holes in the gauges. gauges. 3. Install Install the gauge gauge pins through through the holes holes in the rail rail width g gauge. auge. NOTE: on If the pins cannot dowidth not use force. Dothe thepins hole alignment thegauge workholder gaugeinstall, with rail gauge until can be install. 4. Make sure sure that the ga gauge uge pins install install tthrough hrough th the e holes in the the gauges. 98888-0000-JB3-01 Workholder 2-29 IConn High Performance Wire Bonder Gauge Pins First Hole of the Rail Width Gauge Rail Width Gauge Fi g ure 2-27 2-27 Ins ta tall ll the Rail Width G aug e and and Gaug e Pins J. Do th the e rail rail paral parallel lelism ism (see (see Figure 2-28 2-28): ): 1. Manually Manually push the the front rail rail to the front surface surface of tthe he rail wi width dth gauge. gauge. 2. is Make sure surfront e thatrail. theIfbottom bo ttom surface surface at the front front edge of the the rail width width gauge on the not, a. Lift up the the rail width width gauge gauge until the the edges of the gauge gauge are aligned aligned to the front surface. b. Hold the gauge gauge and manually manually move move the fro front nt rail a smal smalll dista distance nce to the rear until the front, bottom surface of the gauge is on the front rail. 3. Tighten Tighten the four M5 scre screws ws at the two ends of the front front rail assem assembly bly,, that attach the front rail assembly to the base supports (see Figure 2-24 and Figure 2-25). 2-25). 4. Manually Manually push the re rear ar rail to the the rear surface surface of the rail rail width g gauge. auge. 5. Make sure the the bottom surface surface at the the rear ed edge ge of the rail rail width gauge gauge is on the rear rail. If not, a. Lift up the the rail width width gauge gauge until the the edges of the gauge gauge are aligned aligned to the rear rail surface. b. Hold the gauge gauge and manually manually move move the rea rearr rail a smal smalll dista distance nce to the front until the rear, bottom surface of the gauge is on the rear rail. 6. Tighten Tighten the four M5 screws screws at the two end ends s of the rear rail assembly assembly,, that attach the rear rail assembly to the base supports (see Figure 2-24 and Figure 2-25). 2-25). 2-30 Workholder 98888-0000-JB3-01 Material Handling System Manual Push the rear rail Rail Width Gauge Push the front rail Bottom surface of the Rail Width Gauge on the Rear Rail Bottom surface of the Rail Width Gauge on the Front Rail Lift up the Rail Width Gauge to align with the rails surface. 2-28 8 R ail Para Parall llel elis is m Fi g ure 2-2 K. Remove Remove the the gauge gauge pins pins.. L. Move the rail rail width width gauge a across cross the rails. rails. Make Make sure that th the e gauge can can moves smoothly and you can feel the guage with small friction. M. Remove the the rail width gauge and the workholder gauge from the Workholder. N. Continue Continue the preheat heat block block alignment (see (see paragrap paragraph h 2.3.6). 2.3.6). Workholder 98888-0000-JB3-01 2-31 IConn High Performance Wire Bonder 2.3.6 2.3 .6 Pre Prehea heatt H Heat eat Blo Block/ ck/Bon Bond dS Site ite Alig Alignme nment nt The purpose of this adjustment is to align the preheat heat block with the rails and sets the distance between the preheat and bond site. This is to make sure that the carrier is correctly index. The adjustment is necessary, only when the machine is first installed, or if the preheat or bond site heat block assembly is disassembled. It is not necessary to do this alignment frequently. This adjustment will continue after the rail parallelism adjustment is done (see paragraph 2.3.5). 2.3.5). NOTE: Do the rail parallelism adjustment before you do the preheat heat block/ bond site alignment. Tools/ Materials/ Parts • Workho Workholde lderr Setup Setup Gaug Gauge e (P/N: (P/N: 0303 03035-0 5-0908 908-001 -001-XX) -XX) • Gaug Gauge e Pin Pin (P (P/N /N:: 0303 03035-0 5-090 9088-00 005-X 5-XX) X) • Rail Rails s Wid Width Gaug Gauge e • Preheat Preheat Setup Setup Gauge Gauge Assem Assembly bly (P (P/N: /N: 0303503035-050 0502-0 2-000-X 00-XX) X) • Hand Tools Procedure A. Turn temperature controllers OFF: 1. Sel Select ect [4] CONFIGURE from the mode bar. 2. Select [4] TEMPERATURE from the Configure mode menu. 3. Sele Select ct th the e TURN ALL ZONES OFF button from the "Temperature Set Points" dialog box. While the heat blocks cool down, observe their temperature at the temperature status display on the monitor. 4. Sel Select ect DONE when the heat blocks cool down to close the dialog box. 5. Press [ESCAPE] to exit the Configure mode. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. B. Make sure tha thatt the preheat heat heat block is at at the home posi position. tion. If not not,, move the heat block to its home position: 1. Sel Select ect [4] MANUAL from the mode bar. b ar. 2. Select [3] MHS UTILITIES from the Manual menu. 3. Sel Select ect [3] PREHEAT HEAT BLOCK UTILITIES from the MHS utilities menu. 4. Select HOME PREHEAT BLOCK. The preheat heat block moves to its home position. 5. Sel Select ect APPLY then DONE. C. Do a check on the preheat heat block ali alignment gnment with the rail and the dis distance tance between the preheat and bond site. 1. Install Install the workholder workholder setup setup gauge on the preheat preheat heat block as assembly sembly.. 2. Install Install the rail width width gauge between between the rails, rails, above the preheat preheat heat block block assembly. WARNING: DO NOT DAMAGE THE REAR RAIL BOAT BIAS SPRING WHEN YOU PUT THE RAIL WIDTH GAUGE ASSEMBLY BETWEEN THE RAILS. a. Make sure sure that the cut-out cut-out of the gauge gauge is on th the e right side, side, point towards the Output Magazine Handler Assembly (see Figure 2 26). 26). 2-32 Workholder 98888-0000-JB3-01 Material Handling System Manual Output Magazine Handler Assembly Cut-out on the right side Fi g ure 2-29 2-29 Ins tall the the Rail Width Width G aug e - 3.6” 3.6” Pos ition b. Hold Hold tthe he gau gauge ge a att 45o angle (rear edge down) and put the rear edge of 2-30). ). the gauge on the rear rail (see Figure 2-30 c. Without Without moving the the gauge forward, forward, slowly slowly lower lower the gauge gauge until the front edge is on the front rail. d. Move the rail rail width width gauge across across the rails. rails. Make Make sure that th the e gauge can moves smoothly and you can feel the guage with small friction. Gauge at 45o angle Rear Edge of the Gauge Front Edge of the Gauge Rear Rail Front Rail Fi g ure 2-30 Ins ta tall ll the R ail Width G aug e at 45o ang le (R ig ht S ide View) View) 3. Install Install the preheat preheat setup gauge gauge assembly assembly in front of the ffirst irst hole o on n the rail width gauge (see Figure 2-31 ). Workholder 98888-0000-JB3-01 2-33 IConn High Performance Wire Bonder a. Do a check if the pin pin on the preheat preheat setup gauge gauge touches th the e left side o off the bond site heat block assembly (see Figure 2-31 ). If not, do the preheat/bond site alignment in step D. Rail Width Gauge Gauge Pins Preheat Setup Gauge Pin touches the left side of the bond site heat block assembly Bond Site Heat Block Assembly First Hole of the Rail Width Gauge NOTE: The position of the preheat setup gauge pin shown in this figure is possibly different in its position for the other types of applications. Set the pin position to the correct type of application used. Fi g ure 2-31 2-31 Ins ta tall ll the P rehea reheatt S et etup up Gaug e and the G auge Pi ns 4. Instal Installl the gaug gauge e pins pins (se (see e Figure 2-31): 2-31): a. Align the first first hole of of the rail width width gauge gauge to the first first hole of the the workholder setup gauge. b. Continue Continue to align align the remaini remaining ng holes in the gauges. gauges. c. Install Install the gauge gauge pins through through the holes holes in the rail rail widt width h gauge. NOTE: If the gauge pins cannot install, install, do not use force. Do the hole alignment on the workholder gauge with rail width gauge until the pins can be install. d. Do a check ifif the gauge pins pins is installe installed d through the the holes in the the gauges. If not, do the preheat block alignment in step D. D... D. Do the preh preheat eat heat block block alignment alignment (see (see Figure 2-32): 2-32): 1. Remove the the gauge pins pins from the gauges gauges on the preheat preheat as assembly sembly.. 2. Do not not remove remove the the preheat preheat setup setup gauge. gauge. 3. Get access access to the preheat preheat heat heat block assembly assembly a att the left si side de of the preheat block assembly. 4. Hold the preheat preheat heat block assembly assembly,, then loosen the four four M3 screws that attach the heat block to the preheat top plate slowly to 1/4 turn. 2-34 Workholder 98888-0000-JB3-01 Material Handling System Manual . Rail Width Gauge M4 Screws Preheat Setup Gauge Get access to the preheat heat block assembly M4 Screws Fi g ure 2-32 P rehea reheatt Heat B lock Alig nme nment nt (Top View) 5. Manually Manually turn the preheat preheat heat block assembl assembly y until the firs firstt hole of the rail width gauge is aligned to the first hole of the workholder setup gauge. 6. Manually Manually turn the preheat preheat heat block assembly assembly until until:: a. The first hole hole of the rail rail width width gauge is aligned aligned to to the first h hole ole of the workholder setup gauge. b. All the holes holes on the rail rail width gauge gauge are al aligned igned to all all the holes holes on the workholder setup gauge. c. The pin on the the preheat setup setup gaug gauge e touches the the left s side ide of the bond bond site heat block assembly. assembly. 7. Install Install the gauge pins pins through the the holes in the rail width width gaug gauge e (see Figure 2-31). 2-31 ). 8. Make sure that that the gauge gauge pins is instal installed led throu through gh the holes holes in the workworkholder setup gauge. 9. Tighten Tighten each of the the four M3 screws screws on the preheat preheat heat heat block assembly assembly with a 1/4 turn in diagonal sequence, to set the assembly position. 10.Use a torque wrench to apply a torque of 13 lb.in. (1.47 Nm) to the four M3 screws in diagonal sequence. 11.Make sure that the preheat heat block assembly does not move when the screws are tightened. E. Remove Remove the gauge pins, pins, preheat setup setup gauge, rail width width gauge gauge and workholder setup gauge on the rails and preheat assembly. Workholder 98888-0000-JB3-01 2-35 IConn High Performance Wire Bonder 2. 2.3. 3.7 7 Pu Pulle llerr Ra Rack ck B Bac ackl klas ash h Ad Adju just stme ment nt Specification • Backlas Backlash h of 0.0015 0.0015 +/- 0.0010 0.0010 in. (Ra (Range nge = 0.0 0.0005 005 - 0.0025 0.0025 in. in.)) Tools/ Materials/ Parts • Dial Dial In Indi dica cato torr with with Magan Maganet etic ic Sta Stand nd • Hand Tools Procedure A. Remove the lubricant from the puller rack. B. Measure the back backlash lash at the center, center, left, and right positions positions of the rack (see 2-33): ): Figure 2-33 1. Move the puller puller assembly assembly to the the center of of the rack un until til the lef leftt edge is aligned to the notch on the front wall. 2. Put the dial indicator indicator on the linear linear slider slider so that its tip touches touches the low lowest est point on the puller mount. 3. Measure Measure the backlas backlash h at the the center center position. position. 4. Move the puller puller assembly assembly to the the left side side limit limit,, and then back back to the right right approximately 3 mm (1/8 inch). 5. Measure Measure the backlash backlash at at the left left side positio position. n. 6. Move the puller puller assembly assembly until until the right right edge is aligned aligned to th the e right edge of of the rack. 7. Measure Measure the backlas backlash h at the the right right side positi position. on. 8. Reposition Reposition the dial indicato indicatorr and measure the the backlash backlash at the right-si right-side de position. C."" if one of the measured position are out of the specification 9. Go to st step ep "C. of 0.0005 to 0.0025 in. NOTE: If the measurements at all positions are within specification,it is not necessary to continue with this procedure. Slide Block (Puller Assembly) X Axis Linear Slide Assembly Slide Block (Index Assembly) Set Screw Front Wall Notch Pull Puller er Rack Rack Set Set S Scr crew ew Fi g ure 2-33 Pull Puller er R ack B ackla cklass h 2-36 Workholder 98888-0000-JB3-01 Material Handling System Manual C. Move the pull puller er assembly assembly to the output output side of the indexer indexer assembly until it is off of the rack. D. Loosen th the e two M3 screws that that attach the the rack, then tor torque que the screw screws s to 5 in lbs. E. Move the puller puller assembly assembly to the center of the rack until the left left edge is aligned aligned to the notch on the front wall. F. Put the dial indicator indicator on the linear linear slider slider until its tip touches touches the low lowest est point on the puller mount. 2-33). ). G. Measure the the backlash at the the center position position (see Figure 2-33 1. If the backlash backlash is less than 0.0005 0.0005 in., turn turn the se sett screw screws s at the two ends of the rack to the right (in). to move the rack to the rear of the indexer assembly. 2. If the backlas backlash h is greater greater than 0.0025 in., turn turn the se sets ts crew crews s at the two ends of the rack to the left (out) to move the rack to the front of the indexer assembly. 3. Repeat step step 1 to 2 until the backlash backlash is within within the spe specific cification ation of 0.0005 0.0005 to 0.0025 in. H. Move the pull puller er assembly assembly to the left side side limit, and the then n to the right side approximately 1/8 in (3 mm). I. Put the dial dial indicator indicator on on the left left side side and mea measure sure the lleft eft bac backlash klash s specifi pecificacation. If it is not within the specification of 0.0005 to 0.0025 in.: 1. Move the puller assembl assembly y to the far righ rightt side of of the rac rack. k. 2. Turn the left-s left-side ide set screw. screw. a. If it is less than than 0.0005 0.0005 in., turn turn it to th the e right to move tthe he rack to the rear of the indexer assembly. b. If it is greater than 0.0025 0.0025 in., turn turn it to the the left left to move the rac rack k to the front of the indexer assembly. 3. Do the step 2 procedure procedure until the the backlash backlash is within the sp specific ecification ation of 0.0005 to 0.0025 in. J. Move the puller puller assembly assembly until its its right edge is aligned aligned to the rig right ht edge of the rack. K. Put the dial indicator indicator on the right right side and measure measure the right backlash backlash specifispecification. If it is not within the specification of 0.0005 to 0.0025 in.: 1. Move the the puller assembly assembly to the left s side ide lilimit. mit. 2. Turn the right-s right-side ide set screw screw.. a. If it is less than than 0.005 0.005 in., turn turn it to th the e right to move the the rack to to the re rear ar of the indexer assembly. assembly. b. If it is greater than 0.0025 0.0025 in., turn turn it to the the left left to move the rac rack k to the front of the indexer assembly. 3. Do the step 2 procedure procedure until the the backlash backlash is within the sp specific ecification ation of 0.0005 to 0.0025 in. L. Remove the dial dial indicator indicator,, and move the puller puller assembl assembly y away from the rack rack to the output side of the indexer assembly. M. Torque the scr screws ews to 8 in. lbs. (0.9 Nm) Nm) B."" again. N. Do th the e step step "B. O. Torque the screws screws to 14 in. lbs. (1.6 (1.6 Nm). P. Apply a small quatity quatity of lubricate lubricate to the the the rack (refer to Sec Section tion 5: MainteMaintenance). Workholder 98888-0000-JB3-01 2-37 IConn High Performance Wire Bonder 2. 2.3. 3.8 8 He Heat at B Blo lock ck V Vac acuu uum m Se Sens nsor or S Set etup up The purpose of this procedure is to make sure that the heat block vacuum sensor controller is setup to detect if a device is properly held down on the heat block. This procedure also set up the conditions under which the low vaccum sensor operates. All references to ’buttons’ in the steps that follow refer to the control buttons located on the vacuum sensor controller operator panel (see Figure 2-34) 2-34) and not to keys on the machine operator control panel (MMI). 2-34 4 Va Vacuum cuum S ensor C ont ontroll roller er Fi g ure 2-3 NOTE: Make sure that the necessary workholder calibrations, configurations and adjustments, for the correct type of carrier and device used, are done before setting up the vacuum sensor. If not, do the necessary workholder calibration, configurations and adjustments, refer to Section 5 of IConn Operation Manual. Tools/ Materials/ Parts • None. Procedure A. Find the vacuum sensor/controller at the front of the interface panel. B. Unlock Unlock Vacu Vacuum um Sen Sensor: sor: 1. Press SET button and hold for 4 seconds or longer to display the [LOC] setting. 2. Pr Pres ess s the the UP or DOWN arrow button until [UNL] appears on the digital display screen. 3. Press SET button. C. Unit Measurement Measurement Setting 1. Press Press and and hol hold d the the SET button for 2 seconds or longer. 2. Pr Pres ess s the the UP or DOWN arrow button to set the unit of measurement to [INH]. 3. Press SET button to set the unit. Proceed to color setting in step D. D. Co Colo lorr Settin Setting g 1. Pr Pres ess s the the UP or DOWN arrow button and select the display color to [ ] (red). 2. Press SET button to set the colour. Proceed to operating mode setting in step E. E. Set Operatin Operating g Mode Mode 1. Pr Pres ess s the the UP or DOWN arrow button to display [HYS] (Hysteresis). 2. Press SET button to set the operating mode. Proceed to output type setting in step F. 2-38 Workholder 98888-0000-JB3-01 Material Handling System Manual F. Set Outp Output ut Typ Type e 1. Pr Pre ess th the e DOWN arrow button and select [NC] (normally closed). 2. Press SET button to set the output type. Proceed to response time setting in step G. G. Response Response Time Setting 1. Pr Pre ess th the e UP or DOWN arrow button and select [2.5] (2.5 ms). 2. Press SET button to set the response time. Proceed to auto preset setting in step H. H. Auto Preset Preset Setti Setting ng 1. Pr Pre ess th the e UP or DOWN ar arrrow bu button and se select [ ] ((m manual). 2. Press SET button to set the auto preset type. Proceed to vacuum setting in step I. I. Vaccu accum m Sett Settin ing g 1. Press SET button to display the set value. [N_1] (normally closed) and current set value e.g. [.330] will appear on the digital display screen and blink alternately. 2. Press SET button to display the next set value (if available). 3. Set the curren currentt va value lue to [-15.0]. a. Pr Pres ess s the the UP or DOWN arrow button. The first digit, right-most digit on the LCD display will blink. Press the UP or DOWN arrow button and set the first digit value to ‘0’. NOTE: If any of the button has not been pressed for more than 10 seconds, the current value will be automatically set and the function will return to the set value display mode. b. Press SET button to move to the second digit in left direction. The second digit blinks. Press the UP or DOWN arrow button and set the second digit value to ‘.’ . c. Press SET button to move to the third digit. Press the UP or DOWN arrow button and set the third digit value to ‘5’. d. Press SET button to move to the fourth digit. Press the UP or DOWN arrow button and set the fourth digit value to ‘1’. e. Press SET button to move to the fifth digit. Press the UP or DOWN arrow button and set the fifth digit value to ‘-’. f. Pres Press s and and ho hold ld th the e SET button for 3 second or longer to save the vacuum value for [N_1]. 4. Press Press and and hol hold d the the SET button for 4 seconds or longer to return to the normal measuring mode to perform the switch operations. J. Set the Hyst Hystere eresi sis s (H) value to the zero (if necessary). 1. Press SET button once to display current H value. 2. Pres Press s an and d hold hold the the UP and DOWN arrow buttons simultaneously to reset the value to zero [0.0]. 3. Press Press and and hol hold d the the SET button for 3 seconds to save the H value. K. Lock Lock Out 1. Press Press and and ho hold ld the the SET button for 4 seconds or longer to display the current [UNL] setting. 2. Pr Pre ess th the e UP or DOWN arrow button until [LOC] appears on the digital display screen. Press SET button. Workholder 98888-0000-JB3-01 2-39 IConn High Performance Wire Bonder 2. 2.4 4 Wor orkh khol olde derr Ca Cali libr brat atio ion n Proc Proced edur ures es WARNING: WORKHOLDER CALIBRATIONS CALIBRATIONS SHOULD BE PERFORMED WITH WORKHOLDER HEATERS AT OPERATING TEMPERATURE FOR MOST ACCURATE RESULTS. RESULTS. IF T THE HE WORKHOLDER IS HEATED, HEATED, AVOID TOUCHING HEATED PARTS WHEN REMOVING PARTS OR MATERIAL MA TERIAL (CARRIERS, HEA HEAT T BLOCK INSERT, INSERT, CLAMP INSERT) OR WHEN PERFORMING OTHER OPERATIONS. NOTE: The following calibration procedures procedures are designed to provide parameters which allow for the alignment of the workholder so as to ensure correct centerlines of bond. NOTE: Calibrations should be performed with no material in the workholder or magazine handlers. NOTE: It is assumed that the die cavity of the heat block targeted during workholder calibrations is on the workholder X axis and Y axis centerlines. NOTE: MHS calibration should not be done unless the X, Y, Y, and Z servo motion axes have been tuned, bond plane height has been established, and crosshair offset has been calibrated. 2. 2.4. 4.1 1 Workh orkhol olde derr Ca Cali libr brat atio ion n 2.4.1.1 Introduction The Workholder calibration contains a group of routines used to calibrate certain areas of the workholder. Each routine displays a series of dialog boxes in the proper sequence to complete the calibration. Each dialog box contains instructions on how to perform that specific step in the calibration. All instructions should read and understood before select ok to proceed. All workholder calibrations should be performed when the heat blocks are at the operating temperature to produce the most accurate results. 2. 2.4. 4.1. 1.2 2 Do th the e Wor Workh khol olde derr Cal Calib ibra rati tion on WARNING: DO NOT TOUCH THE HEAT BLOCK OR INSERTS WITH UNPROTECTED HANDS IF THE WORKHOLDER HEATERS ARE AT OPERATOPERATING TEMPERATURE. WHEN REMOVING THE HEA HEAT T BLOCKS OR INSERTS, INSTALL A SCREW AT THE REAR EDGE OF THE HEAT BLOCK/INSERT AND GRASP THE SCREW WITH PLIERS. THERE IS ONE M4 TAPPED HOLE IN THE HEA HEAT T BLOCK/INSERT FOR THIS PURPOSE. Tools/ Materials/ Parts • Workholder Workholder Setup Gauge (P/N: 03035-0908-00 03035-0908-001-XX) 1-XX) (Heat Block Gauge) • Heat Heat Block Block In Inse sert rts s (P (P-p -part art)) • Rails Rails Widt Width h Gauge Gauge - 3.6” 3.6” (P/N: (P/N: 0303 03035-0 5-0908908-003 003-XX) -XX) • Workholder Workholder setup and calibration calibration gauge assembl assembly y (P/ (P/N: N: 0 03035-05 3035-0501-000 01-000-XX) -XX) Procedure A. Select [5] CALIBRATION from the mode bar. B. Sel Select ect [4] WORKHOLDER from the Calibration menu. C. Sele Select ct [1] WORKHOLDER from the Workholder menu. D. Remov Remove e all material material from the Workholder Workholder.. 2-40 Workholder 98888-0000-JB3-01 Material Handling System Manual holder er Ca C alibrat libration ion Menu - R em emove ove Ma Mate teri ri al Fi g ure 2-35 Work hold E. Make sure that the correct correct heat block gauge/inse gauge/insert rt is install installed ed on the bond site 2-36). ). heat block assembly, then select OK (see Figure 2-36 Fi g ure 2-36 2-36 Workhold Workholder er C alibra libration tion - Ins ta tall ll B ond Si te Hea Heatt B lo lock ck G aug es/ es/Ins Ins ert ertss F. Do the the heat bloc block k foc focus us (see (see Figure 2-37 2-37)) 1. Use Use tthe he mou mouse se an and d [B2] (center button on the mouse) to move the bond head until the heat block gauge/insert on the bond site appears on the screen. 2. If necessary necessary,, adjust the illuminat illumination ion using using the F10 button on the function bar. 3. Do the heat heat block focus focus by pushing pushing the Up or D Down own arrow buttons buttons on the the MMI until the heat block gauge/insert can be seen clearly on the screen. 4. Se Sellect OK. . Fi g ure 2-37 2-37 Work hold holder er Calibration Calibration - Heat B lock Focus G. Position Position the crosshair crosshair on the the heat block. block. 1. Use Use tthe he mou mouse se an and d [B2] to position the crosshair on the left rear corner of the heat block (see Figure 2-38). 2-38). 2. If necessary necessary,, adjust the illuminat illumination ion using using the F10 button on the function bar. Workholder 98888-0000-JB3-01 2-41 IConn High Performance Wire Bonder 3. Sel Select ect OK. Crosshair Fi g ure 2-38 2-38 Workhold Workholder er Calibrat Calibration ion - Hea Heat B lo lock ck C ros s ha hair ir A lig nm nment ent (Left - R ea earr C orner) 4. Use Use tthe he mouse mouse and [B2] to position the crosshair on the right front corner of 2-39). ). the heat block (see Figure 2-39 5. If necessary necessary,, adjust the the illuminatio illumination n using the F10 button on the function bar. 6. Sel Select ect OK. Crosshair Fig ure 22-39 39 Hea Heatt B lock C ross ha hair ir A lig nm nmen entt (R ig ht - Front Corner) H. Remov Remove e the heat block gauge/insert gauge/insert from the bond site, site, then select OK (see Figure 2-40). 2-40). Fi g ure 2-40 2-40 Work hold holder er Calibration Calibration - R em emove ove Heat B lock Ga G aug e/ e/Ins Ins ert 2-42 Workholder 98888-0000-JB3-01 Material Handling System Manual I. Install Install the the rail width gauge between the rails rails (see Figure 2-41). 2-41). WARNING: DO NOT DAMAGE THE REAR RAIL BOAT BIAS SPRING WHEN YOU PUT THE RAIL WIDTH GAUGE BETWEEN THE RAILS. . Fi g ure 2-41 2-41 Work hold holder er Calibration Calibration - Ins ta tall ll R ail Width G aug e 1. Make sure that that the cut-out cut-out of the gauge gauge is on th the e right side, side, point towards towards the Output Magazine Handler Assembly (see Figure 2-42). 2-42). Output Magazine Handler Assembly Cut-out on the right side Fi g ure 2-42 2-42 Work hold holder er Calibr Calibra ation - Ins ta tall ll the R ail Width G aug e P os ition 2. Hold Hold the the gau gauge ge at at 45o angle (rear edge down) and put the rear edge of the gauge on the rear rail (see Figure 2-43). 2-43). 3. Without moving mov ingfront the rail. gauge gauge forward, forward, slowly lower lower the gauge until until the front edge is on the 4. Make sure that that the gauge gauge can move move along the rrails ails with with small resista resistance. nce. 5. Se Sellect OK. Workholder 98888-0000-JB3-01 2-43 IConn High Performance Wire Bonder Gauge at 45o angle Rear Edge of the Gauge Front Edge of the Gauge Rear Rail Front Rail holder der Calibration Calibration - Ins ta tall ll the R ail Width G aug e at at 45o angle Fi g ure 2-43 Work hol J. Teach the bond bond site heat heat block assembl assembly y at rail level level (see Figure 2-44 2-44): ): Fi g ure 2-44 2-44 Work hold holder er Calibration Calibration - Tea Teach ch Heat Heat B lock As s em embly bly 1. Move the rail rail width gauge gauge and position position it until the bottom bottom surfac surface e of the pin, at the left side of the gauge, is directly above the heat block assembly of bond site (see Figure 2-45). 2-45). 2. Use the Up and and Down arrow arrow button button on the MMI to move move the heat heat block assembly up until the top surface touches the pin of the rail width gauge. 3. Sel Select ect OK (see Figure 2-44). 2-44). Pin touches the top surface of the bond site heat block assembly Bond Site Heat Block Assembly Rail Width Gauge Fi g ure 2-45 2-45 Workhold Workholder er Calibrat Calibration ion - Pin Touches Touches B ond S ite Hea Heatt B lo lock ck A s s em embl blyy 2-44 Workholder 98888-0000-JB3-01 Material Handling System Manual K. Remove tthe he rail width width gauge gauge from the rails, rails, then then select OK (see Figure 2-46). 2-46). Fi g ure 2-46 2-46 Workhold Workholder er Calibrat Calibration ion - R em emove ove Rail Width Gauge L. Install Install the heat block gauge/inser gauge/insertt on the bond site heat block assembly assembly,, then 2-47). select OK (see Figure 2-47). holder er Calibr Calibra ation - Ins ta tall ll B ond S ite Hea Heatt B lock Ga G aug e/ e/Ins Ins ert Fi g ure 2-47 Work hold M. Teach the bond height height position (see Figure 2-48). 2-48). 1. Use the mouse mouse to move the the bond head head positi position on directly directly above tthe he heat block gauge/insert at the bond site. 2. Make sure sure that the capillar capillary y is above the the solid po portion rtion of th the e heat block block gauge/insert surface shown on the screen. 3. Sel Select OK. The capillary will moves up and down on the heat block gauge/ insert surface. Fi g ure 2-48 2-48 Workhold Workholder er Calibrat Calibration ion - Tea Teach ch B ond Heig ht P os osition ition N. Remove the hea heatt block gauge/insert gauge/insert from the bond site, site, then select OK (see 2-49). ). Figure 2-49 2-49 Work hold holder er Calibration Calibration - R em emove ove Heat B lock Ga G aug e/ e/Ins Ins ert Fi g ure 2-49 O. Teach the bond bond center position: position: 1. Put workholder workholder setup setup and calibration calibration gauge assembly assembly between between the rai rails ls (see Figure 2-51). 2-51). WARNING: DO NOT DAMAGE THE REAR RAIL BOAT BIAS SPRING WHEN WHE N YOU PUT THE WORKHOLDER SETUP AND CALIBRATION GAUGE ASSEMBLY BETWEEN THE RAILS. 98888-0000-JB3-01 Workholder 2-45 IConn High Performance Wire Bonder a. Make sure sure that the index index slot of the the gauge iis s on the right right side, point point towards the Output Magazine Handler Assembly (see Figure 2-50). 2-50). Output Magazine Handler Assembly Index slot on the right side. holder er Ca C alibrat libration ion - Ins ta tall ll the Work hold holder er S et etup up and and Calibration Calibration Gaug e Fi g ure 2-50 Work hold A s s embly Pos P os iti ition on b. Hold Hold tthe he gau gauge ge at at 45o angle (rear edge down) and put the rear edge of 2-51). ). the gauge on the rear rail (see Figure 2-51 c. Without moving moving the gauge gauge forward, forward, slowly slowly lower lower the gauge until until it is on the front rail (see Figure 2-51 2-51). ). d. Make sure sure that the the gauge moves smoothly smoothly along the the rails. rails. Gauge at 45o angle Front Rail Rear Rail holder er Ca C alibrat libration ion - Ins ta tall ll the Work hold holder er S et etup up and and Calibration Calibration Gaug e Fi g ure 2-51 Work hold A s s embly at at 45o angle 2. Move the workhold workholder er setup and calibra calibration tion gauge gauge to the bond site. site. 3. Make sure sure the index slot slot is aligned aligned to the bond bond center. center. 4. Install Install the gauge pedestal pedestal on the the workholder workholder setup and calibratio calibration n gauge 2-52). ). (see Figure 2-52 a. Make sure that that the engrave engrave words, “FOCUS “FOCUS BK”, on the gauge gauge pedestal pedestal points to you. 2-46 Workholder 98888-0000-JB3-01 Material Handling System Manual b. Install Install the gauge gauge pedestal pedestal on the right right side of the the workholder setup and calibration gauge. Workholder Setup and Calibration Gauge Assembly Gauge Pedestal 2-52 Work hold holder er Calibr Calibra ation - Insta Ins tall ll the G aug e P ede edess ta tall Fi g ure 2-52 5. Se Sellect OK. 2-53)) 6. Do the the gauge gauge pedesta pedestall focus focus (see Figure 2-53 a. Do the gauge gauge pedestal pedestal focus by pus pushing hing the Up or Do Down wn arrow buttons buttons on the MMI until the gauge pedestal can be seen clearly on the screen. b. If necessary necessary,, adjust the the illumination illumination us using ing the F10 button on the function bar. c. Select OK.. Fi g ure 2-53 Work hol holder der C alibrat libration ion - G au augg e P ede edess ta tall Foc us 7. Position Position the crossha crosshair ir on the gauge gauge pedestal pedestal.. a. Use Use th the e mous mouse e and and [B2] to position the crosshair on the right side of the gauge pedestal (see Figure 2-54). 2-54). b. Make sure that that the crosshair crosshair is aligned aligned on the edge edge of the gauge pedespedestal top shelf. c. If necessary necessary,, adjus adjustt the illuminat illumination ion using using the F10 button on the function bar. Workholder 98888-0000-JB3-01 2-47 IConn High Performance Wire Bonder d. Select OK. Crosshair Align the crosshair on the edge of the top shelf at the right side of the gauge pedestal. Gauge Pedestal Fi g ure 2-54 Workhold Workholder er Calibrat Calibration ion - G aug e Pedesta Pedestall C ros s ha hair ir A lig nm nment ent (R ig ht S ide) e. Use Use the the mous mouse e and and [B2] to position the crosshair on the right side of the gauge pedestal (see Figure 2-55). 2-55). f. Make sure sure that the crosshair crosshair is aligned aligned on the the edge of the gauge gauge pe pedesdestal top shelf. g. If necessary necessary,, adjust adjust the illuminati illumination on using the F10 button on the function bar. h. Select OK. Crosshair Align the crosshair on the the edge of the top shelf at the right side of the gauge pedestal. Gauge Pedestal 2-55 Workhold Workholder er Calibrat Calibration ion - Gauge Pede P edess ta tall Cros s ha hair ir A lig nm nment ent (Left S ide) Fi g ure 2-55 P. Remove th the e gauge pedestal pedestal from the workholder workholder calib calibration ration and setup setup gauge, then select OK (see Figure 2-56 2-56). ). Fi g ure 2-56 2-56 Work hold holder er Calibration Calibration - R em emove ove the G aug e P ede edess ta tall 2-48 Workholder 98888-0000-JB3-01 Material Handling System Manual Q. Make sure that that the input magzine magzine handler area area is clear for the puller to move into. 2-57). ). The index gripper will move the workholder setup R. Sele Select ct OK (see Figure 2-57 and calibration gauge assembly to the X sensor, then to bond site center position. Fi g ure 2-57 Work hold holder er Cal C alibr ibra ation - P ull uller er move move into Input Ma Mag azine Handle Handlerr A rea S. Remove the workholder workholder setup setup and calibration calibration gauge assembly assembly from the bond 2-58). site, then select OK (see Figure 2-58). Fi g ure 2-58 Work hold holder er Ca C alibrat libration ion - R em emove the Workholder the Workholder S et etup up and and Calibr Calibra ation Ga G aug e A ove s s embly T. Teach the preheat preheat heat block block assembly assembly at rail level (se (see e Figure 2-59 2-59): ): Fi g ure 2-59 2-59 Work hold holder er Calibration Calibration - Tea Teach ch Pr ehe eheat at Heat B lock As s em embly bly 1. Install Install the rail width width gauge gauge between between the rails rails (see step step I.). I.). 2. Move the rail width width gauge and and position itit until the bott bottom om surface of th the e pin, at the left side of the gauge, is directly above the preheat heat block assembly of preheat assembly (see Figure 2-60). 2-60). 3. Use the Up and and Down arrow arrow button button on the MMI to move move the hea heatt block assembly up until the top surface touches the pin of the rail width gauge. Workholder 98888-0000-JB3-01 2-49 IConn High Performance Wire Bonder 2-59). 4. Sel Select ect OK (see Figure 2-59). Pin touches the top surface of the preheat heat block assembly Rail Width Gauge Preheat Heat Block Assembly Fi g ure 2-60 2-60 Workhold Workholder er C alibra libration tion - P in Touches Touches P rehe rehea at Hea Heat Blo B lock ck A s s em embl blyy U. Remove the rail wid width th gauge from the prehea preheatt assembly assembly,, then select OK (see Figure 2-61 2-61). ). Fi g ure 2-61 2-61 Work hold holder er Calibr Calibra ation - R em emove ove the R ail Width Width Gaug e V. Make sure that all calibratio calibration n gauge removed from from the workhold workholder er,, then select OK (see Figure 2-62 2-62). ). Fi g ure 2-62 2-62 Work hol holder der C alibrat libration ion - R em emove ove A ll C alibrat libration ion Gauges G auges W. Install the heat block inserts inserts on the bond site and preheat heat block assem2-63). bly, bly, if necessary, then select OK (see Figure 2-63). Fi g ure 2-63 2-63 Work hold holder er Calibr Calibra ation - Ins ta tall ll Heat B lock Ins erts X. Workholder Workholder Calibrati Calibration on compl completes, etes, then then selec selectt OK (see Figure 2-64 2-64). ). Fi g ure 2-64 2-64 Work hold holder er Calibr Calibra ation - C omp omple lete te 2-50 Workholder 98888-0000-JB3-01 Material Handling System Manual 2. 2.4. 4.2 2 He Heat at Bloc Block kC Cal alib ibra rati tion on 2.4.2.1 Introduction The function of this calibration is to teach the bond height position. Bond height is the vertical position of the bond site heat block gauge/insert when the device focus is set. 2. 2.4. 4.2. 2.2 2 Do the the H Hea eatt B Blo lock ck Cali Calibr brat atio ion n Tools/ Materials/ Parts • Workho Workholder lder Setup Gauge (P/N: 03035-0908-00 03035-0908-001-XX) 1-XX) (Heat Block Gauge) • He Heat at B Blo lock ck Ins Inser erts ts (P(P-pa part rt)) Procedure WARNING: DO NOT TOUCH THE HEAT BLOCK OR INSERTS WITH W ITH UNPROTECTED HANDS IF THE WORKHOLDER HEATERS ARE AT OPERAT OPERAT-ING TEMPERATURE. WHEN REMOVING THE T HE HEAT BLOCKS OR INSERTS, INSTALL A SCREW AT THE REAR EDGE OF THE HEAT BLOCK/INSERT AND GRASP THE SCREW WITH PLIERS. THERE IS ONE M4 TAPPED HOLE IN THE HEAT BLOCK/INSERT FOR THIS PURPOSE. A. Select [5] CALIBRATION from the mode bar. B. Se Sele lect ct [4] WORKHOLDER from the Calibration menu. C. Sele Select ct [2] HEAT BLOCK from the Workholder menu. D. Make sure that the corr correct ect heat block gauge/inse gauge/insert rt is install installed ed on the bond site 2-65). ). heat block assembly, then select OK (see Figure 2-65 Fi g ure 2-65 2-65 Hea Heatt B lo lock ck C alibra librattion - Ins ta tall ll B ond Si te Hea Heatt Blo B lock ck G aug es/ es/Ins Ins ert ertss E. Use Use the the mous mouse e and and [B2] to move the bond head until the heat block gauge/ insert on the bond site appears on the screen. fun ction bar. F. If necessary necessary,, adjust th the e illumination illumination using using the F10 button on the function G. Continue to move the bond head until the bond tool is above a solid portion of the heat block gauge/insert (see Figure 2-66). 2-66). H. Sele Select ct OK. The head block assembly moves up and the bond tool (capillary) touches the heat block gauge/insert. 2-66 Hea Heatt B lock Calibration Calibration - Move B ond Hea Head d Fi g ure 2-66 Workholder 98888-0000-JB3-01 2-51 IConn High Performance Wire Bonder 2-67). ). I. Remove Remove the the heat heat block block gauge gauge from from the bond bond site site (se (see e Figure 2-67 Fi g ure 2-67 2-67 Hea Heatt B lock Calibration Calibration - R em emove ove the Heat B lock Ga G aug e J. Heat block block calibra calibration tion complet completes, es, then then select select OK (see Figure 2-68). 2-68). 2-68 Heat B lock Calibration Calibration - C omp omple lete te Fi g ure 2-68 2. 2.4. 4.3 3 Tuc ucke kerr Ej Ejec ectt Ca Calib libra ratio tion n 2.4.3.1 Introduction The tucker eject calibration calculates the distance from the indexer/tucker home position to the position where the end of the tucker pin is aligned with the outer surface of the Output Magazine Handler side wall. This calibration is necessary 2. 2.4. 4.3. 3.2 2 only when the tucker is replaced. Do th the e Tuc Tucke kerr Eje Eject ct Cal Calib ibra rati tion on Tools/ Materials/ Parts • Ruler Procedure A. Select [5] CALIBRATION from the mode bar. B. Sel Select ect [4] WORKHOLDER from the Calibration menu. C. Sele Select ct [3] TUCKER EJECT from the Workholder menu. WARNING: THE OUTPUT MAGAZINE MAY BE EJECTED AS PART OF THE TUCKER CALIBRATION. KEEP HANDS AWAY FROM THE OUTPUT MAGAZINE HANDLER. D. Keep hands awa away y from the Output Magazine Magazine Handle Handler. r. The output output magazine (if the gripper holds the magazine) will eject before the calibration start, then select OK (see Figure 2-69 2-69). ). Fi g ure 2-69 2-69 Tucker E ject C alibra libration tion - Warning Warning 2-52 Workholder 98888-0000-JB3-01 Material Handling System Manual E. Do th the e calibr calibrati ation on (see (see Figure 2-70): 2-70): 2-70 Tucker E ject C alibra libration tion - Alig n the the Tucker Fi g ure 2-70 1. Use the Left Left and Right Right arrow key key on the MMI MMI to move the ttucker ucker un until til the tip extends 1/16 inches through the opening of the Output Magazine Handler wall (see Figure 2-71). 2-71). 2. Se Sellect OK. The tucker moves to home position. Output Magazine Handler Wall Tip extends 1/16 inches through the opening of wall Tucker Fi g ure 2-71 2-71 Tucker E ject Calibrat Calibration ion - Tucker Tip E xten xtends ds 1/ 1/16 16 inches 2.4. 2.4.4 4 Wo Work rkho hold lder er Ca Cali libr brat atio ions ns Selecting [4] WORKHOLDER CALIBRATIONS from the ‘Workholder’ menu displays a dialog box containing the results of all the workholder calibrations. All of the items in the dialog box are for viewing purposes only and cannot be changed by the user. Workholder 98888-0000-JB3-01 2-53 IConn High Performance Wire Bonder 2. 2.5 5 Wor orkh khol olde derr C Con onfi figu gura rati tio on The workholder is configured in the Workholder Configuration menu. Each item in the menu displays a dialog box that contains parameters related to the operational characteristics of the workholder components. To access the Workholder Configuration menu (see Figure 2-72), 2-72), select [4]CONFIGURE from the mode bar then select [5] WORKHOLDER from the Configure mode menu. The dialog box for each item is opened when the item is selected from the menu by the mouse or the number of the specified item is selected on the keyboard. When the specified dimensions, parameters, or options have been configured, the user can select APPLY, DONE, or CANCEL. • Select APPLY to write the settings to the software and the dialog box remains open. • Select DONE to write the settings to the software and close the dialog box. • Select CANCEL to close the dialog box and ignore the changes made. To close the Workholder Configuration menu, push the [ESC] button on the keyboard when necessary. necessary. Boat/device dimensions and indexing parameters are specified in the paragraphs that follow. For information on magazine dimensions and parameters refer to Section 3 of this manual. Fi g ure 2-72 Workhold Workholder er Config urat uration ion Menu Menu 2-54 Workholder 98888-0000-JB3-01 Material Handling System Manual 2. 2.5. 5.1 1 Bo Boat at/D /Dev evic ice e Dim Dimen ensi sion ons s Select [1] DEVICE PARAMETERS from the Workholder Configuration menu (see 2-73). The "Boat/Device Dimensions" dialog box appears. It contains the Figure 2-73). boat dimensions, device dimension and bond plane offset adjustment parameters. Enter the boat and device dimensions to prepare a bond program for a new type of boat and to adjust the bond plane offset. 2-73 B oa oat/ t/Device Device Parame Parametters Dial Dialog og B ox Fi g ure 2-73 2.5.1.1 Boat Di Dimensions The boat dimension parameters in the ‘Boat/Device Parameters’ dialog box are given below (see Figure 2-74): 2-74): • DEVICE PI PITCH Device Pitch is the measurement from the center of one device (center of the index hole marking) to the center of the next device (center of the next index hole marking) to be indexed. It is the distance distance the index assembly moves during each index cycle. The J Boat MHS supports supports a device pitch from 0.25 inch (6.4 mm) to 6.0 inches inches (152.4 mm). • BOAT WIDTH Boat Width is the measurement from the front edge of the boat to the rear edge of the boat. The J Boat MHS supports boat widths from 3.1 inches (78.7 mm) to 4.3 inches (109.2 mm). • IND IN DEX EXES ES PER BO BOAT Indexes per Boat is the total number of the index operations necessary to move the boat through the bond site. • RIG RI GHT CEN CENT TER OFFSE SET T Right Center Offset is the distance measured from the right edge of the boat to the center of the first right-most device. • LEF LE FT CEN CENTE TER R OF OFF FSE SET T Left Center Offset is the distance measured from the left edge of the boat to the center of the first left-most device. • Y FR FRON ONT T CEN CENTE TER R OFF OFFSE SET T Y Front Center Offset is the distance from the front edge of the boat to the t he center of a device. Workholder 98888-0000-JB3-01 2-55 IConn High Performance Wire Bonder • HOLE PITCH Hole Pitch is the distance measured between the centers of two adjacent index holes. IConn Ball Bonder software supports an index hole pitch of 0.5, 0.6, 0.75, 1.0, and 1.5 inches (12.7, 15.2, 19, 25.4, and 38.1 mm). LEFT RIGHT CENTER CENTER OFFSET OFFSET BOAT DEVICE WIDTH DEVICE DEVICE DEVICE Y FRONT CENTER OFFSET DEVICE PITCH HOLE PITCH 2-74 4 B oa oatt Di me mens ns ions Fi g ure 2-7 • CAVITY DOWN SE SET Cavity DownofSet the on distance surface the boat the surface theisboat which measured the device from is onthe thetop edge of theofboat. (see to Figure 2-76). 2-76). • HOLE ON BOAT END • Hole On Boat End is the index index hole hole at the the end of the boat. IItt shoul should d be s set et to ‘True’ if it is machined to represent part of the size of the index hole. For conditions other than this, the parameter must be set to "False" (see Figure 2-75). 2-75). TRUE CONDITION FALSE CONDITION 2-75 Hole On B oa oatt E nd C ond onditions itions Fi g ure 2-75 2.5.1 .1..2 Device Di Dimensions The device dimension parameters in the ‘Boat/Device Parameters’ Paramet ers’ dialog box are given below (see Figure 2-76): 2-76): • BON BO ND PL PLA ANE HEI EIG GHT Bond Plane Height is the distance measured from the center cent er bond plane of the device to the heat surface of the device. • VACUUM HE HEIGHT Vacuum Height is the distance measured from the surface of the device that is on the boat to the heat surface of the device. • LOWER EX EXTENSION Lower Extension is the distance measured from the heat surface of the device to the bottom of the device. • DEVI VIC CES PE PER IN INDEX "Device Per Index" specified the number of devices that are moved up by the heat block for bonding during each index cycle. 2-56 Workholder 98888-0000-JB3-01 Material Handling System Manual BOND PLANE HEIGHT DEVICE BOAT CAVITY DOWN SET VACUUM HEIGHT HEAT SURFACE LOWER EXTENSION BOAT Fi g ure 2-7 2-76 6 Device Di me mens ns ions 2.5 .5..1.3 Bond Plane Offset The Bond Plane Offset adjustment sets the heat block height. It is the value entered in this parameter, which is offset (+/- 50 mils) from the calibrated height heigh t of the heat block. This offset is added to the heat block default value set under ‘Heat Block Utilities’. 2. 2.5. 5.2 2 Inde Indexi xing ng Pa Para rame mete ters rs Select [2] INDEXING PARAMETERS from the Workholder Configuration menu (see Figure 2-77). 2-77). The "Indexing Parameters" dialog box appears. It allows the user to enter the parameters that is related to the indexing operation. Fi g ure 2-7 2-77 7 Index Param Paramet eters ers D ial ialog og B ox The indexing parameters are given below: • MAXI MA XIM MUM SL SLO OT COU COUN NT Maximum Slot Count keeps the count of empty slots that have been detected in the input magazine. It should be set to the maximum number of consecutive empty boat slots allowed for the input magazine during the process program. For process programs, a fully occupied input magazine is required, it should be set to zero. This will cause the machine to stop as soon as an empty input slot is encountered. Workholder 98888-0000-JB3-01 2-57 IConn High Performance Wire Bonder • MAX AXIM IMUM UM NO VA VAC C CO COUN UNT T Maximum No Vac Count determines the maximum number of devices that are allowed to be skipped as a recovery action for a missing vacuum before an error is indicated. If no vacuum is detected at the bond site heat block, a "Missing Vacuum Recovery" dialog box is displayed. This dialog box gives the user several options, including the option to skip the present device at the bond site and resume the process. • BOA BO AT 1ST 1ST IN IND DEX DE DEL LAY • BOAT BO AT 2N 2ND+ D+ IN INDE DEX X DE DELA LAY Y User-specified delay to allow for device thermal expansion prior to bonding alignment. Sets the delay time between securing the material at the bond site and the subsequent align/bond cycle. The delay is applied to the first index of every boat no matter what type of index used (i.e., Index key, Auto index, dry cycle index). Same as the Boat 1st Index Delay parameter except that this delay is applied to subsequent indexes of every boat (i.e., all indexes of the boat after the first index of that boat). • MIN PREH EHE EAT TI TIME Min Preheat Time Time is the minimum amount of time the device is to remain over the preheat block before being indexed to the bond site heat block. • MAX PR PREHEAT TI TIME Max Preheat Time is the maximum amount of time the device is to remain over the preheat block before being indexed to the bond site heat block. block. Thisparameter works in conjunction with the Check Device Overheat parameter in the "Workholder Configuration" dialog box. • PREHEAT LIFT Preheat Lift defines how high the preheat block raises a device above the boat surface on which it rests. This parameter must be set to a value value to have the device lifted high enough so that it is not touching the boat. However However,, since the preheat block does not incorporate a device holding mechanism (vacuum), this parameter should not be set to a height that would cause the device to slip out of its nest on the boat. Therefore, it is boat dependent. • PREH PR EHEA EAT T THI HIC CKNE NESS SS Set the vertical distance between the top and bottom surfaces of the preheat heat block insert. • HEAT HE AT BL BLOC OCK K TH THIC ICKN KNES ESS S Set the vertical distance between the top and bottom surfaces of the bond site heat block insert. • RAIL HEIGHT Set the rail height relative to the preheat and bond site heat block height for the different type of carrier that will be processed. The applicable spacers are installed to the indexer assembly to adjust the rail height. • PREH PR EHEA EAT T DE DEL LAY TIM TIME E The Preheat Delay Time prevents the device from over-heated before bonding. Sets the delay time before the puller starts to inject the next device to the bond site. 2-58 Workholder 98888-0000-JB3-01 Material Handling System Manual 2.5.3 .5.3 Ind Index exin ing gO Op pti tion ons s Indexing Options allow the user to enable or disable the "Count Empty Slot" parameter. The "Index Options" dialog box is displayed by selecting [3] INDEXING OPTIONS from the Workholder Configuration menu (see Figure 2-78). 2-78). 2-78 78 Inde Indexing xing Opt Options ions Dialog Dialog B ox Fig ure 2The indexing options parameters are given below: • COUN CO UNT T EMP EMPTY TY IN INPU PUT T SLO SLOT T Count Empty Input Slot stops the machine if it is enabled and if an input magazine slot is empty. If slots are to be skipped in the input magazine, the Slots/ Step parameter from the "Input Magazine Slot Order" and the "Output Magazine Slot Order" dialog boxes should be used in order to keep the bonder executing the process program (refer to Section 3). • COUN CO UNT T NO VA VAC C SL SLO OT This parameter, when set to "Yes", works in conjunction with the "Check Heat Block Vacuum" setting in the Workholder Configuration dialog and the "Maximum No Vacuum Count" setting in the Index Parameters dialog. For example, if "Check Heat Block Vacuum" is set to "On" and "Maximum No Vacuum Count" is set for three (3) indexes, the bonder will stop indexing after the third "skip index" during a "vacuum not present" condition at the heat block as long as "Count No Vacuum Slot" is set to "Yes". "Yes". 2.5. 2.5.4 4 Wo Work rkho hold lder er Co Conf nfig igur urat atio ion n Workholder Configuration allows the user to set parameters that control the default cycle times used when carried out the diagnostics on the workholder. It also allows the user to check for device overheating at the preheat block and a vacuum-present condition at the bond site heat block. The Workholder Configuration dialog box is displayed by selecting [3] WORKHOLDER CONFIGURATION from the Workholder Configuration menu (see Figure 279.). 79 .). Fi g ure 2-7 2-79 9 Workhold Workholder er C onfig ura uration tion Dial Dialog og B ox Workholder 98888-0000-JB3-01 2-59 IConn High Performance Wire Bonder The Workholder Configuration parameters are given below: • CHEC CH ECK K DEV DEVIC ICE E OVE OVERH RHEA EAT T Check Device Overheat can be set to ON or OFF, but should be set to ON when running a hot process. If running a cold process, it should be set to OFF. When set to ON, the amount of time that the device is heated at the preheat block is compared with the Max Preheat Time parameter in the "Index Parameters" dialog box. If the device is on the preheat block for a time period longer than the one specified by "Maxthe Preheat Time" Time" parameter, an alert recovery dialog box is displayed giving operator the following options: • • Skip D Device evice (skips (skips device device on on the prehea preheatt block block and resume process). process). • Ign Ignore ore Overh Overheat eat (i (igno gnores res overh overheat eat alert alert and and resumes resumes pr proce ocess) ss).. • Skip B Boat oat (skips (skips boat at preheat preheat block block and rresumes esumes process process with with nex nextt boat). • Abor Abortt (re-i (re-init nitial ialize izes s an and d remo removes ves mate material rial)) CHEC CH ECK K HEA HEAT T BLO BLOCK CK VA VACU CUUM UM Check Heat Block Vacuum can be set to ON or OFF, OFF, but should be set to ON when running a process program. When set se t to ON, the presence of vacuum is verified whenever a device is at the bond site pedestal or heat block. If no vacuum is detected, a "Missing Vacuum Recovery" dialog box is displayed giving the operator the following options. • • Skip D Device evice (skips (skips device device at at bond bond site heat block and rresumes esumes process). process). • Che Check ck Vacu Vacuum um Sensor Sensor Again Again (p (perfo erforms rms a ret retry ry using using sam same e devi device) ce).. • Skip Bo Boat at (skips (skips boat at heat heat block block a and nd res resumes umes process process with with next boat). • Abor Abortt (re-i (re-init nitial ialize izes s an and d remo remove ve mate materia rial) l) CYCLE DELAYS Cycle Delays relate directly to the Cycle Period parameters in the dialog boxes that are used to run component diagnostics under the Diagnostic mode (refer to IConn Operation Manual). There are cycle delays for puller, indexer indexer,, and heat block diagnostics. When set by the user, each parameter defines the default value for how much time (pause) there is to be between each cycle during the execution of that component's diagnostic. 2-60 Workholder 98888-0000-JB3-01 Material Handling System Manual 2. 2.6 6 J Bo Boat at Inde Indexe xerr Asse Assemb mbly ly R Rem emov oval al a and nd IIns nsttalla allati tion on Purpose • Remove the J boat indexer indexer assembly assembly fro from m the machine. machine. When necessary necessary,, use the following procedure to remove the J boat indexer assembly from the machine for maintenance. WARNING: INJURY HAZARD. INCORRECT MAINTENANCE COULD CAUSE INJURY.. DO NOT DO MAINTENANCE UNLESS YOU HAVE COMINJURY PLETED THE APPROVED MAINTENANCE TRAINING COURSE. READ THE DATA IN THE SAFETY CHAPTER. CAUTION: Injury Hazard. The J Boat Indexer Assembly weight approximately 44 pounds (20 Kilograms) . To prevent injury, use approved equipment or two persons to lift and move the assembly. Tools/ Materials/ Parts • J Boa Boatt Indexe Indexerr Assemb Assembly ly,, P/N 0303 03035-0 5-0010 010-000 -000-xx -xx • Hand Tools Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Remove the preheat heat block assembly and bond site heat block assembly. D. Open th the e lower console front door door.. E. Remove MMI assembly assembly from the the machine. machine. 1. Make sure that that the electrica electricall cables tto o the MMI asse assembly mbly are c correctl orrectly y identified. If not, make a note of the connection. 2. Remove Remove all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 3. Disconnect Disconnect the fo followin llowing g cables connectors connectors at the rea rearr of the MMI assembly: • USB1 USB1 cabl cable e from from th the e mat matro rox x box box • USB2 USB2 cabl cable e ffrom rom the matro matrox x box box • MMI MMI cabl cable e from from w wir ire e fe feed ed// bi bits ts b boa oard rd 4. Remove Remove two (2) x M4 shoulder shoulder screws screws with with flat nylon nylon washer washers s and wave washers at the bottom of the lower console top plate that attach the MMI onto the lower console top plate. 5. Lift up up the MMI MMI Assembly Assembly and remove remove it from from the m machine achine.. F. Remove the microscope microscope assembly: assembly: 1. Loosen the the M6 screw on on the left side side of the iindexer ndexer ba base se that holds holds the microscope stand. 2. Remove the microsco microscope pe with the stand stand from the J boat indexer indexer assembly assembly.. G. Loosen the two captive captive screws that attach attach the PCB cover to the indexer base base.. H. Remove the PC PCB B cover to access access the indexer intermedi intermediate ate board. 98888-0000-JB3-01 Workholder 2-61 IConn High Performance Wire Bonder I. Remove Remove the input input tra tray y asse assembl mbly: y: CAUTION: Injury Hazard. The Input Tray Tray Assembly weight approximately 17.64 pounds (8 Kilograms). To prevent injury, use approved equipment or one to two persons to lift and move the assembly. 1. Make sure that that the electrical electrical cables to the the input tray assembly assembly ar are e correctl correctly y identified. If not, make a note of the connection. 2. Remove all all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 3. Disconnect Disconnect the in/ in/out out tray cable cable connector connector from the conne connector ctor J14 of the indexer intermediate board. 4. Loosen the the four (4) M6 captive captive screws that attach attach the in input put tray assem assembly bly to the input base plate and machine top plate. 5. Remove the input input tray assembl assembly y from the machin machine. e. J. Rem Remove ove the the output output tray tray assembl assembly: y: CAUTION: Injury Hazard. The Output Tray Assembly weight approximately 17.64 pounds (8 Kilograms). To prevent injury, use approved equipment or one to two persons to lift and move the assembly. 1. Make sure sure that the electrica electricall cables to to the output output tray ass assembly embly ar are e correctly identified. If not, make a note of the connection. 2. Remove all all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 3. Disconnect Disconnect the in/ in/out out tray cable cable connector connector from the conne connector ctor J15 of the indexer intermediate board. 4. Loosen the the four (4) M6 captive captive screws that attach attach the in input put tray assem assembly bly to the input base plate and machine top plate. 5. Remove the output output tray assembly assembly from tthe he machi machine. ne. K. Remove the th three ree (3) M4 screws and and washers th that at attach the the indexer cov cover er assembly to the J boat indexer assembly. L. Remove the indexer indexer cover assembly assembly.. M. Remove the J boat indexer indexer assemb assembly ly from the machine machine (see Figure 2-80 and 2-81). ). Figure 2-81 1. Make sure that that the electrical electrical cables cables to the indexe indexerr assembly a are re correct correctly ly identified. If not, make a note of the connection. 2. Remove all all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 3. Remove the input input and output output present present sensor sensor brackets: brackets: a. Loosen the the M3 set screw screw in the present present sensor sensor brac bracket ket that attach attach the present sensor. b. Remove the present present sensor sensor from from th the e bracket. bracket. c. Remove the the M3 screw screw each at the two two ends of the re rear ar rail as assembly sembly that attach the present sensor bracket. d. Remove the present present sen sensor sor brackets. brackets. 2-62 Workholder 98888-0000-JB3-01 Material Handling System Manual 4. Disconnect Disconnect the fo followin llowing g cables from from the ind indexer exer inte intermedia rmediate te board. Refer to Appendix B on the MHS cable routing for details.: • MHS Sensor Sensor Bus Bus Cable Cable P/N 0888808888-108 1082-0 2-00000-17 17 to board board connec connector tor J2 • Indexe Indexerr DMHS Cabl Cable e P/N 08888-1 08888-1250 250-00 -000-xx 0-xx to to board board connec connector tor J1 • Solenoi Solenoid d Cable Cable P/N 0888808888-125 1251-0 1-000-x 00-xx x to board board con connec nector tor J6 5. Disconnect Disconnect the following following cables cables fro from m the inter interface face panel panel at the right right side of the XY table assembly, attach to the Upper Console. Refer to t o Appendix B on the MHS cable routing for details.: • Preheat Preheat Heater Heater Asse Assembl mbly y P/N 031 03118-0 18-0333 333-00 -000-00 0-00 • Preheat Preheat Ther Thermoco mocoupl uple e Assembl Assembly y P/N 031 0311818-100 1004-0 4-000-1 00-19 9 6. Remove all all the cable cable ties and open open the cable cable clamps clamps if neces necessary sary to release the preheat heater and thermocouple cables on the slider assembly. Make a note of the cable routing and cable clamps positions. 7. Use the T-handle T-handle wrench wrench supplied supplied in the tool kit (P/N: (P/N: 08888-090 08888-0901-0001-000-xx) xx) to remove the four (4) M6 screws and washers from the indexer base. 8. Hold the left left and right right side of the front front wall wall and lift lift up the J boat indexer indexer assembly from the lower console top plate (see CAUTION). Input Tray Assembly Present Sensor Brackets 2-81)) (see Figure 2-81 4x M6 Screws and Washers ‘C’ Plates Output Magazine Handler (Not shown here) Integrated Table Lifting Support Handler J Boat Indexer Assembly Lifting Support Handler J Boat Slider Assembly 2-80 R em emove/ ove/R R ep epla lace ce J B oa oatt Indexer As s em embl blyy Fi g ure 2-80 Workholder 98888-0000-JB3-01 2-63 IConn High Performance Wire Bonder M3 Set Screw M3 Screw M3 Screw M3 Set Screw Input Present Sensor Input Present Sensor Bracket Input Present Sensor Rear Rail Assembly Output Present Sensor Bracket Notch on J boat slider base for indexer pin 4x Threaded holes Indexer pin engages to the notch on the slider base Fi g ure 2-81 2-81 R em emove ove//R epl epla ace J B oa oatt Indexe Indexerr A s s em embl blyy N. Insta Installll the J boat indexer indexer assembly assembly (see (see Figure 2-80 and Figure 2-81 2-81). ). 1. You must have the aid aid of at least two persons persons to hold the J boat ind indexer exer assembly at the left and right side of the front wall, and put on the machine top plate. (See CAUTION.) CAUTION: Injury Hazard. The J Boat Indexer Assembly weight approximately 44 pounds (20 Kilograms) . To prevent injury, use approved equipment or two persons to lift and move the assembly. 2. Make sure that that the rear of the J boat boat indexer indexer assembly points points to th the e front of the slider assembly. assembly. 3. Move the rear rear of J boat indexer indexer assembly assembly to the the front of the s slider lider as assembly sembly until the benching pin is engaged to the notch on the slider base. 4. Install Install the J boat indexer indexer assembly assembly to the lower console console top plat plate e with the screws and washers removed before with the T-handle wrench. 5. Torque the screws screws to 70 in.lb in.lb (7.9 Nm). 6. Install Install the input and output output present present sensor brackets brackets to the the two ends of the rear rail assembly with the screw removed before. 7. Install Install the present present sensors to the sensor sensor brack brackets ets and tighten tighten the setscrews. 2-64 Workholder 98888-0000-JB3-01 Material Handling System Manual 8. Connect Connect the elec electrical trical cables cables to the the indexe indexerr intermediate intermediate board. Refer to your notes. 9. Connect Connect the preheat heater heater cable and and thermocouple thermocouple cable cables s connect connectors ors to the interface panel. Refer to your notes. 10.Attach the electrical cables with cable ties and cable clamps to the J boat indexer assembly and slider assembly. Refer to your notes. 11.Attach the indexer cover assembly to the J boat indexer assembly with the screws and washers removed before. 12.Install the microscope assembly to the left side of the indexer base and tighten the screw loosen before. O. Install Install the input input tray assembly assembly (see CAUTION). 1. Put the input input tray assembly assembly on the front front edge of of the input base base plate. plate. 2. Attach the the input tray tray assembly assembly to the in input put base plate plate with th the e captive screws removed before. 3. Make sure the ‘C’ ‘C’ plates on the input input wall and the input input fixed wall wall interloc interlock k each other. 4. Connect Connect the in/out tray tray cable connecor connecor to the con connector nector J14 J14 of the indexe indexerr intermediate board. Refer to your notes. 5. Attach the the electrical electrical cables with with cable ties ties and cable clamps clamps to the inp input ut tray assembly and indexer assembly. Refer to your notes. P. Install Install the output tray assembl assembly y (see CAUTION). 1. Put the output output tray assembly assembly on the the front edg edge e of the output output base plate. plate. 2. Attach Attach the output output tray assembly assembly to the output output base base plate wi with th the captive captive screws removed before. 3. Make sure the the ‘C’ plates plates on the output output wall wall and the output output fixed fixed wall int intererlock each other. 4. Connect Connect the in/ou in/outt tray cable connecor connecor to the connecto connectorr J15 of the indexer indexer intermediate board. Refer to your notes. 5. Attach Attach the electrical electrical cables cables with cable ties ties and cable cl clamps amps to the inp input ut tray assembly and indexer assembly. Refer to your notes. Q. Install Install the PCB cover to the indexer base and tighte tighten n the two captive screws. screws. R. Insta Installll the MMI MMI Assembly Assembly on the the mach machine. ine. 1. Put the MMI assembly assembly on on the front edge edge of the low lower er console console top plate. plate. 2. Pull the electric electrical al cables cables for the MMI assembl assembly y below and through through th the e opening on the lower console top plate. Refer to your notes. 3. Connect Connect the cabl cables es to the MMI assembl assembly y. Refer to y your our notes notes.. 4. Install, Install, but do not tighten tighten the two (2) shoulders shoulders scr screws ews with flat flat washers and wave washers below the lower console top plate to attach the MMI assembly. 5. Move the MMI MMI assembly assembly to the front front of the J boat boat indexer indexer assembl assembly y. 6. Tighten Tighten the screws screws to attach the MMI MMI assembl assembly y to the lower cons console ole top plate. S. Close the lower lower console console front front door. door. T. Install Install the preheat heat heat block assembly assembly to the preheat preheat assembly assembly.. U. Insta Installll the bond site heat block block assembly to the slider slider assembly assembly.. Workholder 98888-0000-JB3-01 2-65 IConn High Performance Wire Bonder 2.7 2.7 J Bo Boat at S Sli lide derr As Asse semb mbly ly Rem Remov oval al a and nd IIns nsta tall llat atio ion n Purpose • Remove the J boat slider slider assembl assembly y from the ma machine. chine. When ne necessary cessary,, use the following procedure to remove the J boat slider assembly from the machine for maintenance. WARNING: INJURY HAZARD. INCORRECT MAINTENANCE COULD CAUSE INJURY. DO NOT DO MAINTENANCE UNLESS YOU HAVE COMPLETED THE APPROVED MAINTENANCE TRAINING COURSE. READ THE DATA IN THE SAFETY CHAPTER. CAUTION: Injury Hazard. The J Boat Slider Assembly weight approximately 22 pounds (10 Kilograms) . To prevent injury, use approved equipment or two persons to lift and move the assembly. Tools/ Materials/ Parts • J Boat Boat Slider Slider Asse Assembl mbly y, P/N 0303503035-004 0040-00 0-000-xx 0-xx • Hand Tools Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Remove the inpu inputt tray assembly assembly from the machine. Refer Refer to paragraph 2.6, 2.6, step I.. I.. CAUTION: Injury Hazard. The Input Tray Tray Assembly weight approximately 17.64 pounds (8 Kilograms). To prevent injury, use approved equipment or one to two persons to lift and move the assembly. D. Remove the outpu outputt tray assembly from from the machine. Refe Referr to paragraph 2.6 2.6,, J... step J. CAUTION: Injury Hazard. The Output Tray Assembly weight approximately 17.64 pounds (8 Kilograms). To prevent injury, use approved equipment or one to two persons to lift and move the assembly. E. Remove the J boa boatt indexer ass assembly embly from the machine. machine. Refer Refer to paragraph paragraph 2.6. 2.6. CAUTION: Injury Hazard. The J Boat Indexer Assembly weight approximately 44 pounds (20 Kilograms) . To prevent injury, use approved equipment or two persons to lift and move the assembly. F. Remove the the J boat slider slider assembly assembly from from the machi machine. ne. (See Figure 2-82). 2-82). 1. Make sure that that the electrical electrical cables cables to the J boat slide sliderr assembly ar are e correctly identified. If not, make a note of the connection. 2. Remove all all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 2-66 Workholder 98888-0000-JB3-01 Material Handling System Manual 3. Disconnect Disconnect the ffollowi ollowing ng cables connect connectors ors and vacuum vacuum tubing from the interface panel. Refer to Appendix B on the MHS cable routing for details. • Heat Heat Block Block Sensor Sensor P/N 0341 03411-10 1-1031-0 31-001-1 01-17 7 • Heat Heat Block Block Motor Motor Asse Assembly mbly P/N 0 0888 8888-1 8-1101 101-000 -000-xx -xx • Heat Heat Block Block Heate Heaterr Assembl Assembly y P/N 031 0311818-033 0333-0 3-000-0 00-01 1 • • Heat Heat Block Therm Thermocou ocouple ple Ass Assemb embly ly P/N 0311803118-100 1004-0 4-000-2 00-20 0 Clamp Clamp Grou Ground nd W Wire ire Cable Cable P/N P/N 0 0888 8888-10 8-106464-000 000-xx -xx • Vacuum Tubing 4. Remove the the cables and vacuum vacuum hose from the slider slider routi routing ng bracket attach attach to the integrated table assembly. 5. Disconnect Disconnect the va vacuum cuum valve valve hose from the ffitting itting on the rrear ear right edge edge of the J boat slider assembly. 6. Remove the the two (2) M6 screws screws and washers washers on on the left and right side side of the J boat slider assembly that attach the assembly to the integrated table assembly. 7. Use the T-handle T-handle wrench wrench supplied supplied in the tool kit (P/N: (P/N: 08888-090 08888-0901-0001-000-xx) xx) to remove the four (4) M6 screws and washers at the front and rear of the slider base. 8. Hold the left lefrom ft and right rigmachine ht side oftop theplate. slider slider(See ba base seCAUTION and lift lift up slider lider assembly the .) . the J boat s CAUTION: Injury Hazard. The J Boat Slider Assembly weight approximately 22 pounds (10 Kilograms) . To prevent injury, use approved equipment or two persons to lift and move the assembly. G. Install Install the J boat slider slider assembly assembly (See (See Figure 2-82 2-82)) 1. You must have have the aid of at least least two persons persons to h hold old the J boat boat slider slider assembly at the left and right side of the slider base, and put on the machine top plate. (See CAUTION.) 2. Make sure that that the rear rear of the J boat slider slider ass assembly embly po points ints to the the front of the integrated table assembly assembly.. 3. Move the rear rear of J boat slider slider assembly assembly to the front front of the int integrated egrated ttable able assembly. 4. Make sure that that the three three surfaces surfaces on the sli slider der base to touches uches the s surface urfaces s at the front of the integrated table base. 5. Install Install the J boat slider slider assembly assembly to the machine top top plate and front of inteintegrated table assembly with the screws and washers removed before with the T-handle wrench. 6. Torque the screws screws to 70 in.lb in.lb (7.9 Nm). 7. Connect Connect the electr electrical ical cables cables and vacuum tubing tubing to the inte interface rface panel. panel. Refer to your notes. 8. Attach the the electrical electrical cables with with cable ties ties and cable clamps clamps to the J boat slider assembly. Refer to your notes. 9. Put the electrical electrical cables cables and tubing through through the sl slider ider routing routing bracket. bracket. 10.At the rear right edge of the J boat slider assembly, connect the vacuum valve tubing to the elbow fitting. H. Instal Installl the J boat indexer assembly assembly to the machine. Refer to paragraph paragraph 2.6. 2.6. Workholder 98888-0000-JB3-01 2-67 IConn High Performance Wire Bonder CAUTION: Injury Hazard. The J Boat Indexer Assembly weight approximately 44 pounds (20 Kilograms) . To prevent injury, use approved equipment or two persons to lift and move the assembly. I. Instal Installl the input input tray tray assembl assembly y (see p parag aragrap raph h 2.6 2.6,, step O. O.). ). J. Install Install the output tray assembly assembly (see paragrap paragraph h 2.6, 2.6, step P.) 4x M6 Screws and Washers Benching Surfaces See detail below Integrated Table Slider Assembly Lifting Support 2x M6 Screws and Washers Lifting Support Surfaces on the Integrated table base touch the surfaces on the Slider Base Left Threaded holes Surfaces on the Slider base touch Right Threaded holes the surfaces on the Integrated T Table able Base 4x Threaded holes Fi g ure 2-82 2-82 R em emove ove//R ep epla lace ce J B oa oatt S lide liderr A s s em embl blyy 2-68 Workholder 98888-0000-JB3-01 Material Handling System Manual 2.8 Pr Prev even enti tive ve Ma Maiint nten enan ance ce A preventive maintenance schedule for the workholder subsystem is provided in 2-2. Table 2-2. WARNING: REMOVE POWER FROM THE MACHINE BEFORE CHECKING THE SECURITY AND INTEGRITY OF THE WORKHOLDER ELECTRICAL CONNECTIONS. MAKE SURE ALL HEATING SURFACES HAVE COOLED BEFORE PROCEEDING. WARNING: REMOVE POWER FROM THE MACHINE BEFORE CHECKING THE TIGHTNESS OF THE WORKHOLDER ATTACHING HARDWARE AND INSPECTING THE PNEUMATIC LINES. MAKE SURE ALL HEATING SURFACES HAVE COOLED BEFORE PROCEEDING. Table 2-2 Workholder Preventive Maintenance Maintena nce Schedule Action Period Tools Procedure Clean heat block 8 hours Vacuum Hose Remove any dirt or contaminates from the preheat and bond site heat block area. Clean workholder and 40 hours Vacuum Hose Remove any dirt or contaminates from magazine handlers exposed and moving parts of the workholder. Lubricate puller drive rack on workholder 1000 hours Lubriplate #630-2 P/N: Apply thin coat of Lubriplate to rack teeth, making sure that all teeth are com39086-6004-000 pletely filled. Remove excess lubricant from top of rack and around rack when done. Replace heat block vacuum hose 1000 hours 1. Hand tools 2. Silicone Tubing, 9” long, P/N 82719-3000-000 1. Replace the vacuum hose between the rear of the heat block and the heat sink. Make sure all attaching hardware (screws, washers, nuts, etc.) are securely installed. 2. Make sure that there are no leaks or kinks in the hose before resuming production. Check hardware tightness 1000 hours Hand Tools Inspect electrical connections 1000 hours — Check for security and integrity of all electrical connections on the workholder. Refer to Section 4 for connector locations. Inspect pneumatic lines 1000 hours — Check for cracks, cuts, leaks, pinching or kinks. Also check for loose fittings or signs of stretching or wear. Correct as required. See Section 4 for connections. Workholder 98888-0000-JB3-01 2-69 IConn High Performance Wire Bonder Action Period Tools Lubricate X-slide bearing on the indexer assembly 3 months to 6 months 1. Lubricant (10 ml, in syringe), P/N: 27790-5020-000 2. Lint-Free Cloth 3. Hand gloves 4. Cotton buds 5. Hex Wrench Set Procedure 1. Push the [Motor Stop] button. 2. Remove the indexer assembly front cover. 3. Move the gripper assembly to the left or right side manually when neccessary. 4. Clean the v-grooves of the X-slide bearing on the front wall using the lintfree cloth. 5. Apply about 0.1 ml to 0.2 ml of the lubricant to the top and bottom of the v-grooves of the X slide bearings. 6. Move the puller assembly and index assembly along the X-slide bearing manually for 10 times. 7. Do steps 5 to 6 again for four times. 8. Remove the unwanted lubricant from the X-slide bearing with the lint-free cloth. 2-70 Workholder 98888-0000-JB3-01 Material Handling System Manual 2.9 2.9 Pa Part rts s Re Repl plac acem emen entt Pr Proc oced edur ures es 2.9.1 2.9 .1 Bon Bond d Si Site/ te/Pre Prehea heatt He Heat at B Bloc lock k As Assem sembly bly Par Parts ts 2. 2.9 9.1 .1.1 .1 Compr pre ess ssio ion n Spri ring ng Purpose • Replac Replace e the compression compression spring on the the bond site or preheat preheat heat b block lock assembly. Tools/ Materials/ Parts • Compre Compressi ssion on Spring Spring,, P/N: P/N: 6354363543-122 1229-0 9-036 36 • Hand Tool Procedure WARNING: IF THE WORKHOLDER IS HEATED, AVOID TOUCHING HEA HEATED TED PARTS PAR TS WHEN REMOVING PARTS OR MATERIAL (CARRIERS AND HEAT HEA T BLOCK INSERTS OR WHEN PERFORMING OTHER OPERATIONS. WAIT FOR HEATERS TO COOL. A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP]. Turn off machine power. C. Remov Remove e the heat block gauge gauge or inserts inserts (see section section 1). D. Remove the heat heat block block assembly: assembly: 1. Make sure sure that the el electrica ectricall cables to tthe he heat blo block ck assembly assembly are correctly identified. If not, make a note of the connection. 2. Disconnect Disconnect the hea heater ter and thermocoupl thermocouple e cable conne connectors ctors from th the e interface panel. 3. Remove Remove all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 4. Remove Remove the applicable applicable ground ground strap/wire strap/wire on the the bond site site (see step a.) a.) or preheat (see b. b.)) heat block assembly: a. At the left side side of the bond site heat heat block assembly assembly,, loosen the M2. M2.5 5 screw and pull out the metal jacket of the ground strap. b. At the front of the preheat preheat heat heat block assembly assembly,, remove th the e M2.5 screw then remove the ground wire terminal. 5. Remove Remove the four (4) M3 screws screws an and d washers that that attach attach the heat block block assembly to the preheat or bond site assembly. 6. Remove the the heat block assembly assembly and put it on a work work bench. bench. 2-83): ): E. Remove the compres compression sion spring (see Figure 2-83 1. Hold the lock lock pin and latch bar bar that are attach attach to the heat block assembly assembly.. 2. Remove Remove the two (2) (2) M3 flat head head s screws. crews. 3. Remove Remove the lock pin, pin, the latch latch bar and the compress compression ion spri spring. ng. 4. Discar Discard d the compres compression sion spring spring.. 2-83): ): F. Install Install the replacem replacement ent comp compressio ression n spring spring (see Figure 2-83 1. Install Install the spring into into the hole at the front front of the heat block assembly assembly.. 2. Install Install the latch bar to the front front of the heat bloc block k assembly. assembly. Make sure that the ledge is at the top and points to the rear of the heat block assembly. 3. Hold the latch latch bar in position position against against the front of the heat block block assembly assembly.. Make sure that the ledge is on the pin on the top of the heat block assem- bly. Workholder 98888-0000-JB3-01 2-71 IConn High Performance Wire Bonder 4. Align the front front surface surface of the latch latch bar with with the front front surface surface of the heat block assembly, while the spring is compressed. 5. Position Position the center center of the lock lock pin to the groove groove in the la latch tch bar. bar. 6. Torque the flat flat screws screws removed removed before to 6 in.Ibs in.Ibs (0.68 (0.68 Nm). Heat Block Assembly Compression Spring Lock Pin Latch Bar 2x M3 Flat Head Screws 2-83 83 Comp Compress ress ion S pring Fig ure 2G. Install Install the heat heat block block assembly: assembly: 1. Put the heat heat block block assembly assembly on tthe he prehe preheat at or bond site. 2. Install Install the heat block block assembly assembly to the preheat or bond bond site with the screws screws and washers removed before. Tighten the screws. 3. Connect Connect the electrical electrical cables cables to the interface interface panel. Refer Refer to your note notes. s. 4. Attach the the electrical electrical cables with with cable ties ties and cable cla clamps mps to the wor workkholder. Refer to your notes. 5. Install Install the ground ground strap/wire strap/wire to the applicable applicable preheat preheat or bond site heat heat block assembly with the screw removed before . H. Insta Installll the heat block gauge or inserts inserts removed before before to the heat block assembly (see section 1). I. Push Push tthe he green green machi machine ne ON switch switch.. J. Se Sellect OK to start initialization. K. Do the setup and ca calibrati libration on procedures procedures (see paragragphs paragragphs 2.3 and 2.4). 2.4). 2-72 Workholder 98888-0000-JB3-01 Material Handling System Manual 2. 2.9 9.1 .1.2 .2 Preh reheat Heater ter Ass Asse embly bly Purpose • Replac Replace e the heater assembly assembly in the preheat preheat heat block assembly assembly. This assembly contains a heating element that heats the preheat area up to a temperature set during configuration. Tools/ Materials/ Parts • • Hea Heater ter Assemb Assembly ly,, 0311803118-033 0333-00 3-000-0 0-00 0 Hand Tool Procedure WARNING: IF THE WORKHOLDER IS HEATED, AVOID TOUCHING HEA HEATED TED PARTS PAR TS WHEN REMOVING PARTS OR MATERIAL (CARRIERS AND HEAT HEA T BLOCK INSERTS) OR WHEN PERFORMING OTHER OPERAOPE RATIONS. WAIT FOR HEATERS TO COOL. A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP]. Turn off machine power. C. Remov Remove e the heat block gauge gauge or inserts inserts (see section section 1). D. Remov Remove e the preheat preheat heat heat block assembly: assembly: 1. Make sure sure that the el electrica ectricall cables to tthe he heat blo block ck assembly assembly are correctly identified. If not, make a note of the connection. 2. Disconnect Disconnect the pre preheat heat heater and and thermocouple thermocouple cabl cable e connectors connectors from the interface panel. 3. Remove Remove all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 4. At the front of the preheat preheat heat block as assembly sembly,, remove the M2. M2.5 5 screw then remove the ground wire terminal. 5. Remove the the four (4) M3 screws screws and and washers washers that attach attach the pre preheat heat heat block assembly to the preheat assembly. 6. Remove the the preheat preheat heat block assembly assembly and put it on a w work ork benc bench. h. 2-84): E. Remove the heater heater element element assembly assembly (see Figure 2-84): 1. Loosen the the heater element element set set screws at th the e top rear su surface rface of the the heat block assembly assembly.. 2. At the front of the heat block block assembly assembly,, pull out the hea heater ter elemen elementt assembly and discard. 2-84): F. Install Install the replacemen replacementt heater element element assembly assembly (s (see ee Figure 2-84): 1. Install Install the new heater heater element element assembly assembly into tthe he bore at the ffront ront of the heat block assembly. Workholder 98888-0000-JB3-01 2-73 IConn High Performance Wire Bonder 2. At the top rear surface surface of the heat block block assembl assembly y, carefull carefully y tighten the the heater element set screws until it is engaged to the heater elements. Heater Element Set Screw Thermocouple Set Screw Preheat Heat Block Assembly Preheat Thermocouple Preheat Heater Assembly Heater Element Set Screw Fi g ure 2-84 2-84 P rehea reheatt Hea Heate terr and and Thermocouple Thermocouple A s s em embl blies ies G. Install Install the preheat preheat heat block assembly: assembly: 1. Put the heat block block assembly assembly on the the preheat assembl assembly y. 2. Install Install the heat block block assembly assembly to the preheat assembly assembly with with the screws and washers removed before. Tighten the screws. 3. Connect Connect the electrical electrical cables cables to the interface interface panel. Refer Refer to your note notes. s. 4. Attach the the electrical electrical cables with with cable ties ties and cable cla clamps mps to the wor workkholder. Refer to your notes. 5. Install Install the ground ground wire to the front of the preheat preheat heat block block assembly assembly with the screw removed before. H. Insta Installll the heat block gauge or inserts inserts removed before before to the preheat heat block assembly (see section 1). I. Push Push tthe he green green machi machine ne ON switch switch.. J. Se Sellect OK to start initialization. 2.4). K. Do the setup and ca calibrati libration on procedures procedures (see paragragphs paragragphs 2.3 and 2.4). 2-74 Workholder 98888-0000-JB3-01 Material Handling System Manual 2. 2.9. 9.1. 1.3 3 Preh Prehea eatt Ther Thermo moco coup uple le Asse Assemb mbly ly Purpose • Replac Replace e the thermocouple thermocouple assemb assembly ly in the pre preheat heat heat heat b block lock a assembl ssembly y. This assembly monitors the temperature of the heater cartridge. Tools/ Materials/ Parts • Ther Thermoc mocoup ouple le Assembl Assembly y, P/N: 031 0311818-1004 1004-000 -000-19 -19 • Hand Tool Procedure WARNING: IF THE WORKHOLDER IS HEATED, AVOID TOUCHING HEA HEATED TED PARTS PAR TS WHEN REMOVING PARTS OR MATERIAL (CARRIERS AND HEAT HEA T BLOCK INSERTS) OR WHEN PERFORMING OTHER OPERAOPE RATIONS. WAIT FOR HEATERS TO COOL. A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP]. Turn off machine power. C. Remov Remove e the heat block gauge gauge or inserts inserts (see section section 1). 2.9.1.2,, step D. D.). ). D. Remov Remove e the preheat heat heat block assembly assembly (see paragraph paragraph 2.9.1.2 E. Remove the thermocou thermocouple ple assembly assembly (see Figure 2-84): 2-84): 1. Loosen the the thermocouple thermocouple set set screw at the the top rear surface surface of the the heat block assembly assembly.. 2. At the rear of the heat block block assembly assembly,, pull the thermo thermocouple couple assembly assembly rearward and discard. 2-84): F. Install Install the replacement replacement thermoc thermocouple ouple assembly assembly (s (see ee Figure 2-84): 1. Install Install the new tthermoco hermocouple uple assembly assembly in into to the bore at th the e rear of the hea heatt block assembly assembly.. 2. At the top rear surface surface of the heat block block assembly assembly,, carefull carefully y tighten the thermocouple set screw until it is engaged to the thermocouple. G. Install Install the preheat heat block block assembly (see paragraph paragraph 2.9.1.2, 2.9.1.2, step G.). H. Insta Installll the heat block gauge or inserts inserts removed bef before ore to the preheat heat block assembly (see section 1). I. Push the green green machin machine e ON ON swit switch. ch. J. Sel Select OK to start initialization. 2.4). ). K. Do the setup and and calibration calibration procedures procedures (see paragragp paragragphs hs 2.3 and 2.4 Workholder 98888-0000-JB3-01 2-75 IConn High Performance Wire Bonder 2.9 .9.1 .1.4 .4 Bon Bond Si Site Heater ter Ass Asse embly bly Purpose • Replace Replace the heater assembly assembly in the bond bond site heat bl block ock assembly assembly.. This assembly contains a heating element that heats the bond site area up to a temperature set during configuration. Tools/ Materials/ Parts • • Heater Heater Assembl Assembly y, 0311803118-033 0333-00 3-000-0 0-01 1 Hand Tool Procedure WARNING: IF THE WORKHOLDER W ORKHOLDER IS HEA HEATED, TED, AVOID TOUCHING HEATED PARTS PA RTS WHEN REMOVING PARTS OR MATERIAL (CARRIERS AND HEAT HEA T BLOCK INSERTS) OR WHEN PERFORMING OTHER OPE OPERARATIONS. WAIT FOR HEATERS TO COOL. A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP]. Turn off machine power. C. Remove the he heat at block gauge gauge or inserts inserts (see section section 1). D. Remove th the e bond site site heat block block assembly: assembly: 1. Make sure sure that the electrica electricall cables to to the heat block block assembly assembly are c cororrectly identified. If not, make a note of the connection. 2. Disconnect Disconnect the bon bond d site heater and and thermocouple thermocouple cable co connecto nnectors rs from the interface panel. 3. Remove all all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 4. At the left rear rear side of the bond site heat heat block ass assembly embly,, loosen the M2.5 screw and pull out the metal jacket of the ground strap. 5. Remove four four M3 screws screws and washers washers that attach attach th the e bond sit site e heat block block assembly to the bond site heat block assembly. 6. Remove the the bond site site heat block block assembly assembly and put iitt on a work bench. bench. 2-85): E. Remove the heater heater element element assembly assembly (see Figure 2-85): 1. Remove the the two M2.5 screws screws at the the bottom rrear ear of the heat heat block. 2. Remove the cable cable shield that that attach to the rear of the heat block block assembly assembly.. 3. Loosen the the heater element element set set screws at at the front to top p surface o off the heat block assembly. 4. At the rear of the heat block block assembly assembly,, pull the heater heater element assembly assembly rearward and discard. 2-85): F. Install Install the replaceme replacement nt heater e element lement assembly assembly (see (see Figure 2-85): 1. Install Install the new heater heater element element assembly assembly into tthe he bore at th the e rear of the heat block assembly. 2. At the front top surface surface of the heat block block assembly assembly,, carefull carefully y tighten the heater element set screws until it is engaged to the heater elements. 2-76 Workholder 98888-0000-JB3-01 Material Handling System Manual 3. Install Install the cable cable shield to to the rear of the the heat block block with the the screws removed before. Cable Shield Bond Site Heater Assembly Thermocouple Set Screw 2x M2.5 Screws Bond Site Thermocouple Heater Element Set Screw Bond Site Heat Block Assembly Fi g ure 2-85 2-85 B ond S ite Heat Heater er and and Thermocoupl Thermocouple e A s s em emblies blies G. Install Install the bond site heat heat block assembly: assembly: 1. Put the heat heat block assembly assembly on the the bond si site te assembly assembly.. 2. Install Install the heat block block assembly assembly to the bond site assembly assembly with th the e screws and washers removed before. Tighten the screws. 3. Connect Connect the electrical electrical cables cables to the interface interface panel panel.. Refer to your notes. notes. 4. Attach Attach the electrical electrical cables cables with cable ties ties and cable cl clamps amps to the wo workrkholder. Refer to your notes. 5. Install Install the ground ground strap to the the left rear rear side of the the bond site site heat block block assembly with the screw removed before. H. Insta Installll the heat block gauge or inserts inserts removed bef before ore to the bond site heat block assembly (see section 1). I. Push the green green machin machine e ON ON swit switch. ch. J. Sel Select OK to start initialization. 2.4). ). K. Do the setup and and calibration calibration procedures procedures (see paragragp paragragphs hs 2.3 and 2.4 Workholder 98888-0000-JB3-01 2-77 IConn High Performance Wire Bonder 2. 2.9. 9.1. 1.5 5 Bond Bond Sit Site e Ther Thermo moco cou uple ple Asse Assemb mbly ly Purpose • Replace Replace the thermocouple thermocouple assembly assembly in the bon bond d site site heat block assemb assembly ly.. This assembly monitors the temperature of the heater cartridge. Tools/ Materials/ Parts • Thermoc Thermocoup ouple le Assemb Assembly ly,, P/N: 0311803118-100 1004-00 4-000-20 0-20 • Hand Tool Procedure WARNING: IF THE WORKHOLDER W ORKHOLDER IS HEA HEATED, TED, AVOID TOUCHING HEATED PARTS PA RTS WHEN REMOVING PARTS OR MATERIAL (CARRIERS AND HEAT HEA T BLOCK INSERTS) OR WHEN PERFORMING OTHER OPE OPERARATIONS. WAIT FOR HEATERS TO COOL. A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP]. Turn off machine power. C. Remove the he heat at block gauge gauge or inserts inserts (see section section 1). D.). ). D. Remove the bo bond nd site heat block block assembly assembly (see parag paragraph raph 2.9.1.4, 2.9.1.4, step D. E. Remove the thermocou thermocouple ple assembly assembly (see Figure 2-85): 2-85): 1. Remove the the two M2.5 screws screws at the the rear bot bottom tom of the heat heat block. 2. Remove the cable cable shield that that attach to the rear of the heat block block assembly assembly.. 3. Loosen the the thermocouple thermocouple set set screw at the the rear top surface surface of the heat heat block assembly. 4. At the rear of the heat block block assembly assembly, pull the therm thermocoupl ocouple e assembl assembly y rearward and discard. 2-85): F. Install Install the replacement replacement thermoco thermocouple uple assembly assembly (se (see e Figure 2-85): 1. Install Install the new thermocou thermocouple ple assembly assembly into the b bore ore at the rear of th the e heat block assembly. 2. At the rear top surface surface of the heat block block assembl assembly y, carefull carefully y tighten the the thermocouple set screw until it is engaged to the thermocouple t hermocouple assembly. 3. Install Install the cable cable shield to to the rear of the the heat block block with the the screws removed before. G. Install Install the bond site heat block assembly assembly (see paragraph paragraph 2.9.1.4 2.9.1.4,, step G.). H. Insta Installll the heat block gauge or inserts inserts removed before before to the bond site heat block assembly (see section 1). I. Push Push tthe he green green machi machine ne ON switch switch.. J. Se Sellect OK to start initialization. K. Do the setup and ca calibrati libration on procedures procedures (see paragragphs paragragphs 2.3 and 2.4). 2.4). 2-78 Workholder 98888-0000-JB3-01 Material Handling System Manual 2. 2.9. 9.1. 1.6 6 Preh Prehea eatt Heat Heat Bl Bloc ock k Asse Assemb mbly ly Purpose • Replac Replace e the preheat preheat heat block block assembly assembly.. This assembly assembly in increases creases the temtemperature of the device before it is at the bond position. It contains the heat block and the heat block insulator, which are replaced as a set. Tools/ Materials/ Parts • • Preh Preheat eat Heat Heat Block Block Assem Assembly bly,, P/N: P/N: 0303 03035-0 5-0063 063-00 -000-XX 0-XX Hand Tools Procedure WARNING: IF THE WORKHOLDER IS HEATED, AVOID TOUCHING HEA HEATED TED PARTS PAR TS WHEN REMOVING PARTS OR MATERIAL (CARRIERS AND HEAT HEA T BLOCK INSERTS) OR WHEN PERFORMING OTHER OPERAOPE RATIONS. WAIT FOR HEATERS TO COOL. A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP]. Turn off machine power. C. Remov Remove e the heat block gauge gauge or inserts inserts (see section section 1). 2-86): D. Remov Remove e the preheat preheat heat block block assembly assembly (see Figure 2-86): 1. Make sure that that the electrica electricall cables to tthe he heat blo block ck assembly assembly are correctly identified. If not, make a note of the connection. 2. Disconnect Disconnect the pre preheat heat heater and and thermocouple thermocouple cabl cable e connectors connectors from the interface panel. 3. Remove all all the cable cable ties and open open the cable cable clamps clamps if neces necessary sary to release the cables. Make a note of the cable routing and cable clamps positions. 4. At the front of the preheat preheat heat block as assembly sembly,, remove the M2. M2.5 5 screw then remove the ground wire terminal. 5. Remove four four M3 screws screws and washers washers that attach attach th the e preheat h heat eat block assembly to the preheat assembly. 6. Remove the the preheat preheat heat block assembly assembly and put it on a w work ork benc bench. h. 7. Remove Remove the heater heater assembly assembly from the preheat preheat hea heatt block assembly assembly ((see see paragraph 2.9.1.2). 2.9.1.2). 8. Remove the the thermocouple thermocouple assembly assembly from the the preheat heat heat block assembly assembly 2.9.1.3). ). (see paragraph 2.9.1.3 9. Discard Discard the preheat heat block block assembly assembly.. E. Install Install the replacement replacement preheat preheat heat block block assembly assembly (see Figure 2-86): 2-86): 1. Install Install the heater assembly assembly to the preheat preheat heat block block assembly assembly removed before. 2. Install Install the thermocouple thermocouple assembly assembly to the preheat preheat heat block block assembly assembly removed before. 3. Put the preheat preheat heat block block assembly assembly on th the e preheat as assembly sembly.. 4. Install Install the preheat preheat heat block assembly assembly to the preheat preheat asse assembly mbly with th the e screws and washers removed before. Tighten the screws. 5. Connect Connect the electrical electrical cables cables to the interface interface panel. R Refer efer to your notes. notes. 6. Attach Attach the electrical electrical cables cables with cable ties ties and cable cl clamps amps to the wo workrkholder. Refer to your notes. 7. Install Install the ground wire wire to the front of the preheat preheat heat bloc block k assembl assembly y with the screw removed before. F. Install Install the heat block block gauge or inserts inserts removed before before to the prehe preheat at heat block assembly (see section 1). Workholder 98888-0000-JB3-01 2-79 IConn High Performance Wire Bonder G. Push the the green machine machine ON ON switch. switch. H. Sele Select ct OK to start initialization. I. Do the the setup setup and calibration calibration procedures procedures ((see see paragra paragragphs gphs 2.3 and 2.4). 2.4). 4x M3 Screws M3 Washers Heater Element Set Screw Thermocouple Set Screw Heater Element Set Screw Preheat Thermocouple M2.5 Screws Preheat Heat Block Assembly Preheat Heater Assembly Ground Wire Terminal (not shown) Preheat Assembly Fi g ure 2-86 2-86 R ep epla lace ce Preheat Preheat Hea Heatt B lo lock ck A s s em embl blyy 2. 2.9. 9.1. 1.7 7 Bond Bond Si Site te Heat Heat Bl Bloc ock kA Ass ssem embl bly y Purpose Replace the bond site heat block assembly. This assembly heats the devices while at bond site to the temperature required for bonding. It contains the heat block, heater assembly, thermocouple assembly, and the heat block insulator. These parts are replaced as a set but the heater assembly or thermocouple assembly can be replaced as a single part. Tools/ Materials/ Parts • Bond Site Site Heat Heat Block Block Assembly Assembly,, P/N: P/N:030 0303535-0061 0061-00 -000-XX 0-XX • Hand Tools Procedure WARNING: IF THE WORKHOLDER W ORKHOLDER IS HEA HEATED, TED, AVOID TOUCHING HEATED PARTS PA RTS WHEN REMOVING PARTS OR MATERIAL (CARRIERS AND HEAT HEA T BLOCK INSERTS) OR WHEN PERFORMING OTHER OPE OPERARATIONS. WAIT FOR HEATERS TO COOL. A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP]. Turn off machine power. C. Remove the he heat at block gauge gauge or inserts inserts (see section section 1). D. Remove the bo bond nd site heat heat heat block assembly assembly (see Figure 2-87): 2-87): 1. Make sure sure that the electrica electricall cables to to the heat block block assembly assembly are c coror- rectly identified. If not, make a note of the connection. 2-80 Workholder 98888-0000-JB3-01 Material Handling System Manual 2. Disconnect Disconnect the b bond ond site heater heater and thermocou thermocouple ple cable cable connectors from the interface panel. 3. Remove all all the cable cable ties and open open the cable cable clamps clamps if neces necessary sary to release the cables. Make a note of the cable routing and cable clamps positions. 4. At the left rear rear side of the bond site heat heat block ass assembly embly,, loosen the M2.5 M2.5 screw and pull out the metal jacket of the ground strap. 5. Remove four four M3 screws screws and washers washers that attach attach th the e bond site h heat eat bloc block k assembly to the bond site heat block assembly. 6. Remove the the bond site heat heat block assembly assembly from the b bond ond site and discard discard it. 2-87): E. Install Install the replacement replacement bond bond site heat block block assembl assembly y (see Figure 2-87): 1. Put the heat heat block assembly assembly on on the slider slider assemb assembly ly.. 2. Install Install the heat block block assembly assembly to the slider assembly assembly with th the e screws and washers removed before. Tighten the screws. 3. Connect Connect the electrical electrical cables cables to the interface interface panel panel.. Refer to your notes. notes. 4. Attach Attach the electrical electrical cables cables with cable ties ties and cable cl clamps amps to the wo workrkholder. Refer to your notes. 5. Install Install the ground ground strap to the the left rear rear side of the the bond site site heat block block assembly with the screw removed before. F. Install Install the heat block block gauge or inserts inserts removed before before to the bond sit site e heat block assembly (see section 1). G. Push the green green machine machine ON ON switch. switch. H. Sele Select ct OK to start initialization. 2.4). ). I. Do the the setup setup and calibration calibration procedures procedures ((see see paragra paragragphs gphs 2.3 and 2.4 4x M3 Screws 4x Washers Ground Strap Silder Assembly Bond Site Heat Block Assembly Fi g ure 2-87 2-87 R epl epla ace Bond Si te Hea Heatt B lo lock ck A s s em embl blyy Workholder 98888-0000-JB3-01 2-81 IConn High Performance Wire Bonder 2.9.1.8 Preheat Motor Purpose • Replace Replace the preheat preheat motor motor that moves the pr preheat eheat assemb assembly ly in vertic vertical al di direcrection. Tools/ Materials/ Parts • Prehe Preheat at Moto Motorr, P/N 13565 13565-6 -604 0433-00 001 1 • Hand tools Procedure WARNING: IF THE WORKHOLDER W ORKHOLDER IS HEA HEATED, TED, AVOID TOUCHING HEATED PARTS PA RTS WHEN REMOVING PARTS OR MATERIAL (CARRIERS AND HEAT HEA T BLOCK INSERTS) OR WHEN PERFORMING OTHER OPE OPERARATIONS. WAIT FOR HEATERS TO COOL. A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP]. Turn off machine power. C. Remove the he heat at block gauge gauge or inserts inserts (see section section 1). D. Remove th the e indexer assembly assembly (see paragraph paragraph 2.6). 2.6). E. Remove the preheat preheat assembly assembly (see (see Figure 2-88): 2-88): 1. Make sure that that the electrical electrical cables cables to the preheat as assembly sembly are are correctly correctly identified. If not, make a note of the connection. 2. Loosen two two captive captive screws that that attach attach the PCB cover cover to the ind indexer exer base. base. 3. Remove the the PCB cover to to access the the indexe indexerr intermediate intermediate board. board. 4. Disconnect Disconnect the pre preheat heat motor home home sensor connector connector J10 fr from om the index indexer er board. 5. At the rear of the preheat preheat assemb assembly ly,, disconnect disconnect the prehe preheat at motor cable cable from the motor. Make a note of the connection. 6. Remove all all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 7. Remove Remove two M5 screws screws that attach attach the preheat preheat bas base e to the front of of the indexer base. 8. Remove the the preheat preheat assembly assembly from the rear rear of the workholder workholder.. 9. Put the preheat assembly assembly on tthe he work work bench. bench. 2-82 Workholder 98888-0000-JB3-01 Material Handling System Manual Preheat Assembly Preheat Base 2x M5 Screws PCB Cover Indexer Base 2x Captive Screws Fi g ure 2-88 2-88 R em emove ove Pr ehe ehea at A s s em embl blyy (Front (Fr ont View) F. Remove Remove the the preheat preheat motor motor (see (see Figure 2-89 2-89): ): 1. Get access access to the preheat preheat motor motor from the rear rear side of the preheat preheat as assemsembly. 2. Remove the the four M4 screws screws that that attach the the motor to tthe he rear of the the preheat base. 3. Remove Remove the motor motor with the the cam an and d preheat preheat home sensor sensor.. 4. Loosen two two set screws screws that attach attach the ca cam m to the moto motorr shaft. 5. Remove Remove the the motor motor and and discar discard. d. G. Install Install the replacement replacement preheat preheat motor (see Figure 2-89): 2-89): 1. Install Install the cam to the the preheat motor motor with the the set screws screws remov removed ed before before.. 2. Install Install the pre preheat heat motor motor with the cam cam and preheat preheat home sensor sensor to the preheat base with the screws removed before. 3. Take note of the preheat preheat home sen sensor sor when you install install the the motor. motor. Make sure that the home sensor is correctly installed at the bottom right of the preheat base. H. Insta Installll the preheat preheat assembl assembly y (see Figure 2-88): 2-88): 1. Position Position the preheat preheat assembly assembly on the left left side of the the indexe indexerr base. 2. Install Install the preheat preheat assembly to the the indexer base base with the screws screws removed before. 3. Connect Connect the preheat preheat home sensor sensor cable cable to the conn connector ector J1 J10 0 on the indexer intermediate board. Refer to your notes. 4. Connect Connect the prehest mo motor tor cable connector connector to the preheat preheat motor. motor. Refer to your notes. Workholder 98888-0000-JB3-01 2-83 IConn High Performance Wire Bonder 5. Attach the the cables with with cable ties ties and cable clamps clamps to the wor workholde kholder. r. Re Refer fer to your notes. I. Install Install the the indexer indexer assembl assembly y to the machine machine (see paragraph paragraph 2.6). 2.6). J. Install Install the heat heat block gauge gauge or inserts inserts removed removed befor before e to the preheat preheat heat block assembly (see section 1). K. Push the green green machine machine ON switch. switch. L. Sel Select OK to start initialization. M. Do the setup and calibration procedures procedures (see paragragphs paragragphs 2.3 and 2.4). 2.4). 2x Set Screws Preheat Motor Preheat Base 4x M4 Screws Preheat Home Sensor Cam Fi g ure 2-89 2-89 R epl epla ace Prehea Pr eheatt Mot Motor or - E xplode xploded d Rea R earr View 2-84 Workholder 98888-0000-JB3-01 Material Handling System Manual 2.9.1.9 Bond Site Motor Purpose • Replac Replace e the bond bond site site motor motor that moves the hea heatt block block asse assembly mbly v vertical ertically ly.. Tools/ Materials/ Parts • Hand tools • Hea Heatt Block Block Motor Motor Assemb Assembly ly,, P/N 08888 08888-1 -1101 101-000 -000-xx -xx Procedure (Figure 2-90). WARNING: IF THE WORKHOLDER IS HEATED, AVOID TOUCHING HEA HEATED TED PARTS PAR TS WHEN REMOVING PARTS OR MATERIAL (CARRIERS AND HEAT HEA T BLOCK INSERTS) OR WHEN PERFORMING OTHER OPERAOPE RATIONS. A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP]. Turn off machine power. C. Remov Remove e the heat block gauge gauge or inserts inserts (see section section 1). D. Remove th the e indexer indexer assembly assembly (see paragraph paragraph 2.6 2.6). ). 2.7). ). E. Remove Remove the slider slider assembly assembly (see (see par paragraph agraph 2.7 F. Remove the the bond site site motor from the the slider slider assembly assembly (see Figure 2-90): 2-90): 1. Get access access to the bond site site motor from the rear rear side of the sl slider ider assem assembly bly.. 2. Hold the motor motor and remove remove the four four M4 screws with flat flat washers washers that attach the motor to the rear of the slider assembly. 3. Remove Remove the motor with motor motor couplin coupling g from the slider slider assembl assembly y. 4. Loosen the the two set screws screws that that attach the the motor co coupling upling to to the motor shaft. 5. Remove the motor motor coupling coupling from the the motor motor shaft. shaft. 2-90): ): G. Install Install the replacement replacement bond site site motor (see Figure 2-90 1. Install Install the motor coupling coupling to tthe he moto motorr shaft: shaft: a. Make sure sure the motor coupling coupling end end is flush with with the mo motor tor shaft shaft end. b. Make sure sure that the set set screws are are on the flat c cutout utouts s of the moto motorr shaft shaft.. c. Tighten Tighten the two (2) setscr setscrews ews in the the motor coupling. coupling. 2. Position Position the motor with with the motor motor cable connector connector points points downwa downward. rd. 3. Make sure sure the pins on th the e motor coupling coupling are aligned aligned to to the holes on the heat block coupling. Workholder 98888-0000-JB3-01 2-85 IConn High Performance Wire Bonder 4. Install Install the motor with with coupling coupling to the slider assembly assembly with with the screws and and flat washers removed before. 2x Set Screws Bond Site Motor 4x Washers 4x M4 Screws Motor Coupling Fi g ure 2-90 2-90 R ep epla lace ce B ond S ite Mot Motor or - Ex pl plode oded d R ea earr View H. Insta Installll the slider assembly assembly back to the machine. machine. Refer to paragraph paragraph 2.7 2.7,, steps G.. I. Install Install the the indexer indexer assembl assembly y to the machine machine (see paragraph paragraph 2.6). 2.6). J. Install Install the heat heat block gauge gauge or inserts inserts removed removed befor before e to the preheat preheat heat block assembly (see section 1). K. Push the green green machine machine ON switch. switch. L. Sel Select OK to start initialization. 2.4). M. Do the setup and calibration procedures procedures (see paragragphs paragragphs 2.3 and 2.4). 2.9.1. 2.9 .1.10 10 Prehe Preheat at Linear Linear Sli Slide de Assemb Assembly ly Procedure Replace the preheat linear slide assembly. This assembly moves the preheat heat block assembly in the vertical direction through the preheat motor. Tools/ Materials/ Parts • Preheat Preheat Linear Linear Bear Bearing ing,, P/N: P/N: 0303 03035-00 5-004343-004 004-xx -xx • Hand Tools Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP]. Turn off machine power. C. Remove the he heat at block gauge gauge or inserts inserts (see section section 1). 2.7). ). D. Remove th the e indexer assembly assembly (see paragraph paragraph 2.7 E. Remove tthe he preheat preheat assembly assembly (see (see para paragraph graph 2.9.1.8, 2.9.1.8, step E. E.). ). F. If the preheat preheat heat block assembly assembly is on the preheat preheat assembly assembly,, remove the four M3 screws and washers, then remove the assembly. 2-86 Workholder 98888-0000-JB3-01 Material Handling System Manual G. Remove the the preheat slide slide assembly assembly (s (see ee Figure 2-91): 2-91): 1. Disengage Disengage the two two springs springs at the front front of the preheat preheat assem assembly bly.. 2. Remove the the four M3 screws screws at the front front of the pr preheat eheat ass assembly embly.. 3. Remove the the preheat slide slide assembly assembly from the preh preheat eat assemb assembly ly.. H. Remove tthe he preheat preheat linear slide slide assembly assembly (s (see ee Figure 2-91): 2-91): NOTE: Hold the linear slide in its its position when you remove the screws on the linear slide. CAUTION: Do not move the preheat linear slide block out from the rail. The ball bearings will fall out. 1. Remove the the two M4 screws screws that attach attach the preh preheat eat linear linear slide assembly assembly to the preheat assembly. assembly. 2. Remove the preheat preheat linear linear slide slide assembly assembly and discar discard d it. I. Install Install the the replacemen replacementt preheat preheat linear linear slide assemb assembly ly (se (see e Figure 2-91): 2-91): 1. Put the preheat preheat linear linear slide assembly assembly tto o the mount mounting ing position position of the prepreheat assembly. 2. Install Install the screws screws removed before before to attac attach h the preheat lin linear ear slide assemassembly to the preheat assembly. J. Install Install the the preheat preheat slide assembly assembly (see (see Figure 2-91): 2-91): 1. Put and hold the preheat preheat slide slide assembl assembly y against th the e preheat lin linear ear slide block. 2. Make sure that that the holes holes in the rear rear of the sli slide de assem assembly bly is ali aligned gned to the holes in the linear slide block. 3. Install Install the preheat preheat slide assembly assembly with th the e screws removed removed befor before. e. 2.9.1.8,, K. Install Install the preheat assembly assembly to the indexer assembly assembly (see par paragraph agraph 2.9.1.8 step H. H.). ). L. Install Install the indexer indexer assembly assembly to the machine machine (see p paragrap aragraph h 2.7 2.7). ). M. Install the heat b block lock gauge or inserts removed before to the preheat heat block assembly (see section 1). N. Push tthe he green green machine machine ON switch. switch. O. Sele Select ct OK to start initialization. P. Do the setup and calibrati calibration on procedures procedures (see paragragp paragragphs hs 2.3 and 2.4 2.4). ). Preheat Linear Slide Assembly 2x M4 Screws Preheat Slide Assembly 4x M3 Screws 2x Springs Fi g ure 2-91 2-91 R ep epla lace ce Preheat Preheat Li nea nearr S lide A s s em embl blyy Workholder 98888-0000-JB3-01 2-87 IConn High Performance Wire Bonder 2.9.2 Pulle ller Parts 2.9.2.1 Puller Finger Purpose • Replace Replace the puller finger. finger. The puller puller finger hook th the e carrier carrier to pull iitt out of the input magazin input magazine. e. Tools/ Materials/ Parts • Puller Puller Finger Finger,, P/N 03201-0 03201-01 113-00413-004-xx xx • Hand tools Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Remov Remove e the puller puller finger finger (see Figure 2-92 2-92): ): 1. Remove the the two M2 screws that that attach the puller puller fing finger er to the puller mou mount. nt. 2. Move the puller puller finger finger out from from the rear of the the front rai raill slot. 3. Discar Discard d the pull puller er finger finger.. D. Insta Installll the replacement replacement puller puller finger finger (see Figure 2-92 2-92): ): 1. Hold the the puller finger finger along along the rear of of the front rail rail slot. 2. Make sure that that the puller finger finger is parallel parallel to the front rail, rail, and the pin points points up at the left side of the indexer assembly. 3. Hold the the puller puller finger on on the puller puller finger finger mount. mount. 4. Install Install two screws screws removed before before to attach attach the puller fing finger er to the puller finger mount. 5. Torque the the screws screws to 7 in. lbs. (0.8 (0.8 Nm). E. Push the green green machine machine ON switch. switch. F. Sel Select ect OK to start initialization. 2.3.2). ). G. Do the puller puller setup procedures procedures (see paragraph paragraph 2.3.2 Front Rail Slot Pin Puller Mount Puller Finger Fi g ure 2-92 2-92 Pulle Pullerr Fi ng er (Front Wa Wall ll A s s em embl blyy - Rear Rear View) 2-88 Workholder 98888-0000-JB3-01 Material Handling System Manual 2.9.2.2 Puller Rack Purpose • Replac Replace e the puller puller rack for for the puller rack-and rack-and pin pinion ion drive. drive. This This rac rack k is installed on the front wall assembly. Tools/ Materials/ Parts • Pul Pulle lerr Rack Rack,, P/N 030 03035 35-00 -0010 10-04 -0477-xx xx • Hand Tools Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Move the pu puller ller assembly assembly to the the right lilimit. mit. D. Remov Remove e the puller rack (see (see Figure 2-93 2-93): ): 1. Remove the the two M3 screws screws that attach attach th the e puller rrack ack to the front front rail su suppport. 2. Remove Remove the puller rack and di discard scard it. 2-93): ): E. Install Install the replace replacement ment puller puller rack rack (see Figure 2-93 1. Put the rack on the front rail support. support. 2. Make sure that that the teeth teeth points points to you and the the screw ho holes les are aligned aligned to the mounting holes in the front rail support. 3. Install Install the puller rack rack to the front rail support support with the screws screws removed removed before. 4. Carefu Carefully lly tight tighten en the screw screws. s. 2.3.7). ). 5. Do the the backlash backlash adjust adjustment ment (see (see paragrap paragraph h 2.3.7 F. Push the the green green machin machine e ON switch. switch. G. Sele Select ct OK to start initialization. 2x M3 Screws Front Rail Support Puller Rack ulle lerr Rack Fi g ure 2-93 P ul Workholder 98888-0000-JB3-01 2-89 IConn High Performance Wire Bonder 2.9.2.3 Puller Motor Purpose • Replace Replace the puller motor. motor. This motor has has a pinion pinion gear instal installed led on the motor motor shaft. The puller rack-and-pinion provides drive to move puller assembly along the X axis linear slider in the X axis direction. Tools/ Materials/ Parts • • Pulle Pullerr Moto Motorr P/N 03 0310 1022-10 1006 06-00 -000-x 0-xx x Hand Tools Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. 2.9.2.1). ). C. Remov Remove e the puller finger finger (see (see paragraph paragraph 2.9.2.1 D. Remov Remove e the puller puller assembl assembly y (see Figure 2-94 2-94): ): 1. Make sure that that the electrical electrical cables cables to the puller ass assembly embly are correctl correctly y identified. If not, make a note of the connection. 2. Remove all all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 3. Disconnect Disconnect all the ca cables bles connectors connectors on the circuit circuit pa panel nel that attach attach to the puller mount. 4. Remove the the two M3 screws and washers washers tha thatt attach the pu puller ller flex ca cable ble assembly with circuit panel to the puller mount. 5. Pull out the puller puller flex cable cable assembly assembly with circu circuit it panel from from the puller assembly. 6. Remove the the three M3 screws screws that that attac attach h the pull puller er mount to the the plate adapter on the X axis linear slide assembly. 7. Remove the the puller assembl assembly y from the indexer indexer assembly assembly and and put it on a work bench. E. Remove Remove the the puller puller motor motor (see (see Figure 2-94): 2-94): 1. Remove the the four M3 screws screws that attach attach the the motor to the p puller uller mount. mount. 2. Remove the the puller puller motor from the the puller puller assemb assembly ly and dis discard card it. 2-94): ): F. Install Install the replacement replacement puller puller motor motor (see (see Figure 2-94 1. Put the the motor motor on the pull puller er mount. mount. 2. Make sure that that the cable cable points points to you and th the e pinion ge gear ar points points down through the opening in the base of the mount. 3. Install Install the motor motor to the puller puller mount with with the screws screws remo removed ved before. before. G. Install Install the puller puller assembly assembly (see Figure 2-94): 2-94): 1. Put the puller puller assembly assembly on the plate plate adapter adapter on the X axi axis s linear guide. guide. 2. Make sure sure tha thatt the motor motor cable cable points points to to you. 3. Install Install the puller puller assembly to the the plate adapter adapter with the screws screws removed before. 4. Lightly Lightly turn the screws screws to attach the puller puller assembly assembly to the plate adaptor adaptor loosely. 2-90 Workholder 98888-0000-JB3-01 Material Handling System Manual 5. Move the puller mount forward forward until until the rear of tthe he mount mount is flush with the rear of the plate adaptor. 6. Hold the puller puller mount mount and torque torque the screws screws to 14 in. in. lbs. (1.6 N Nm). m). 7. Hold the puller puller flex cable cable assembly assembly with circ circuit uit pane panell into positi position on agains againstt the mount until the flat surface points to the front wall. 8. Install Install the puller flex flex cable assembly assembly with circuit circuit panel to the mount mount with the screws and washers removed before. 9. Torque the the screws screws to 7 in. in. lbs. (0.8 (0.8 Nm) Nm).. 10. Connect the electrical cables to the circuit panel on the puller assembly. Refer to your notes. 11.Attach the electrical cables with cable ties and cable clamps to the indexer assembly.. Refer to your notes. assembly H. Insta Installll the puller finger finger to the puller assembly assembly (see paragraph paragraph 2.9.2.1). 2.9.2.1). I. Do the the back backla lash sh adj adjus ustm tmen ent. t. J. Push the the green green machi machine ne ON s swit witch. ch. K. Se Sele lect ct OK to start initialization. Workholder 98888-0000-JB3-01 2-91 IConn High Performance Wire Bonder Puller Finger Puller Motor 3x M3 Screws 2x M3 Screws and Washers Puller Mount Puller Flex Circuit Cable Assembly with with Circuit Panel 4x M3 Screws Plate Adapter Fi g ure 2-94 P ull uller er Mot Motor or X Axis Linear Guide 2-92 Workholder 98888-0000-JB3-01 Material Handling System Manual 2.9.2.4 Puller So Solenoid Purpose • Replac Replace e the puller solenoid solenoid that that mov moves es the puller finger up and down. Tools/ Materials/ Parts • Pul Pulle lerr Soleno Solenoid id,, P/N 03107 03107-1 -1080 080-0 -000 00-x -xx x • Hand tools • Allen key set Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Remov Remove e the puller puller finger (see (see paragraph paragraph 2.9.2.1 2.9.2.1). ). D.)) D. Remove th the e puller assembl assembly y (see paragraph paragraph 2.9.2.3, 2.9.2.3, step D. E. Remove the puller puller solenoid solenoid (see (see Figure 2-95 2-95): ): NOTE: Do not loosen or tighten the top set screw in the left side of the puller arm or it will be difficult to put the arm back to its original position. 1. Make sure that the the electrical electrical cable cables s to the puller ass assembly embly are cor correctly rectly identified. If not, make a note of the connection. 2. Remove all all the cable cable ties and open open the cable cable clamps clamps if neces necessary sary to release the cables. Make a note of the cable routing and cable clamps positions. 3. Disconnect Disconnect all the ca cables bles connectors connectors on the cir circuit cuit pan panel el that attach attach to the puller mount. 4. Loosen the the set screw on on the puller puller finger mount mount that sets sets the mount mount to the pivot pin. 5. Loosen the the set screw screw that sets the the arm tto o the pi pivot vot pin. 6. Pull the the pivot pivot pin out from from the puller puller mount. 7. Pull the puller puller arm from from th the e pull puller er mount. mount. 8. Remove the the two nuts nuts that attach attach the sol solenoid enoid to th the e puller mount. mount. 9. Remove the the solenoid solenoid from the the puller mount mount and discard discard it. it. F. Install Install tthe he replacement replacement puller solenoid solenoid (see Figure 2-95): 2-95): 1. Hold the puller puller solenoid solenoid against against the right right side of the the wall on th the e puller mount. 2. Make sure that that the cable cable points points downwa downward rd and the threaded threaded s studs tuds are to the left side through the holes in the mount. 3. Apply a small small quatity quatity of screw locking locking c compoun ompound d to the threaded threaded stud studs s on the solenoid. 4. Install Install the nuts nuts and and torque them to 7 in lbs. (0.8 Nm Nm). ). 5. Put the puller arm to the puller puller mount. 6. Make sure that that the finger flag flag on the puller puller arm, is at the rear and points points to the top. 7. Hold the the puller puller arm behind behind the wall on the the pull puller er mount mount.. Workholder 98888-0000-JB3-01 2-93 IConn High Performance Wire Bonder 8. Make sure sure that the hole hole for the pivot pivot pin is aligned aligned wi with th the holes holes for the bearings. The bearings are in the bearing housing in the mount. 9. Turn the the pivot pin pin until the the flat surface surface is at th the e left si side. de. 10.Push the pivot pin into the holes for the front bearing, puller arm, and rear bearing until it stops. 11 11.. Tighten the set screw in the puller arm that sets the arm to the pivot pin until the screw is aligned with the flat surface of the pin. 12.Tighten the set screw in the puller finger mount that sets the mount to the pivot pin until the screw is aligned with the flat surface of the pin. 13. Connect the electrical cables to the circuit panel on the puller assembly. Refer to your notes. 14.Attach the electrical cables with cable ties and cable clamps to the indexer assembly. Refer to your notes. G. Do the backlash backlash adjustment adjustment.. H. Push tthe he green green machine machine ON switch. switch. I. Select OK to start initialization. Puller Motor 2x Puller Solenoid Nuts Puller Arm (set screw not in view) Finger Flag Puller Finger Mount (set screw nit in view) 2x Threaded Studs 2x Bearings Puller Solenoid Pivot Pin Puller Mount and Wall 2-95 5 P ul ulle lerr S ol oleno enoid id Fi g ure 2-9 2-94 Workholder 98888-0000-JB3-01 Material Handling System Manual 2. 2.9. 9.3 3 Inde Index/ x/T Tuc ucke kerr P Par artts 2.9.3.1 Index Ar Arm an and Pi Pin Purpose • Replac Replace e the index index arm arm and pin. Th These ese pa part rt are used to index the boa boatt to put put the device at the bond site. Tools/ Materials/ Parts • Ind Index ex Arm, Arm, P/N P/N 032 03201 01-0 -001 0144-018 018-x -xx x • Ind Index ex Pin, Pin, P/ P/N N 0320 03201-0 1-001 0144-00 0099-xx xx • Hand Tools • Small Press Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Remove the index index arm arm holder holder (see Figure 2-96): 2-96): 1. Make sure that the the electrical electrical cable cables s to the index asse assembly mbly are corr correctly ectly identified. If not, make a note of the connection. 2. Remove all all the cable cable ties and open open the cable cable clamps clamps if neces necessary sary to release the cables. Make a note of the cable routing and cable clamps positions. 3. Disconnect Disconnect all the ca cables bles connectors connectors on the cir circuit cuit pan panel el that attach attach to the index mount. 4. Remove the two two M3 screws and washers washers that attach attach the holder holder to the inde index x slider. 5. Remove Remove the index arm arm holder from from the indexer indexer ass assembly embly and put put it on a work bench. D. Remov Remove e the spring cap and and the compress compression ion spring spring (see Figure 2-96 2-96): ): 1. Remove Remove the two M1.6 screws screws from from the righ rightt side of the iindex ndex arm ho holder lder that attach the spring cap to the index arm holder. 2. Remove the the spring cap cap and the spring spring from th the e index arm arm holder. holder. 2-96): ): E. Remove the index index arm and pin pin (see Figure 2-96 1. Remove Remove the two M1.6 M1.6 screws that that attach attach the arm to th the e index arm holder holder.. 2. Pull the the arm away from from the the index arm ho holder lder.. 3. Pull the the sensor sensor bar from of the ind index ex arm. arm. 4. Go to step step "E.5" "E.5" to remove the pin pin or the the arm. 5. To remove the the pin and the the arm, discard discard them a and nd go to step "F". "F". NOTE: The arm is easy to damage. Carefully push the pin out from the arm. 6. Push the pin pin out of of the arm and and discard discard the necessary necessary par part. t. 98888-0000-JB3-01 Workholder 2-95 IConn High Performance Wire Bonder F. Install Install the replacement replacement index index pin pin and the the ind index ex arm (see Figure 2-96 2-96): ): 1. Set the the index index ar arm m to the correct correct positi position. on. a. Make sure sure that the arm with with the slot slot point points s to the righ rightt side. b. Make sure sure that the tip tip of the pin points points up and and perpendicula perpendicularr (at a dimension of 0.0033 in.) to the side of the arm with the slot (see suface 2-96). ). A on Figure 2-96 NOTE: The arm is easy to damage. Carefully push the pin into the arm. 2. Push the the round round end of of the pin pin into into the arm. arm. 3. Set the sensor bar to the correct correct position position.. a. Make sure sure that the raised raised step on on the sens sensor or bar poin points ts to the slot slot in the arm. b. Make sure sure that the angle angle at the bar bar end points points to the pin at the the end of the arm. 4. Install Install the sensor bar into into the index arm with with the screws removed removed bef before. ore. 5. Set the the index index arm holder holder positi position. on. a. Make sure sure the the slot slot on the index index arm holder holder is at the left left side. b. Make sure sure that the the overload overload sensing sensing ca cables bles are are at the top. top. 6. Set the index arm with with the sensor bar position. position. a. Make sure sure that the end of of the pin on the the index arm iis s at the rear of of the index assembly and points down. 7. Install Install the index index arm with the the sensor bar bar to the index index arm holder holder until it stops. G. Install Install the compression compression spring spring and the spring spring cap (see Figure 2-96): 2-96): 1. Hold the the spring spring cap against against the the index arm arm holder. holder. 2. Install Install one of the M1.6 M1.6 screw screw removed before before to the the top hole of the the index arm holder to attach the spring cap to the ho holder. lder. 3. Tighten Tighten the scr screw ew lightly lightly to hold the the spring cap cap in its pos position. ition. 4. Turn the bottom bottom of the spring spring cap cap to 9 90 0 ο clockwise until the the spring cap is away from the index arm holder. 5. Install Install the spring spring against against the round surface surface of the the sprin spring g cap. 6. Turn the the spring cap cap with spring spring against against the index index arm hol holder der.. 7. Install Install the other M1.6 M1.6 screw removed removed before before to the bottom bottom hole of the inde index x arm holder to attach the spring cap. 8. Torque the the screws to 6 in. lbs. lbs. (0.68 (0.68 Nm). H. Insta Installll the index index arm holder holder (see (see Figure 2-96): 2-96): 1. Install Install the index index arm holder holder with the index index arm to the top of the the index slide slide with the screws and washers removed before. 2. Make sure that that the index arm is at the left left side of the index index assemb assembly ly.. 3. Make sure that that the holes holes in the index arm arm holder are are aligned to the the holes in the top of the index slide. 4. Tighten Tighten the screws screws lightly lightly to hold the index arm arm holder in its po position sition.. 5. Pull the the index arm arm holder holder forward forward to its its maximu maximum. m. 6. Torque the the screws screws to 10 in. in. lbs. (1.1 (1.1 Nm). Nm). 7. Connect Connect the electrical electrical cables to the circuit circuit panel on the index assem assembly bly.. Refer to your notes. 2-96 Workholder 98888-0000-JB3-01 Material Handling System Manual 8. Attach the the electrical electrical cables cables with cable cable tie ties s and cable c clamps lamps tto o the index assembly. Refer to your notes. I. Push the green green machin machine e ON ON swit switch. ch. J. Sel Select OK to start initialization. K. Calibrate Calibrate the index ho home me position position to the center of the bon bond d positio position. n. Spring Index Arm Index Pin 2x M3 Screws 2x M3 Washers Spring Cap 2x M1.6 Screws 2x M1.6 Screws SURFACE A Sensor Bar Overload Sensing Cable Index holder Index Mount Circuit Panel 2-96 6 Index A rm and P in Fi g ure 2-9 Workholder 98888-0000-JB3-01 2-97 IConn High Performance Wire Bonder 2.9.3.2 Tucker Purpose • Replace Replace the tucker blade. blade. This tucker moves the bo boat at in into to the output magazine. Tools/ Materials/ Parts • Tucker ucker,, P/N 032 03201 01-01 -0114 14-01 -0133-xx xx • Hand Tools • Small Press Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Remove Remove the the tucker tucker (see (see Figure 2-97 2-97): ): 1. Remove the the two M2 screws screws that attach attach the the tucker lleaf eaf spring spring to the tuck tucker er mount. NOTE: Make sure that the tucker leaf spring do not fall into the indexer assembly. Hold the tucker leaf spring in its position. 2. Remove the the tucker tucker leaf spring spring from the index index assembly assembly.. 3. Push the dowel dowel pin out out of the tucker tucker mount and remove remove it from from the index index assembly. NOTE: Make sure that the dowel pin do not fall into the indexer assembly. assembly. Put one of your hands below the tucker mount and hold the dowel pin. 4. Move the tucker tucker out from from the slot slot in the tucker tucker mount an and d discard discard it. D. Insta Installll the replacemen replacementt tucker tucker (see Figure 2-97): 2-97): 1. Set the position pos ition of the thedown. tucker until until the tip tip is at the rig right ht side of the the index assembly and points 2. Put the end end of the tucker into into the slot on the the tuck tucker er moun mount. t. 3. Make sure sure that the holes holes at the tucker tucker end are are aligned to to the holes in the tucker mount. 4. Push Push the pin pin into into the tuck tucker er mount mount.. 5. Put and hold hold the tucker tucker leaf spring spring against against the right right side of th the e tucker mount. 6. Install Install the tucker tucker and tucker leaf spring spring to the inde index x mount with the the screws removed before. 7. Torque the the screws to 6 in. lbs. lbs. (0.68 (0.68 Nm). E. Push the green green machine machine ON switch. switch. F. Sel Select ect OK to start initialization. G. Calibrate Calibrate the the tucker tucker eject. eject. 2-98 Workholder 98888-0000-JB3-01 Material Handling System Manual 2x M2 Screws Tucker Leaf Spring Dowel Pin Tucker Tucker Mount Figure 2-97 Tucker 2.9.3.3 Tucker Soienoid Purpose • Re Relp lpac ace e tthe he tu tuck cker er so sole leno noid id.. Tools/ Materials/ Parts • Tu Tucke ckerr Sole Solenoi noid, d, P/N: P/N: 0310 03107-10 7-1080-0 80-00000-xx xx • Hand Tools • Scre Screw w Lock Lockin ing gC Com ompo poun und d • Tweezers Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off the machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Remove the tucker tucker mount (see Figure 2-98 2-98): ): 1. Make sure that the the electrical electrical cable cables s to the index asse assembly mbly are corr correctly ectly identified. If not, make a note of the connection. 2. Remove all all the cable cable ties and open open the cable cable clamps clamps if neces necessary sary to release the cables. Make a note of the cable routing and cable clamps positions. 3. Disconnect Disconnect all the ca cables bles connectors connectors on the cir circuit cuit pan panel el that attach attach to the index mount. 4. Loosen the the set screw that that attach attach the tucker tucker moun mountt to the indexer indexer mount mount.. 5. Remove the the spring from from the notched notched groo groove ve pin in the tucker tucker mou mount.. nt.. NOTE: Make sure that the pivot pin and bearings do not fall into the indexer assembly. Hold the tucker mount with the pivot pin and bearings in its position. Workholder 98888-0000-JB3-01 2-99 IConn High Performance Wire Bonder 6. Pull the the pivot pin from the right right side of of the tucker tucker moun mount. t. 7. Remove the the pivot pin pin and the two bearing bearings s that attach attach the tuc tucker ker mount tto o the indexer mount. 8. Remove the the tucker mount mount from from the index assembl assembly y and put it on a work work bench. D. Remove the two nut nuts s that attach the tucker tucker solenoid to the tucker mount mount and discard the solenoid. E. Insta Installll the replacement replacement tucker tucker solenoid solenoid (see (see Figure 2-98): 2-98): 1. Put the solenoi solenoid d against against the front front of the the tucker tucker mount. 2. Make sure sure that the cable cable points points down and the the threaded threaded studs are are into the holes of the tucker mount. 3. Apply a small small quatity quatity of screw locking locking compoun compound d to the threaded threaded stud studs s on the solenoid. 4. Install Install the solenoid solenoid to the tucker mount mount with the nuts nuts removed bef before. ore. 5. Tighten Tighten the the nuts nuts to 7 in. lbs. lbs. (0.79 Nm). F. Instal Installl the tucke tuckerr mount mount (see Figure 2-98): 2-98): 1. Install Install the two bearings bearings and pivot pin to the the right side of the tu tucker cker moun mount. t. 2. Put the tucker tucker mount with with the bearings bearings and and the pivot pin pin agains againstt the index index mount. 3. Hold the tucker tucker mount mount in its positio position n and tight tighten en the set screw screw.. 4. Install Install the spring spring removed removed before to the notch groove groove pin o on n the tucker tucker mount. 5. Connect Connect the electrical electrical cables to the circuit circuit panel on the index assem assembly bly.. Refer to your notes. 6. Attach the the electrical electrical cables with with cable ties ties and cable cla clamps mps to the inde index x assembly. Refer to your notes. G. Push the the green machine machine ON ON switch. switch. H. Sele Select ct OK to start initialization. 2x Nuts Pivot Pin Index Mount Solenoid 2x Bearings Tucker Mount (notched groove pin and spring not shown) Fi g ure 2-9 2-98 8 Tucker S ol oleno enoid id 2-100 Workholder 98888-0000-JB3-01 Material Handling System Manual 2.9.4 Rail Parts 2.9.4.1 Indexer Motor Purpose • Re Repla place ce th the e in inde dexe xerr moto motorr. Tools/ Materials/ Parts • • Ind Index exer er Motor Motor,, P/N 08888 08888-10 -1066 66-00 -0000-xx xx Hand Tools Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off the machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Remove tthe he indexer indexer assembly assembly (see p paragrap aragraph h 2.6 2.6). ). 2-99): ): D. Remove the indexer indexer motor (see Figure 2-99 1. At the front of the indexer indexer assembly assembly,, loosen two captive captive scre screws ws that atta attach ch the PCB cover to the indexer base. 2. Remove the the PCB cover to to access the the indexe indexerr intermediate intermediate board. board. 3. Make sure that that the electrical electrical cable cable to the indexer indexer motor are are correctly correctly identiidentified. If not, make a note of the connection. 4. Disconnect Disconnect the ind indexer exer motor cable cable connector connector J21 from the indexer indexer inte interrmediate board. 5. Remove all all the cable cable ties and open open the cable cable clamps clamps if neces necessary sary to release the cables. Make a note of the cable routing and cable clamps positions. 6. Loosen the set set screw in the flexible flexible coupling coupling that attach attach to the shaf shaftt of the X-axis leadscrew assembly. assembly. 7. Remove the the two M4 screws screws that attach attach the top lleft eft sid side e of the fron frontt wall to the front wall input support. 8. Loosen the the two M4 screw screw top right right side of the front front wal walll to the front wall wall output support. 9. Remove the the two M5 screws screws with washers washers tha thatt attac attach h the base of tthe he front wall input support to the input base support. 10.Carefully lift the front wall assembly a small distance up until the front wall input support with shim can remove easily. 11.Remove the front f ront wall input support with shim. 12.Hold the indexer motor with one of your hands. 13.Remove the four M4 screws with washers that attach the indexer motor with flexible coupling to the motor mount. 14.Loosen the set screw in the flexible coupling that attach to the shaft of the indexer motor. 15.Remove the flexible coupling. 16.Remove the indexer motor. Workholder 98888-0000-JB3-01 2-101 IConn High Performance Wire Bonder E. Insta Installll the the replacement replacement indexer motor (see Figure 2-99): 2-99): 1. Install Install the flexible flexible coupling coupling to the shaft of the indexer indexer motor an and d tighten the set screw. 2. Torque the the set screw screw to 12 lbs. in. in. (1.36 Nm). 3. Put the indexer indexer motor with the the flexible flexible couplin coupling g against the motor motor mount. Make sure that the motor cable is at the bottom. 4. Install Install the indexer indexer motor with flexible flexible coupling coupling to the mot motor or mount wit with h the screws and washers removed before. 5. Make sure the shaft shaft of the X-axi X-axis s leadscrew leadscrew assembl assembly y goes into the flexible flexible coupling hole. 6. Torque the the screws screws to 28 lbs. lbs. in. (3.16 (3.16 Nm). Nm). 7. Torque the set screw screw in the flexible flexible coupling coupling to 12 lbs. in. (1.3 (1.36 6 Nm). 8. Carefully Carefully lift the the front wall assembly assembly a small small distance distance up until the fro front nt wall input support with shim can install easily. 9. Install Install the front wall wall input support support with shim to the input input base and fron frontt wall with the screws and washers removed before. 10.Make sure that the base of the front wall input support is attached to the front wall nut bar in the input base support. 11 11.. Tighten the four M4 screws at the top, two ends of the front wall. F. Connect Connect the indexer motor motor cable to the connector connector J21 on th the e indexer intermeintermediate board. Refer to your notes. G. Push the the green machine machine ON ON switch. switch. H. Sele Select ct OK to start initialization. 2.4). I. Do the the setup setup and calibration calibration procedures procedures ((see see paragra paragragphs gphs 2.3 and 2.4). 2x M4 Screws 2x M4 Screws Top Right Side of Front Wall Top Left Side of Front Wall 2x M5 Screws with Washers Shim Set Screws Front Wall Output Support X Axis Leadscrew Assembly 4x M4 Screws Indexer Motor Flexible Coupling Motor Mount 4x M4 Washers Input Base Support Front Wall Input Support Fi g ure 2-9 2-99 9 Indexer Mot Motor or 2-102 Workholder 98888-0000-JB3-01 Material Handling System Manual 2. 2.9 9.4 .4.2 .2 X Axi Axis s Lea Lead dsc scre rew w Ass Asse embly Purpose • Rep Replac lace e th the e X axis axis llead eadscr screw ew assemb assembly ly.. Tools/ Materials/ Parts • X Axis Leadsc Leadscrew rew Asse Assembl mbly y, P/N 0 03101 3101-05 -053535-000 000-xx -xx • Hand Tools • Scre Screw w Lock Lockin ing gC Com ompo poun und d Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off the machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Remove tthe he indexer indexer assembly assembly (see p paragrap aragraph h 2.6 2.6). ). D. Remove the three M3 scre screws ws that attac attach h the bearing retai retainer ner to the right side of the front wall output support and remove the bearing retainer. 2-100): ): E. Remove the the X axis axis leadscrew leadscrew assembly assembly (see Figure 2-100 1. Loosen the set set screw in the flexible flexible coupling coupling that attach attach to the shaf shaftt of the X-axis leadscrew assembly. assembly. 2. Remove the three three M4 screws screws and washers washers that attac attach h the leadsc leadscrew rew nut to the adapter nut. 3. Remove the hex hex nut that attach attach the right side side (threaded) (threaded) of the leadscrew leadscrew to the front rail support. 4. Move the leadscre leadscrew w to the right right to release release the left left side of th the e leadscr leadscrew ew from the flexible coupling. 5. Tilt the the leadscrew leadscrew up to the left and pull pull it from the front wall wall output sup support port 6. Discar Discard d the leadsc leadscrew rew.. F. Install Install the replacemen replacementt X axis leadscrew leadscrew as assembly sembly (see (see Figure 2-100 2-100): ): leadscrew NOTE: Do a preload check of the leadscrew nut. The preload of the leadscrew nut should be on the fourth tooth from the point of the spring and clockwise of the leadscrew. 1. Move the leadscre leadscrew w nut to the right right side of of the leadscrew leadscrew.. 2. Put the X axis leadscr leadscrew ew assembly assembly to the front front wall s support upport : a. Make sure sure that the smooth smooth end of the the leadscrew leadscrew is at the m motor otor moun mountt and into the flexible coupling hole. b. Make sure sure that the threaded threaded end end of the leadscrew leadscrew is is at the fron frontt wall output support and into the bearing hole. 3. Put the leadscrew leadscrew nu nutt against against the the adapter adapter nut. 4. Install Install the leadscrew leadscrew nut nut to the adapter adapter nut with with the screws screws removed removed before. 5. Torque the the screws screws to 14 lbs. lbs. in. (1.6 Nm Nm). ). 6. Apply a small quatity quatity of screw screw locking locking compou compound nd to the threads threads on the right end of the leadscrew. 7. Install Install the hex hex nut and and torque torque it to 20 lbs. in in.. (2.26 N Nm). m). 8. Put the bearing bearing retainer retainer against the right right side of the fron frontt wall output output support. Workholder 98888-0000-JB3-01 2-103 IConn High Performance Wire Bonder 9. Install Install the bearing bearing retainer retainer to the front wall output output support support with the screws screws removed before. 10.Torque the screws to 14 lbs. in. (1.6 Nm). 11 11.. Torque the set screw in the flexible coupling to 12 1 2 lbs. in. (1.36 Nm). G. Install Install the indexer assembly assembly to the machine (see paragraph paragraph 2.6). 2.6). H. Push tthe he green green machine machine ON switch. switch. I. Select OK to start initialization. . Flexible Coupling X Axis Linear Slider Slide Block for Index Assembly Leadscrew Bearing Bearing Retainer X Axis Leadscrew Assembly Adapter Nut Hex Nut Leadscrew Nut 3x M4 Screws 2-10 100 0 X Axi s L ea eadscr dscr ew A s s em embl blyy Fig ure 2- 3x M3 Screws 2-104 Workholder 98888-0000-JB3-01 Material Handling System Manual 2.9.4 .4.3 .3 Leadscrew Bearing Purpose • Replac Replace e the leadscr leadscrew ew bearing bearing that that supports supports the rig right ht end o off the X axis lleadeadscrew assembly assemb ly.. Tools/ Materials/ Parts • Bear Bearin ing, g, P/N P/N 206 20604 04-6 -602 0222-00 00 • Hand Tools • Scre Screw w Lock Lockin ing gC Com ompo poun und d Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off the machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Move the index asse assembly mbly to the left limit on the X axis linear slider slider.. D. Remove the leadscre leadscrew w bearing bearing (see (see Figure 2-100 2-100): ): NOTE: Make sure that the bearing retainer do not fall into the indexer assembly. assembly. Hold the bearing retainer in its position. 1. Remove the the three M3 screws screws that that attach attach the beari bearing ng retainer retainer to the front front wall output support. 2. Remove the the bearing bearing retainer retainer from in indexer dexer assembly assembly.. 3. Remove Remove the hex nut that that attach attach the right e end nd (threa (threaded) ded) of the leadscrew leadscrew to to the front wall output support. 4. Push the bearing bearing from the the left side side of the bearing bearing housing housing out through through th the e right and discard it. NOTE: Make sure that the bearing do not fall into the indexer assembly. assembly. Put one of your hands below the right side of the front wall output support and hold the bearing. E. Use alcohol alcohol to remove the remainin remaining g of the screw locking locking compo compound und on the threads at the right side of the leadscrew. F. Install Install the replacem replacement ent lead leadscrew screw bearing bearing (see (see Figure 2-100): 2-100): 1. Push the bearing bearing in through through the right right side of of the bearing bearing housing housing until it is is flush with the right side of the front wall output support. 2. Apply a small small quatity quatity of the screw screw locki locking ng compo compound und to the threads threads on the the right side of the leadscrew. 3. Install Install the nut nut and torque torque it to to 20 in lbs. lbs. (2.26 Nm). 4. Put the bearing bearing retainer retainer against against the right right side of the ffront ront rai raill support. support. 5. Install Install the bearing bearing retainer retainer to the front wall output output suppor supportt with the screws screws removed before. 6. Torque the the screws screws to 14 in in lbs. (1.6 (1.6 Nm). Nm). G. Push the green green machine machine ON ON switch. switch. H. Sele Select ct OK to start initialization. Workholder 98888-0000-JB3-01 2-105 IConn High Performance Wire Bonder 2. 2.9 9.5 Se Sens nso or As Asse semb mbli lies es 2.9 .9.5 .5.1 .1 X Reg Regiistra strati tio on Se Sens nso or Purpose • Repl Replac ace e the the X regis registr trat atio ion n sens sensor or.. Tools/ Materials/ Parts • • Hand tools X Regist Registrati ration on Senso Sensorr, P/N 0320103201-001 0019-0 9-000-x 00-xx x Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off the machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. 2.6). ). C. Remove th the e indexer assembly assembly (see paragraph paragraph 2.6 D. Remov Remove e the X registration registration sensor: sensor: 1. At the front of the indexer indexer assembly assembly,, loosen two cap captive tive scre screws ws that att attach ach the PCB cover to the indexer base. 2. Remove the the PCB cover to to access the the index indexer er intermediate intermediate board. board. 3. Make sure that that the X registration registration sensor sensor cable is cor correctly rectly id identifi entified. ed. If not, make a note of the connection. 4. Disconnect Disconnect the X regis registration tration sensor sensor conn connector ector J9 from from the indexer interintermediate board. 5. Remove all all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 6. Remove the the four M2 screws screws that that attach the the sensor emitter and and receiver receiver to the mount. 7. Remove the the sensor sensor from the rear rear rail assembly assembly and and discard it. it. E. Insta Installll the replacement replacement X registra registration tion semsor: semsor: 1. Put the sensor sensor emitter emitter to the bottom bottom of the mount mount with tthe he screw ho holes les points down. 2. Install Install the sensor sensor emitter to the mount mount with the screws screws removed removed before. 3. Put the sensor sensor recevier recevier to the top top of the mount mount with the screw screw hole holes s points points to the top. 4. Install Install the sensor sensor receiver to the moun moun with the scr screws ews removed removed before. 5. Ti Tighte ghten n the screws screws.. 6. Connect Connect the X registration registration sensor sensor cable cable to conn connector ector J9 on on the indexer indexer intemediate board and do the cable routing. Refer to your notes. 7. Attach the the electrical electrical cables cables with cable cable ties and cable cable clamps to th the e indexer assembly. Refer to your notes. F. Install Install the indexer indexer assembly assembly to the machine machine (see (see parag paragraph raph 2.6). 2.6). G. Push the the green machine machine ON ON switch. switch. H. Sele Select ct OK to start initialization. I. Calibrate Calibrate the distanc distance e between between the X registrati registration on sensor sensor and the center center of the bond site. 2-106 Workholder 98888-0000-JB3-01 Material Handling System Manual 2x M2 Screws Receiver Sensor Mount X Registration Sensor Emitter 2x M2 Screws Fig ure 22-101 101 X Reg is tra rattion S en enss or 2. 2.9. 9.5. 5.2 2 Opti Optica call Swit Switch ch Asse Assemb mbli lies es Purpose • Replac Replace e the optical switch assemblies assemblies u used sed thr throughou oughoutt the indexer indexer and slider slider assemblies. Tools/ Materials/ Parts • Hand tools • Tie wraps • Opti Optical cal Switch Switch Assembl Assembly y, as as rrequ equire ired: d: • Indexe Indexerr Home, Home, 60 mm mm (2.36” (2.36”)) long, long, P/N P/N 088 0888888-102 1027-00 7-000-0 0-09 9 • Indexe Indexerr Pin Left, Left, 160 160 mm (6.3 (6.30”) 0”) long, long, P/N P/N 088 0888888-1027 1027-00 -000-1 0-10 0 • Indexe Indexerr Pin Right, Right, 160 160 mm (6.30”) (6.30”) long, long, P/N P/N 0888 08888-1 8-1027027-000 000-1 -11 1 • Puller Puller Mo Motor tor Home Home,, 120 mm (4.7 (4.72”) 2”) long, long, P/N P/N 0888808888-102 1027-0 7-000-1 00-12 2 • Puller Puller Pi Pin n Sensor Sensor,, 75 mm (2.95”) (2.95”) long, long, P/N P/N 0888 08888-10 8-102727-000 000-13 -13 • Preheat Preheat Moto Motorr Home, Home, 228.6 228.6 mm (9”) long long,, P/N 0341 03411-1031 1-1031-001 -001-28 -28 • Heat Block Sensor, Sensor, 736.6 736.6 mm mm (2 (29”) 9”) long, long, P/N 0 0341 3411-10311-1031-001-17 001-17 Workholder 98888-0000-JB3-01 2-107 IConn High Performance Wire Bonder Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off the machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. 2.6). ). C. Remove th the e indexer assembly assembly (see paragraph paragraph 2.6 D. Remove th the e slider assembly assembly (see (see paragraph paragraph 2.7). 2.7). E. Discon Disconnect nect the op optical tical switch(s switch(s)) to be replaced. replaced. 1. Find the optical optical switch switch position. position. Refer to Section Section 4 of this manu manual al for the illustration on the optical switch position in the indexer assembly and slider assembly. NOTE: It is necessary to remove the indexer assembly and slider assembly to replace the optical switch. 2. Make sure that that the optical switch switch cables cables to the index indexer er interme intermediate diate board board or interface panel are correctly identified. If not, make a note of the connection. 3. Make a note on the orientat orientation ion of the five (5) optical optical switch switch wires (re (red, d, black, white, blue and yellow insulation). 4. Remove all all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 5. Remove Remove the screw that that attach attach the optical optical switch switch to the mou mount. nt. NOTE: Make sure that the optical switch do not fall into the indexer assembly. assembly. Hold the optical switch in its position. 6. Disconnect Disconnect the opti optical cal switch switch cable and discard discard it. Make Make a note of the reference designator (”J” number) of the connector. F. Install Install tthe he replacem replacement ent sensor. sensor. 1. Put the optical optical switch switch against the mount mount until until the optica opticall switch wires wires are in the same way as it was removed. 2. Install Install the optical optical switch switch with the the screw removed removed before. before. 3. Connect Connect the optica opticall switch cable cable to the connector connector on the ind indexer exer inter intermedimediate board or interface panel. Refer to your notes. 4. Attach the the optical switch switch cable with with cable ties ties and cable clamps clamps to the indexer assembly or slider assembly. Refer to your notes. 2.6). ). G. Install Install the indexer assembly assembly to the machine (see paragraph paragraph 2.6 H. Insta Installll the slider assembly assembly to the machine (see paragraph paragraph 2.7 2.7). ). I. Push Push tthe he green green machi machine ne ON switch switch.. J. Se Sellect OK to start initialization. Make sure that the optical switch operates correctly. NOTE: The Sensor Diagnostic display, display, accessed through Diagnostic Mode, can be used to do a check if the replacement sensor operates correctly. Refer to paragraph 5.4.4 in Section 5 of this manual for more information. 2-108 Workholder 98888-0000-JB3-01 Material Handling System Manual 2. 2.9. 9.5. 5.3 3 J Boa Boatt Pr Pres esen entt S Sen enso sorr Ampl Amplif ifie ierr Purpose • Replac Replace e and set set up the the sensor sensor amplifie amplifierr that is part part of th the e J bo boat at present present se sennsor on the rear rail assembly of the indexer assembly (Figure ( Figure 2-2, 2-2, Figure 2102). 102 ). Tools/ Materials/ Parts • • Hand tools Sensor Amplifier Amplifier Assembly Assembly,, P/N 0885808858-1032-00 1032-000-12 0-12 (for input side) • Sensor Amplifier Amplifier Assembly Assembly,, P/N 0885808858-1032-0 1032-000-13 00-13 (for output side) Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off the machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Remove the sens sensor or amplifier amplifier from the rear rail assembly assembly. 1. Make sure that that the sensor amplifier amplifier cable cable to the indexer indexer interm intermediate ediate board board is correctly identified. If not, make a note of the connection. 2. Remove Remove all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 3. Disconnect Disconnect the app applicabl licable e cable connector connector from the iindexer ndexer int intermedia ermediate te board connector J19 (for input) or J20 (for output). Refer to Section 4 for connector position. 4. Identify Identify the polarity polarity of the two fiber optic optic cables with with arrows on the the amplifier. 5. Pull up the latch latch on the amplifi amplifier er and remo remove ve the two fiber fiber optic optics. s. 6. Remove the the sensor amplifie amplifierr cable fro from m cable clamps clamps (if a any). ny). 7. Remove Remove and retain retain the two (2) (2) socket head head cap scr screws ews (SHC (SHCSs) Ss) and flat washers that attach the J boat present sensor amplifier for assembling as stated in step C. Discard the failed sensor amplifier with J boat present sensor. Fi g ure 2-102 2-102 J B oa oatt Pr esent S ensor A mp mplifier lifier C ont ontrols/ rols/Indicat Indicators ors 98888-0000-JB3-01 Workholder 2-109 IConn High Performance Wire Bonder D. Insta Installll the replacement replacement sensor sensor amplifier amplifier.. 1. Install Install two (2) socket socket head cap screws screws (SHCSs) and flat flat washers to attach attach the replaced J boat present sensor amplifier to the rear side of the rear rail. 2. Put the J boat present present sensor amp amplifier lifier cable cable to the indexer indexer interm intermediate ediate board. Close the cable clamps (if any) and attach with the cable tie if necessary. 3. Connect Connect the leadframe leadframe present sensor sensor amplifier amplifier cable(s) cable(s) to J19 connector connector (for input) or J20 connector (for output) on the indexer intermediate board. 4. Lift the fiber fiber optic latch latch and install install the end of each fiber fiber optic cabl cable e into its correct hole in the amplifier. Close the fiber optics latch. E. Turn on mac machine hine power power.. Select Select OK in the Standby Mode dialog box. 2-102)) . F. Set up the the J boat present present sensor sensor amplifie amplifierr (see Figure 2-102 sensitivity, teach the J boat where most holes are present. NOTE: For maximum sensitivity, 1. Make sure sure that the ”LO” ”LO” and ”HS” lights lights are are turned ON before before you teach teach the replaced amplifier: a. Press and hold hold the TEACH TEACH (or ”-”) button button of the the amplifier amplifier for two tto o three seconds until ”LO” and ”DO” of the Status LEDs flash after another. b. To set the ‘unblock’ ‘unblock’ condition condition (without (without J boat), boat), press the TEACH TEACH (or ”-”) button one [1] time. c. To set the ‘block’ ‘block’ condition, condition, put the sample sample J boat on the work workholder holder rails and in the path of the sensor beam, then press the TEACH (or ”-”) button one (1) time. 2. Manually Manually index the the whole J boat at at the sensor and and make sure the the amplifier amplifier detects the whole J boat. 3. If false triggering triggering occurs, occurs, press press Manual Adjustment Adjustment Bu Button tton (or ”+” and ”-”) to change the sensitivity of amplifier. 4. Do s sttep 1. if manual adjustment does not improve the false triggering of amplifier. 2-110 Workholder 98888-0000-JB3-01 Material Handling System Manual 2.9. 2.9.6 6 Inde Indexe xerr Fl Flex ex Ca Cabl ble e As Asse semb mbly ly 2. 2.9. 9.6. 6.1 1 Pull Puller er Fl Flex ex Cabl Cable e Asse Assemb mbly ly Purpose • Rep Replac lace e th the e pulle pullerr fflex lex cable cable assemb assembly ly.. Tools/ Materials/ Parts • • Pull Puller er Flex Flex Cable Cable As Assemb sembly ly,, P/N 08 08888888-129 1297-00 7-000-x 0-xx x Hand Tools • Elec Electro trosta static tic Disc Dischar harge ge (ES (ESD) D) Protect Protective ive C Cont ontain ainer er Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off the machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Remove tthe he indexer indexer assembly assembly (see p paragrap aragraph h 2.6 2.6). ). D. Remove th the e puller flex flex cable cable assembly assembly (see Figure 2-103 2-103): ): CAUTION: Operation Hazard. Obey all ESD procedures before you remove or put the PCBs into storage. 1. Make sure that the the electrical electrical cable cables s to the puller ass assembly embly are cor correctly rectly identified. If not, make a note of the connection. 2. Remove all all the cable cable ties and open open the cable cable clamps clamps if neces necessary sary to release the cables. Make a note of the cable routing and cable clamps positions. 3. Disconnect Disconnect all the ca cables bles connectors connectors on the cir circuit cuit pan panel el that attach attach to the puller mount. 4. Loosen two two captive captive screws screws that attach attach the PCB co cover ver to the in indexer dexer base. base. 5. Remove the the PCB cover to to access the the indexe indexerr intermediate intermediate board. board. 6. Disconnect Disconnect the pul puller ler flex cable cable connector connector on connect connector or J3 of the indexe indexerr intermediate board. 7. Remove the the two M3 screws screws that attach attach th the e ribbon c clamp lamp to the center center of the front wall. 8. Remove the the ribbon clamp clamp that that attach tthe he pulle pullerr flex cab cable le to the center center of the front wall. 9. Move Move the pu pulle llerr to the left left limi limit. t. 10.Remove the two M2.5 screws that attach the ribbon cable clamp to the left side of the front wall. 11.Remove the ribbon r ibbon cable clamp that attach the puller flex cable along the front wall. 12.Remove the two M3 screws and washers that attach the puller flex cable assembly with circuit panel to the puller mount. 13.Remove the puller flex cable from the indexer assembly and put it in an ESD protective container. Workholder 98888-0000-JB3-01 2-111 IConn High Performance Wire Bonder . Puller Assembly Puller Flex Cable Assembly with Circuit Panel Ribbon Clamp 2x M3 Screws and Washers 2x M3 Screws Ribbon Cable Clamp Puller Flex Cable Assembly 2x M2.5 Screws Slide Block For Puller Assembly Indexer Intermediate Board Fi g ure 2-10 2-103 3 P ul ulle lerr Flex Cable Cable A s s em embl blyy E. Insta Installll the replacement replacement puller puller flex flex cable (see (see Figure 2-103 2-103): ): 1. Hold the puller puller flex cable cable assembly assembly with circuit circuit panel against against the pu puller ller mount. Make sure the flat surface of the circuit panel points to the front wall. 2. Install Install the puller puller flex cable cable assembly assembly with circuit circuit panel to th the e mount with th the e screws and washers removed before. 3. Torque the the screws screws to 7 in. lbs. (0.8 (0.8 Nm). 4. Put the puller puller flex cable assembly assembly against against the left left side of the front ra railil support behind the indexer motor, then put it along the left side of the front wall. 5. Install Install the ribbon ribbon cable clamp clamp at the left side of the front front wall to atta attach ch the puller flex cable assembly. assembly. 6. Tighten Tighten the screws on the ribbon cable c clamp. lamp. 7. Connect Connect the puller flex flex cable assembly assembly connector connector to conn connector ector J3 of indexer intermediate board. 8. Connect Connect the electrical electrical cables to the circuit circuit panel on the puller ass assembly embly.. Refer to your notes. 2-112 Workholder 98888-0000-JB3-01 Material Handling System Manual 9. Attach the the electrical electrical cables cables with cable cable tie ties s and cable c clamps lamps tto o the indexer assembly. Refer to your notes. 10.Install the ribbon clamp to the center of the front wall with the screws removed before. 11.Make sure that th at the puller flex cable assembly is behind the ribbon clamp. 12.Install the PCB cover to the indexer base and tighten the captive screws. F. Install Install the indexer indexer assembly assembly to the machine machine (se (see e paragraph paragraph 2.6 2.6). ). G. Push the green green machine machine ON ON switch. switch. H. Sele Select ct OK to start initialization. 2. 2.9. 9.6. 6.2 2 Grip Grippe perr Fl Flex ex Cabl Cable e Asse Assemb mbly ly • Rep Replac lace e th the e pulle pullerr fflex lex cable cable assemb assembly ly.. Tools/ Materials/ Parts • Gri Gripper pper Flex Flex Cabl Cable e Assembl Assembly y, P/N 08888 08888-12 -128080-000000-xx xx • Hand Tools • Elec Electro trosta static tic Disc Dischar harge ge (ES (ESD) D) Protect Protective ive C Cont ontain ainer er Procedure A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off the machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Remove tthe he indexer indexer assembly assembly (see p paragrap aragraph h 2.6 2.6). ). D. Remove tthe he gripper flex flex cable cable assembly assembly (see Figure 2-104): 2-104): CAUTION: Operation Hazard. Obey all ESD procedures before you remove or put the PCBs into storage. 1. Make sure that the the electrical electrical cable cables s to the index asse assembly mbly are corr correctly ectly identified. If not, make a note of the connection. 2. Remove all all the cable cable ties and open open the cable cable clamps clamps if neces necessary sary to release the cables. Make a note of the cable routing and cable clamps positions. 3. Disconnect Disconnect all the ca cables bles connectors connectors on the cir circuit cuit pan panel el that attach attach to the index mount. 4. Loosen two two captive captive screws screws that attach attach the PCB co cover ver to the in indexer dexer base. base. 5. Remove the the PCB cover to to access the the indexe indexerr intermediate intermediate board. board. 6. Disconnect Disconnect th the e gripper flex flex cable connect connector or on connector connector J23 of the the indexer intermediate board. 7. Remove the the two M3 screws screws that attach attach th the e ribbon c clamp lamp to the center center of the front wall. 8. Remove the the ribbon clamp clamp that attach attach the grip gripper per flex cable cable to the cente centerr of the front wall. 9. Move the the index index assembly assembly to to the right limit. 10.Remove the two M2.5 screws that attach the ribbon cable clamp to the right side of the front wall. 11.Remove the ribbon cable cab le clamp that attach the gripper flex cable along the front wall. Workholder 98888-0000-JB3-01 2-113 IConn High Performance Wire Bonder 12.Remove the air tube clips that attach the gripper flex cable along the routing to the center of the front wall. 13.Remove the two M3 screws and washers that attach the gripper flex cable assembly with circuit panel to the index mount. 14.Remove the gripper flex cable from the indexer assembly and put it in an ESD protective container. Index/tucker Assembly Ribbon Clamp Ribbon Cable Clamp 2x M3 Screws 2x M2.5 Screws 2x M3 Screws and Washers Gripper Flex Cable Assembly with Circuit Panel Gripper Flex Cable Assembly Slide Block For Index/Tucker Assembly Indexer Intermediate Board Fi g ure 2-1 2-104 04 G ripper Flex C abl ble e A s s em embl blyy E. Insta Installll the replacement replacement gripper gripper flex flex cable (see (see Figure 2-104): 2-104): 1. Hold the gripper gripper flex cable cable assembly assembly with circ circuit uit panel a against gainst the index index mount. Make sure the flat surface of the circuit panel points to the front wall. 2. Install Install the gripper gripper flex cable assembly assembly with with circuit p panel anel to the moun mountt with the screws and washers removed before. 3. Torque the the screws screws to 7 in. lbs. (0.8 (0.8 Nm). 4. Put the gripper gripper flex flex cable assembly assembly along along the ri right ght side of the the front wa wallll behind the index assembly. assembly. 2-114 Workholder 98888-0000-JB3-01 Material Handling System Manual 5. Install Install the ribbon ribbon cable clamp clamp at the ri right ght side of the the front wa wallll to attach the gipper flex cable assembly. 6. Tighten Tighten the the screws screws on the the ribbon ribbon cable cable clamp. clamp. 7. Install Install the air tube clips clips along the gripper gripper flex cable cable assembly assembly.. 8. Put the tubings tubings to the air tube clips, clips, along with with the routing routing of the gripper flex flex cable assembly. assembly. 9. Connect Connect the grip gripper per flex cable cable assembly assembly conn connector ector to co connector nnector J23 J23 of indexer intermediate board. 10.Connect the electrical cables to the circuit panel on the index assembly. Refer to your notes. 11.Attach the electrical cables with cable ties and cable clamps to the indexer assembly.. Refer to your notes. assembly 12.Install the ribbon clamp to the center of the front wall with the screws removed before. 13.Make sure that the gripper flex cable assembly is behind the ribbon clamp. 14.Install the PCB cover to the indexer base and tighten the captive screws. F. Install Install the indexer indexer assembly assembly to the machine machine (se (see e paragraph paragraph 2.6). 2.6). G. Push the green green machine machine ON ON switch. switch. H. Sele Select ct OK to start initialization. Workholder 98888-0000-JB3-01 2-115 IConn High Performance Wire Bonder 2.9.7 2.9 .7 Hea Heatt B Bloc lock kV Vacu acuum um Sol Soleno enoid id Valv alve e Purpose • Replace Replace the solenoi solenoid d valve valve that controls controls the vacuum flow to the heat bl block ock insert. Tools/ Materials/ Parts • Hand tools • Vacuum acuum valve valve asse assembl mbly y, P/N 03 03107 107-100 -1000-00 0-000-xx 0-xx Procedure (Figure 2-105) Solenoid Valve Bracket Fitting (Port 2) - Blue Tubing to Heatsink manifold Heat Block Vacuum Solenoid Valve XY Table Assembly 2x SHCSs Elbow Fitting (Port 1)- Blue Tubing to Vacuum quick-disconnect connector Fig ure 2-105 2-105 Hea Heatt Blo B lock ck V acuum Solenoid Solenoid Valve Valve (XY Ta Tabl ble e As s em embl blyy - R ig ht View) View) A. Remove all material from the workholder. B. Pr Pre ess [MOTOR STOP] and turn off the machine power. WARNING: TO PREVENT ACCIDENTAL BURNING OF THE SKIN, DO NOT CONTINUE WITH THIS PROCEDURE UNTIL BOTH HEAT BLOCKS HAVE COOLED DOWN. C. Remov Remove e the upper console console output output cover. cover. D. Find the heat block vacuum valve assembly (P/N 03118-0330-006-xx) attach to the right side of the XY Table assembly (see Figure 2-105 2-105). ). E. Remove s solenoi olenoid d valve from from the solenoid solenoid bracket bracket (see Figure 2-105). 2-105). 1. Make sure that that the pneumatic pneumatic tubings tubings to the the vacuum v valve alve on the XY ttable able are correctly identified. If not, make a note of the connection. 2. Remove all all the cable clamps clamps if necessary necessary to relea release se the tubings. tubings. Make a note of the pneumatic tubings position and cable clamps positions. 3. Disconnect Disconnect the pn pneumati eumatic c tubes from from the solenoid solenoid val valve. ve. 4. Remove the two (2) SHCSs SHCSs from the the solenoid solenoid val valve. ve. 5. Remove Remove the solenoid solenoid valve valve from from the the solenoid solenoid valve bracke bracket. t. 6. Remove the air fittings fittings from the the solenoid solenoid val valve. ve. 2-116 Workholder 98888-0000-JB3-01 Material Handling System Manual F. Install Install the replacement replacement solenoid solenoid valve. 1. Install Install the air fittings fittings into the solenoid solenoid valve valve assembly assembly.. 2. Make sure the the air fittings fittings are installe installed d into the ports ports corr correctly ectly (see (see Figure 2105). 105 ). 3. Put the solenoid solenoid valve against against the bracket. bracket. Make sur sure e the clearan clearance ce holes in the solenoid valve are aligned with the holes in the bracket. 4. Attach Attach the solenoid solenoid valve valve to the brac bracket ket with screws screws remo removed ved before. before. 5. Tig ight hten en the the screw screws. s. 6. Connec Connectt the pneumat pneumatic ic tubing tubings: s: a. Connect Connect the blue p pneumati neumatic c tubing from from the sli slider der asse assembly mbly (via tthe he heatsink manifold) to the front fitting (port 2) on the valve. b. Connect Connect the blue pneu pneumatic matic tubing tubing (from the quic quick–disc k–disconnect onnect con connecnector on the rear of the machine) to the rear fitting on the vacuum valve (port 1). G. Install Install the upper console console output output cover. cover. H. Push tthe he green green machine machine ON switch. switch. I. Select OK to start initialization. J. During initializ initialization, ation, make sur sure e that MHS initializatio initialization n is completed successsuccessfully. K. Do a cycle operation operation with several several sample carriers carriers through the workh workholder older (refer to Section 1 for procedure). L. Stop Stop the cycle at intervals intervals to make sure sure that the vacu vacuum um attach attach the device at the bond site. 98888-0000-JB3-01 Workholder 2-117 IConn High Performance Wire Bonder This pa pagg e is le left ft inte intentiona ntionall llyy bla blank nk 2-118 Workholder 98888-0000-JB3-01 Material Handling System Manual 3 Magazine Handlers 3.1 About T Th his Se Section Here is what you will find in this section: • Section 3.2 3.2,, Description Description,, gives an overview of the Input and output magazine handlers. • Each Each se sect ctio ion n from from Sect Sectio ion n 3.3 through 3.9 describes various instructions, calibrations, operation guidelines, maintenance and procedures for the magazine handlers: • Section 3.3, 3.3, Setup • Section 3.4, 3.4, Magazine Handler Calibrations • Section 3.5, 3.5, Magazine Handler Configurations • Section 3.6, 3.6, Magazine Handler Adjustments • Section 3.7, 3.7, Magazine Handler Removal and Installation • Section 3.8, 3.8, Preventive Maintenance • Section 3.9, 3.9, Part Replacement Procedures Magazine Handlers 98888-0000-JB3-01 3-1 IConn High Performance Wire Bonder 3.2 Description 3.2.1 General The Material Handling System contains of two magazine handler subsystems (3035) to handle magazines during bonding operations. Each Magazine Handler Sub-system is made up of two assemblies. The input magazine handler uses devices the inputfor Z Tower T ower Assembly to carry magazines containing carrier with unbonded delivery to the indexer subsystem. After bonding occurs, the index/eject assembly ejects the completed carriers into an empty magazine held by the output Z tower Assembly at the output magazine handler. Both magazine handlers automatically place finished magazines (empty input or full output) onto a magazine unload tray at the Tray Assembly, and then pick up another magazine (full input or empty output) from a magazine load tray at the Tray Assembly. 3. 3.2 2.2 Ma Majo jorr C Com omp pon one ent nts s The major subassemblies/components of the magazine handlers (see Figure 3-1 and Figure 3-2) 3-2) are: • Y–Ax Y–Axis is Driv Drive e Asse Assemb mbly ly Moves magazine held by the Z T Tower ower Magazine Gripper Assembly in the Y-axis direction (forward and backward). • Z– Z–Ax Axis is Driv Drive e Asse Assemb mbly ly Moves magazine held by the Z T Tower ower Magazine Gripper Assembly in the Z-axis direction direct ion (up and down). • Maga Magazi zine ne Gri Gripp pper er Ass Assem embl bly y Grips magazine at the load tray assembly of the Input/Output Tray Assembly and holds the magazine during carrier insertion/ejection. After the magazine has been processed, releases the magazine onto the unload tray of the Input/Output Tray Assembly.. Assembly • Lo Load ad Tra ray y As Asse semb mbly ly Holds unprocessed magazines for pickup by the magazine gripper assembly a ssembly.. After a magazine is removed from the load tray assembly, a belt–drive mechanism positions the next magazine on the tray for pickup. The load tray is positioned so that magazines can ca n be easily added by the th e user. • Unlo Unload ad Tra ray y Asse Assemb mbly ly Holds processed magazines placed on the unload tray assembly by the magazine gripper assembly. The unload tray assembly is positioned so that tha t magazines can be easily removed by the user. • In Inte term rmed edia iate te Bo Boards ards The Magazine Handler Intermediate Boards drives and controls the Z T Tower ower Assembly motors and sensors. The Input/Output Tray Assemblies motors and sensors are driven and control by the Indexer Intermediate Board. (Refer to Section 4 of this manual for more information) 3-2 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual 3.2. 3.2.3 3 Ma Maga gazi zine ne Ha Hand ndle lerr Po Posi siti tion ons s Separately driven motors of the Z Tower Tower Assembly, Y and Z axes, position the magazine gripper assembly that holds magazines during bonding operations. The Y axis and Z axis assemblies are capable of moving to positions independently of the each each other other.. 3. 3.2. 2.3. 3.1 1 In Inpu putt and and Outp Output ut Pick Pickup up Posi Positi tion on Pickup position is where the t he Y and Z axes of Z To Tower wer Assembly move the magazine gripper assembly to pickup a magazine with unbonded carriers from the load tray of Input Tray Assembly or an empty magazine from the load tray of the Output Tray Assembly. Magazine Handlers 98888-0000-JB3-01 3-3 IConn High Performance Wire Bonder Z Axis Drive Magazine Gripper Magazine Handler Intermediate Board (behind Z Tower Casting) Assembly Upper Paw Jaw Magazine Gripper Assembly Upper jaw Magazine Stop Button Lower Paw Jaw Y Axis Drive Magazine Stop Button Lower Jaw Magazine Gripper Assembly Tray Sensor Magazine Gripper Motor (beneath lower jaw bracket - not shown) Z Tower Assembly Fi g ure 3-1 3-1 Ma Magg azine Handle Handlers rs Ma Major jor C omp omponent onentss 3-4 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual Tray Full Sensor (Hidden ) Input Magazine Wall Input Retainer Unload Tray Magazine Present Sensor Retainer Thumbscrew (2 Places) Load Tray Driven Timing Belt (4 Places) Drive Timing Belt (Hidden) Input Tray Assembly Output Magazine Wall Tray Full Sensor (Hidden) Output Retainer Unload Tray Magazine Present Sensor Load Tray Drive Timing Belt (Hidden) Retainer Thumbscrew (2 Places) Driven Timing Belt (4 Places) Output Tray Assembly Fig ure 3-2 Tray As s em embl blyy (Loa (L oad d and and Unloa Unload d Trays Trays ) Magazine Handlers 98888-0000-JB3-01 3-5 IConn High Performance Wire Bonder 3. 3.2. 2.3. 3.2 2 In Inpu putt a and nd Outp Output ut Sl Slot ot Posi Positi tio ons At the Input Z Tower Tower Assembly, the Y and Z axes are positioned at which the indexer puller pulls an unbonded leadframe from a magazine slot. At the Output Z Tower Assembly, the Y and Z axes are positioned at which the index tucker ejects a bonded device into a magazine slot. The number of slot positions are limited to the number of slots in the magazine. 3.2 .2.3 .3.3 .3 In Inp put St Stagin ging Pos Posiitio tion Input Staging Position is the Input Z Tower Assembly Y and Z axes positions where the magazine gripper assembly can release an empty magazine onto the unload input tray. tray. 3.2.3 .3..4 Deposit Position Deposit Position is the Output Z T Tower ower Assembly Y and Z axes positions where the paws release a filled magazine onto the unload output tray. tray. 3. 3.2. 2.4 4 Op Opti tion onal al Eq Equi uipm pmen entt 3.2.4.1 Safety Covers Safety covers that completely enclose the magazine handlers are available as an added-cost option. These covers prevent injury by keeping personnel away from the moving mechanisms of the magazine handlers while the machine is operating. Each cover has an electrically–latched and interlock switch protected door through which the operator can add new magazines or remove finished magazines when the machine is stopped. If a safety cover door is forced open during operation, the interlock switch stops the machine by removing power from all motors and signals an error condition that must be cleared before operation can be resumed. When magazine replacement is required, software options on the Mag Handler Utilities menu are used to unlatch the door so that it may be opened and latch the door after it has been closed. 3. 3.2. 2.4. 4.2 2 Bar Bar Code Code Read Reader ers s (O (Opt ptio iona nal) l) Bar code readers are available that may be mounted on the magazine handlers. They allow machines that are connected to an external host processor proce ssor to read bar code labels todata magazines during magazine load andthe unload and send theattached bar code to the host processor. Therefore host operations processor can track processing of the individual magazines. 3.3 Setup The magazine handlers require no mechanical setup after the machine is ins instal talled led.. 3-6 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual 3.4 3.4 Ma Maga gazi zine ne Ha Hand ndle lerr Ca Cali libr brat atio ion n The Magazine Handler calibrations consist of software routines that are used to calibrate the input slot, output slot, input trays and output trays. Using a series of dialog boxes, the software steps the user through each calibration process. NOTE: Each magazine handler calibration must be executed in its entirety. entirety. Clicking the CANCEL button any time before the calibration is completeon requires a restart of theatcalibration procedure. 3.4. 3.4.1 1 Inpu Input/ t/Ou Outp tput ut T Tra rays ys Ca Calib libra ratio tion n The Input/Output Trays calibrations contain the software routines that prompt the user to move the input/output magazine handler gripper assembly to specific positions in the Y axis. It also teach the machine to move to the correct positions for picking up and ejecting magazines. WARNING: DURING THE CALIBRATION CALIBRATION PROCEDURES, MAG HANDLER COMPONENTS MOVE. BEFORE EXECUTING EACH STEP, STEP, REMOVE HANDS FROM THE MAG HANDLER AREA. WARNING: THE HEAT HEAT BLOCKS AND HE HEA AT BLOCK INSERTS ARE HOT. EX EXERERCISE WITH EXTREME CAUTION WHEN WORKING IN THESE AREAS. NOTE: a) The steps steps for calibrating calibrating the the input trays trays and the output output trays trays are the same. Therefore, only ‘Input Trays’ calibration operation procedures are shown here. b) Either an empty empty magazine magazine or a straightedge straightedge may be used used in this calicalibration. In the steps below, the use of a magazine is described. Required Gauges • Emp Empty ty maga magazi zine ne or st stra raigh ighted tedge ge Tools/ Materials/ Parts • None Procedure CALIBRATION from the mode bar, then select MAG HANDLER from the A. Select Calibration mode menu. The ‘Mag Handler’ menu appears. B. From the ‘Mag ‘Mag Handler’ Handler’ menu, select INPUT TRAYS. Follow the instructions in the dialog boxes. C. Remov Remove e magazines magazines or other material material from the unload unload and load trays trays of the input magazine handler. Select OK when done. D. Do th the e unload unload tray calibration: calibration: 1. Put an empty empty magazine magazine on the rear of the unload unload tray tray. 2. Push the magazine magazine until until the rear rear surfac surface e of the magazine magazine is against against the magazine stop surfaces at the th e rear end of the th e tray. 3. Use your your hand and apply apply a force force on the fron frontt of the magazine magazine to m make ake sure that the magazine is fully touched against the magazine stop surfaces. At the same time, hold the magazine at this position. 4. Use the Left Left and Right Right arrow keys keys on the MMI, MMI, and move tthe he grippe gripperr (fork) of the Z tower assembly to the unload tray. 5. Observe Observe the gripper gripper as you adjust adjust the gripper gripper posi position. tion. Move Move the gripper gripper until the two buttons touch the rear surface of the magazine (see Figure 33). Magazine Handlers 98888-0000-JB3-01 3-7 IConn High Performance Wire Bonder 6. Select OK in the dialog box when the gripper is at the correct position. E. Do the unload tray calibra calibration tion check: check: 1. Remove the magazine magazine from the the top tray tray.. 2. Select OK in the dialog box. The tray sensor at the front of the gripper finds the sensor flag at the unload tray. The gripper then moves to the bottom of the unload tray and stops. The T he next dialog box appears on the display. F. Do the the load tray tray calib calibrati ration: on: 1. Put an empty empty magazine magazine on the rear of of the load load tray tray.. 2. Push the magazine magazine until until the rear rear surface surface of the magazine magazine is against against the surfaces of the stop blocks at the rear end of the tray. 3. Use your hand hand and apply apply a force on on the front front of the magazine magazine to ma make ke sure that the magazine is fully touched against the surfaces of the stop blocks. At the same time, hold the magazine at this position. 4. Use the Left Left and Right Right arrow keys keys on the MMI, and m move ove the gripper gripper (fork) (fork) of the Z tower assembly to the unload tray. 5. Observe Observe the gripp gripper er as you adjust adjust the gripper gripper posi position. tion. Move Move the gripper gripper until the two buttons touch the rear surface of the magazine (see Figure 33). 6. Select OK in the dialog box when the gripper is at the correct position. G. Do the load load tray calibratio calibration n check: 1. Remove the magazine magazine from the the load tray. tray. 2. Select OK in the dialog box. The tray sensor at the front of the gripper finds the sensor flag at the load tray. The gripper then moves to the bottom of the load tray and stops.. NOTE: This completes the Input Trays calibration procedures. If needed, perform the Output Trays calibration procedures. Magazine Stop Surfaces or Stop Block Surfaces Fig ure 33-3 3 To Touchin uchingg B en enching ching B ut utttons (S ide View View)) 3-8 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual 3.4. 3.4.2 2 Inpu Input/ t/Ou Outp tput ut S Slo lott C Cal alib ibra rati tion on The Input/Output Slot calibrations contain the software routines that prompt the user to move the input/output magazine handler gripper assembly to specific positions in the Y and Z axes. It also teaches the machine to move to the correct slot positions for boat injection and ejection. Figure 3-4 shows the gauges used in the Input/Output Slot calibrations. The figure describes each gauge relating to how it isbe used when performing the Input and Output Slot calibrations. This figure should referenced when performing the calibrations. Input Top Y Axis Hole Use this end for Output Slot Calibration Input Bottom Y Axis Hole Use this end for Input Slot Calibration Input Calibration Pin Input Z Axis Hole Output Calibration Pin Magazine-Sized Gauge Install on the load tray as shown: 1. Put the left or right side against the magazine handler wall. 2. Make sure that the label ‘FRONT’ on the gauge points to the user . Workholder Setup & Calibration Gauge Fi g ure 3-4 Ma Magg azinezine-S S ized Gauge and and Workholde Workholderr S et etup up & C alibra libration tion G aug e WARNING: DURING THE CALIBRATION CALIBRATION PROCEDURES, MHS COMPONENTS MOVE. BEFORE EXECUTING EACH STEP, REMOVE HANDS FROM THE MAG HANDLER AND WORKHOLDER AREAS. WARNING: HOT SURFACES EXIST ON HEAT BLOCKS AND HEAT BLOCK INSERTS. BE CERTAIN TO EXERCISE EXTREME CAUTION WHEN WORKING IN THESE AREAS. NOTE: The steps for calibrating the input slot and output slot are the same. Therefore, only the operations required to perform the ‘Input Slot’ calibrations are given in the t he steps that follow. Tools/ Materials/ Parts • Maga Magazin zine-Si e-Sized zed Gauge, Gauge, P/N 034 0341212-0999 0999-00 -007-x 7-xx x • Workho Workholder lder setup & calibrati calibration on gauge gauge assembly assembly ((P/N: P/N: 0303503035-0501-00 0501-000-XX) 0-XX) Procedure A. Select CALIBRATION, from the mode bar, then select MAG HANDLER from the Calibration mode menu. B. From the Mag Mag Handler Handler menu, select INPUT SLOT. This causes the first in a series of instructional prompts to appear. C. Remove all boats boats from the the workhold workholder er.. Select Select OK. 98888-0000-JB3-01 Magazine Handlers 3-9 IConn High Performance Wire Bonder D. Remove ha hands nds from the workholder workholder area, area, then select select OK in the ‘Warning’ prompt. CAUTION: In the next step, the rail height will be measured by the bond head. The bond head will move down and touches with the rear rail. Make sure there is no ball at the capillary tip before you do this step. E. Observe tthe he warning warning in the dialog dialog box and select select OK to continue with the rail height measurement. F. Remove all material material from the workholder workholder.. Remove the heat block inserts. inserts. If present. Select OK when done. G. Install the magazine-sized gauge and workholder setup & calibration gauge: 1. Put the magazine-si magazine-sized zed gauge against against the input magazine magazine wa wall, ll, on the load tray. Make sure that the label FRONT points to you. 2. Put workholder workholder setup setup & calibration calibration gauge assembly assembly between between the rails rails (see 3-6). Figure 3-5 and Figure 3-6). WARNING: DO NOT DAMAGE THE REAR RAIL BOAT BIAS SPRING WHEN YOU PUT THE WORKHOLDER SETUP & CALIBRATION GAUGE ASSEMBLY BETWEEN THE RAILS. a. Make sure sure that the index index slot of the the gauge iis s on the right right side, point point towards the Output Magazine Handler Assembly (see Figure 3-5). 3-5). Rear Rail Output Magazine Handler Assembly Front Rail Index slot on the right side. 3-5 Ins ta tall ll the Workholde Workholderr S et etup up & Calibrat Calibration ion G aug e As s em embl blyy Pos P osition ition Fi g ure 3-5 b. Hold Hold tthe he gau gauge ge at at 45o angle (rear edge down) and put the rear edge of the gauge on the rear rail (see Figure 3-6). 3-6). c. Without moving moving the gauge gauge forward, forward, slowly slowly lower lower the gauge until until it is on the front rail (see Figure 3-6). 3-6). 3-10 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual Gauge at 45o angle Front Rail Rear Rail o Fi g ure 3-6 Ins ta tall ll the Work hold holder er Set S etup up & Calibr Calibra ation G aug e A s s em embly bly at 45 angle 3. Move the gauge gauge to the left left side of of the indexer indexer assem assembly bly to the in input put magazine handler assembly. assembly. 4. Make sure that that the pin on the the left side side of the wor workholder kholder setup setup & calibration calibration gauge points to the input magazine mag azine handler assembly. (see Figure 3-7). 3-7). 5. Select OK in the dialog box. The input mag handler picks up the magazinesized gauge. H. Do the Z axis slot calibra calibration: tion: 1. Make sure that that the magazine-s magazine-sized ized gaug gauge e is picked picked up by the gri gripper pper assembly. 2. Use the Up and and Down arrow arrow keys on the the MMI, and mo move ve the grip gripper per assembly with the magazine-sized gauge until the Z axis hole on the gauge is aligned to the rails position. 3. Move the workholder workholder setup setup & calibration calibration gauge to the magazine magazine-sized -sized gauge. 3-4)) on the magazine4. Engage the input input pin pin into the Z axis axis hol hole e (see Figure 3-4 sized gauge (see CAUTION below). 5. When the Z axis axis position position is correct, correct, move tthe he workh workholder older setup setup & calib calibraration gauge to the preheat assembly, make sure that the pin is free from the magazine-sized gauge. Select OK in the dialog box. CAUTION: Do not put the input pin of the workholder setup & calibration gauge into the magazine-sized gauge while you move the gripper with magazine-sized gague. Magazine Handlers 98888-0000-JB3-01 3-11 IConn High Performance Wire Bonder Magazine-sized Gaug Ga uge e Sl Slot ot Workholder Setup & Calibration Gauge Input Pin Output Pin Fi g ure 3-7 3-7 Ins ta tall ll the Work hold holder er Setup & C alibrat libration ion Ga G aug e I. Do the the botto bottom m Y axis axis slot slot cali calibrat bration ion:: 1. Make sure sure that the magazinemagazine-sized sized gauge gauge is pick picked ed up by the gr gripper ipper assembly. 2. Use the Up and and Down arrow arrow keys on on the MMI, and m move ove the gri gripper pper assembly with the magazine-sized gauge until the bottom Y axis hole on the gauge is aligned to the rails position. 3. Move the workholder workholder setup setup & calibration calibration gauge to the the magazine-sized magazine-sized gauge. 3-4)) on the 4. Engage the the input input pin into into the bottom bottom Y axis axis hole ((see see Figure 3-4 magazine-sized gauge (see CAUTION below). 5. When the bottom bottom Y axis positio position n is correc correct, t, move th the e workhol workholder der setup setup & calibration gauge to the preheat pr eheat assembly, make sure that the pin is free from the magazine-sized gauge. gauge. Select OK in the dialog box J. Do th the e top Y axis axis slot slot calib calibrati ration: on: 1. Make sure sure that the magazinemagazine-sized sized gauge gauge is pick picked ed up by the gr gripper ipper assembly. 2. Use the Up and and Down arrow arrow keys on on the MMI, and m move ove the gri gripper pper assembly with the magazine-sized gauge until the top Y axis hole on the gauge is aligned to the rails position. 3. Move the workholder workholder setup setup & calibration calibration gauge to the the magazine-sized magazine-sized gauge 4. Engage the input input pin into into the top Y axis axis hole (see Figure 3-4) 3-4) on the magazine-sized gauge (see CAUTION below). 5. When the top top Y axis position position is correct, correct, mo move ve the workholder workholder setup setup & calicalibration gauge to the preheat assembly, make sure that the pin is free from the magazine-sized gauge. Select OK in the dialog box K. If necessar necessary y, adjust the retainer retainer to remove the magazine-siz magazine-sized ed gauge when the gauge ejects. Select OK in the dialog box to eject the magazine gauge. L. Remove Remove the workholder workholder setup setup & calibration calibration gauge gauge from the rrails. ails. Select Select OK when done. M. Install Install the heat block and clamp inserts. inserts. Select Select OK when done. NOTE: This completes the Input Slot calibration. If needed, do the Output Slot calibration. 3-12 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual 3.5 3.5 Ma Maga gazi zine ne Ha Hand ndle lerr Con Confi figu gura rati tion on Magazine dimensions and magazine slot order are entered using dialog boxes 3-8)) in available through the Magazine Handler Configuration menu (see Figure 3-8 Configuration mode. Refer to Section 5 of IConn Operation Manual for descriptions of GUI menus, illustrated definitions of configuration parameters and options, and other information concerning magazine handler configuration. Fi g ure 3-8 Ma Magg azine Handl Handler er C onfig urat uration ion Menu 3.6 3.6 Ma Maga gazi zine ne Ha Hand ndle lerr Ad Adju just stme ment nts s 3. 3.6. 6.1 1 Se Sett-up up tthe he Be Belt lt T Ten ensi sion on Purpose • Adjust tthe he tension tension of of the input/o input/output utput lload oad tray tray belts belts to m make ake su sure re that the belts belts move the magazine smoothly on the tray. Tools/ Materials/ Parts • Hand tools • Allen Key Set • Torque wrench • Belt Belt Ten ensi sion on Tes este terr Procedure (Figure 3-9) A. Remove all material from the Magazine Handler Assembly. B. Pr Pre ess [MOTOR STOP]. Turn off machine power. C. Remove the inpu inputt or output tray assembly assembly.. Refer to paragraph paragraph 3.7.2 step C. for input tray assembly and paragraph 3.7.2 step C. for output tray assembly. D. Put the inp input ut or output output tray assembly assembly on a wo work rk bench bench.. E. Do the driven timing timing belts belts tension tension setup: setup: 1. Find the pulley holder at at the bottom bottom of the the load ttray ray.. 2. Loosen the M5 screw on on the pulley pulley holder holder.. 3. Put the sensor of the belt belt tension tester tester over the applicab applicable le driven tim timing ing belt. 4. Loosen the M4 nut on the pulley pulley holder holder.. 5. Turn the the M4 screw to to adjust the the tension tension of the driv driven en belt. 6. Make sure that that the measured measured value value show shows s on the belt tension tension ttester ester is between 43 Hz and 48 Hz. 7. Ti Tight ghten en the the M5 M5 screw screw.. 8. Tighten Tighten the M4 nut nut on the pulley pulley holder to to lock the M4 M4 screw screw.. F. Do the drive timing belt tension tension setup: 1. Find the the motor bracket bracket at the bottom bottom of the the load ttray ray.. Magazine Handlers 98888-0000-JB3-01 3-13 IConn High Performance Wire Bonder 2. Loosen the the two M4 counter counter sunk sunk screws that that attac attach h the load tr tray ay motor with motor bracket and clamping plate to the bottom of the load tray. 3. Loosen the M4 M4 nut on the tensioner tensioner block. block. 4. Turn the the M4 screw to to adjust the the tension tension of the drive drive timing b belt. elt. 5. Use the torque torque wrench and apply apply a torque between between 0.1 0.11 1 Nm (1 lb.in.) and 0.14 Nm (1.24 lb.in.) to the M4 screw to put tension on the drive dr ive timing belt. 6. Tighten Tighten the M4 nut on the tensioner tensioner blo block. ck. 7. Tighten Tighten the two M4 counter counter sunk screws screws at the top of the load tray. tray. G. Install the input or output tray assembly to the machine. Refer to paragraph 3.7.2 step E. for input tray assembly and paragraph 3.7.2 step E. for output tray assembly. Driven Belts Pulley Holder M5 Screw Load Tray Assembly Driven Belt (Hidden - N Not ot Shown Here) Tensioner Block Drive Belt M4 Nut M4 Screws M4 Screws M4 Nut Load Tray Motor Motor Bracket with Clamping Plate M4 Counter Sunk Screws Idler Pulley Motor Pulley Drive Belt Common Pulley Drive Belt Common Pulley Driven Belt Pulley Driven Belts (4 places) Detail - Timing Belt Routing Fi g ure 3-9 3-9 Load Tray, B el eltt Tensi on C omp omponent onentss 3-14 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual 3.6.2 .6.2 Tray Ad Adju just stme ment nt Purpose • Adju Adjust st the the retain retainer er to the speci specifie fied d magazi magazine ne le lengt ngth. h. Tools/ Materials/ Parts • None Procedure A. Loosen the two thumbscrews below the unload tray. B. Move the retainer retainer along along the guide rails rails to set the distance distance for the mag magazines azines that you use. C. Tig Tighten hten the the two two thumbscre thumbscrews. ws. 3. 3.7 7 Ma Maga gazi zine ne H Han andl dler er Rem Remov oval al a and nd IIns nsttalla allati tion on The procedures for removing and installing the input magazine handler are basically the same for the output magazine handler. The user should also read and understand the Warnings and Cautions listed throughout the procedures before removing or installing the magazine handler. WARNING: THE Z TOWER ASSEMBLY WEIGHS APPROXIMATELY APPROXIMATELY 33 POUNDS (15 KILOGRAMS) AND TRAY ASSEMBLY WEIGHS 15.6 POUNDS (7.08 KILOGRAMS). ONLY ONE PERSON SHOULD BE PRESENT TO LIFT THE SUBASSEMBLIES OFF FROM THE MACHINE ONE AT A TIME (STEP B AND C) AND INSTALL IT ON THE MACHINE (STEP D AND E). WARNING: THE BONDER’S X AND Y MOTORS CONTAIN HIGH MAGNETIC FIELDS WHICH MAY AFFECT MAGNETICALLY MAGNETICALLY SENSITIVE DEVICES DEV ICES (PACEMAKERS, IMPLANTS, WATCHES, WATCHES, ELECTRICAL COMPONENTS, ETC.). KEEP ALL MAGNETICALLY SENSITIVE DEVICES CLEAR OF XY MOTORS. CAUTION: Comply with the ESD requirements procedure for all electrostatic discharge precautions and restrictions used during the removal and installation of the input magazine handler. 3. 3.7. 7.1 1 Inpu Inputt Ma Maga gazi zine ne H Han andl dler er The illustration in Figure 3-10 shows an input magazine handler and various points of interest the user should refer to when performing the removal or installation procedures. Purpose • Rem Remove ove/in /insta stall ll input input magazi magazine ne han handle dlerr for mainten maintenanc ance. e. Tools/ Materials/ Parts • Stra traig ight ht hex hex dri drive verr se sett (met (metri ric) c) • 5m 5mm m he hex x ti tip, p, 3/ 3/8” 8” dr driv ive e • 3/ 3/8” 8” dr driv ive, e, 6” ex exte tens nsio ion n • Ball Ball h hex ex d dri rive verr set set (met (metri ric) c) • 3/8” drive drive male male to to 1/4’ 1/4’ driv drive e femal female e ad adapt aptor or • 5mm lo long ng ba ball ll he hex x ttip ip,, 3/8” 3/8” dr driv ive e • • 1/ 1/4” 4” dr driv ive e rrat atch chet et wr wren ench ch Torq orque ue w wrenc rench, h, 70 in. lb. (7.91 (7.91 N Nm), m), 3/8” dri drive ve • Shim Shim,, 0. 0.00 001” 1” (0 (0.0 .025 25 mm) mm) • Cr Cros ossh shea ead d Scre Screwd wdri rive verr Magazine Handlers 98888-0000-JB3-01 3-15 IConn High Performance Wire Bonder Procedure A. Turn off machine power. Remove Remove magazines (if any) from the input magazine handler. Remove input tower cover, tower flap cover and Y-axis motor cove cover. r. B. Remove Z Tower Tower Assembly Assembly ((Figure Figure 3-10). 3-10). CAUTION: When lifting the Z Tower Tower Assembly and Input Tray Assembly during its removal or installation, do not grasp the assembly at the ends of the base plate. Doing this may cause the base plate to bow. Grasp and lift the assembly at points near the center of the base plate. 1. At the rear of the Z Tower Tower Assembly Assembly,, disconnect disconnect conne connector ctor P2 of Input Magazine cable (P/N 08888-1054-000-06) from connector J1 on the Input Magazine Handler Intermediate Board. See Figure 3-10 for connector location. 2. Disconnect Disconnect conne connector ctor P3 of Input Magazine Magazine cable cable (P/N 08888-1054-0 08888-1054-0000006) from Y-axis motor cable connector (P/N 08888-1070-000-xx) . 3. Loosen the the M4 socket head cap screw screw (SHCS) that that secures the the Y Y-axis -axis motor’s ground wire cable of Input Magazine cable (P/N 08888-1054-00006) to the Y-axis motor. Disconnect the ground wire. 4. Disconnect Disconnect the Inp Input ut MHS sensor sensor bus cables (P/N (P/N 08888-1 08888-1082-00 082-000-07 0-07 and 08888-1082-000-08) from connectors J2 and J3 on the Input Magazine Handler Intermediate Board. See Figure 3-10 for connectors location on the board 5. Locate two two (2) M4 x 10 mm SHCS SHCS that sec secure ure the E-ch E-chain ain brac bracket ket (with (with flexible cable track - E-chain) to the rear of the Z Tower Machining Plate. Loosen the two (2) screws and lift up the E-chain bracket. See Figure 3-10 6. Remove four four (4) M6 x 20 mm SHCSs SHCSs with wa washers shers tha thatt secure the the Z T Tower ower Assembly to the base plate. The screws located at the front and rear of the Z Tower Tower base machining plate. Move the Z To Tower wer forward in Y-axis direction towards the user to access the screws at the rear and backwards to access the screws at the front. 7. Using sufficient sufficient personnel personnel,, lift the Z Tower Tower Assem Assembly bly off from the machin machine e (see Caution). 8. Perform Z Tower Tower Assembly Assembly maintenanc maintenance, e, if required. required. 3-16 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual Remove Four SHCSs from Base Plate. (two SHCSs at both front and rear of Z Tower Assembly) Disconnect Appropriate Cables from Input Magazine Handler Intermediate Board (see below) Remove Two SHCS Securing The E-Chain Bracket to The Rear of Z Tower Machining Plate (see below) MHS Sensor Bus Cable Connector (J2) MHS Sensor Bus Cable Connector (J3) E-Chain Bracket Two SHCSs Rear of Z Tower Assembly Backplane Magazine Handler Cable Connector (J1) (Y Axis Motor Cable is connected to this cable) Input Magazine Handler Intermediate Board (top view) Fi g ure 3-10 R em emove/ ove/Ins Ins ta tall ll Ma Magg azine Handler Handler (Input Mag Mag azine Handler Handler S hown) 98888-0000-JB3-01 Magazine Handlers 3-17 IConn High Performance Wire Bonder C. Remove the Input Input Tray Tray Assembly: Assembly: CAUTION: Injury Hazard. The Input Tray Tray Assembly weight approximately 17.64 pounds (8 Kilograms). To prevent injury, use approved equipment or one to two person(s) to lift and move the assembly. 1. Make sure that that the electrical electrical cables to the the input tray assembly assembly ar are e correctl correctly y identified. If not, make a note of the connection. 2. Remove all all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 3. Loosen the the two captive captive screws screws that attach attach the P PCB CB cover to tthe he indexe indexerr base. 4. Remove the the PCB cover to to access the the index indexer er intermediate intermediate board. board. 5. Disconnect Disconnect the inpu input/outpu t/outputt tray cable connector connector from the connector connector J14 of the indexer intermediate board (see Figure 3-11 3-11). ). 6. Loosen the the four (4) M6 captive captive screws that attach attach the in input put tray assem assembly bly to the input base plate and lower console top plate. 7. Remove the input input tray assembl assembly y from the the machine. machine. 8. Use sufficien sufficientt personnel personnel to remove the input input tray assembly assembly from the machine (see Caution). 9. Do the maintenance maintenance on the input input tray assembly assembly,, if necessary necessary.. 3-18 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual . Indexer Assembly Disconnect the applicable cables from the Indexer Intermediate Board (see below) Input Tray Assembly In/Out Cable for Input Tray Cable to Connector J14 In/Out Cable for Output Tray Cable to Connector J15 contains: - Tray Motor Cable - Tray Full Sensor Cable - Magazine Present Sensor contains: - Tray Motor Cable - Tray Full Sensor Cable - Magazine Present Sensor Indexer Intermediate Board (top view) Fi g ure 3-1 3-11 1 Input Tra Trayy As s em embl blyy D. Insta Installll the Input Input Z Tower Tower Assembly Assembly CAUTION: When lifting the Z Tower Tower Assembly and Input Tray Assembly during its removal or installation, do not grasp the assembly at the ends of the base plate. Doing this may cause the base plate to bow. Grasp and lift the assembly at points near the center of the base plate. 1. Using sufficien sufficientt personnel, personnel, lift the Input Input Z T Tower ower Assem Assembly bly and place it onto the left side of the lower console top t op plate, besides the XY Table Assembly. 2. Make sure the two two (2) benching benching surfaces on on the right sid side e of Z Tower Tower base machining plate position against the two (2) benching pins on the base plate. plate. 3. Slide the Z Tower Tower Assembly Assembly to the rear. Make Make sure the rear of YY-axis axis motor mounting surface locates against the benching pin on the base plate. 4. Install Install four (4) M6 x 20 mm SHCSs with with washers to sec secure ure the Z Tower Tower Assembly to the base plate. 98888-0000-JB3-01 Magazine Handlers 3-19 IConn High Performance Wire Bonder 5. Slide the Z Tower Tower forward forward in Y-axis Y-axis direction direction towards towards the user to access access the screws at the rear and backwards to access the screws at the front. In a crisscross pattern, torque each of the four (4) SHCSs to 70 in. lb. (7.91Nm). (7.91 Nm). 6. At the rear of the Input Z Tower Tower Assembly Assembly,, mount the E-chain E-chain bracket (with (with flexible cable track - E-chain) onto the rear re ar of the Z Towe Towerr Machining Plate. Tighten the two (2) M4 x 10 mm SHCS. 7. Connect Connect connector connector P2 of Input Magazine Magazine cable (P/N 08 08888-105 888-1054-000-0 4-000-06) 6) to connector J1 on the Input Magazine Handler Intermediate Board. 8. Connect Connect connector connector P3 of Input Magazine Magazine cable (P/N 08 08888-105 888-1054-000-0 4-000-06) 6) to Y-axis motor cable connector (P/N 08888-1070-000-xx). 9. Secure the Y-axis Y-axis motor’s motor’s ground wire wire cable of Input Magazine Magazine cable cable (P/N 08888-1054-000-xx) to the Y-axis motor with the existing M4 SHCS. Tighten the screw. 10.Connect the Input MHS sensor bus cables P/N 08888-1082-000-07 to connector J2 and P/N 08888-1082-000-08 to connector J3 on the Input Magazine Handler Intermediate Board. 11 11.. Install the input tower cover, tower flap cover and Y motor cover. E. Insta Installll the the input input tra tray y assembly assembly 1. Put the input input tray assembly assembly on the the front edge edge of the input input base plate. plate. 2. screws Attach the th e input tray assembly assembly to the input input base plat plate e with the captive captive removed before. 3. Make sure the ‘C’ ‘C’ plates on the input input wall and the input input fixed wal walll interlo interlock ck each other. 4. Connect Connect the input/output input/output tray cable cable connecor connecor to the connector connector J14 of the 3-11). ). Refer to your notes. indexer intermediate board (see Figure 3-11 5. Attach the the electrical electrical cables with with cable ties ties and cable cla clamps mps to the inpu inputt tray assembly and indexer assembly. Refer to your notes. F. Install Install the PCB cover to the indexer indexer base and and tighten th the e two captive screws. screws. G. Push the the green machine machine ON ON switch. switch. H. Sele Select ct OK to start initialization. 3-20 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual 3. 3.7. 7.2 2 Ou Outp tput ut Ma Maga gazi zine ne H Han andl dler er The user should read and understand the Warnings and Cautions listed below before removing or installing the output magazine handler. See Figure 3-10 for connector locations. WARNING: THE Z TOWER ASSEMBLY WEIGHS APPROXIMATELY APPROXIMATELY 33 POUNDS (15 KILOGRAMS) ANDONE TRAY ASSEMBLY WEIGHS 15.6 POUNDS (7.08 KILOGRAMS). ONLY PERSON SHOULD BE PRESENT TO LIFT THE SUBASSEMBLIES OFF FROM THE MACHINE ONE AT A TIME (STEP B AND C) AND INSTALL IT ON THE MACHINE (STEP D AND E). WARNING: THE BONDER’S X AND Y MOTORS CONTAIN HIGH MAGNETIC FIELDS WHICH MAY AFFECT MAGNETICALLY MAGNETICALLY SENSITIVE DEVICES DEV ICES (PACEMAKERS, IMPLANTS, WATCHES, WATCHES, ELECTRICAL COMPONENTS, ETC.). KEEP ALL MAGNETICALLY SENSITIVE DEVICES CLEAR OF XY MOTORS. CAUTION: Comply with the ESD requirements procedure for all electrostatic discharge precautions and restrictions used during the removal and installation of the input magazine handler. Purpose • Rem Remove ove/in /insta stall ll output output magaz magazine ine ha handl ndler er for maint maintena enance. nce. Tools/ Materials/ Parts • Stra traig ight ht hex hex dri drive verr se sett (met (metri ric) c) • 5m 5mm m he hex x ti tip, p, 3/ 3/8” 8” dr driv ive e • 3/ 3/8” 8” dr driv ive, e, 6” ex exte tens nsio ion n • Ball Ball h hex ex d dri rive verr set set (met (metri ric) c) • 3/8” drive drive male male to to 1/4’ 1/4’ driv drive e femal female e ad adapt aptor or • 5mm lo long ng ba ball ll he hex x ttip ip,, 3/8” 3/8” dr driv ive e • 1/ 1/4” 4” dr driv ive e rrat atch chet et wr wren ench ch • Torq orque ue w wren rench, ch, 9 90 0 in. in. lb. lb. (10.2 (10.2 Nm), Nm), 3/8” 3/8” drive drive • Shim Shim,, 0. 0.00 001” 1” (0 (0.0 .025 25 mm) mm) • Screwdriver Procedure A. Turn off machine power. Remove magazines (if any) from the output magazine handler. Remove output tower cover, tower flap cover and Y-axis motor covers. B. Remove Z Tower Tower Assembl Assembly y. CAUTION: When lifting the Z T Tower ower Assembly and Output T Tray ray Assembly during its removal or installation, do not grasp the assembly at the ends of the base plate. Doing this may cause ca use the base plate to bow. Grasp and lift the assembly at points near the center of the base plate. 1. At the rear of the Z Tower Tower Assembly Assembly,, disconn disconnect ect connec connector tor P2 of Output Magazine cable (P/N 08888-1054-000-07) from connector J1 on the Output Magazine Handler Intermediate Board. See Figure 3-10 for connector location. 2. Disconnect Disconnect the co connector nnector P3 of Output Output Magazine Magazine cable (P/N 08888-105 08888-10544000-07) from Y-axis motor cable connector (P/N 08888-1070-000-xx). 3. Loosen the M4 socket socket head cap screw screw (SHCS) that that secures the the Y Y-axis -axis motor’s ground wire cable of Output Magazine cable (P/N 08888-1054000-07) to the Y-axis motor. Disconnect the ground wire. 98888-0000-JB3-01 Magazine Handlers 3-21 IConn High Performance Wire Bonder 4. Disconnect Disconnect the Outp Output ut MHS sensor bus bus cables (P/N 08888-108 08888-1082-000-1 2-000-12 2 and 08888-1082-000-18) from connectors J2 and J3 on the Output Magazine Handler Intermediate Board respectively. See Figure 3-10 for connectors location on the board. 5. Locate two two (2) M4 x 10 mm SHCS SHCS that sec secure ure the E-ch E-chain ain brac bracket ket (with (with flexible cable track - E-chain) to the rear of the Z Tower Machining Plate. Loosen the two (2) screws and lift up the E-chain bracket. See Figure 3-10 6. Remove four four (4) M6 x 20 mm SHCSs and washers washers that that secure the Z Tower Tower Assembly to the output base plate. The screws are located at the front and rear of the Z Tower Tower base machining plate. Move the Z T Tower ower forward in Yaxis direction towards the user to access the screws at the rear and backwards to access the screws at the front. 7. Using sufficient sufficient personnel personnel,, lift the Z Tower Tower Assem Assembly bly off from the machin machine e (see Caution). 8. Perform Z Tower Tower Assembly Assembly maintenanc maintenance, e, if required. required. C. Remove the Output Output Tray Tray Assembly: Assembly: CAUTION: Injury Hazard. The Output Tray Tray Assembly weight approximately 23 kg (50 lbs). To prevent injury, injury, use approved equipment or two persons to lift and move the assembly. assem bly. 1. Make sure sure that the electrica electricall cables to to the output output tray ass assembly embly ar are e correctly identified. If not, make a note of the connection. 2. Remove all all the cable cable ties and open open the cable cable clamps clamps if nece necessary ssary to release the cables. Make a note of the cable routing and cable clamps positions. 3. Loosen the the two captive captive screws screws that attach attach the P PCB CB cover to tthe he indexe indexerr base. 4. Remove the the PCB cover to to access the the index indexer er intermediate intermediate board. board. 5. Disconnect Disconnect the inpu input/outp t/output ut tray cable connecor connecor fr from om the connector connector J15 of 3-11). ). the indexer intermediate board (see Figure 3-11 6. Loosen the the four (4) M6 captive captive screws screws that attach attach the out output put tray ass assembly embly to the output base plate and lower console top plate. 7. Remove the output output tray assembly assembly from tthe he machi machine. ne. 8. Use sufficient sufficient personnel personnel to remove remove the output output tray assem assembly bly from the machine (see Caution). 9. Do the maintenance maintenance on the output output tray assembly assembly,, if necessary necessary. D. Insta Installll the Output Z Tower Tower Assembly Assembly CAUTION: When lifting the Z Tower Tower Assembly and Output Tray Assembly during its removal or installation, do not grasp the assembly at the ends of the base plate. Doing this may cause the base plate to bow. Grasp and lift the assembly at points near the center of the base plate. 1. Using sufficien sufficientt personnel, personnel, lift the Output Z Tower Tower Assemb Assembly ly and put it on the output base plate, adjacent to the right side of the XY Table Assembly. 2. Make sure that that the two (2) benching benching surfaces surfaces on the left side side of Z T Tower ower base machining plate position is against the two (2) benching pins on the base plate. 3. Slide the Z Tower Tower Assembly Assembly to the rear. rear. Make sure the rear of Y-axis Y-axis moto motorr mount locates against the benching pin on the output base plate. 4. Install Install four (4) M6 x 20 mm SHCSs and and washers washers to secure the the Z T Tower ower Assembly to the output base plate. 3-22 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual 5. Slide the Z Tower Tower forward forward in Y-axis Y-axis dir direction ection to towards wards the user user to access the screws at the rear and backwards to access the screws at the front. In a crisscross pattern, torque each of the four (4) SHCSs to 70 in. lb. (7.91 Nm). 6. At the rear of the Output Output Z Tower Tower Asse Assembly mbly,, mount the E-ch E-chain ain bracke brackett (with flexible cable track - E-chain) onto the rear of the Z Tower Machining Plate. Tighten the two (2) M4 x 10 mm SHCS. 7. Connect Connect connect connector or P2 of Output Magazine Magazine cable cable (P/N 0888808888-1054-00 1054-000-07) 0-07) to connector J1 on the Output Magazine Handler Intermediate Board. 8. Connect Connect connect connector or P3 of Output Magazine Magazine cable cable (P/N 0888808888-1054-00 1054-000-07) 0-07) to Y-axis motor cable connector (P/N 08888-1070-000-xx). 9. Secure the Y-axis Y-axis motor’s motor’s ground wire wire cable of Output Output Magazine c cable able (P/N 08888-1054-000-07) to the Y-axis motor with the existing M4 SHCS. Tighten the screw. 10.Connect the Output MHS sensor bus cables P/N 08888-1082-000-12 to connector J2 and P/N 08888-1082-000-18 to connector J3 on the Output Magazine Handler Intermediate Board. 11.Install the output tower cover, tower flap cover and Y motor cover. E. Install Install the the output output tray tray assembly assembly:: 1. Put the output output tray assembly assembly on the the front edg edge e of the output output base plate. plate. 2. Attach the the output tray tray assembly assembly to the out output put base p plate late with the captive captive screws removed before. 3. Make sure the the ‘C’ plates plates on the output output wall wall and the output output fixed fixed wall int intererlock each other. 4. Connect Connect the input/output input/output tray tray cable connecor connecor tto o the connector connector J15 of the the 3-11). ). Refer to your notes. indexer intermediate board (see Figure 3-11 5. Attach Attach the electrical electrical cables cables with cable ties ties and cable cl clamps amps to the inp input ut tray assembly and indexer assembly. Refer to your notes. F. Install Install the PCB cover to the indexer indexer base and tighten tighten the two cap captive tive screws. screws. G. Push the green green machine machine ON ON switch. switch. H. Sele Select ct OK to start initialization. Magazine Handlers 98888-0000-JB3-01 3-23 IConn High Performance Wire Bonder 3. 3.8 8 Pre reve vent ntiive Maint ainten enan ance ce A preventive maintenance schedule for the magazine handlers is outlined in Table 3-1.. 3-1 WARNING: REMOVE POWER FROM THE MACHINE BEFORE CHECKING THE SECURITY AND INTEGRITY OF THE MAGAZINE HANDLER’S ELECTRICAL CONNECTIONS. IF WORKING IN THE AREA OF THE WORKHOLDER, MAKE SURE ALL HEATING SURFACES HAVE COOLED BEFORE PROCEEDING. WARNING: REMOVE POWER FROM THE MACHINE BEFORE CHECKING THE TIGHTNESS OF THE MAGAZINE HANDLER’S ATTACHING HARDWARE. IF WORKING IN THE AREA OF THE WORKHOLDER, MAKE SURE ALL HEATING SURFACES HAVE COOLED BEFORE PROCEEDING. Table 3-1 Magazine Handler Preventive Preventive Maintenance Schedule Schedule Action Period Tools Procedure Clean magazine handlers 40 hours Vacuum Hose Remove any dirt or contaminates from exposed and moving parts of the input and output magazine handler. Check hardware tightness 1000 hours Hand Tools Make sure all attaching hardware (screws, washers, nuts, etc.) is securely installed. Inspect electrical connections 1000 hours Replace magazine stop buttons 2000 hours Check for security and integrity of all electrical connections on input magazine handler, and output magazine handler. Refer to Section 4 for connector locations. Hand Tools Replace all six (6) magazine stop buttons. One (1) stop button is located on the upper jaw magazine gripper assembly; two (2) stop buttons are located on the lower jaw magazine gripper assembly. See paragraph 3.9.6.2 for procedure. 3-24 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual Action Lubricate Y-slide bearings on Magazine Handler Assembly Period 3 months to 6 months Tools 1. Lubricant (10 ml, in syringe), P/N: 27790-5020-000 2. Lint-Free Cloth 3. Hand gloves 4. Cotton buds 5. Hex Wrench Set Procedure 1. Push the [Motor Stop] button. 2. Remove the Magazine Handler assembly cover. 3. Move the Z Tower assembly to the front or rear manually when neccessary. 4. Clean the v-grooves of the Y-slide bearings on the Z Tower Tower assembly using the lint-free cloth. 5. Apply about 0.1 ml to 0.2 ml of the lubricant to the left and right sides of the v-grooves of the Y-slide bearings. 6. Move the Z Tower assembly along the Y-slide bearings manually for 10 times. 7. Do steps 5 to 6 again for four times. 8. Remove the unwanted lubricant from thecloth. Y-slide bearings with the lint-free Lubricate Z-slide bearing on Magazine Handler Assembly 3 months to 6 months 1. Lubricant (10 ml, 1. Push the [Motor Stop] button. in syringe), P/N: 2. Remove the Magazine Handler 27790-5020-000 assembly cover. 2. Lint-Free Cloth 3. Move the magazine gripper 3. Hand gloves assembly up or down manually 4. Cotton buds when neccessary n eccessary.. 5. Hex Wrench Set 4. Clean the v-grooves of the Z-slide bearing on the th e Z Tower assembly using the lint-free cloth. 5. Apply about 0.1 ml to 0.2 ml of the lubricant to the left and right sides of the v-grooves of the Z-slide bearings. 6. Move the magazine gripper assembly along the Z-slide bearings manually for 10 times. 7. Do steps 5 to 6 again for four times. 8. Remove the unwanted lubricant from the Y-slide bearings with the lint-free cloth. Magazine Handlers 98888-0000-JB3-01 3-25 IConn High Performance Wire Bonder 3. 3.9 9 Par artt Re Repl plac ace eme ment nt P Pro roce cedu dure res s 3. 3.9. 9.1 1 Re Repl plac ace e Se Sens nsor or As Asse semb mblie lies s Purpose • Replace Replace the optical optical switch switch (sensor (sensor)) assemblies assemblies in a magazi magazine ne ha handler ndler assem3-13). ). bly (See Figure 3-12 and Figure 3-13 Tools/ Materials/ Parts • Hand tools • 29–Inc 29–Inch h Optical Optical Switch Switch Assembl Assembly y, P/N 0341 03411-1 1-1031 031-001 -001-17 -17 • 29–Inc 29–Inch h Optical Optical Switch Switch Assembl Assembly y, P/N 0341 03411-1 1-1031 031-001 -001-18 -18 • 15–Inc 15–Inch h Optical Optical Switch Switch Assembl Assembly y, P/N 0341 03411-1 1-1031 031-001 -001-19 -19 • 29–Inc 29–Inch h Optical Optical Switch Switch Assembl Assembly y, P/N 0341 03411-1 1-1031 031-001 -001-20 -20 • 17–Inc 17–Inch h Optical Optical Switch Switch Assembl Assembly y, P/N 0341 03411-1 1-1031 031-001 -001-23 -23 • 41–Inc 41–Inch h Optical Optical Switch Switch Assembl Assembly y, P/N 0341 03411-1 1-1031 031-001 -001-27 -27 Procedure A. Press [MOTOR STOP]. Turn off machine power. B. Discon Disconnect nect the sensor that that is to be replaced. replaced. 1. Locate the sensor sensor.. See input magazine magazine handler handler example example in Figure 3-12 and Figure 3-13 for sensor locations. See Section 4, paragraph 4.3.2.7 for wiring diagrams illustrating cable and sensor connections. NOTE: Sensor locations are shown in Figure 3-12 and Figure 3-13. 3-13. load and unload tray sensors are shown in Figure 3-2. 3-2. See Section 4 for wiring diagrams illustrating cable and sensor connections. 2. Trace Trace the sensor cable cable to its mating mating connector connector on the magazi magazine ne handler intermediate board and indexer intermediate board (for tray assembly sensors) (see Note above). Disconnect the sensor cable. Note the label on the mating connector. C. Loosen cab cable le clamps (if (if any) that secure the sensor sensor cable. Note Note how the cable is routed through the clamps. Remove the sensor cable from the cable clamps. D. Remove the scre screw w that secures the sensor sensor to its mount. Note the orientation orientation of the colored wires within the cable. Remove the sensor assembly from the machine. E. Read the sens sensor or part number number from the label on the the sensor cabl cable. e. Obtain a replacement sensor assembly that has the same part number. F. Install Install tthe he replacem replacement ent sensor. sensor. 1. Mount the sensor sensor at its its mounting mounting location. location. Use one (1) (1) screw to secure secure the sensor. Make sure the sensor wires are oriented in the same way as the original sensor. 2. Route the sensor sensor cable to its its connection connection point on the input input or output maga maga-zine handler intermediate board or the appropriate interconnect board. Refer to Figure 3-12, 3-12, Figure 3-13 and the sensor location and cable routing illustrations in Section 4. Connect the sensor to the mating connector on the appropriate board. 3. Route the sensor sensor cable through through flexible flexible cabl cable e track(s track(s)) and cable cla clamps mps (if necessary). Secure the cable clamps. 3-26 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual G. Turn on on machine machine power. power. Select OK in the Standby Mode dialog box to start machine initialization. Verify that initialization is completed successfully. Z Axis Motor Z-Axis Motor Cable: Connects to J4 on Input Magazine Handler Intermediate Board Input Magazine Handler Intermediate Board See Section 4 for Connector Locations Y Axis Home Sensor Cable Y-Axis Motor Cable: Connects to J9 on DMHS Backplane Y Axis Motor Z-Axis Brake Cable: Connects to J19 on Input Magazine Z Axis Brake (not shown - Located underneath the Intermediate Board Z Tower Assembly Flexible Cable (E-chain): Housing MHS Sensor Bus Cables and Backplane Magazine Cable Fi g ure 3-12 3-12 C abl ble e Routing & S ensors (Input Ma Magg azine Handl Handler er S hown - Deta Detail A) Magazine Handlers 98888-0000-JB3-01 3-27 IConn High Performance Wire Bonder Flexible Cable (E-chain) Containing: - Z Axis Home Sensor Cable - Magazine Gripper Assembly Motor Cable - Tray Sensor Cable - Magazine Gripper Home Sensor Cable - Top Paw Home Sensor Cable - Bottom Paw Home Sensor Cable Z Axis Home Sensor Cable Connects to J9 on Input Magazine Handler Intermediate Board Z Axis Home Sensor Top Paw Home Sensor (not shown - mounted under the Upper Jaw Plate near the Top Paw Home Sensor Cable Connects to J11 on Input Magazine Handler Intermediate Board Top Paw Assembly Magazine Gripper Assembly Motor (not shown - mounted under Lower Jaw Plate) Magazine Gripper Home Sensor Bottom Paw Home Sensor (not shown - mounted under the Lower Jaw Plate near the Bottom Paw Assembly Magazine Gripper Assembly Motor Cable Connects to J5 on Input Magazine Handler Intermediate Board Bottom Paw Home Sensor Cable Connects to J17 on Input Magazine Handler Intermediate Board Tray Sensor Fi g ure 3-13 3-13 C abl ble e Routing & S ensors (Input Ma Magg azine Handl Handler er S hown - Deta Detail B ) 3-28 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual 3. 3.9. 9.2 2 Re Repl plac ace e Ca Cabl ble e As Asse semb mbli lies es The following topics list the procedures required to remove and replace motor cables (refer to Figure 3-12 and Figure 3-13 ) from the magazine handler intermediate boards (input/output). The magazine handler is fitted with flexible cable tracks (E-chain) that house some of the cables. The flexible cable tracks can be disassembled for easy cable removal. Refer to Section 4 for connector locations. 3. 3.9. 9.2. 2.1 1 Maga Magazi zine ne Grip Grippe perr Ass Assem embl bly y Mot Motor or Ca Cabl ble e Purpose • Replac Replace e the magazine magazine gr gripper ipper assembly assembly mo motor tor ca cable. ble. The cable cable is is routed routed fr from om the magazine handler intermediate board through the flexible cable track to the motor. Tools/ Materials/ Parts • Hand tools • Tie wraps • Maga Magazin zine e Grip Gripper per Assemb Assembly ly Motor Motor Cabl Cable, e, P/N 08888-1 08888-1081 081-00 -000-0 0-00 0 Procedure A. Press [MOTOR STOP]. Turn machine power off. Remove all covers required to access the input or output ou tput magazine handler. B. Locate the flexible flexible cable track track that houses the magazine magazine gripper assembly assembly motor cable. C. Cut tie wraps alo along ng the route of the magazine gripper gripper assembly assembly motor cable. Unfasten the cable clamps at the entry and exit points of the flexible cable track. D. Remove and ret retain ain the magazine magazine gripper assembly assembly motor cable from from cable clamps on the Z Tower Tower Assembly. Save hardware for fo r reuse. E. Disconnect Disconnect the maga magazine zine gripper gripper assembly assembly motor cable con connector nector J5 from from the magazine handler intermediate board (see Figure 3-12 and Section 4 for connector locations). F. Remove one (1) (1) SHCS that secures secures the magazine magazine grippe gripperr assembly motor motor cable’s ground wire to the Lower Jaw Block. G. Disconnect Disconnect the magazine grip gripper per assembl assembly y motor cable from its connect connector or on the motor. H. Starting Starting at one end of the flexible cab cable le track, unsna unsnap p the top portion of each chain link section until enough sections are removed to extract the cable. I. Remove the magazine magazine gripper assembly assembly moto motorr cabl cable e from the the cab cable le track. track. Note how the cable is routed through the cable track. J. Insert the replacemen replacementt magazine magazine gripper assembly assembly motor motor cable in the flex flexible ible cable track making sure that the polarity of the cable is correct (motor connector to motor). Route and dress the cable as it was before removal. Snap in place the top portion of each chain link section of the cable track that was removed in step H.. H.. K. Install Install one (1) SHCS securing securing the magazine gripper gripper assembl assembly y motor cable’ cable’s s ground wire to the Lower Jaw Block. Tighten the screw. L. Connect Connect the magazine magazine gripper assembly assembly motor motor cable to its con connector nector on the motor. M. Secure the magazine gripper assembly motor cable into cable clamps clamps on the Z Tower Assembly. N. Connec Connectt the magazine gripper gripper assembly assembly motor cable to connec connector tor J5 on the magazine handler intermediate board. Magazine Handlers 98888-0000-JB3-01 3-29 IConn High Performance Wire Bonder O. Place the magazine magazine gripper assembly assembly motor cable and other cables into cable clamps at the entry and exit points of the flexible cable track. Close the cable clamps. Install tie wraps where needed. P. Replac Replace e all covers removed in step step A. Q. Turn on on machine machine power. power. Select OK in the Standby Mode dialog box to start machine initialization. Verify MHS operation during initialization and that initialization completes successfully successfully.. 3.9.2 .2..2 Y Axis Motor Cable Purpose • Replace Replace the Y axis motor cable that connect connects s from from the magazine magazine han handler dler interinterface board to the Y axis motor. Tools/ Materials/ Parts • Hand tools • Y Axis Axis Motor Motor Cable, Cable, P/N 0888808888-107 1070-0 0-000-x 00-xx x Procedure A. Press [MOTOR STOP]. Turn machine power off. Remove all covers required to access the input or output magazine handler. B. Remove th the e Y axis motor cable cable from cable cable clamps. clamps. C. Discon Disconnect nect the Y axis motor conn connector from backp backplane lane magazine magazine cable P/N 08888-1054-000-XX (seecable Section 4ector for connector location). D. Remove one (1 (1)) SHCS that secures secures the cable’s cable’s ground wire wire to the Y axis motor. E. Discon Disconnect nect the Y axis moto motorr cable from its its connect connector or on the Y axis motor motor.. Remove and discard the cable. F. Connect Connect the motor-end motor-end of the replacement replacement cable cable to the Y axis motor. motor. G. Use one (1) SHCS to secure the cable’s ground wire wire to the Y axis motor. H. Conne Connect ct the other end of the cable to backplane mag magazine azine cabl cable. e. Dress and route the cable through the cable clamps. I. Replac Replace e al alll cover covers s remov removed ed iin n step step A. J. Turn Turn on machi machine ne po power wer.. Select Select OK in the Standby Mode dialog box to start machine initialization. Verify MHS operation during initialization and that initialization completes successfully successfully.. 3.9.2 .2..3 Z Axis Motor Cable Purpose • Replace Replace the Z axis motor cable that is is routed routed from the ma magazine gazine handle handlerr interintermediate board to the Z axis motor. Tools/ Materials/ Parts • Hand tools • Tie wraps • Z Axis Axis Motor Motor Cabl Cable, e, P/N 08888-1 08888-1093 093-000 -000-XX -XX Procedure (refer to Figure 3-12 and Figure 3-13) A. Press [MOTOR STOP]. Turn machine power off. Remove all covers required to access the input or output magazine handler. B. Cut and remove tie wra wraps ps (if any) and unfasten unfasten any cable clamps clamps securing securing the Z axis motor cable to the rear of Z Tower Plate. Note how cable is routed and dressed. C. Discon Disconnect nect the Z axis motor cable from it its s mating connector connector J4 on the magazine handler intermediate board (see Figure 3-12 and Section 4 for connector location). 3-30 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual D. Remov Remove e one (1) SHCS that secures secures the Z axis motor motor cable’ cable’s s ground wire to the rear of Z Tower Plate. E. Disconnect Disconnect the Z axis mo motor tor cable from from its connector connector on the Z axis moto motor. r. Remove and discard cable. F. Connect the the motor-end of the the replacement replacement cable to the Z axi axis s motor motor.. G. Use one (1) SHCS SHCS to secure secure the Z axis motor motor cabl cable’s e’s ground ground wire to the the rear of Z Tower Plate. H. Connec Connectt the other end of the cable to its mating mating connect connector or J4 on the magazine handler intermediate board. Route and dress the cable as it was before removal. Fasten cable with cable clamp and tie wraps where needed. A... I. Replac Replace e al alll covers covers remo removed ved in s step tep A. J. Tu Turn rn on machi machine ne power power.. Select Select OK in the Standby Mode dialog box to start machine initialization. Verify MHS operation during initialization and that initialization completes successfully. successfully. 3.9.3 3.9 .3 Rep Replac lace e Mag Magazi azine ne Ha Handl ndler er C Circ ircuit uit B Boar oard d Ass Assemb embly ly Refer to the magazine handler board replacement procedure in Section 4 of this manual. 3.9. 3.9.4 4 Re Repl plac ace eL Loa oad dT Tra ray yT Tim imin ing gB Bel eltt 3. 3.9. 9.4. 4.1 1 Repl Replac ace e Driv Driven en Tim imin ing g Belt Belt Purpose • Replac Replace e the driven driven timing belt in in the load load tray tray assembly assembly of the mag magazine azine handler assembly. assembly. Tools/ Materials/ Parts • Hand tools • Torque Gauge • Belt Belt Ten ensi sion on Tes este terr • Dri Driven ven Ti Timin ming gB Belt elts, s, P/N 21060-6 21060-6140 140-00 -000 0 Procedure (Figure 3-14) A. Press [MOTOR STOP]. Turn machine power off. Remove magazine(s) from the load tray if any are present. B. Loosen the the two captive screws screws that attach attach the PCB cov cover er to the indexe indexerr base. C. Remove the PC PCB B cover to access access the indexer intermedi intermediate ate board. D. Remove lo load ad tray from the tray tray assembly assembly (input and out output). put). 1. Make sure that that the electrical electrical cables cables to the tray assembly assembly are corre correctly ctly identified. If not, make a note of the connection. 2. Disconnect Disconnect the in/ou in/outt tray extension extension cable from from the intermediate intermediate indexer indexer board. 3. Disconnect Disconnect the tra tray y full sensor sensor cable conne connector ctor from the sensor sensor on the bottom of the unload tray. 4. Loosen the the four (4) M5 screws screws from from the load tray tray assembly assembly.. 5. Remove Remove the load load tray tray assembly assembly from from the machine. machine. E. Loosen the the two (2) M4 screws from from the front of the load load tray assemb assembly ly.. F. Remove the tray tray cover cover and loading loading plate. G. Disconnect the electrical connections from the load tray motor motor.. Make a note of the connection. Magazine Handlers 98888-0000-JB3-01 3-31 IConn High Performance Wire Bonder H. Remove the driven driven timing timing belt(s): belt(s): 1. Loosen the the applicable applicable M3 screw(s) screw(s) on the stop block block (if installed). installed). 2. Loosen the the applicable applicable M4 nut(s) and M4 screw(s) screw(s) on the pu pulley lley holder holder.. 3. Loosen the the applicable applicable M5 screw(s) screw(s) that attach attach the drive drive pull pulley ey to the pulley pulley holder. 4. Loosen ap plicable le two (2) M4 count counter er sunk screw th that at attach the the pulley holder tothe theapplicab tray. 5. Carefully Carefully remove remove the applicable applicable driven driven timing belt(s) belt(s) from the drive drive and common pulleys. I. Instal Installl the the drive driven n ti timin ming g be belt( lt(s): s): 1. Put the timing timing belt(s) in position position on the applicabl applicable e drive and common common pulleys. 2. Tighten Tighten the app applicabl licable e two (2) M4 screws screws that that loosen before. before. 3. Tighten Tighten the applicable applicable M3 screw(s) screw(s) on the the stop block (if install installed). ed). 4. Tighten Tighten the applicable applicable M5 screw(s) screw(s) loosen before before to attach the pulley. pulley. 5. Tighten Tighten the a applica pplicable ble M4 nu nut(s) t(s) and and screw(s). screw(s). 6. Adjust the the tension tension of the timing belt. belt. Ref Refer er to paragrap paragraph h 3.6.1. 3.6.1. J. Connect Connect the electr electrical ical connection connections s to the load tray motor. motor. Use Use your notes notes.. K. Put the tray cover and lloading oading pla plate te to the front of the load load tray tray.. L. Attach the the tray cover cover and loading loading plate plate to the loa load d tray with the the two (2) M4 screws removed before. M. Install Install the load tray to the the tray assembly: assembly: 1. Put the load load tray in position position on the the tray assembly assembly.. 2. Make sure sure that the applicabl applicable e side of the load load tray to touches uches th the e bottom sursurface of the inner side plate. The inner side plate is attached to the input/outinput /output wall plate. 3. Attach the the load tray tray to the tray assembl assembly y with the four four (4) M5 scr screws ews removed before. 4. Connect Connect the electrical electrical cables cables to the module. module. Use the label labels s or your notes. 5. Connect Connect the tray full full sensor cable cable connector connector to the sen sensor sor on the bott bottom om of the unload tray. 6. Connect Connect the in/out tray extensio extension n cable to the intermediate intermediate in indexer dexer board. board. 3. 3.9. 9.4. 4.2 2 Repl Replac ace e Dr Driv ive e Tim imin ing g Belt Belt Purpose • Replace Replace the drive timing belt in in the load tray tray assembly assembly of the magazi magazine ne handler assembly. Tools/ Materials/ Parts • Hand tools • Torque Ga Gauge • Driv Drive e Ti Timi ming ng Belt Belt,, P/N 210 21059 59-6 -6003 003-0 -000 00 Procedure (Figure 3-14) A. Press [MOTOR STOP]. Turn machine power off. Remove magazine(s) from the load tray if any are present. B. Loosen the tw two o captive screws screws that attach attach the PCB cover to the in indexer dexer base. base. C. Remove the PC PCB B cover to access the the indexer intermedia intermediate te board. 3-32 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual D. Remove lo load ad tray from the tray tray assembly assembly (input and out output). put). 1. Make sure that that the electrical electrical cables cables to the tray assembly assembly are corre correctly ctly identified. If not, make a note of the connection. 2. Disconnect Disconnect the in/ou in/outt tray extension extension cable from from the intermediate intermediate indexer indexer board. 3. Disconnect Disconnect the tra tray y full sensor sensor cable conne connector ctor from the sensor sensor on the bottom of the unload tray. 4. Loosen the the four (4) M5 screws screws from from the load tray tray assembly assembly.. 5. Remove Remove the load load tray tray assembly assembly from from the machine. machine. E. Loosen the the two (2) M4 screws from from the front of the load load tray assemb assembly ly.. F. Remove the tray tray cover cover and loading loading plate. G. Disconnect the electrical connections from the load tray motor motor.. Make a note of the connection. H. Remov Remove e the drive timing belt: 1. Loosen the locknut locknut on the the tensioner tensioner block. 2. Turn the the M4 screw to release release the the tensi tension on on the dri drive ve timing timing belt. 3. Remove Remove the two (2) M4 counter counter sunk sunk screws screws from the ro rod d suppor supportt block. 4. Remove the the four (4) M4 counter counter sunk sunk screws screws at the two sides sides of the lo load ad tray assembly, at the front. 5. Remove the the pulley pulley rod with with all the comm common on pull pulleys. eys. NOTE: Remove the driven timing belts from the common pulleys when you remove the pulley rod. 6. Carefully Carefully remove remove the drive timing timing belt from the drive drive and common common pulleys pulleys.. I. In Inst stall all the the dr driv ive e timin timing g belt: belt: 1. Put the drive timing timing belt in position position on the motor motor pulley, pulley, together together with the common pulley and pulley rod. 2. Put the driven timing timing belts belts in position on the the drive and common common pulley pulleys. s. 3. Put the pulley pulley rod with with the pulleys pulleys to the bottom bottom front of of the tray tray.. 4. Attach Attach the rod support support block to the bottom bottom of the tray wit with h the counte counterr sunk screws removed before. 5. Attach the the pulley pulley rod with the the pulleys pulleys with the four four (4) M4 scr screws ews removed removed before, at the two sides of the load tray assembly. 6. Install Install the driven driven timing timing belt(s). belt(s). Refer Refer to paragrap paragraph h 3.9.4.1, 3.9.4.1, step I. 7. Apply a torque torque of between between 0.11 0.11 Nm (1 lb.in.) lb.in.) and 0.14 0.14 Nm (1.24 lb.in.) lb.in.) to the M4 screw on the tensioner block to put tension on the drive timing belt. 8. Ti Tight ghten en the locknu locknut. t. J. Connect Connect the electrical electrical connections connections to the load load tray motor motor.. Use your notes. notes. K. Put the tray cover cover and loading loading plate to the front front of the load tray tray.. L. Attach the the tray cover cover and loading loading plate plate to the load tray tray with the two two (2) M4 screws removed before. M... M. Install the load tray to the tray assembly. assembly. Refer to p paragraph aragraph 3.9.4.1, 3.9.4.1, step M. Magazine Handlers 98888-0000-JB3-01 3-33 IConn High Performance Wire Bonder Motor Pulley Drive Timing Belt Motor Bracket with Clamp Plate Load Tray Motor Electrical Cable Positions 4x M3 Screws Pulley Holder M3 Grub Screws Drive Pulley M5 Screw Rod Support Block 4x Driven Timing Belts 5x Common Pulleys M4 Screw and Nut 4x M4 Counter Sunk Screws Tension Block Tray Cover Stop Block Loading Plate M3 Screws M4 Counter Sunk Screws M4 Screw and Nut 2x M4 Screws 3-14 Loa Load d Tray Tray A s s em embl blyy (E xplo xplode ded d View - B ot otto tom m of of Tray) Tray) Fi g ure 3-14 3-34 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual 3. 3.9. 9.5 5 Re Repl plac ace e Lo Load ad T Tra ray y Mo Moto torr Purpose • Replac Replace e the motor motor that that operates operates the belts in the load tray tray on the input input and output tray assemblies. Tools/ Materials/ Parts • • Hand tools Torque Gauge • Loa Load d Tray Tray Mo Moto torr, P/N 1356 135655-60 6070 70-01 -018 8 Procedure (see Figure 3-14) A. Press [MOTOR STOP]. Turn machine power off. Remove magazine(s) from the load tray if any are present. B. Loosen the the two captive screws screws that attach attach the PCB cov cover er to the indexe indexerr base. C. Remove the PC PCB B cover to access access the indexer intermedi intermediate ate board. D. Remov Remove e the load tray from the the tray assembly assembly (input and ou output) tput) (see parapara3.9.4,, step D. D.). ). graph 3.9.4 E. Loosen the the two (2) M4 screws from from the front of the load load tray assemb assembly ly.. F. Remove the tray tray cover cover and loading loading plate. G. Disconnect the electrical connections from the load tray motor motor.. Make a note of the connection and the electrical cable positions on the motor. H. Remove the load tray motor: 1. Loosen the locknut locknut on the the tensioner tensioner block. 2. Turn Turn the M4 scre screw w to release release the tension tension on the drive drive timing timing belt. 3. Remove Remove the two (2) M4 counter counter sunk sunk screws from from the tra tray y that atta attach ch the motor bracket. 4. Remove the the motor together together with with the motor motor bracket bracket and the clamp clamp plate plate.. 5. Remove Remove the two (2) M3 grub grub screws screws from the motor motor pull pulley ey.. 6. Remove the motor motor pulley pulley from from the m motor otor.. 7. Remove the four (4) M3 screws screws fro from m the motor motor brac bracket. ket. 8. Remove Remove the the load load tr tray ay motor motor.. I. In Inst stall all th the e load load tra tray y moto motor: r: 1. Put the load load tray motor motor in position position on the mo motor tor bracket. bracket. Make sure sure that the positions of the electrical cable on the motor is the same as before (see Figure 3-14). 2. Attach Attach the motor bracket bracket to the the motor wi with th the four (4) (4) M3 screws screws removed before. 3. Attach Attach the motor pulley pulley to the the motor wi with th the two (2) (2) M3 grub screws screws removed before. 4. Loosely attach attach the motor motor bracket, bracket, together together with the clamp pl plate ate and the motor, to the bottom of the tray with the two (2) M4 counter sunk screws removed before. 5. Put the drive timing timing belt in position position on the motor motor pulley, pulley, together together with the common pulley and pulley rod. 6. Connect Connect the electr electrical ical connections connections to th the e load tray moto motor. r. Use Use your notes. 7. Apply a torque torque of between between 0.11 0.11 Nm (1 lb.in.) lb.in.) and 0.14 0.14 Nm (1.24 lb.in.) lb.in.) to the M4 screw on the tensioner block to put tension on the drive timing belt. 8. Tighten Tighten the locknut locknut on tthe he tensioner tensioner block. 9. Tighten Tighten the the two (2) (2) M4 counter counter sunk screws screws.. J. Put the tray cover cover and loading loading plate plate to the front front of the loa load d tray. tray. Magazine Handlers 98888-0000-JB3-01 3-35 IConn High Performance Wire Bonder K. Attach the tra tray y cover and loading loading plate to the the load tray with the the two (2) M4 screws removed before. 3.9.4.1,, step M. L. Install Install the load tray to the the tray assembly assembly.. Refer to para paragraph graph 3.9.4.1 3. 3.9. 9.6 6 Re Repl plac ace e Ma Maga gazi zine ne G Gri ripp pper er P Par arts ts 3.9.6. 3.9 .6.1 1 Repla Replace ce Magaz Magazine ine Gripp Gripper er Paw Paw/Pa /Paw w Re Retur turn n Spri prings ngs Purpose • Replace Replace magazine magazine gripper paw and/or paw return return springs on the upper or lower magazine gripper assembly (see Figure 3-15 and Figure 3-16 3-16). ). The procedure is the same for magazine grippers on both magazine handlers. Tools/ Materials/ Parts • Hand tools • Paw, Paw, Top Top,, P/N 034 03401 01-05 -0512 12-0 -000 00-xx -xx • Paw, Paw, Bot Bottom tom,, P/N 034 03401 01-0 -054 5433-00 000-x 0-xx x • Paw Return Return Spri Spring, ng, Right, Right, P/N P/N 03101 03101-01 -0122-0 22-03939-xx xx • Paw Retur Return nS Spri pring, ng, Left, Left, P/N P/N 03101 03101-01 -0122-0 22-04040-xx xx Procedure (See Figure 3-15 and Figure 3-16) 3-16) A. Press [MOTOR STOP]. Turn machine power off. B. Remove the bottom bottom paw assembly assembly 1. Remove one (1) (1) M4 x 20mm SHCS SHCS on the the Magazine Magazine Stop Stop Button Button Assembly bly.. Remove the assembly. Retain the hardware for reuse. r euse. 2. Locate the the pivot shaft shaft set screw screw in the the paw bracket bracket of the bottom bottom paw assembly.. It may be necessary assembly necessar y to move the lower jaw magazine gripper assembly to the center in the Y axis direction to gain access to the set screw. 3. Loosen the the pivot shaft shaft set screw. screw. Do not remove the set set screw screw.. 4. While holding holding the bottom paw paw assembly assembly in place, place, use a sma smallll tool to pu push sh the pivot shaft out of the lower jaw magazine gripper assembly. Retain Retain the pivot shaft for reuse. 5. Slowly remove remove the b bottom ottom paw paw assembly assembly away from from the lower lower jaw magamagazine gripper assembly. While removing the bottom paw assembly, take note that two (2) compressed springs may fall out from the assembly. Retain the springs for reuse. 6. Place the the bottom bottom paw assembly assembly on a clean clean work surface. surface. C. Remove Remove the the bottom bottom paw paw 1. Locate the the pivot shaft shaft set screw screw at the undersid underside e of the bottom paw paw assem assem-bly. 2. Loosen the the pivot shaft shaft set screw. screw. Do not remove the set set screw screw.. 3. While holding holding the bottom paw paw in place, place, use a smal smalll tool to pus push h the pivot pivot shaft out of the bottom paw assembly. assembly. 4. Slowly remove remove the bottom bottom paw away from from the assembly assembly,, making sure th that at the two (2) paw return springs do not escape. 5. Retain Retain the pivot sha shaft ft for reuse. reuse. Discard Discard the bottom pa paw w and return springs. springs. 3-36 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual D. Insta Installll the replacement replacement bottom bottom paw and return return springs springs on the bottom paw assembly. assembly. 1. Position Position the two (2) replacement replacement paw paw return springs springs in the bottom bottom paw as shown in Figure 3-15 3-15.. Make sure the spring arms are positioned in the corners of the paw pocket as shown in the figure. Make sure the spring coils are aligned with the holes in the paw. 2. Place the bottom bottom paw on the bottom bottom paw assembly assembly.. Press the paw agai against nst the paw bracket so that the springs compress and the holes in the paw are aligned with the mounting hole on the paw bracket. Bottom Paw Assembly Pivot Shaft Set Screw Bottom Paw Pivot Shaft Bottom Paw Assembly Magazine Stop Button Assembly Lower Jaw Bracket Magazine Stop Buttons (2 places) Flat Cutout Compressed Spring (2 places) Paw Bracket Bottom Paw Bottom Paw Assembly Pivot Shaft Bottom Paw Pivot Shaft Set Screw Paw Return Spring (2 places) Magazine Gripper Assembly Motor 3-15 B ot otto tom m Paw/ Paw/S S pring R ep epla lacem cement ent (Lower J aw Gripper G ripper As s em embl bly) y) Fi g ure 3-15 3. Insert the pivot pivot shaft into into one side of the bottom bottom paw, paw, through the paw paw bracket mounting hole, and into the other side of the bottom paw. Make sure the flat cutout in the pivot shaft is facing down toward the set screw at the underside of the paw bracket. 4. Tighten Tighten the set set screw screw to secure secure the pi pivot vot shaft. shaft. Magazine Handlers 98888-0000-JB3-01 3-37 IConn High Performance Wire Bonder E. Insta Installll the bottom paw assembly assembly 1. Place the the bottom paw paw assembly assembly onto the lower lower jaw magazin magazine e gripper assembly.. Position two (2) compressed springs retained from step B.5. assembly between the guided slots in the paw bracket and lower jaw bracket. 2. Press the bottom bottom paw assembly assembly against against the lower ja jaw w magazine magazine gripper assembly so that the springs compress and the holes in the paw bracket are aligned with the mounting hole on the lower jaw bracket. 3. Insert the the pivot shaft shaft into one side side of the lower lower jaw bracket, bracket, through through the bottom paw assembly mounting hole, and into the other side of the lower jaw bracket. Make sure the flat cutout in the pivot shaft is facing up toward the set screw in the top of paw bracket. 4. Tighten Tighten the set screw to se secure cure the piv pivot ot shaft. Ma Make ke sure that the bot bottom tom paw assembly sensor flag (part of the paw bracket) can pass between the bottom paw assembly sensor elements without interference. 5. Use one (1) (1) M4 x 20mm SHCS SHCS to secure the the Magazi Magazine ne Stop Stop Button Assembly to the lower jaw magazine gripper assembly assembly.. For Input Magazine Handler, insert the SHCS to the far right mounting hole of the button holder, and far left mounting hole for f or Output Magazine Handler. F. Remo Remove ve the the top top paw paw 1. Locate the the pivot shaft shaft set screw screw in the the upper jaw bracket bracket of of the upper ja jaw w magazine gripper assembly. It may be necessary to move the upper jaw magazine gripper assembly to the center in the Y axis for access to the set screw. 2. Loosen the the pivot shaft shaft set screw. screw. Do not remove the set set screw screw.. 3. While holding holding the top top paw in place, place, use a small small tool tto o push the pivot pivot shaf shaftt out of the upper jaw magazine gripper assembly. Retain the pivot shaft for reuse. 4. Slowly move move the top paw paw away from from the upper upper jaw magazine magazine gripper gripper assembly,, making sure that the two (2) paw return springs do assembly d o not escape. 5. Retain Retain the pivot sha shaft ft for reuse. Discard Discard the top top paw and paw ret return urn springs. G. Install the replacement top paw and return springs on the upper jaw magazine magazine gripper assembly a ssembly.. 1. Position Positi two 3-16. (2) (2) replacement replac ement pa w spring return arms springs springs the the top paw as corshownoninthe 3-16 Figure . Make sure paw the areinpositioned in the ners of the paw pocket as shown in the figure. Make sure the spring coils are aligned with the holes in the top paw. 2. Place the top top paw on the upper upper jaw bracket. bracket. Press the the top paw aga against inst the jaw bracket so that the springs compress and the holes in the top paw are aligned with the mounting hole on the jaw bracket. 3-38 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual Leadscrew Nut Paw Return Spring (2 places) Top Paw Pivot Shaft Set Screw Upper Jaw Bracket Flat Cutout Top Paw Pivot Shaft Top Paw Magazine Stop Button Fi g ure 3-16 3-16 To Top p Paw/S Paw/S pring R ep epla lacem cement ent (Uppe (Upperr J aw Mag Mag azine Gr ippe ipperr A s s em embl blyy S hown hown)) 3. Insert the pivot pivot shaft into into one side of the top paw paw,, through the jaw bracket bracket mounting hole, and into the th e other side of the top paw. Make sure the flat cutout in the pivot shaft is facing up toward the set screw in the upper jaw bracket. 4. Tighten Tighten the set screw screw to secure the pivot pivot shaft. shaft. Make sure that th the e top paw sensor flag (part of the top paw) can pass between the top paw sensor elements without interference. H. Tur Turn n on machine power and initi initialize alize the machine. machine. During During operation, operation, make sure that the magazine gripper assembly successfully grasps and locates the magazine against the wear points and benching buttons. Magazine Handlers 98888-0000-JB3-01 3-39 IConn High Performance Wire Bonder 3. 3.9. 9.6. 6.2 2 Repl Replac ace e Mag Magaz azin ine eS Sto top p Bu Button ttons s Purpose • Repl Replac ace e maga magazi zine ne sto stop p butto buttons ns (se (see e Figure 3-15 and Figure 3-16 3-16). ). One (1) button is located on the upper jaw magazine gripper assembly; two (2) buttons are located on the lower jaw magazine gripper assembly. The procedure is the same for magazine gripper assembly on both magazine handlers. buttons should be replaced as a set. The buttons NOTE: The magazine stop buttons should be replaced according to the preventive maintenance schedule outlined in Table 2-2. 2-2. If a single button is worn, it may be time to replace all six buttons (three in each magazine handler). Frequency • The stop stop buttons buttons on both both magazine magazine handler assemblies assemblies should be rep replaced laced after every 2000 hours of machine operation. Tools/ Materials/ Parts • Hand tools • Magazi Magazine, ne, Stop Button, Button, P/N 0340103401-002 0020-04 0-042-x 2-xx x Procedure (refer to Figure 3-15 and Figure 3-16) A. Press [MOTOR STOP]. Turn machine power off. B. Replac Replace e stop buttons on lower jaw magazine magazine gripp gripper er assembly. assembly. 1. Locate the the magazine magazine stop button button assembly assembly on the llower ower jaw m magazin agazine e gripper assembly. assembly. 2. Locate the stop stop buttons on the magazine magazine st stop op button ass assembly embly.. Remove one (1) SHCS from each button. Remove the buttons and save hardware for reuse. 3. Use one (1) SHCS SHCS to secure each each replacement replacement button button to the button button hold holder. er. Do not over-tighten the screws. C. Replac Replace e stop button on upper jaw magazine magazine gripper assembly assembly.. 1. Locate the stop stop button on the upper upper jaw magazi magazine ne gripper assembl assembly y. 2. Remove one one (1) SHCS from from the stop button. button. Re Remove move the button button and sa save ve hardware for reuse. 3. Before removing removing the button, button, take note note of its orientatio orientation n and positio position n in the counter bore. 4. Use one (1) (1) SHCS to secure secure the replaceme replacement nt button to tthe he upper jaw jaw bracket of the upper jaw magazine gripper assembly. Do not over-tighten the screw. 3-40 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual 3. 3.9. 9.7 7 Re Repl plac ace eB Bra rake ke As Asse semb mbly ly To replace the Brake Assembly, the entire Z Tower Assembly must be removed from the machine. Purpose • Replac Replace e the brake brake assembl assembly y that reside resides s at the the under underside side of the in input/out put/output put Z Tower Assembly (see Figure 3-17 3-17). ). The brake assembly prevents Z-axis movement when the Z-axis stepper motor power is off. Tools/ Materials/ Parts • Hand tools • Tie wraps • Verni ernier er Ca Cali lipe pers rs • Brak Brake e assemb assembly ly,, P/N 08888-1 08888-1085 085-000 -000-XX -XX Procedure A. Press [MOTOR STOP]. Turn machine power off. B. Remove input/outp input/output ut tower cover, cover, tower flap cover and Y motor cover. cover. Tower ower C. Remove Z T Tower ower Assembly Assembly.. Refer to paragraph 3.7.1 step B. for Input Z T Assembly and paragraph 3.7.2 step B. for Output Z Tower Assembly. D. Place the Z T Tower ower Assembly on a flat work surface. Position the assembly such that the tower lay horizontally on the work surface in order to the to gain access to the brake assembly at the underside of the Z Tower Assembly Assembly.. E. Rem Remove ove brake brake assembl assembly y. 1. Disconnect Disconnect the brak brake e cable connector connector J19 from the Input/Outp Input/Output ut Magazine Magazine Handler Intermediate Board (refer to Figure 3-12 and Section 4 for connector locations). Loosen the screws that secure the cable clamps and cut tie wraps as needed to release the brake assembly cable routed to the underside of the Z Tower Assembly. 2. Remove one one (1) SHCS that that secure secures s the brake g ground round cab cable le to the underunderside of the Z Tower Assembly. 3. Note the position position of the brake brake cable relating relating to how the brake brake assembly assembly is mounted at the underside of the Z Tower Assembly Assembly.. Remove three (3) SHCSs that secure the brake assembly to the underside of Z T Tower ower Assembly.. Remove the brake assembly. Assembly 4. Remove the the brake square square nut attach attach to the the end of Z-ax Z-axis is leadsc leadscrew rew by loosening two (2) set screws in the nut. See Figure 3-17. 3-17. F. Install Install replacemen replacementt brake assembly assembly.. 1. Remove Remove the brake square square nut from the replacement replacement brake brake assemb assembly ly.. 2. Slide the square square nut onto onto the end of the Z-axis Z-axis leadscrew leadscrew.. Orientate Orientate the nut such that the two (2) set screws in the nut are positioned on the two flat surfaces on the leadscrew. Set a gap of 16 mm (630 mil) between the nut surface and the base surface of the Z Tower Machining plate using the ver3-17.. Tighten the set screws. nier calipers. See Figure 3-17 3. Mount the replacemen replacementt brake assembly assembly onto base base of the Z T Tower ower mach machinining plate ensuring that the cable exits the brake assembly in the direction noted in step E.3. E.3... Align the brake assembly mounting holes with the tapped holes in the base of Z T Tower ower plate. 4. Install Install three (3) SHCSs to secure secure the replacement replacement brake brake assembly assembly and one (1) SHCS to secure the ground wire to the underside the Z Tower Assembly bly.. Tighten all four screws. 98888-0000-JB3-01 Magazine Handlers 3-41 IConn High Performance Wire Bonder 5. Connect Connect the brake cable cable to connector connector J19 J19 on the inp input/outp ut/output ut magazi magazine ne handler intermediate board. Route and secure the cable in the cable clamps and tie wraps as it was before being removed in step E.1. G. Install Z Tower Assembly.Refer Assembly.Refer to paragraph paragraph 3.7.1 step D. for Input Z Tower Assembly and paragraph 3.7.2 step D. for Output Z Tower Assembly. H. Turn o on n machine machine powe power. r. Select Select OK when the Standby Mode dialog box appears to start initialization. Verify that MHS initialization completes successfully. I. Use the Magazine Magazine Util Utilities ities menu menu to lload oad a maga magazine zine fu fullll of ca carriers rriers onto onto the magazine handler where the brake was replaced. Press [MOTOR STOP], then turn off machine power. Verify that the magazine gripper assembly does not drop, which indicates that the brake is operating correctly. J. Replace Replace input/output input/output tower tower cover, cover, tower flap flap and Y motor cover cover.. 3-42 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual Z axis Leadscrew Flat Cutout on Shaft (2 places) Square Nut Set Screws Z Tower Base 16 mm Bearing Z-Axis Leadscrew Brake Assembly Z Brake Assembly Square Nut Mounting Detail Brake Mounting SHCSs (3 places) Cable Clamps (2 places) Brake assembly square nut (hidden) (see mounting detail) Fi g ure 3-1 3-17 7 B rake A s s em embl blyy R ep epla lacem cement ent Magazine Handlers 98888-0000-JB3-01 3-43 IConn High Performance Wire Bonder 3. 3.9. 9.8 8 Re Repl plac ace eS Ste tepp pper er Mo Moto tors rs 3.9.8.1 Z Axis Motor Purpose • Replac Replace e the m motor otor that that drive drives s the Z T Towe owerr Z axis lead leadscr screw ew 3-18). ). (see Figure 3-18 Tools/ Materials/ Parts • Hand tools • Feeler Ga Gauge • Tor orque que wren wrench ch,, 12 iin. n. lb. lb.,, 28 in. in. lb. lb. • Torque orque Sc Screw rew Drive Driverr with with 3/32 3/32 in. Hex Hex Inser Insertt Bit • Torque orque Sc Screw rew Dri Driver ver with with 3mm 3mm Hex Hex Insert Insert Bit • Z motor motor assemb assembly ly,, P P/N /N 0888 08888-1 8-1093 093-00 -000-xx 0-xx Procedure A. Press [MOTOR STOP]. Turn machine power off. B. Remove the tow tower er cover, cover, tower flap cover and motor motor cover on the Input/Output Magazine Handler Assembly. C. Locate the Z-axis motor at the top of the Z Tower. Tower. Disconnect the Z-axis motor cable from connector J4 on the Magazine Handler Intermediate Board. Make note of the connector position on the Z motor. D. Turn the scre screw w in the Z-axis motor such that the screws screws on the rigid coupling are accessible through the opening o pening of Z Tower. Tower. This procedure may lift up or bring down the magazine gripper assembly. E. Loosen two (2 (2)) SHCSs in the rigid coupling coupling to release release the leadscrew leadscrew fro from m the coupling by using a torque screw driver with 3/32 in. hex insert bit. F. Remove four four (4) SHCSs that that secure the Z-axis Z-axis motor to the motor motor mounting surface, located at the top of Z Tower Tower.. Remove the motor with rigid coupling. G. Loosen two (2) SHCSs in the rigid coupling to release the coupling from the motor shaft by using a torque screw driver with 3/32 in. hex insert bit. Set aside the rigid coupling for reuse. H. Insert a 20 mils feeler gauge into the center slot slot in the rigid coupling. Install Install the rigid coupling with feeler gauge onto the shaft of replacement motor. Tighten the screw in the rigid coupling to a torque of o f 12 Ib. in., securing the coupling to the motor shaft. Remove the feeler gauge. NOTE: Before installing the rigid coupling onto the motor shaft, use a lint-free cloth to remove any grease or dirt on the motor shaft and rigid coupling hole. I. Place the the replacement replacement Z-axis Z-axis motor motor wi with th rigid coupling coupling agai against nst the motor motor mounting surface at the top of Z Tower. Tower. J. Position Position the Z-axis motor motor properly properly (check position position of conn connector ector on motor) motor) and align the motor mounting holes with the tapped holes in the motor mounting surface. Make sure the end of the Z axis leadscrew enters the hole in the rigid coupling. Install four (4) SHCSs to secure the motor to the motor mounting surface. Tighten the four (4) screws to a torque of 28 lb. in. K. Tigh Tighten ten the two (2) bottom screws in the rigid coupling coupling to secure the leadscrew leadscrew to the coupling, to a torque of 12 in.lb. L. Connect Connect the Z-axis Z-axis motor cable cable to connector connector J4 on the the Magazi Magazine ne Handler Handler Intermediate Board. M. Install the tower cover, tower flap and motor cover onto the Input/Output Magazine Handler Assembly. Turn on machine power. 3-44 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual N. Sele Select ct OK from the Standby Mode dialog box to start machine initialization. Verify that MHS initialization is completed successfully. SHCS in Z axis Motor (hidden) SHCS (4 places) Z Axis Motor Rigid Coupling Z Tower Plate Motor Mounting Surface Z Axis Leadscrew Leadscrew Nut Fi g ure 3-18 R em emove/ ove/R R epl epla ace Z A xi s Motor Motor Magazine Handlers 98888-0000-JB3-01 3-45 IConn High Performance Wire Bonder 3.9.8.2 Y Axis Motor Purpose • Replace Replace the motor that that drives drives the the Z Tower Tower Assembly Assembly Y axi axis s lead leadscrew screw (see 3-19). ). Figure 3-19 Tools/ Materials/ Parts • • Hand tools Torque orque w wrenc rench, h, 12 in. lb. lb.,, 2 28 8 iin. n. lb. lb. • Feeler Ga Gauge • Torque orque Sc Screw rew Drive Driverr with with 3/32 3/32 in. Hex Hex Inser Insertt Bit • Torque orque Sc Screw rew Dri Driver ver with with 3mm 3mm Hex Hex Insert Insert Bit • Y motor motor ass assemb embly ly,, P/N P/N 0888 08888-1 8-1070070-000 000-xx -xx Procedure A. Press [MOTOR STOP]. Turn machine power off. Remove the tower, tower flap and motor covers on the Input/Output Magazine Handler Assembly. B. Discon Disconnect nect the Y Y-axis -axis motor motor cable connect connector or P1 from connecto connectorr P3 of backplane magazine cable (P/N 08888-1070-000-xx), which is routed from the DMHS backplane. C. Turn the screw in the Y-axis Y-axis motor to move the Z Tower Tower Assembly towards the operator, in order to access the rigid coupling screws. D. Loosen two (2) SHCSs in the rigid coupling to release the Y-axis Y-axis leadscrew from the coupling by using a torque screw driver with 3/32 in. hex insert bit. E. Take note of the connector position on the Y-axis motor. Remove four (4) SHCSs that secure the Y-axis motor to the motor mounting surface, located at the rear of Z Tower Base Plate. Remove the motor with rigid coupling. F. Loosen two two (2) SHCSs in the rigid rigid coupling coupling to release the coupling coupling from from the motor shaft by using a torque screw driver with 3/32 in. hex insert bit. Set aside the rigid coupling for reuse. G. Insert a 20 mils feeler gauge into the center slot in the rigid coupling. Install the rigid coupling with feeler gauge onto the shaft of replacement motor. Tighten the screw in the rigid coupling to a torque of o f 12 Ib. in., securing the coupling to the motor shaft. Remove the feeler gauge. NOTE: Before installing the rigid coupling onto the motor shaft, use a lint-free cloth to remove any grease or dirt on the motor shaft and rigid coupling hole. H. Place the replacement Y-axis Y-axis motor with rigid coupling against the motor mounting surface at the rear of Z Tower Base. I. Position Position the Y-axis Y-axis motor motor properly properly (check (check positi position on of conne connector ctor on motor) motor) and align the motor mounting holes with the tapped holes in the motor mounting surface. Make sure the end of the Y axis leadscrew enters the hole in the rigid coupling. Install four (4) SHCSs to secure the motor to the motor mounting surface. Tighten the four (4) screws to a torque of 28 in. lb. J. Tighten Tighten the two (2) screws screws in the rigid rigid coupling coupling to secure the lea leadscrew dscrew to the coupling, to a torque of 12 in. Ib. K. Connec Connectt the Y-axis Y-axis motor motor cable connecto connectorr P1 to connector connector P3 of backp backplane lane magazine cable (P/N 08888-1070-000-xx) L. Install Install the tower cover, cover, tower flap cover cover and motor cover onto the Input/Outpu Input/Outputt Magazine Handler Assembly. Turn on machine power. M. Se Sele lect ct OK from the Standby Mode dialog box to start machine initialization. Verify that MHS initialization is completed successfully. 3-46 Magazine Handlers Material Handling System Manual . Leadscrew Nut Y Axis Leadscrew Rigid Coupling SHCS in Y axis Motor (hidden) SHCS (4 places) Y Axis Motor Z Tower Base Fi g ure 3-19 3-19 R em emove/ ove/R R epl epla ace Y A xis Mot Motor or 98888-0000-JB3-01 Magazine Handlers 98888-0000-JB3-01 3-47 IConn High Performance Wire Bonder 3. 3.9. 9.8. 8.3 3 Maga Magazi zine ne Gri Gripp pper er Ass Assem embl bly y Moto Motorr Purpose • Replace Replace the motor that drives the magazin magazine e gri gripper pper leadscr leadscrew ew and and controls controls the gripping motion of the upper and lower jaws in Z-axis. (see Figure 3-15) 3-15) Tools/ Materials/ Parts • • Hand tools Tor orque que wren wrench ch,, 12 iin. n. lb. lb.,, 28 in. in. lb. lb. • Torque orque Sc Screw rew Drive Driverr with with 3/32 3/32 in. Hex Hex Inser Insertt Bit • Torque orque Sc Screw rew Dri Driver ver with with 3mm 3mm Hex Hex Insert Insert Bit • Magazi Magazine ne Gri Grippe pperr Assembl Assembly y moto motorr, P/N 1356513565-6049 6049-00 -003-x 3-xx x Procedure A. Press [MOTOR STOP]. Turn machine power off. Remove the tower cover, tower flap and motor cover on the Input/Output Magazine Handler Assembly Assembly.. B. Locate the magaz magazine ine gripper assembly assembly motor. motor. T Turn urn one (1) SHCS in the Z Axis motor to lift up the magazine gripper assembly to the center position of Z linear bearing assembly. Make sure the screws in the rigid coupling are accessible. C. Disconn Disconnect ect the magazine gripper gripper assembly assembly motor cable (P/N 08888-108108888-1081000-xx) from its connector on the magazine gripper motor. Place the cable in an out-of-the-way safe location. Take note of the connector position on the motor. D. Loosen two (2) SHCSs in the rigid cou coupling pling to release release the leadscrew from from the coupling by using a torque screw driver with 3/32 in. hex insert bit. E. Remove fou fourr (4) M4 x 12 mm SHCSs at the underside underside of the magazine magazine gripper assembly that secure the magazine gripper motor with rigid coupling to the lower jaw bracket. Pull the motor with rigid coupling downwards from the underside of the magazine gripper assembly. Remove the motor with rigid coupling. F. Loosen two two (2) SHCSs in the rigid rigid coupling coupling to release the coupling coupling from from the motor shaft by using a torque screw driver with 3/32 in. hex insert bit. Set aside the rigid coupling for reuse. G. Insert a 20 mils feeler gauge into the center slot in the rigid coupling. Install the rigid coupling with feeler gauge onto the shaft of replacement motor. Tighten the screw in the rigid coupling to a torque of o f 12 Ib. in., securing the coupling to the motor shaft. Remove the feeler gauge. NOTE: Before installing the rigid coupling onto the motor shaft, use a lint-free cloth to remove any grease or dirt on the motor shaft and rigid coupling hole. H. Place the repla replacement cement motor motor with rigid coupling coupling at the underside of the lower lower jaw bracket against the motor mounting surface. Make sure the end of the Y axis leadscrew enters the hole in the rigid coupling. I. Position Position the motor motor such such that its its cable connector connector is iin n the sa same me posi position tion as it was when removed in step C. Align the motor mounting holes with tapped holes in the motor mounting surface. J. Install Install four (4) SHCSs SHCSs to secure secure the motor motor to the motor motor mountin mounting g surface. surface. Tighten the screws to 28 in. lb. K. Tigh Tighten ten the two (2) screws screws in the rigid coupling coupling to secure secure the leads leadscrew crew to the coupling, to a torque of 12 in. Ib. L. Connect Connect the magazine magazine gripper assembly assembly motor motor cable to its co connecto nnectorr on the motor. M. Move the magazine gripper assembly down to the bottom of the Z linear bearing assembly. 3-48 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual N. Install the tower cover, tower flap cover and motor cover. cover. Turn on machine power. O. Sele Select ct OK from the Standby Mode dialog box to start machine initialization. Verify that MHS initialization is completed successfully. 98888-0000-JB3-01 Magazine Handlers 3-49 IConn High Performance Wire Bonder This pa pagg e is le left ft inte intentiona ntionall llyy bla blank nk 3-50 Magazine Handlers 98888-0000-JB3-01 Material Handling System Manual 4 4.1 Electronics About T Th his Se Section Here is what you will find in this section: • 4.2, Description,Wire Description, gives an overview of thedescription Electronicsoffunction S ction 4.2, Overall ofethe IConn High Performance Bonder and a brief each item in the calibration menu. • Each Each se sect ctio ion n from from Sect Sectio ion n 4.3 through 4.5 describes a calibration feature and the operation guidelines on carrying out the various calibration procedures. • Section 4.3, 4.3, Subsystem/Board Descriptions • Section 4.4, 4.4, MHS Sensor • Section 4.5, 4.5, Cable Assemblies Electronics 98888-0000-JB3-01 4-1 IConn High Performance Wire Bonder 4.2 Overa ralll Descripti tio on 4. 4.2. 2.1 1 Sy Syst stem em Or Orga gani niza zati tion on The electronic control system system for the Material Handling System (MHS) is controlled by the Distributed Material Handling System (DMHS) back plane board mounted at the rear of the card rack assembly a ssembly.. This backplane interconnects the circuit boards and provides electrical connections to external devices such as motors, sensors, solenoids and other interface circuit boards mounted on the MHS. Figure 4-1 provides a simplified diagram of the MHS electronics system. The DMHS backplane is communicated via the ethernet (host) from the PC-On-ABoard (PCOAB). The sensor logic on the Stepper Controller board monitors the status of all sensors on the workholder, input magazine handler, and output magazine handler, receiving sensor data from the interface boards via a synchronous serial interface. The sensor logic converts the sensor data into a form that is usable by other boards in the system and makes the sensor data available through the backplane. (Paragraphs 4.2.3 and 4.4 provide descriptions and show locations of MHS sensors.) An additional function of the stepper controller board is to generate gener ate motor control signal to three boards thatboards can control upethernet. to 16 motors. trol signals are stepper passed driver to stepper driver via the MotorMotor drive consignals from the stepper drivers are passed through backplane connectors to individual steppers motors via the interface boards. The controller monitors fault signals from the driver boards and home/limit sensor data from the sensor logic. (Refer to paragraph 4.2.2 for more information concerning stepper motor drive.) The Indexer Solenoid Driver board is to generate solenoid drive enable signals from DMHS data. These signals each activate one of the 24 individual solenoid driver circuits on the Solenoid Driver board, which operate workholder solenoids, MHS solenoid valves, magazine handler Z–axis brakes, and load tray motors. Temperatures of the two workholder heating zones (Preheat and Bond Site) are controlled by the I/O and Temperature Controller circuit board, which has eight (8) temperature control circuits. The controller heats a workholder zone by switching a solid–state relay that connects 56V to a resistive heater, and monitors temperature with a type K thermocouple mounted close to the heater. The Input/Output (I/ O) portion of the circuit board generates a board enable signal for the solenoid driver logic (enables or disables all drivers). Refer to IConn Maintenance Manual for more information concerning the I/O and Temperature Controller board. Most of the printed circuit boards are located in a card rack within the IConn machine lower console. MHS interface boards are mounted on the input magazine handler, output magazine handler, and indexer assembly. 4-2 Electronics 98888-0000-JB3-01 Material Handling System Manual Serial Interface, Motor Out . Solenoids 1 to 24 Motors 1 to 16 Indexer Input Mag Output Mag sensors c . a . Sensor Bus Direct Sensor Input 0 to 7 Host enal p k . Ethernet S H M D 96 Micro/TripleHalf Stepper Driver Board Serial Interface, Motor Out HEX Half Stepper Board 96 B Serial Interface, Motor Out HEX Half Stepper Board 96 SPI, Solenoid Out 96 96 HEX Serial Interface, SPI, Ethernet, Sensor Bus, Sensors With speed sensor Indexer/Solenoid Driver Board Stepper Fans Controller Board 1&2 Power 5V, 12V, 48V, Gnd Modell 3131 C ontrol S ys te tem m Org anizat nization ion Fi g ure 4-1 Mode Electronics 98888-0000-JB3-01 4-3 IConn High Performance Wire Bonder 4.2.2 Stepper D Drrive Figure 4-2 shows the signals generated by the stepper controller logic for control of a typical stepper motor and shows how the motor is connected to its driver circuit on the stepper driver board in the card rack via an interface board. Stepper Motor A1 B2 A2 B1 Motor Cable Cable P1 P2 P3 P4 MHS Interface Board Power Cable P1 P2 P3 P4 Backplane Board A1 A2 P1 B1 P2 B2 P3 P4 P4 STEP Stepper/Sensor Board 1/2 Step Driver MOTOR SERIAL BUS PCOAB ETHERNET Fi g ure 4-2 Typical S te tepper pper Mot Motor or Control C ontrol P ath 4-4 Electronics 98888-0000-JB3-01 Material Handling System Manual All motors are operated in an open–loop mode where there is no motor or equipment position feedback to the control system during motions. The controller determines the position of motor–driven equipment eq uipment by finding a sensor– marked home position (zero point) and keeping track of the motion commands issued to the motor. For specific information concerning motor connections at the interface boards and motor drive signal paths board the backplane, 4.3. and stepper/sensor logic,from referthe to interface the diagrams in to paragraph 4.3. driver circuit, 4.2.3 .2.3 Sen enso sorr Ha Hand ndli ling ng Figure 4-3 shows how the status of a typical MHS sensor can be read by the control system. Sensor state data is sent to the sensor logic on the Stepper/Sensor board by means of a synchronous serial data stream. At the interface board, the states of all sensors connected to the board are loaded onto multiple eight–bit long “frames” of data by a serial data transmitter, with the status of each sensor being assigned to one bit of a frame. As many or as few frames as needed are assigned to each board. If there are eight sensors or less connected to a board, then only one frame will be needed. A frame is sent onto the serial sensor data bus that also carries frames of sensor state data from the other two MHS Interface boards. The sequence in which the frames are transmitted is determined by the master serial transmitter on the Stepper/Sensor board, which sends commands and a synchronizing clock signal to the serial transmitters on the interface boards via the serial sensor data da ta bus. Each interface board is assigned unique time slots in which to transmit their frames of data. From the output magazine handler interface board (last device in the serial communications path), the serial data stream is sent via the backplane to the sensor logic, which strips out the sensor state data and makes them available to the stepper controller logic, CPU2 (servo CPU), and I/O board through the VME bus. Figure 4-6 shows the serial communications path. Electronics 98888-0000-JB3-01 4-5 IConn High Performance Wire Bonder Fiber Optic Sensor Amp Photo Sensor Output Serial Data Diode GND +5V GND Voltage Serial Serial Data Transmitter Serial Communications Path (Figure 4-4) Output +12V GND MHS Interface PC Board Power Cable Serial Data +12V +5V GND Backplane Board Serial Sensor Input/Serial Interface Control Sensor Data Bits (SENB1 - SEN B53) Stepper/Sensor Board CPU2 I/O & Temp. Controller Board Fi g ure 4-3 4-3 S ensor Data Data Input to Control Control S ys te tem m 4-6 Electronics 98888-0000-JB3-01 Material Handling System Manual 4.2. 4.2.4 4 DM DMHS HS Ba Back ckpl plan ane e As Asse semb mbly ly The DMHS Backplane circuit board assembly (P/N:08888-4000-000-xx) (see Figure 4-4) 4-4) is attached to the rear of the upper card rack assembly. It interconnects all MHS related circuit boards assemblies in the upper card rack, supplies operating power to the MHS related circuit boards, and provides connection points for external equipment. Signals transmitted through the backplane include: • Ste Stepper pper Control Controller ler Board Board c connecte onnected d to backpla backplane ne are communicated communicated via host host ethernet connection (from integrated magnetics transformer). • Diffe Differentiat rentiate e pair for the LVDS LVDS is assigne assigned d for the individual individual 4 channel channel of motor motor serial bus and indexer/solenoid communication. • Single RJ45 connec connector tor provides provides connection connection for th the e sensor sensor bus bus connecting connecting between the individual intermediate board and the stepper controller board. • Fan spe speed ed signal signal is routed to both both the s stepper tepper controller controller an and d the indexer indexer/sole/solenoid board to detect fan failure condition. • To distr distribute ibute all all signal, signal, power power and driver driver to the the indi individual vidual interm intermediate ediate b board. oard. • Interco Interconnect nnect for parallel parallel sensors sensors that is conn connected ected to stepper stepper co controlle ntrollerr board. board. • Provide Provide ttest est point point for for DMHS DMHS supp supply ly moni monitori toring. ng. The backplane board requires no preventive maintenance and should require no other maintenance action during the life of the machine. In the event of a malfunction traced to the backplane, the board should be replaced. No attempt should be made to repair the board. Fig ure 4-4 4-4 DMHS Backplane Board P/N 08888-4000-000-xxx,, Major C omponents Electronics 98888-0000-JB3-01 4-7 IConn High Performance Wire Bonder 4. 4.3 3 Su Subs bsys yste tem/ m/Bo Boar ard d Desc Descri ript ptio ions ns 4. 4.3. 3.1 1 Circ Circui uitt Bo Boar ard d Lo Loca cati tion ons s Circuit board assembly locations within the card rack assembly are shown in Figure 4-7 and the boards are identified in Table 4-1 4-1.. Any circuit board may be located by noting its slot number in the appropriate table, then finding the circuit board assembly with that slot number in Figure 4-7 4-7.. Locations of the MHS interface circuit boards and the solid–state relay circuit board are shown in Figure 4-8 For more information concerning the card rack circuit board assemblies, the card rack, and other control system assemblies, refer to IConn Maintenance Manual. NOTE: All circuit board assemblies are considered Field Replaceable Units (FRUs). Refer to paragraphs 4.3.3 through 4.3.5 for circuit board replacement procedures. Fiber Optic Sensor Amp Photo Sensor Output Serial Data Diode GND +5V GND Voltage Serial Serial Data Transmitter Serial Communications Path (Figure 4-4) Output +12V GND MHS Interface PC Board Power Cable Serial Data +12V +5V GND Backplane Board Serial Sensor Input/Serial Interface Control Sensor Data Bits (SENB1 - SEN B53) Stepper/Sensor Board CPU2 I/O & Temp. Controller Board Fi g ure 4-5 4-5 S ensor Data Data Input to Control Control S ys te tem m 4-8 Electronics 98888-0000-JB3-01 Material Handling System Manual Input MH Sensor States O u tp u t M H Sensor States A Serial Data Transmitter J2 J20A* J3 J20A* J3 J20B* J2 J20B* Serial Data Transmitter Workholder Sensor States Input Magazine Handler Input Magazine Magazine Intermediate Board Handler Interface 08888-4116-000-xx 08001--4116--000--xx Output Magazine Handler Interface 08001--4116--000--xx B J2 J1 Serial Data Transmitter C Indexer Intermediate Indexer Interface Board 08888-4202-000-xx 08002--4207--000--xx J16 J45 Sensor Cables 08088 --- 3027 --- 000 --- 00 A: 08888-1082-000-18 08088 --- 3027 --- 000 --- 03 B: 08888-1082-000-17 C: 08888-1082-000-12 08088 --- 3027 --- 000 --- 00 Backplane DMHS Backplane 08888-4000-000-xx 08002--4191--000--xx Fi g ure 4-6 4-6 S erial C om ommu municat nications ions P ath 98888-0000-JB3-01 Electronics 4-9 IConn High Performance Wire Bonder (Top Level) Table 4-1 DMHS Circuit Boards, 3U Circuit Board (Top Slot No. Part Number PCB Assembly Name Function/Reference B 08888-4000-000-xx DMHS Backplane Board Controls, drives, and monitors the indexer and solenoid operations 1 08888-4032-000-xx DMHS Indexer/ Solenoid Board Monitor and controls operations on solenoid driver circuits, solenoid valves, Puller Assembly Assembly,, Index Assembly, DMHS fan monitor and Stepper Controller Board Communication. See paragraph 4.3.2.1.. 4.3.2.1 2 08888-4166-000-xx DMHS Hex-half Stepper Driver Board Each board drives six half stepper motors in the Input Z Tower Assembly,, Input Tray Assembly . Assembly Drives the Input Z, Input Gripper, Input Y, Y, Heat Block Motor. See paragraph 4.3.2.2. 4.3.2.2. 3 08888-4300-000-xx DMHS St Stepper Co Controller Board Controls all MHS Stepper motors. See paragraph 4.3.2.3 4.3.2.3.. 4 08888-4166-000-xx DMHS Hex-half Stepper Driver Board Drives the Output Z, Output Gripper, Output Y, Y, Input and Output Tray,, Motors. See paragraph Tray 4.3.2.2 4.3.2.2.. 5 08888-4214-000-xx DMHS Micro/Tri-Half Stepper Driver Board Drives the Indexer X Motor. See paragraph 4.3.2.4. 4.3.2.4. 4-10 Electronics 98888-0000-JB3-01 Material Handling System Manual Air Filter 2x Cooling Fans Upper Deck 3U Circuit Boards 1 3 5 2 4 Cable Routing Track A Lower Deck 6U Circuit Boards 2 1 4 3 6 5 8 7 2x Exhaust Fans 1 s d r a o B k c e D r e p p U s d r a o B k c e D r e w o L k s i D h s X 0 0 0 0 0 7 0 2 3 4 5 d i o x n x le o rd 0 S a 0 /r o -0 e B 2 x r 3 0 e 4 d e v i In r 8 D 8 8 8 S H 0 M D r e p x p x e t rd -0 S a 0 fl 0 a o 6 B H r 6 1 x e e v ir -4 8 H D 8 8 8 S H 0 M D r lle o x tr x n 0 o 0 C 0 r rd 0 e a 0 p o 3 p 4 te B 8 S 8 8 S 8 H 0 M D r e x p x p te rd 0 0 S 0 fl a o a B 6 6 H r 1 x e 4 e iv 8 H r 8 D 8 8 0 S H M D r e p x x p e t d 0 S ra 0 0 fl o a B 4 H r 1 2 4 ir- e v T ri 8 8 S D 8 8 H 0 M D x x 0 0 0 7 2 3 4 1 0 d r a o B r to a r e n e G ic n rd x a o -x B 0 0 re -0 u t 0 1 ra 0 e 4 p -8 2 m8 rd a o x B x r e 0 0 iv r 0 D 5 6 p 1 m4 a l 8 8 C 8 U P C in a M t lo S e r a p S x x 0 0 0 2 0 3 4 8 8 x rd -x a 0 o 0 B -0 U 1 P 6 C 2 4 o -1 v r 0 0 t lo S e r a p S t lo S re a p S a l F A 0 8 1 1 0 8 0 1 2 o s a tlr U 3 8 8 0 e 8 S 0 4 e 8 T 0 /IO 5 6 e 8 ir 0 W 7 8 Fig ure 44-7 7 C ard Rack Circuit B oa oard rd As s em embl blyy Locat Locations 98888-0000-JB3-01 Electronics 4-11 IConn High Performance Wire Bonder Input Magazine Intermediate Board Input Z Tower Assembly Indexer Intermediate Board (without PCB cover) Output Magazine Intermediate Board Output Z Tower Assembly J Boat Indexer Assembly Fi g ure 4-8 4-8 MHS Inte Interfa rface ce Location Locationss 4-12 Electronics 98888-0000-JB3-01 Material Handling System Manual Power Supply Air Filter Hinged Card Cage (Out position) DMHS Back Plane Board Main Back Plane Board General Servicing Area at Lower Console Console Com Components ponents Cooling Fans (2x) Lower Console Frame (Covers Removed) Upper Deck DMHS Circuit Boards Hinged Card Cage Cover PC-on-a-Board Assembly Flash Disk Lower Deck Circuit Boards Exhaust Fans (2x) Lower Console owerr S upp upply ly Locat Locations ions Fi g ure 4-9 P owe Electronics 98888-0000-JB3-01 4-13 IConn High Performance Wire Bonder 4. 4.3. 3.2 2 Circ Circui uitt Bo Boar ard d As Asse semb mbli lies es 4.3. 4.3.2. 2.1 1 DMHS DMHS Inde Indexe xer/ r/So Sole leno noid id Dr Driv iver er Bo Boar ard d Table 4-2 4- 2 provides a summary of the functions, controls/indicators, and test points p oints of the Indexer/Solenoid driver board. In addition, a listing of pertinent references is included in the table. Table 4-2 DMHS Indexer/Solenoid Indexer/ Solenoid Driver Board, P/N 08888-4032-000-xx Functions Controls/Indicators Test Points Reference • Co Cont ntain ains s six sixtee teen n (16) (16) s sol oleno enoid id driver circuits. Each can be operated individually by a signal from the DMHS Stepper Controller Board. As a group, the drivers are enabled or disabled by a signal from the I/O board. Ea Each ch d driv river er cir circu cuit it h has as ove overc rcur urren rentt detection circuit and back EMF protection. • Bo Boar ard d ge gene nera rate tes s a fau fault lt sig signal nal if any driver indicates an overcurrent condition. TP1: DGND TP1: TP2:: AGND TP2 TP3:: GRIP3_VREF TP3 TP4:: GRIP1_VREF TP4 TP5:: PULLER_VREF TP5 TP6:: ENDCODER_A TP6 TP7:: Index Gripper TP7 Control Hall Sensor Input Signal. TP8:Spare TP8 :Spare PWM current control driver 2 reference voltage. Figure 4-7 Figure 4-10 • The board consist of two seven-segment LEDs for error code displaying and board diagnostic. The function of the LED display should be changeable through host command. • Co Cont ntain ain si six x (6) (6) chan channe nels ls of of curr curren enttcontrollable drivers (48V, 0-2A) for • solenoid/DC motor actuator control. • Co Cont ntain ain si sixt xtee een n (1 (16) 6) c cha hann nnel els s of ON/OFF solenoid drivers (12V, (12V, 0700mA) with external OT protection. • Co Cont ntain ain ei eigh ghtt (8) (8) ch chann annel els s of ON/ ON/ OFF solenoid drivers (optional, 12V,, 0-400mA) 12V 0-400mA ) • Co Cont ntai ain n mult multip iple le jjam am d dete etect ct int intererface and handling circuit. • Co Cont ntain ain two two (2 (2)) chan channe nels ls of D DMH MHS S fan monitor • FAULT LED (RED): (RED ): Goes Goes on if overcu overcurren rrentt TP9 detecte detected d or if board board is TP9:Spare rent :Spare control PWM drivercur4 refdisabled. erence voltage. ENABLE LED (GRN): On when board enable signal is active. DS2 - LED: LED: Green indicates board has power up. Test Points TP10 To J4 DMHS Back Plane TP1 Fig ure 4-10 4-10 DMHS Indexer/Solenoid Driver Board, P/N 08888-403 08888-4032-000-x 2-000-xx x,, Major C omponents 4-14 Electronics 98888-0000-JB3-01 Material Handling System Manual 4. 4.3. 3.2. 2.2 2 DMHS DMHS Hex Hex Hal Halff Ste Stepp pper er Dri Drive verr Circ Circui uitt Boar Boards ds 4- 3 provides a summary of the functions, controls/indicators, and test points Table 4-3 of the DMHS Hex Half Stepper Stepper Driver Circuit Board. There are two (2) DMHS Hex Half Stepper Driver Circuit Boards present in the DMHS card rack r ack assembly. assembly. In addition, a listing of pertinent references is included in the table. Table 4-3 DMHS Hex Half-Stepper Drivers, P/N 08888-4166-00008888-4166-000-xx xx Functions • Dr Driv ives es six six h hal alff s ste tepp pper er • motors under control of the DMHS Stepper Controller Board by motor serial bus. • Mo Moto torr c cur urre rent nt and and sup sup-ply voltage monitored • for each driver. drive r. Stepper fault is returned to stepper controller and driver is disabled if overcurrent detected or supply voltage lost. • Each Ea chpeak driv driver errun is se set t ffor or 2 Amp current • Controls/Indicators Test Points D14 - LED: Red indicates communication error occurs with Stepper Controller Board. LED - OFF indicates communication enable. TP1: +48V DRV TP1: TP2:: PGND DRV TP2 TP3:: +5V DRV TP3 TP4:: DGND DRV TP4 TP5:: STEP CLOCK SIGNAL TP5 of: 1) Input Y-axis motor when connected to J2 of DMHS backplane. 2) Output Y-axis motor when connected to J5 of DMHS backplane. LED1 to LED5 and LED12 (six Half-stepper motors): Each LED represent a driver motor. Light turns red if over current or fault occur. Light turns green when signal is active. LED unlit if over-temperature condition occurs or driver is disabled. LED6 (Power Supply): Light turns red if fuse blow or fault occur. Light turns green indicates high voltage enable. LED unlit if power supply is disabled. TP6: STEP CLOCK SIGNAL TP6: of Heat Block motor when connected to J2 of DMHS backplane. TP7: STEP CLOCK SIGNAL TP7: of Clamp motor when connected to J2 of DMHS backplane. J1 pin 6: STEP CLOCK SIGNAL of: 1) Index Theta motor when connected to J2 of DMHS backplane. 2) Eject Theta motor when connected to J5 of DMHS backplane. Reference Figure 4-7 Figure 4-11 98888-0000-JB3-01 Electronics 4-15 IConn High Performance Wire Bonder To J5 DMHS Back Plane TP8 Test Points TP1 Fi g ure 4-1 4-11 DMHS Hex Half-Stepper Drivers, P/N 08888-4166-000-xx, Major C omponents 4-16 Electronics 98888-0000-JB3-01 Material Handling System Manual 4. 4.3. 3.2. 2.3 3 DMHS DMHS Stepp tepper er Co Cont ntro roll ller er Bo Boar ard d Table 4-4 4- 4 provides a summary of the functions, controls/indicators, and test points of the DMHS Stepper Controller board. In addition, a listing of pertinent references is included in the table. Table 4-4 DMHS Stepper Controller Controll er Board, P/N 08888-4300-000-xx Functions Controls/Indicators • Rece Receiv ives es sy sync nchr hron onou ous s serial sensor data from sensors interface boards. • • Dist Distri ribu bute tes s sens sensor or sta state te through ethernet bus. • • In Inte terf rfac ace e for for com commu muni nica ca-tions with index board digital signal processor (DSP). • Moni Monito tors rs MHS MHS sen senso sorr data data • and stepper fault signals • from stepper drivers. • Send Send st step eppe perr mot motor or motion commands to DMHS hex half stepper driver boards, DMHS Indexer/Solenoid driver board and DMHS micro-tri half stepper driver board by motor serial bus. Can control up to 16 stepper motors. • Se Send nds s sol solen enoi oid d con contr trol ol data from host to indexer/ solenoid board in JDC command. Controls 24 solenoids. • • • Test Points TP1: \REQA - PCI bus TP1: request A (low active) TP2:: \REQB - PCI bus TP2 request B (low active) D1 - LED (Yellow): Light TP3:: \GNTA - PCI bus TP3 blinking indicates signal present in network traffic; grant A (low active) light unlit indicates no net- TP4 TP4:: \GNTB - PCI bus work present. grant B (low active) D2 - LED (Green): Light TP5:: GND TP5 indicates FPGA is ready. TP6 TP6:: PGND TP7:: SFRAME TP7 D3 - LED (Green): Light TP8:: SLOCK indicates motor serial bus TP8 is active. TP9:: MBTEST0 TP9 TP10:: MBTEST1 TP10 D4 - LED (Red): Light TP11:: MBTEST2 TP11 indicates board error. TP12:: MBTEST3 TP12 W1 - Jumper: Ethernet MAC address (optional). When it is shorted, another MDM (Material handling Distributed Module board) is supported. RESET (S1) (S1):: Push button switch. Resets the stepper control CPU. W2 - Jumper: FPGA flash programming. During SPI flashing programming, this jumper is shorted. Reference Fig ure 4-12 4-12 DMHS Stepper Controller Board, P/N 08888-4300-000-xx , Major C omponents Electronics 98888-0000-JB3-01 4-17 IConn High Performance Wire Bonder 4.3. 4.3.2. 2.4 4 DMHS DMHS Mic Micro ro/T /Tri ri Hal Halff Ste Stepp pper er Dri Drive verr Boar Board d Table 4-5 4- 5 provides a summary of the functions, controls/indicators, and test points p oints of the Indexer Interface Circuit Board. In addition, a listing of pertinent references is included in the table. Table 4-5 DMHS Micro/Tri Half Stepper Board, P/N 08888-4214-000-xx Functions • Drives Drives th the e workhol workholder der indexer microstepper motor under control of the Stepper Controller Board. Controls/Indicators • • Motor current and supply supply voltage monitored for each driver. Stepper fault is returned to stepper control- • ler and driver is disabled of overcurrent detected, supply voltage lost or overtemperature. • Provide Provide steppe stepperr pulse signal to Index board for jam detection. • Control Control a microstepper microstepper motor and three (3) hex half stepper motor. • Test Points TP1: +48V TP1: TP2:: PGND DRV TP2 TP3:: +5V DRV TP3 TP4:: DGND DRV TP4 TP5:: PROG1(CommuTP5 nication error signal) TP6:: PROG2 (Signal TP6 LED1 (Indexer Microstepper from Indexer Micromotor): Light turns red if overstepper Motor) current or fault occur, motor TP7:: PROG3 (Signal TP7 stop. Light turns green when sigfrom Front Rail Motor) nal is active. LED unlit if over6: STEP temperature condition occurs or J1pin 6: CLOCK SIGNAL of driver is disabled. Rear Rail Motor. LED2 (48V Power Supply): Light turns red if fuse blow or fault D14 (Communication Indicator LED):: Red indicates communiLED) cation error occurs from DMHS Stepper Controller board (K&S P/N: 08888-4300-000-XX). Light unlit indicates communication is in operation. occur. Light turns green indicates high voltage enable. LED unlit if power supply is disabled • LED3 (Front Rail motor): Light turns red if over-current or fault occur, motor stop. Light turns green when signal is active. LED unlit if over-temperature condition occurs or driver is disabled. • LED4 (Rear Rail motor): Light turns red if over-current or fault occur, motor stop. Light turns green when signal is active. LED unlit if over-temperature condition occurs or driver is disabled. • LED5 (Programmable Focus motor): Light turns red if overcurrent or fault occur, motor stop. Light turns green when signal is active. LED unlit if overtemperature condition occurs or driver is disabled. Reference 4-18 Electronics 98888-0000-JB3-01 Material Handling System Manual Fi g ure 4-13 4-13 DMHS Micro/ Micro/Tri Tri Ha H alf S te teppe pperr D river B oa oard, rd, Major Major C om ompone ponent ntss Electronics 98888-0000-JB3-01 4-19 IConn High Performance Wire Bonder 4.3.2. 4.3 .2.5 5 Magazi Magazine ne Handl Handler er Inter Interme media diate te Board Board (088 (0888888-41 4116 16-00 -0000-xx) xx) The function of the Magazine Handler Intermediate board is listed in Table 4-6 . The circuit board layout and cable connections are shown in Figure 4-14 4-14.. Figure 4-16 Illustrates cable and sensor connections for the Gripper Interface Circuit Board. Table 4-6 Magazine Handler Intermediate Board, P/N 08888-4116-000-xx Functions Controls/Indicators Reference • Provides connections for magazine handler motors, sensors and Z axis brake. W1: Input Magazine Handler W2: Output Magazine Handler • Has Has c cir ircu cuit itry ry to lo load ad se sens nsor or state data onto the synchronous serial sensor data bus. NOTE: Remove jumper on W1 will set the board for use on the Input Magazine Handler. Figure 4-14, 4-14, NOTE: Remove jumper on W2 will set the board for use on the t he Output Magazine Handler. J13, Tray Sensor J14, Y Axis Home Sensor J19, Z Brake Solenoid J16, Spare J8, In Used Jumper W2: Output Magazine Handler J4, Z Axis Motor Jumper W1: Input Magazine Handler J9, Z Axis Home Sensor J15, Spare J7, In Used J12, Spare J18, Spare J10, Magazine Gripper Home Sensor J17, Bottom Paw Home Sensor J11, Top Paw Sensor J5, Axis Magazine MotorGripper J2, MHS Sensor Bus Cable J1, Backplane Magazine Cable J3, MHS Sensor Bus Cable Fi g ure 4-14 Ma Magg azine Handler Handler Intermediat Intermediate e B oa oard rd L ayout, Major Major C omp omponent onentss 4-20 Electronics 98888-0000-JB3-01 Material Handling System Manual 4.3.2. 4.3 .2.6 6 Indexe Indexerr Interm Intermedi ediate ate Board Board (08888 (08888-42 -422626-000 000-xx -xx)) Table 4-7 shows the connection points of the cable and sensor assemblies on the Indexer Intermediate Board. The connection points receive interface signals from the DMHS Backplane board through J2. The circuit board layout and cable connections are shown in Figure 4-15. 4-15. Table 4-7 Indexer Intermediate Board, P/N 08888-4226-000-xx 08888-4226-000- xx Functions • Prov Provid ides es c con onne nect ctio ions ns for for workholder motors, sensors and flex cable assembly. • Has Has c cir ircu cuit itry ry to lo load ad sens sensor or state data onto the synchronous serial sensor data bus. • Has Has c cir ircu cuit itry ry to pro proces cess s jam jam detector signal. • Two ch chan anne nels ls of hi high gh curre current nt solenoid for driving tray motor. J10, Preheat Motor Home Sensor Cable Test Points Jumper W1 - W3: Not connected. Use for new option. None Reference Figure 4-15 4-15,, J3, Puller Flex Assembly Cable Cable J19, J Boat Present Sensor Cable (input) J14, In/Out Tray Extension Cable • Controls/Indicators J9, X Sensor Cable J23, Gripper Flex Assembly Cable Cable J21, Indexer Motor Cable J25, Grip Air Press Assembly Cable Cable J6, Solenoid Cable J4 Preheat J1, Indexer J15, In/Out Tray Motor Cable DMHS Cable Extension Cable J2, MHS Sensor Bus Cable J20, J Boat Present Sensor Cable (output) Fi g ure 4-15 4-15 Indexer Intermedia Intermediate te B oa oard rd Connection P oints Electronics 98888-0000-JB3-01 4-21 IConn High Performance Wire Bonder 4. 4.3. 3.2. 2.7 7 Maga Magazi zine ne Hand Handle lerr Con Conne nect ctio ions ns Figure 4-16 shows the connection points for cable and sensor assemblies for the input and output magazine handlers. The Z Tower Tower Assembly and Tray Assemblies connections are controlled by the Magazine Handler Intermediate Board and Indexer Intermediate Board. The connection points receive interface signals from the DMHS Backplane board through MHS Sensor Bus cable. Fi g ure 4-16 4-16 Input or Output Interconnect B oa oards rds , Cable Cable and S ens ensor or Connections 4-22 Electronics 98888-0000-JB3-01 Material Handling System Manual 4.3.3 4.3 .3 Rep Replac lace eD DMHS MHS Car Card dR Rack ack Cir Circui cuitt B Boar oards ds Purpose • Repl Replace ace a ci circu rcuit it board board in in the DMHS DMHS card card rac rack k assemb assembly ly (see (see Figure 4-7 4-7). ). Tools/ Equipment • Scre Screw w driver drivers s (for (for slotte slotted d or Phill Phillip ips s head head screws screws)) • ESD P Prot rotec ecti tive ve Equi Equipme pment nt/M /Mate ateri rial als s CAUTION: OBEY ALL EST ESTABLISHED ABLISHED ESD PROCEDURES WHEN HANDLING OR STORING CIRCUIT BOARD ASSEMBLIES. CAUTION: MAKE SURE MACHINE POWER IS OFF BEFORE REMOVING ANY CIRCUIT BOARD FROM THE CARD RACK. WAIT AT LEAST FIVE (5) SECONDS AFTER SWITCHING OFF POWER AT THE CIRCUIT BREAKER BEFORE PULLING ANY CIRCUIT BOARD OUT OF THE RACK. THIS DELAY DELA Y ALLOWS ANY RES RESIDUAL IDUAL CHARGE IN THE POWER SUPPLY SUPPLY TO DISSIPATE. CAUTION: PC BOARDS MUST BE INSTALLED IN THE CORRECT SLOT IN THE RACK, THESLOT, LABELTHE ON BOARD THE CARD DOOR. IF A BOARD IN THE PER WRONG OR RACK OTHER MACHINE EQUIP- IS MENT MAY BE DAMAGED WHEN POWER IS APPLIED Procedure A. Press [MOTOR STOP]. Turn off machine power and wait for five [5] minutes to discharge all hazardous voltages. Open the front door of the lower console. B. Remove circuit circuit board board assembly assembly from from the DMHS c card ard rack. 1. Loosen the the captive captive screw on the the cardcage cardcage door and open open the door. door. Locate the DMHS card rack at the top level of the card cage assembly. 2. Using each each hand to hold hold on to the card card puller on tthe he top and bottom bottom edge of the card, eject the card by pulling out the card puller. 3. Immediately Immediately place place the circuit circuit board assembly assembly in an ESD–pr ESD–protectiv otective e enclosure. C. Insta Installll the replacement replacement circuit circuit board in the the card rack. 1. Slide the circuit circuit board board into its slot slot in the card rack un until til connec connector(s) tor(s) se seats ats in mating connector(s) on the DMHS backplane board. 2. Press firmly firmly on the top and and bottom bottom edges of the card, card, wit with h equal pre pressure ssure applied until the board connector(s) fully seats in the backplane connector(s). Do not press against connectors, switches, or indicators on the board edge (if any). 3. Close the the card cage door door and tighten tighten the captive captive screw screw.. D. Close th the e lower console console front front door. door. E. Turn Turn on machine power power.. Star Startt machine and verify verify that the machine operates operates normally. Electronics 98888-0000-JB3-01 4-23 IConn High Performance Wire Bonder 4.3.4 Repla Replacing cing the Input/ Input/Outpu Outputt M Magaz agazine ine Hand Handler ler Inter Intermedia mediate te Boar Board d Purpose • Replace Replace the input/output input/output magazine magazine han handler dler intermediate intermediate circuit circuit boa board rd as assemsembly mounted at the rear of the Input/output Z Tower Assembly. (see Figure 417). 17 ). Tools/ Equipment • Hex wrench set • ESD Prote Protect ctiv ive e Equip Equipme ment nt/M /Mat ateri erial als s • Magazi Magazine ne Ha Handle ndlerr Interm Intermedi ediate ate Boar Board d Assemb Assembly ly,, P/N 08888-4116-000-xx Procedure A. Press [MOTOR STOP]. Turn off machine power. CAUTION: OBEY ALL ESTABLISHED ESTABLISHED ESD PROCEDURES WHEN HANDLING OR STORING CIRCUIT BOARD ASSEMBLIES. B. Remove the mag magazine azine handler handler intermediate intermediate board from from the rear of the input or output Z Tower assembly. 1. Remove input/outp input/output ut tower cover cover,, tower flap cover cover and Y axis motor cover cover.. 2. Locate the magazine magazine handler handler intermediat intermediate e board at the rear of the Z Tower Tower Assembly (Z Tower Tower machining structure). 3. Disconnect Disconnect senso sensors, rs, motors, and and cables from the Z Tower Tower Asse Assembly mbly connected to the magazine handler intermediate board (mounted (mount ed at the rear of the Z Tower Assembly). (see Figure 4-16 for connecto connectorr location). location). a. MHS Sensor Sensor Bus cables, cables, conn connectors ectors J2 and J3 b. Z Brake Brake Motor Motor cable, cable, connec connector tor J1 J19 9 c. Z M Moto otorr cab cable le,, J4 J4 d. Z Home Home S Senso ensorr ca cable ble,, J9 e. G Mot Motor or cab cable le,, J J5 5 f. G Hom Home e Sens Sensor or ca cabl ble, e, J10 J10 g. Touch Home Sensor cable, J1 J11 1 h. Tray Tray S Sens ensor or cabl cable, e, J13 J13 i. Grip Grip Home Home Senso Sensorr c cab able le,, J J17 17 j. Y Home Sensor cable, J14 k. Y M Mot otor or cabl cable, e, J1 4. Remove four four (4) SHCSs SHCSs that secure secure the board board to the four four (4) hex st standof andoffs fs on the rear of the input/output inp ut/output Z Tower assembly. assembly. 5. Remove the the board from from the machine machine and store store it in an ESD–protecti ESD–protective ve enclosure. 4-24 Electronics 98888-0000-JB3-01 Material Handling System Manual . Z Tower Assembly Standoffs (4 places) Magazine Handler Intermediate Board SHCS (4 places) NOTE: a) Input/output Magazine Handler Intermediate Boards are mounted with the component side facing the rear of the machine. b) See Figure 416 for magazine handler intermediate board connector locations and reference designators. Reference designators are also printed on the solder side of the board. c) See Figure 4-16 for part numbers of cables, sensors, and motors connected to board. Fi g ure 4-17 R epl epla ace Input or or Output Ma Magg azine Handle Handlerr Inte I ntermedia rmediate te B oa oard rd (Input (I nput S ide) C. Insta Installll the replacement replacement board on the input or output maga magazine zine handler. handler. 1. Position Position the board on the rear of the Z Tower Tower machining machining structure structure with its its component side facing the rear of the machine. Place the board against the standoff on the rear of the Z Tower machining structure. 2. Install Install four (4) SHCSs through through the board board and into the standoff standoffs s to secure the board Electronics 98888-0000-JB3-01 4-25 IConn High Performance Wire Bonder 3. Connect Connect sensors, sensors, motors, and cables cables to the following following board co connector nnectors: s: • J1: J1: Y Motor Motor Cab Cable le,, 08888 08888-1 -107 070-0 0-00000-xx xx • J2 and and J3: MHS MHS Senso Sensorr Bus Cable Cables, s, 08 08888 888-10 -1082-0 82-00000-xx xx • J4: J4: Z Motor Motor Cab Cable le,, 0888 08888-1 8-109 0933-00 000-x 0-xx x • J5: J5: G Moto Motorr Cable Cable,, 0888 088888-108 10811-000 000-00 -00 • J9: Z Home Home S Sens ensor or Cabl Cable, e, 0341 03411-1 1-1031 031-000 -000-19 -19 • J10: J10: G Home Home Senso Sensorr Cable Cable,, 0341 03411-10311-1031-001 001-17 -17 • J11: J11: Touc Touch h Home Sensor Sensor Cable Cable,, 03411-1 03411-1031 031-00 -001-21 1-21 • J13: J13: T Tray ray Sensor Sensor Cable, Cable, 0341 03411-1031 1-1031-001 -001-18 -18 • J14: J14: Y Home Home Senso Sensorr Cable, Cable, 0341 03411-1 1-1031 031-00 -001-23 1-23 • J17: J17: Grip Grip Home Home Sen Sensor sor Cabl Cable, e, 0341 03411-1 1-1031 031-00 -001-20 1-20 • J19: J19: Z Brake Brake Moto Motorr Cabl Cable, e, 0888 08888-10 8-1085-0 85-000-x 00-xx x 4. Setup for board board use on the the Input Magazine Magazine Handler Handler and O Output utput Magazine Magazine Handler. a. For Magazine Magazine Handler Handler Intermediate Intermediate board install installed ed on the Input Mag Magaazine Handler, remove the jumper on W1. This will set the board for use on the Input magazine handler. b. For Magazine Magazine Handler Handler Intermediate Intermediate board install installed ed on the Output Ma Maggazine Handler, remove the jumper on W2. This will set the board for use on the Output magazine handler. D. Mount the input/output tower cover, tower tower flap cover and Y motor cover. cover. E. Turn on machine powe power. r. Verify Verify that the magazine handler handler operates prope properly rly during MHS initialization. 4.3.5 4.3 .5 Rep Replac lace e Ind Indexe exerr Inte Interme rmedia diate te Boa Board rd Replace the indexer intermediate circuit board assembly installed in the front of the J boat indexer assembly. Tools/ Equipment • Hex wrench set • Open Open–e –end nd wre renc nch h set set • ESD Prote Protect ctiv ive e Equip Equipme ment nt/M /Mat ateri erial als s • Indexer Indexer Inter Intermed mediat iate e Board Assemb Assembly ly,, P/N 08888-42 08888-422626-000 000-xx -xx CAUTION: OBEY ALL ESTABLISHED ESTABLISHED ESD PROCEDURES WHEN HANDLING OR STORING CIRCUIT BOARD ASSEMBLIES. Procedure A. Press [MOTOR STOP] and turn off machine power. B. Loosen the tw two o captive screws screws that attach attach the PCB cover to the in indexer dexer base. base. C. Remove the PC PCB B cover to access the the indexer intermedia intermediate te board. D. Make sure that the elect electrical rical cables cables to the indexer intermediate intermediate board board are correctly identified. If not, make a note of the connection. E. Disconn Disconnect ect the following following electrical electrical cables from the indexer intermedia intermediate te board at the front of the indexer assembly. (See Figure 4-15 for connector locations on the intermediate board.) • DM DMHS HS Ind Index exer er cabl cable e from from conn connect ector or J J1 1 • MH MHS S Bus Bus Se Sens nsor or Cab Cable le fro from m conn connect ector or J J2 2 • Sol Solen enoi oid d Cab Cable le from from con conne nect ctor or J6 J6 4-26 Electronics 98888-0000-JB3-01 Material Handling System Manual • In In/O /Out ut Tra Tray y Cabl Cable e from from con conne nect ctor or J J14 14 • In In/O /Out ut Tra Tray y Cabl Cable e from from con conne nect ctor or J J15 15 • Grippe Gripperr Flex Flex C Cabl able e Assem Assembly bly fro from m conne connector ctor J23 • Puller Puller Flex Cab Cable le Asse Assembl mbly y fr from om conn connect ector or J J3 3 • Gr Grip ip Air Air Pre Press ss Ass Assy y fr from om con conne nect ctor or J J25 25 • Preheat Preheat Motor Motor Home Home S Sens ensor or Ca Cable ble fro from m connec connector tor J J10 10 • In Inde dexe xerr Moto Motorr Cable Cable ffro rom m conn connect ector or J J21 21 • Prehe Preheat at Mot Motor or Cabl Cable e from from co conn nnec ector tor J J4. 4. • See Thro Through ugh S Sens ensor or Assem Assembly bly C Cabl able e (X senso sensor) r) co conne nnecto ctorr J9 • J Boat Boat Prese Present nt Senso Sensorr Cable Cable ((inp input) ut) con connec nector tor J J19 19 • J Boat Boat Prese Present nt Senso Sensorr Cable Cable (ou (output tput)) conne connector ctor J20 F. Remove the Indexer Indexer Intermediate Intermediate Board Board from the J boat inde indexer xer assembly assembly.. 1. Remove the six six M3 screws and washers washers that attach attach the Ind Indexer exer Inter Intermedimediate board to the front of the indexer base (see Figure 4-18 4-18.) .) 2. Remove Remove the board from from the indexer indexer base and keep keep it in an ESD–protective ESD–protective container. G. Install the replacement indexer intermediate board on the workholder. 1. Put the indexer indexer intermediate intermediate board board on the ffront ront of the indexer indexer ba base. se. 2. Attach Attach the board with with the screws screws and washers washers removed removed before. before. 3. Connect Connect the electr electrical ical cables cables to the indexer indexer intermediate intermediate board removed removed before. Refer to your notes. J Boat Indexer Assembly 6 x M3 Screws 6x M3 Washers Indexer Base Indexer Intermediate Board Fi g ure 4-18 4-18 R ep epla lace ce Indexer Indexer Interme Intermedia diate te B oa oard rd (Fr ont View of of J B oa oatt Indexer As s em embl bly) y) H. Instal Installl the PCB cover to the indexer base and tighte tighten n the two captive screws. screws. I. Tu Turn rn on machi machine ne po powe werr. Electronics 98888-0000-JB3-01 4-27 IConn High Performance Wire Bonder 4.4 MHS Sensors 4.4.1 Sensor T Ty ypes Three types of sensors are used on the MHS: • Refl Reflec ecti tive ve fi fibe berr o opt ptic ic se sens nsor ors s The reflective sensors trigger when light from the sensor fiber optic reflects from a surface (in this case a leadframe) and returns to the fiber optic. These sensors have amplifiers that must be adjusted for sensitivity by the user. • Optica Opticall switch switch sensor sensors s (photos (photosens ensors ors)) Optical switch sensors mark positions for the axes of motion or indicate the location of material in the MHS. A flag on the moving part of an axis, or on a mechanism that can be displaced by a piece of material, interrupts the sensor light beam which signals the control system. • Jam De Detector The jam detector on the index/tucker arm can sense the increased resistance to carrier motion during indexing or ejection, which indicates that a carrier is jammed. A signal from this sensor will stop the ejection and indicate an error. The operator can then clear the jam at the output magazine. Components of this sensor include two contact pins and a spring-loaded bar that electrically connects the pins of the index arm). When theconnection carrier is jammed, bar loses contact with (part the pins, breaking the electrical betweenthe them. 4-28 Electronics 98888-0000-JB3-01 Material Handling System Manual 4.4. 4.4.2 2 Wo Work rkho hold lder er Se Sens nsor or Lo Loca cati tion ons s The locations of workholder sensors are shown in Figure 4-19 4-19.. Heat Block Home Sensor Detail- Slider Assembly, Rear View J Boat Present Sensor (Input) Indexer Pin Left Sensor (Hidden - not shown) Indexer Pin Right Sensor (Hidden - not shown) X Registration Sensor Puller Pin Sensor Carrier Jam Sensor (Hidden - not shown) J Boat Present Sensor (Output) Puller Connector Board (Part of Flex Cable) Index Connector Board (Part of Flex Cable) Puller Motor Home Sensor Preheat Motor Home Sensor Indexer Home Sensor J Boat Indexer Assembly, Front View 4-19 9 Workhold Workholder er S ensor Locations Locations Fi g ure 4-1 Electronics 98888-0000-JB3-01 4-29 IConn High Performance Wire Bonder 4. 4.4. 4.3 3 Ma Maga gazi zine ne Ha Hand ndle lerr Sen Senso sorr Loc Locat atio ions ns The locations of sensors and routing of sensor cables, for both input and output magazine handlers, are shown in Figure 4-20, 4-20, Figure 4-21 and Figure 4-22 4-22.. Figure 4-20 and Figure 4-21 show the z tower assembly on the input magazine handler. The z tower assembly is identical on both the input and output magazine handlers. Figure 4-22 shows the load and unload tray sensors for the output magazine handler. The tray assembly on the input magazine handler is a mirror mirro r image of output magazine handler. Y Axis Home Sensor Cable Y Axis Home Sensor (not shown) Mounted under Z Tower Base Machining Plate - Connects to J14 on Magazine Handler Intermediate Board. Fi g ure 4-20 4-20 Ma Magg azine Handle Handlerr S ens ensors ors - Detail Detail A (Input ( Input Ma Magg az azine ine Handle Handlerr S hown) 4-30 Electronics 98888-0000-JB3-01 Material Handling System Manual Flexible Cable Track Containing: - Z Axis Home Sensor Cable - Tray Sensor Cable - Magazine Gripper Home Sensor Cable - Top Paw Home Sensor Cable - Bottom Paw Home Sensor Cable Z Axis Home Home Sensor Cable Connects to J9 on Input Magazine Handler Intermediate Board Z Axis Home Sensor Top Paw Home Sensor (not shown - mounted under the Upper Jaw Plate near the Top Paw Home Sensor Cable Connects to J11 on Input Magazine Handler Intermediate Board Top Paw Assembly Magazine Gripper Home Sensor Bottom Paw Home Sensor (not shown - mounted under the Lower Jaw Plate near the Bottom Paw Assembly Bottom Paw Home Sensor Cable Connects to J17 on Input Magazine Handler Intermediate Board Tray Sensor Fi g ure 4-21 4-21 Ma Magg azine Handl Handler er S ensors - Deta Detail B (Input Ma Mag azine Handl Handler er S hown hown)) Electronics 98888-0000-JB3-01 4-31 IConn High Performance Wire Bonder Output Magazine Wall Tray Full Sensor (Hidden - bottom of unload tray) Unload Tray Magazine Present Sensor Load Tray NOTE: See Figure 4-16 for magazine handler cable, motor and sensor part numbers. See Section 3 for complete cable routing. Fi g ure 4-22 4-22 Tra Trayy A s s em embl blyy S ensors - Deta Detail C (Output Tra Trayy As s em embl blyy S how hown) n) 4-32 Electronics 98888-0000-JB3-01 Material Handling System Manual 4.4. 4.4.4 4 Re Refl flec ectiv tive e Sen Senso sorr Amp Amplif lifie ierr Set Setup up There are two (2) reflective sensors in the MHS (refer to Figure 4-23 4-23). ). The J Boat present amplifiers/sensors, one mounted on the input side (left side) of the rear rail assembly and the other one is one mounted on the output side (right side). This sensor finds a J boat is between the indexer assembly and the magazine. The control system will attempt to move a magazine only if the appropriate sensor is clear. The procedures that follow provide only a sensitivity adjustment for the sensor amplifiers. Other adjustments may be necessary. Rear Rail Assembly J Boat Present Sensor Amplifier (Input) J Boat Present Sensor Amplifier (Output) J Boat Indexer Assembly J Boat Indexer Assembly, Rear View Switching Threshold Configuration Status LEDs (Green) Programing Push Buttons Bargraph Display (Red) Power LED (Green) Yellow Output LED Sensor Amp Controls/Indicators 23 R efl eflect ective ive S ensor A mp mplifier lifier S et etup up Fi g ure 4 23 Electronics 98888-0000-JB3-01 4-33 IConn High Performance Wire Bonder 4. 4.4. 4.4. 4.1 1 J Boat Boat Pres Presen entt Se Sens nsor or Se Setu tup p Tools/ Materials • Sample J Boat Procedure A. Locate the sensor amplifier. The input (load) J boat present sensor amplifier is mounted on the rear left side of the rear rail assembly. The output (unload) J boat present sensor amplifier is mounted on the rear right side of the rear rail assembly. B. Setup and te teach ach the J boat boat present sensor sensor amplifier amplifier.. NOTE: At factory setting, the LED lights (green) on the ‘LO’ and ‘HS’ are turned ON. 1. Make sure sure that the ”LO” ”LO” and ”HS” lights lights are are turned ON before before you teach teach the replaced amplifier: a. Press and hold hold the TEACH TEACH (or ”-”) button button of the the amplifier amplifier for two tto o three seconds until ”LO” and ”DO” of the Status LEDs flash after another. b. To set the ‘unblock’ ‘unblock’ condition condition (without (without J boat), boat), press the TEACH TEACH (or ”-”) button one [1] time. c. To set the ‘block’ ‘block’ condition, condition, put the sample sample J boat on the work workholder holder rails and in the path of the sensor beam, then press the TEACH (or ”-”) button one (1) time. Table 4-8 Recommended Recommended Signal values for output signal signal Bargraph LED Relative Signal Difference 6 to 8 4 to 5 2 to 3 1 Excellent: Very stable Operations. Excellent: Good: Minor sensing variables will not affect sensing reliability reliability.. Low:: Minor sensing variables may Low ma y affect sensing reliability. Unreliable:: Consider an alternate sensing scheme. Unreliable 2. If teach is accepted accepted,, the amplifier amplifier returns returns to Run mode. mode. If not accepted, accepted, the Power (green) LED will be OFF and the bargraph signal will flash after another at 1 & 3 and 5 & 7 which will automatically return to step B1. b. for the ‘unblock’ condition re-setup. 3. Manually Manually moves the the J boat to the sensor sensor and make make sure that that the amplifier amplifier detects the whole J boat and the output signal integrity is not affected by the movement of the J boat. If affected, reteach again. See Table 4-8 for the relative output signal difference. 4. 4.4. 4.5 5 Se Sens nsor or Stat atus us Disp Displa lay y The MHS sensors are monitored and their status is updated continuously by the machine control system. Sensor state information can be displayed on the monitor by selecting an option in Diagnostic Mode. Sensor status is updated continuously by the control system. If the user manually triggers the sensor the result should appear immediately in the display. display. Refer to Section 5, paragraph 5.4.4, 5.4.4, Maintenance Diagnostics for more information concerning the sensor status dis- play. 4-34 Electronics 98888-0000-JB3-01 Material Handling System Manual 4.5 Cable Assemblies Cable assemblies involved in MHS functions are listed in Table 4-9 4-9.. Part number, name, and cable terminations are provided in the table. See Section 3, paragraph 3.9, 3.9, for routing cables on the input and output magazine handler assemblies. NOTE: Table 4-9 lists cables for the MHS with magazine handlers assembly (z tower and tray input assembly a ssembly.. There are some differences (additional cables, part number changes) when the magazine handlers are configured for back load or top load operation. Table 4-9 MHS Cable Assemblies Cable Part No. 08888 08888-1 -108 0822-000 000-x -xx x Cable Name MHS MHS Senso Sensorr Bus Cable From To Indexe Ind exerr Inter Intermed mediat iate e Board, Board, J2 Inpu Inputt Magazin Magazine e Hand Handler ler Intermediate Board, J3 Input Magazine Handler Intermediate Board, J2 Output Magazine Handler Intermediate Board, J3 DMHS Backplane, J16 Output Magazine Handler Intermediate Board, J2 08888 08888-1 -125 250-0 0-00000-xx xx Index Indexer er DMH DMHS S cable cable DMHS DMHS Back Backpla plane ne,, J7, J7, J1 J19 9 and J21 Indexer Intermediate Board, J1 08888 88-1 -12 251-000-xx Sol ole enoid Cable DMHS Bac Backplane, J11, J14, J39 and J42 Indexer Intermediate Board, J6 08858-1 0885 8-1032 032-000 -000-xx -xx Rem Remote ote Teach each Fibe Fiberr Sensor Assembly Cable Remote Teach Fiber Sensor (Amplifiers) Indexer Intermediate Board, J19 08 0888 8888-12 1280 80-0 -000 00-x -xx x Gr Grip ippe perr Flex Flex C Cab able le In Inde dexe xerr Inte Interm rmed edia iate te Boa Board rd,, J23 Gripper Board 08 0888 888 8-1 -129 2977-00 0000-xx xx Pull Puller er Fl Flex ex Cabl Cable e In Inde dexe xerr IInt nter erme medi diat ate e Boa Board rd,, J3 J3 Pull Puller er Boar Board d 08089-1016-000-xx TC Ext I/O Temperature Board, J1 Interface Panel - MHS Thermocouples: Indexer Intermediate Board, J20 A1: Preheat A2: Bond Site 08888 08888-20 -2009 09-0 -000 00-x -xx x Heat Heater er Po Powe werr c cab able le TDI TDI R RoH oHS S PD PDU/ U/Ca Cabl ble e Ass Assy y, J J6 6 Inter Interfa face ce Pan Panel el - M MHS HS Heat Heat-ers: P2: Preheat P3: Bond Site 08888-1 0888 8-1069 069-000 -000-xx -xx Bac Backpl kplane ane Vacuum acuum Valve cable DMHS Backplane, J18 XY Table Assembly - MHS Vacuum Assembly 08888 08888-1 -106 0611-00 000-x 0-xx x Heat Heat Blo Block ck & Clamp Clamp Ext cable DMHS Backplane, J6 Interface Panel - Heat Block Motor Assembly P2: Heat Block 08888 08888-1 -108 0844-00 000-x 0-xx x Heat Heat Blo Block ck & Clamp Clamp Sensor Ext cable DMHS Backplane, J29 (P1) & J30 (P2) Interface Panel - Heat Block Sensor Assembly P3: Heat Block 08888-1 0888 8-1054 054-000 -000-06 -06 Backpla Backplane ne Input Input Magazine Handler cable DMHS Backplane, J9 Input Magazine Handler Intermediate Board, J1 Electronics 98888-0000-JB3-01 4-35 IConn High Performance Wire Bonder Cable Part No. Cable Name From To 08888088 88-105 1054-00 4-000-0 0-07 7 Backpla Backplane ne Output Output Magazine Handler cable DMHS Backplane, J8 Output Magazine Handler Intermediate Board, J1 08888088 88-128 1283-00 3-000-0 0-00 0 In/Out In/Out Tr Tray ay Ext. Ext. Cable Indexer Intermediate Board, J14 Input Tray Motor, Input Tray Full Sensor and Input Magazine Present Sensor. 08888088 88-128 1283-00 3-000-0 0-01 1 In/Out In/Out Tr Tray ay Ext. Ext. Cable Indexer Intermediate Board, J15 Output Tray Motor, Output Tray Full Sensor and Output Magazine Present Sensor. 4-36 Electronics 98888-0000-JB3-01 Material Handling System Manual 5 5.1 Maintenance About T Th his Se Section Here is what you will find in this section: • Schedule, gives an overview of the MHS Section 5.2, 5.2, Preventive Maintenance Schedule, maintenance plan. • Each Each se sect ctio ion n from from Sect Sectio ion n 5.3 through 5.6 offers information on toolings and MHS related errors and help. • Section 5.3, 5.3, Special Tools and Gauges • Section 5.4, 5.4, Troubleshooting • Section 5.5, 5.5, MHS Errors • Section 5.6, 5.6, MHS Related Bonding Problems Maintenance 98888-0000-JB3-01 5-1 IConn High Performance Wire Bonder 5. 5.2 2 Prev Preven enti tive ve Ma Main inte tena nanc nce eS Sch ched edul ule e Table 5-1 lists the required preventive maintenance (PM) procedures for the J boat material handling system. This schedule combines the PM schedules found in Sections 2 and 3 of this manual. WARNING: THE REMOVE THE POWER FROM THE MACHINE BEFORE CHECKING ELECTRICAL CONNECTIONS OF THE MHS OR BEFORE CHECKING HARDWARE TIGHTNESS AND INSPECTING PNEUMATIC LINES OF THE MHS. MAKE SURE ALL HEATING SURFACES HAVE COOLED BEFORE PROCEEDING. Table 5-1 MHS Preventive Maintenance Schedule Action Clean heat block Period 8 hours Tools/Parts/Supplies 1. Vacuum Hose 2. Solvent Procedure 1. Remove dirt or contaminates from the heat block area. 2. Remove heat block insert and inspect heat block vacuum hole screen. Remove and clean screen if it appears clogged. 3. If screen cannot be cleaned successfully,, replace the screen. cessfully Remove any dirt or contaminates from exposed and moving parts. Clean workholder and mag- 40 hours azine handlers Vacuum Hose Replace heat block vacuum hose. 1000 1000 hour hours s Tubin ubing, g, Si Sili lico cone ne RubRubber Remove vacuum tube between rear of heat block and heatsink. Replace it with a 9” (228 mm) length of the specified tubing. Make sure that there are no air leaks or kinks in the hose before resuming operation. Check hardware tightness 1000 hours Hand Tools Make sure all attaching hardware (screws, nuts, etc.) are securely installed. Inspect electrical connections on workholder and 1000 hours — Check for security and integrity of all electrical connections. Refer to Sec- magazine handlers Inspect pneumatic lines on workholder tion 4 for connector locations. Check for cracks, cuts, leaks, etc. Check for loose fittings or signs of stretching or wear. Correct as required. See Sections 2 and 3 for tubing and pneumatic fitting locations. 1000 hours — Replace magazine stop buttons on magazine handlers 2000 hours Hand Tools Replace all six (6) magazine stop buttons (see paragraph 3.9.6.2 for procedure). Lubricate puller drive rack on workholder 1000 1000 hour hours s Lubr Lubrip ipla late te #630630-2 2 P/N: 39086-6004-000 Apply a thin coat of Lubriplate to rack teeth, make sure that all the teeth are completely filled. Remove excess lubricant from top of rack and around rack when done. 5-2 Maintenance 98888-0000-JB3-01 Material Handling System Manual Action Lubricate X-slide bearing on the indexer assembly Period Tools/Parts/Supplies 3 months to 6 1. Lubricant (10 ml, in months syringe), P/N: 1001140 2. Lint-Free Cloth 3. Hand gloves 4. Cotton buds 5. Hex Wrench Set Procedure 1. Push the [Motor Stop] button. 2. Remove the indexer assembly front cover. 3. Move the gripper assembly to the left or right side manually when neccessary. 4. Clean the v-grooves of the X-slide bearing on the front wall using the lint-free cloth. 5. Apply about 0.1 ml to 0.2 ml of the lubricant to the top and bottom of the v-grooves of the X slide bearings. 6. Move the gripper assembly along the X-slide bearing manually for 10 times. 7. Do steps 5 to 6 again for four times. 8. Remove the unwanted lubricant from the X-slide bearing with the lint-free cloth. Lubricate Y-slide bearings on Magazine Handler Assembly 3 months to 6 1. Lubricant (10 ml, in months syringe), P/N: 1001140 2. Lint-Free Cloth 3. Hand gloves 4. Cotton buds 5. Hex Wrench Set 1. Push the [Motor Stop] button. 2. Remove the Magazine Handler assembly cover. 3. Move the Z Tower assembly to the front or rear manually when neccessary. 4. Clean the v-grooves v-gr ooves of the Y-slide bearings on the Z Tower Tower assembly using the lint-free cloth. 5. Apply about 0.1 ml to 0.2 ml of the lubricant to the left and right sides of the v-grooves of the Y-slide bearings. 6. Move the Z T Tower ower assembly along the Y-slide bearings manually for 10 times. 7. Do steps 5 to 6 again for four times. 8. Remove the unwanted lubricant from the Y-slide bearings with the lint-free cloth. Maintenance 98888-0000-JB3-01 5-3 IConn High Performance Wire Bonder Action Period Tools/Parts/Supplies Lubricate Z-slide bearing on 3 months to 6 1. Lubricant (10 ml, in Magazine Handler Assem- months syringe), P/N: bly 1001140 2. Lint-Free Cloth 3. Hand gloves 4. Cotton buds 5. Hex Wrench Set Procedure 1. Push the [Motor Stop] button. 2. Remove the Magazine Handler assembly cover. 3. Move the magazine gripper assembly up or down manually when neccessary. neccessary. 4. Clean the v-grooves of the Z-slide bearing on the Z Tower Tower assembly using the lint-free cloth. 5. Apply about 0.1 ml to 0.2 ml of the lubricant to the left and right sides of the v-grooves of the Z-slide bearings. 6. Move the magazine gripper assembly along the Z-slide bearings manually for 10 times. 7. Do steps 5 to 6 again for four times. 8. Remove the unwanted lubricant from the Y-slide bearings with the lint-free cloth. 5-4 Maintenance 98888-0000-JB3-01 Material Handling System Manual 5.3 5.3 Spe peci cial al Tools ols and and Gaug Gauge es Table 5-2 list the special K&S tools and gauges that are required for setup and calibration of the MHS. The table also gives a description of each tool. Table 5-2 Special Tools Tools and Gauges Part Number Description Quantity 03035-0501-000-00 Workholder Setup & Calibration Gauge Assembly 1 03035-0502-000-00 Preheat Setup Gauge Assembly 1 03035-0908-001-00 Workholder Setup Gauge 1 03035-0908-005-00 Gauge Pin 2 NOTE: Items listed above are part of the IConn J Boat Adjustment Tool Tool Kit, which can be ordered under part number 03035-0909-000-XX 5.4 Troubleshooting The MHS provides software options designed to aid the operator in assessing the performance of the system. These options are available in: • • MH MHS S Di Diag agno nost stic ics s mode mode MHS Uti Utilit lities ies Menus Menus (T (Tool oolbar bar Opt Option ions) s) • MH MHS S Manu Manual al Mode Mode Ut Util ilit itie ies s • Ma Main inte tena nanc nce e Diag Diagno nost stic ics s Procedures for software options can be found in IConn Operation Manual. The paragraphs that follow contain short descriptions of the software options. 5.4.1 5.4 .1 MHS Wo Workh rkhold older er a and nd M Moto otorr Cy Cycli cling ng D Diag iagnos nostic tics s Diagnostics mode allows the user to home and cycle the motors of MHS subsystems by selecting options from Graphical User Interface (GUI) dialog boxes (see 5-1). The following diagnostic dialog boxes are available: Figure 5-1). • In Inde dexe xerr Diag Diagno nost stic ics s (See (See 5.4.1.1 5.4.1.1)) • 5.4.1.2)) Pull Puller er Di Diag agno nost stic ics s (See (See 5.4.1.2 • • He Heat at Block Block Diag Diagnos nostic tics s (See (See 5.4.1.3) 5.4.1.3) 5.4.1.4)) Inpu Inputt Magazin Magazine e Han Handle dlerr (Mag Handl Handler er In) D Diag iagnos nostic tics s (Se (See e 5.4.1.4 • Outp Output ut Magazi Magazine ne Han Handle dlerr (Mag Hand Handler ler Out) Out) Diagno Diagnosti stics cs (Se (See e 5.4.1.4 5.4.1.4)) Select #1 Select #2 Select #3 Select #2 Select #1 Select #5 Select DONE to exit Select #1 Fi g ure 5-1 5-1 A cces s to Workhold Workholder er and and Ma Mag azine Handl Handler er Cyc ling Menus Maintenance 98888-0000-JB3-01 5-5 IConn High Performance Wire Bonder 5.4 .4.1 .1.1 .1 In Inde dexe xerr Dia iag gnos osti tics cs Displayed by selecting (1) INDEXER from the MHS Workholder menu (Figure ( Figure 5-1 5-1). ). Provides the user with options (Figure 5-2) to home the index gripper X–axis motor, cycle the motor (either for an operator–entered number of o f times or continuously), and stop the motor (if cycling). If the CYCLE option is selected, the SET TIMES TO CYCLE value controls how many cycles will be performed and the CYCLE PERIOD value controls the duration of a dwell (delay period) between each cycle. The operator can enter a value or select the default for either setting. CONTINUOUSLY Y option is selected. the motor will cycle until the operIf the CYCLE CONTINUOUSL ator selects the STOP CYCLING option. The CYCLE PERIOD value controls the duration of dwell between each cycle. Enter Number of times to Cycle Indexer Motor (Cycle function) Enter Duration of Dwell Between Cycles in milliseconds (Cycle and Cycle Continuously Functions) Enter Default Value Function Selections (Select One) Activate Selected Function Activate Selected Function and Exit Dialog Box Exit Dialog Box Fig ure 55-2 2 Inde Indexer xer Mot Motor or Diag Diag nostics D ia iallog B ox 5.4.1 .1..2 Puller Dia Diagnostic tics Displayed by selecting (3) PULLER from the MHS Workholder menu (Figure (Figure 5-1). 5-1). Provides the user with options (Figure (Figure 5-3) 5-3) to home the puller motor, cycle the motor (either for an operator-entered number of times or continuously), and stop the motor (if cycling). If the CYCLE option is selected, the SET TIMES TO CYCLE value controls how many cycles will be performed and the CYCLE PERIOD value controls the duration of each cycle. The operator can enter a value or select the default for either of these settings. If the CYCLE CONTINUOUSL CONTINUOUSLY Y option is selected. the motor will cycle until the operator selects the STOP CYCLING option. The CYCLE PERIOD value controls the duration of each cycle. Enter Number of times to cycle Puller Motor (Cycle function) Enter Duration of Dwell Between Cycles in milliseconds (Cycle and Cycle Continuously Functions) Function Selections (Select One) Enter Default Value Activate Selected Function Function Activate Selected Function Function Exit Dialog Box and Exit Dialog Box Fig ure 55-3 3 Pull Puller er Diagnos tics Dial Dialog og B ox 5-6 Maintenance 98888-0000-JB3-01 Material Handling System Manual 5. 5.4 4.1 .1.3 .3 Heat Blo Block ck Dia iag gnost nostic ics s Displayed by selecting (4) HEAT BLOCK from the MHS Workholder menu (Figure (Figure 5-1). Provides the user with options (Figure 5-1). ( Figure 5-4) 5-4) to select the preheat block motor, bond site heat block motor, or both motors. The selected motor or motors can be homed, cycled for an operator–entered number of times, or cycled continuously. There is also an option to stop the motor if it is cycling. If the CYCLE option is selected, the SET TIMES TO CYCLE value controls how many cycles will be performed and the CYCLE PERIOD value controls the duration of a dwell (delay period) between each cycle. The operator can enter a value or select the default for either of these settings. If the CYCLE CONTINUOUSLY option is selected. the motor(s) will cycle until the operator selects the STOP CYCLING option. The CYCLE PERIOD value controls the duration of each cycle. Enter Number of times to cycle Selected Motor (Cycle function) Enter Duration of Dwell Between Cycles in milliseconds (Cycle and Cycle Continuously Functions) Motor Selection Enter Default Value (Select One) Function Selections (Select One) Activate Selected Function Function Activate Selected Function Function and Exit Dialog Box Exit Dialog Box 5-4 4 Hea Heatt B lock Diag Diag nostics Di alo logg B ox Fig ure 55. 5.4. 4.1. 1.4 4 Maga Magazi zine ne Hand Handle lerr Dia Diagn gnos osti tics cs (1) MAG HANDLER IN or (2) MAG HANDLER OUT from the Displayed by selecting MHS Magazine Handlers menu (Figure (Figure 5-1). 5-1). Provides the user with options (Fig(Figure 5-5) 5-5) to select the magazine handler Y axis motor, Gripper motor, Z axis motor, motor, or all three motors in the magazine handler assembly. Separate menus are available for the input magazine handler (shown in Figure 5-5 5-5)) and output magazine handler. The selected motor or motors can be homed, cycled for an operator– entered number of times, or cycled continuously. There is also an option to stop the motor when it is cycling. If the CYCLE option is selected, the SET TIMES TO CYCLE value controls how many cycles will be performed. The operator can enter a value or select the default for this setting. The CYCLE PERIOD parameter can not be set on this menu; dwell between cycles duration is controlled by machine programming. If the CYCLE CONTINUOUSLY option is selected. the motor(s) will cycle until the operator selects the STOP CYCLING option. Maintenance 98888-0000-JB3-01 5-7 IConn High Performance Wire Bonder Enter Number of times to Cycle Selected Motor(s) (Cycle function) Cycle Period Value entry not active on this dialog box Enter Default Value Motor Selection (Select One) Function Selections (Select One) Activate Selected Function Function Activate Selected Function Function and Exit Dialog Dialog Box Exit Dialog Box 5-5 Ma Magg azine Hand Handller Mot Motor or Diagnos tics D ial ialog og B ox Fi g ure 5-5 5.4.2 5.4 .2 Temp empera eratur ture e Con Contro trolle llerr Dia Diagno gnosti stics cs The Temperature Temperature Control Diagnostics option allows the user to display error status indicators that relate to the temperature temp erature control system for the two workholder heating zones. This option should be used to investigate a suspected temperature control problem. Selecting [3] TEMPERATURE CONTROLLER from the Diagnostic Mode menu displays the Temperature Control Diagnostics dialog box (see Figure 5-6). 5-6). Clicking on the DONE button in the dialog box ends the Temperature Control Diagnostics session and displays the Diagnostic Mode menu. 5.4.2.1 System Errors The System Errors section of the dialog box reports errors that relate directly to the temperature control circuitry on the I/O and Temperature Controller circuit board. When the bonder is powered up, the temperature controller circuitry undergoes power–on confidence testing. If any portion of the circuitry named in the System Errors section fails the confidence test, the error is logged into the software that displays the Temperature Control Diagnostics dialog box. Later, when this dialog box is displayed, the appropriate indicator will be colored Red. If an error exists, the user should ensure that it is a valid error by removing power from the bonder, then: • Checking Checking al alll ele electrica ctricall connectio connections ns in the tthermoc hermocouple ouple temperature temperature sensor input circuit • Reseat Reseating ing the boar board d in the card card rack rack con connec nectors tors • Reapplying pow power If the same error appears when the Temperature Temperature Control Diagnostics dialog box is displayed again, then the I/O and Temperature Temperature Controller circuit board boar d probably needs replacement. 5-8 Maintenance 98888-0000-JB3-01 Material Handling System Manual Select #3 Select Diagnostic E rror Indicat Indicators ors Red = Error Green = Normal Operation Select Done to exit Fi g ure 5-6 5-6 Te Temp mpera eratu ture re Controll Controller er Diagnos tics D ial ialog og B ox 5.4.2.2 Any Zone Errors The Any Zone Errors indicator will be RED if a zone error exists in either the Preheat or Bond Site heating zones. The error that is active in the zone will have its error indicator colored Red in the Zone Errors section of the dialog box. The zone, Preheat, Bond, or Post Heat, for which errors are displayed can be selected using the ZONE button. When selected, a drop down menu will appear from which the user can select the desired zone. 5.4.2.3 Zone Errors Unlike system errors, zone errors are monitored in real time. For example, if the user displays the Temperature Control Diagnostics dialog box and, at that instant, a zone error occurs, the user would see the corresponding error indicator change its state from Green to Red. If a zone error does occur, the problem may be a faulty temperature controller circuit, thermocouple sensor, heater power control relay, or heater element. • Loop Break Loop break indicates an open circuit in the output circuit of the temperature controller (heater relay control). • Se Sens nsor or Out Out A/D A/D Ra Rang nge e Sensor out of analog to digital (A/D) range indicates a probable open thermo couple input circuit • Se Sens nsor or Ove verr Rang Range e Over range is an input value that is higher than the normal upper limit of the control loop. This is often an indication of an open thermocouple input circuit. Maintenance 98888-0000-JB3-01 5-9 IConn High Performance Wire Bonder • Sens Sensor or Unde Underr Rang Range e Under range is an input value that is lower than the normal lower limit of the control loop. This is often an indication of a shorted thermocouple or short elsewhere in the sensor input circuit. • Low Alarm Low alarm is a condition in which the measured temperature is below the control band specified relative to the control set point. For example, if a ±5 degree alarm limit is set, this indicates the temperature is more than 5 degrees below set point. • High Alarm High alarm is a condition in which the measured temperature is above the band specified relative to the control set point. For example, if a ±5 degree alarm limit is set, this indicates the temperature is more than 5 degrees above set point. 5. 5.4 4.3 Re Re–I –Ini niti tia aliz lize MH MHS S Selecting option 4 RE-INITIALIZE MHS from the Diagnostic Mode menu starts an MHS initialization sequence, the same sequence that is performed whenever the machine exits Standby Mode. (See Figure 5-6 for Diagnostics Menu.) All axes of motion in the MHS workholder and magazine handlers are sent to their home positions. Each stepper motor will turn in the direction that will drive the equipment toward its home sensor. When the home sensor s ensor is actuated, the motor will stop, then turn in the opposite direction to t o place the equipment at its programmed home position. If there is any material in the workholder (carriers), or magazines in the magazine handler grippers, the user will be asked to remove the material and magazines. When the user signals that this has been done by selecting OK in the dialog box, the initialization begins. Magazines on load/unload trays may remain in place. Refer to Section 1 of this manual for material removal procedures. NOTE: Any stepper motor driven assembly can be sent to home position individually by selecting an option in the appropriate motor cycling dialog box. Refer to paragraph 5.4.1 for more information. 5. 5.4. 4.4 4 Ma Main inte tena nanc nce e Diag Diagno nost stic ics s The Maintenance Diagnostics allows the user to view and test all of the sensors throughout the bonder and material m aterial handler system. To access the Maintenance Diagnostics dialog box, select MAINTENANCE DIAGNOSTICS from the Diagnostic menu (see Figure 5-7). 5-7). Select #5 Select DONE to exit Fi g ure 5-7 Ma Mainte intena nance nce Diag nos nosttics Dial Dialog og B ox 5-10 Maintenance 98888-0000-JB3-01 Material Handling System Manual Selecting SENSOR from the Maintenance Diagnostics dialog box 5-8)) after a slight causes the Sensor Diagnostics dialog box to appear (see Figure 5-8 delay. The delay is due to the software collecting and computing all of the sensor data throughou throughoutt the machine. machine. The Sensor Diagnostics dialog box contains indicators which reflect the change status and the On/Off (i.e., blocked /unblocked) state of the sensor. The dialog box also contains a color legend informing the user how to decode the meaning of an indicator when it is set to a specific color. Status: Sensor values (ON or OFF) White = ON, Black = OFF White Black Fig ure 55-8 8 S en enss or Diagnos tics Dialog Dialog B ox The control buttons that appear in the “Sensor Diagnostics” dialog box are defined as follows. • FREEZE • • UNFREEZE • • Clicking Clicking on this button button freezes freezes the display display of the indica indicators tors iin n the “Sensor Diagnostics” dialog box. Clicking Clicking on on this button unfreezes unfreezes the the dis display play of the indica indicators tors iin n the “Sensor Diagnostics” dialog box. DONE • Exits the Sensor Sensor Diagnostics Diagnostics dialog box and and displays displays the Ma Maintena intenance nce Diagnostics main dialog box. The following topics define the workholder and magazine handler sensors that appear in the Sensor Diagnostics dialog box. • INPUT Z HOME • Optica Opticall swi switch tch senso sensorr used to detect detect when when th the e Z axis mo movem vement ent of tthe he input magazine handler is at its home position. The magazine handler Z axis controls the up and down positioning of the gripper assembly. Maintenance 98888-0000-JB3-01 5-11 IConn High Performance Wire Bonder • INPUT G HOME • • INPUT_GRIP • • Optica Opticall switch switch sensor sensor used to detect detect when when tthe he Z axis moveme movement nt of the o oututput magazine handler is at its home position. The magazine handler’s Z axis controls the up and down positioning of the grip gripper per assembly. OUTPUT G HOME • • Sensor located on the input mag mag handler handler lload oad tra tray y. Used to detect detect whe when na magazine on the input load tray is in the correct position to be picked up (gripped) by the gripper assembly. assembly. The input load tray feeds magazines to the gripper containing unprocessed material. OUTPUT Z HOME • • Sensor llocated ocated at the bottom of the input mag handler’s handler’s gripper assembly assembly.. As the gripper assembly moves forward in the Y axis, this sensor detects the edge of the tray. The sensor informs the t he software that the gripper is at the correct position to pick up a magazine. INPUT Y HOME • • Sensor located located on the upper upper paw paw of the input input mag mag han handler dler g gripper ripper assemassembly bly.. Used to detect when the upper paw of the gripper assembly comes in contact with (grips) a magazine. This sensor informs the software that the magazine is properly registered in the gripper jaws. INPU IN PUT T TR TRAY AY DET ETEC ECT T • • Sens Sensor or located located unde underr the lower lower paw paw if the input input ma mag g handler handler gr gripp ipper er assembly.. Used to detect when the lower paw of the gripper assembly gr ipper assembly comes in contact with (grips) a magazine. This sensor informs the software that the magazine is properly registered in the gripper jaws. INPUT TOUCH • • Optica Opticall switch switch sensor sensor used used to detect detect when tthe he uppe upperr and lower paws of of the input magazine handler gripper assembly are at their home position (i.e., the gripper is fully opened, ready to grip magazine). Optica Opticall switch switch sensor sensor used used to detect detect when tthe he uppe upperr and lower paws of of the output magazine handler gripper assembly are at their home position (i.e., the gripper is fully opened, ready to grip magazine). OUTPUT_GRIP • Sens Sensor or located located unde underr the lower lower paw paw if the outpu outputt mag handle handlerr gripper gripper assembly assembly. Used towith detect when the lower paw the gripper grinforms ipper assembly comes in .contact (grips) a magazine. This of sensor the software that the magazine is properly registered in the gripper jaws. • OUTPUT TOUCH • • Sensor located located on the upper upper paw paw of the ou output tput m mag ag han handler dler gripper gripper assembly bly.. Used to detect when the upper paw of the gripper assembly comes in contact with (grips) a magazine. This sensor informs the software that the magazine is properly registered in the gripper jaws. OUT UTPU PUT T TR TRAY DET ETEC ECT T • Sensor located at the bottom of the output mag handler’s handler’s gripper assembly assembly.. As the gripper assembly moves forward in the Y axis, this sensor detects the edge of the tray. The sensor informs the t he software that the gripper is at the correct position to pick up a magazine. • OUTPUT Y HOME • • Sensor located on the the base base plate plate of the o output utput mag h handler andler assembly assembly.. Used to detect when the Y-axis movement of the magazine handler is at its home position. The magazine handler’s Y-axis controls the forward and backward positioning of the gripper assembly. PULLER HOME • Optica Opticall switch switch sensor sensor that that detects detects when when the puller assembly assembly is at its home position. The sensor is located locate d on the puller assembly. 5-12 Maintenance 98888-0000-JB3-01 Material Handling System Manual • PREH PR EHEA EAT T BL BLOCK HO HOM ME • • PULLER PIN • • • Referred Referred to the J Boat Present Present Sensor Sensor.. The sensor detects detects that that a J boa boatt has been injected into the workholder. The sensor is on the left side of the rear rail assembly. It contains the fiber optic and sensor amplifier. OUTPUT TRAY 1 Sensor located located on the output output mag h handler andler unload tray. tray. Us Used ed to detect when the unload tray is full of magazines. OUTP OU TPUT UT TR TRAY AY 2 / GUI GUIDE DE DO DOOR OR • • Sensor located located on the the input input mag handler handler load tray tray.. Used to detect detect wh when en a magazine on the input load tray is in the correct position to be picked up (gripped) by the gripper assembly assemb ly.. The input load tray feeds magazines to the gripper containing unprocessed device. INPUT WALL • • Sensor located on the input mag handler handler unload tray. tray. Use Used d to detect when the unload tray is full of magazines. INPUT TRAY 2 • • Optical Optical switch switch sensor that detects detects the up/dow up/down n position position of the the ind index ex pi pin. n. INPUT TRAY 1 • • Optical Optical switch switch sensor that detects detects the presenc presence e of a boat under the index index pin. INDE IN DEXE XER R PI PIN N RI RIG GHT • • Mechanical-c Mechanical-contac ontactt sensor sensor that that detects detects when a jam occurs in th the e ind index/ ex/ tucker area. The sensor is spring loaded and detects a jam when a force pushes the index pin to its left. This force can be the result of a jammed boat during an index (pin in the boat) or the tucker pushing against the index pin because of a jam during boat ejection. INDEXER PIN LEFT • • Optical Optical switch switch sensor sensor that that detects detects when th the e inde index/tuck x/tucker er ass assembly embly is at its home position. The sensor is on the index/tucker assembly. IND NDE EXE XER R JA JAM DET DETEC ECT T • • Sensor that detects detects the leading leading edge edge of a boat as it is pull pulled ed into the workworkholder by the puller assembly. The puller will continue making an attempt to pull more of the boat into the workholder until this sensor is blocked or the software times out. The sensor is on the rear rail assembly. assembly. INDEXER HO HOME • • Optical Optical sw switch itch sensor that reports reports the u up/down p/down posit position ion of the puller puller pin. REGISTRATION X • • • Optical Optical switch switch sensor sensor that that detects detects w when hen th the e prehe preheat at block block is at it its s home position. Sensor located on the output mag handler handler load ttray ray.. Used to det detect ect wh when en a magazine on the output load tray is in the correct position to be picked up (gripped) by the gripper assembly. The output load tray feeds empty magazines to the gripper. OUTPUT WALL • • JAM MODULE • • Referred Referred to the J Boat Present Present Sensor Sensor.. The sensor detects detects that that a J boa boatt has been ejected from the workholder. The sensor is on right side of the rear rail assembly. It contains the fiber optic and sensor amplifier. For For iint nter erna nall us use e onl only y. SYST SY STEM EM LO LOW W PRE PRESS SSU URE • Sensor Sensor locat located ed in the the main input input air air assembl assembly y at the lo lower wer co conso nsole. le. Maintenance 98888-0000-JB3-01 5-13 IConn High Performance Wire Bonder • HEAT BLOCK HOME • • HEAT HE AT BL BLO OCK VAC ACUU UUM M • 5. 5.4. 4.5 5 Sensor located located in the sl slider ider assembly assembly th that at is used to detect detect wh when en the bond site heat block is at its home position. Vacuum sensor used to detect detect the the presence presence of vacuum vacuum a att the bond site heat block. MH MHS ST Too oolb lbar ar Ut Utili ility ty Me Menu nus s Selecting one of the MHS utilities buttons from the toolbar in the display provides a dialog box from which common workholder or magazine handler functions can be carried out. Entry into other modes to use these functions can ca n thus be avoided. 5.4 .4.5 .5.1 .1 MHS Wo Work rkho hold lde er Util Utilit itie ies s The Workholder Utilities menu appears when W/H OPER is selected from the tool 5-9).The ).The functions listed in this menu allow the operator to send sen d a bar (see Figure 5-9 command to the workholder to do a single action. Tool Bar Select DONE to exit dialog Select #8 Fi g ure 5-9 5-9 A cces s to Work hold holder er and and Ma Magg H andle ndlerr Utilities Utilities (without ( without s afet fetyy cover) The workholder utilities are defined as follows: • [1]] [1 STOP ST OP IN INDE DEXI XING NG:: Stop the indexing of boat through the workholder. • PULL PU LL BO BOAT AT IN IN:: Causes the workholder to pull a boat from the supply [2] [2] (left-side) magazine. • EJEC EJ ECT T BO BOAT AT:: Causes the workholder to push a boat into the receiving [3] [3] (right-side) magazine. • CLEA CL EAR R WORK WORKHO HOLD LDER ER:: Causes the workholder to remove all boats. [4 [4]] 5-14 Maintenance 98888-0000-JB3-01 Material Handling System Manual • [5] [5] 5-10)) BOAT BO AT IN INJE JECT CT:: Opens another dialog box (see Figure 5-10 that allows the operator to set the t he ON or OFF status of the puller for p pulling ulling boats from the supply (left-side) magazine. Once the desired setting is made, the user selects DONE which causes the Workholder Utilities dialog box to appear. Fi g ure 5-10 B oa oatt Inject Dial Dialog og B ox • [1] BOAT INJECT OFF: Stop boat injection. No additional boats are pulled into the workholder. Those boats in the workholder are processed normally unless unless Stop Indexing Indexing is activated. activated. • • [6 [6]] [2] BOAT INJECT ON: Restores normal operation. HEA EAT T BL BLOC OCK: K: Allows the user to perform heat block related functions. The dialog box shown in Figure 5-11 appears. Once the desired setting is made, the user selects DONE which causes the Workholder Utilities dialog box to appear. Fi g ure 5-1 5-11 1 Hea Heatt B lo lock ck Dialog Dialog B ox • [1] LOWER HEAT BLOCK: Causes the heat block to be lowered to the index- ing height (i.e., the position below the boat, so as to clear the boat during the indexing of a device). • [2] RAISE HEAT BLOCK: Causes the heat block to be raised to the bonding height. • [3] HOME HEAT BLOCK: Causes the heat block to be lowered to the home position. • [7]] [7 HEAT HE AT BL BLOC OCK K VAC VACUU UUM: M: Opens the dialog box (see Figure 5-12 5-12). ). The user may then set the vacuum to On or Off. Once the desired setting is made, the user selects DONE which causes the Workholder Utilities dialog box to appear. Fi g ure 5-12 5-12 Hea Heatt B lo lock ck Vacuum Vacuum Dial Dialog og B ox • [1] HEAT BLOCK VACUUM ON: Applies heat block vacuum. • [2] HEAT BLOCK VACUUM OFF: Removes heat block vacuum. vacuum. Maintenance 98888-0000-JB3-01 5-15 IConn High Performance Wire Bonder 5.4 .4.5 .5.2 .2 MHS MHS Ma Magaz azin ine e Uti Utili liti tie es The Magazine Handler Utilities menu appears when MAG OPER is selected from the tool bar (see Figure 5-9).The 5-9).The functions listed in this menu allow the operator to send a command to either magazine handler to do a single action. The magazine handler utilities are defined as follows: • • JOG MAGAZINE (Input and Output) • Moves the magazine magazine held in in the gripper gripper to its next s slot, lot, a as s defi defined ned by the programmed sequenced or user–defined user–defin ed slot order. If no magazine is in the gripper, a magazine will be picked up from the load tray. REVERSE JOG MAGAZINE (Input and Output) • • Moves the magazine magazine held in in the gripper gripper to its its prev previous ious slot, slot, as define defined d by the programmed sequenced or user–defined slot order. EJECT MAGAZINE (Input and Output) • • Dep Deposi osits ts th the e magazin magazine e held b by y the grippe gripperr on the unloa unload d tray. tray. MAG SELECTION • 5. 5.4. 4.6 6 Toggl oggles es IINPU NPUT T mode mode or or OUTPU OUTPUT T mode. mode. MH MHS SM Man anua uall Mo Mode de Ut Util ilit itie ies s Manual mode has MHS utility dialog boxes that allow the user to operate the MHS subsystems through the Graphical User Interface (GUI) (See Figure 5-13). 5-13). The following utility dialog boxes are available: • Index Ut Utiliti tie es • Heat Heat Bl Bloc ock k Uti Utili liti ties es • Preh Prehea eatt Blo Block ck Ut Util ilit itie ies s • Pin Utilities Select #3 Select DONE to exit Fi g ure 5-13 5-13 A cces s to MHS Ut Utilit ilities ies ( Ma Manua nuall Mod Mode) e) 5.4.6.1 Index Ut Utilities Provides options that allow the user to operate the workholder either continuously or for a user–entered number of index cycles (Figure ( Figure 5-14 5-14). ). Indexing can be done with material in the MHS (“Normal” index commands) or with no material in the MHS (“Dry” index commands). A count of index cycles is kept and displayed in the dialog box, which can be reset to zero at any time by the user. Boat injection can be set to On or Off before index cycling is started. Index commands available on the menu are: 5-16 Maintenance 98888-0000-JB3-01 Material Handling System Manual • NORMAL INDEX and DRY INDEX • • CONTINUOUSLY LY NORMAL INDEX CONTINUOUSLY and DRY INDEX CONTINUOUS • • Stops tops workhol workholder der opera operation tion w when hen th the e work workhold holder er is cycli cycling. ng. PARK IN INDEXER • • Workholder Workholder will operate operate until stopped stopped by the the user user.. Normal Normal Index Index ContinuContinuously requires material (boats) in the workholder. Dry Index Continuously will take place without material in the workholder. The number of index cycles completed appears in the TOTAL INDEX COUNT area. STOP IN INDEXING • • When either command command is select selected, ed, th the e wor workholde kholderr wil willl perform perform the the number number of index cycles shown in the INDEX TIMES area at the top of the dialog box (unless stopped by the user before completion). Normal index requires material (boats) in the workholder. Dry index will take place without material in the workholder. The number of cycles completed appears in the TOTAL INDEX COUNT area. Moves indexer indexer to “parked” “parked” position. position. When parked, parked, each subsy subsystem stem is is at a programmed distance from its sensor–marked home position. HOME IN INDEXER • Indexe Indexerr seeks seeks its home home sens sensor or the then n moves moves to its its ho home me po posit sition ion.. Set number of index cycles to perform (Normal Index and Dry Index Commands) Set the bond time to perform (Normal Index Command) Enter Default Value Number of Indexes Performed Enable/Disable Boat Inject Function Reset Total Index Count to Zero Command Selection (Select One) Activate Selected Function Function Activate Selected Function Function and Exit Dialog Box Exit Dialog Box Fi g ure 5-14 5-14 Index Utilitie Utilitiess Dial Dialog og B ox (Manua (Manuall Mode Mode)) Setup Options available in the dialog box are: • INDEX TIMES • Controls Controls how how many many ind index ex cycles cycles will be performed performed for Normal Normal Index and Dry Index Commands. User can enter a value or select the default number of cycles. • BOND TIME • • Controls Controls the the bonding bonding time time that that will will b be e perf performed ormed for Normal Normal Index Commands. User can enter a value or select the default time. CLEA CL EAR R TOT TOTAL AL IN INDE DEX X COUN COUNT T • Resets Resets the index index cycle cycle counte counterr to to z zero ero.. Maintenance 98888-0000-JB3-01 5-17 IConn High Performance Wire Bonder • BOAT INJECT • 5.4 .4.6 .6.2 .2 Can be set to ON or OFF. If OFF, boats will not be pulled in from the input magazine handler when required during a Normal Index cycle or Normal Index Continuously cycle. After the last boat in the workholder is moved into the output magazine handler, h andler, the index cycle will stop. If ON, leadframes will be injected as needed. Heat Bl Bloc ock k Util tilit itie ies s The Heat Block Utilities allow the user to force or set several bond site operations. Selecting [2] HEAT BLOCK UTILITIES from the MHS Utilities menu displays the heat block dialog box (see Figure 5-15 5-15). ). Utilities available are: • LOWER HE HEAT BL BLOCK • • RAISE HE HEAT BL BLOCK • • When tthis his command command is selected selected the bond bond s site ite heat heat block block is rai raised sed to its bond plane level, where it is placed during bonding operations. CLOSE OFFSET • • When th this is command command is is selected selected the the bond site heat heat blo block ck moves moves to its boat boat clearance level which it is placed at during an index cycle. When tthis his command command is selected selected,, the bond site h heat eat bl block ock is is pos positione itioned d at the entered offset value from its raised position. HOME HEAT BLOCK • When th this is command command is is selected selected the bond site site he heat at block block move moves s to iits ts ho home me position. Fi g ure 5-15 5-15 Hea Heatt B lock Utilities Utilities D ial ialog og B ox (Manua (Manuall Mode Mode)) 5.4 .4.6 .6.3 .3 Pr Pre ehea heat Blo Block ck Utili tiliti tie es The Preheat Block Utilities allow the user to force or set several preheat block operations. Selecting [3] PREHEAT BLOCK UTILITIES from the MHS Utilities menu 5-16). ). Utilities available are: displays a dialog box (see Figure 5-16 • LOWE WER R PR PREH EHEA EAT T BL BLOCK • • RAIS RA ISE E PRE PREHE HEA AT BLO BLOC CK • • When tthis his command command is selected selected the preheat preheat heat block block moves to it its s boat clearance level which it is placed at during an index cycle. When tthis his command command is selected selected the preheat preheat heat block block is ra raised ised to its its device heating level. HOM HO ME PRE PREH HEA EAT T BLO BLOC CK 5-18 Maintenance 98888-0000-JB3-01 Material Handling System Manual • When When thi this s comman command d is selec selected ted th the e pre prehea heatt heat heat blo block ck mo moves ves to its home position. Fi g ure 5-16 P rehea reheatt B lock Utilities Utilities Dial D ialog og B ox (Manua (Manuall Mode Mode)) 5.4.6.4 Pin Utilities Options on the Pin Utilities dialog box allow the user to operate the puller arm, indexer pin, and tucker actuator (see Figure 5-17). 5-17). The user can also home the puller and the indexer indexer.. Puller functions available in the dialog box a are: re: • LOWER PULLER PI PIN • • HOME PULLER • • When this this command command is is selected selected tthe he puller puller pin is rai raised sed to its "boat p pulling ulling"" position. The puller pin solenoid is de-energized when the puller pin is in this position. LIFT TUCKER • • When this this command command is selected selected the iindexer ndexer pin is is lowered lowered to its its ind indexing exing position (within the index hole on the boat). The indexer pin solenoid is energized when the indexer pin is in this position. LIFT PULLER PIN • • When this this command command is is selected selected the the tuck tucker er is lowered lowered to its its tu tucking cking positi position on (tucks the boat into the output magazine). The tucker solenoid is energized when the tucker is in this position. LOWER IN INDEXER PIN PIN • • Moves Moves tthe he puller puller assemb assembly ly to to it its s ho home me p posi ositio tion. n. LOWER TUCKER • • When this this command command is is selected selected tthe he puller puller pin is low lowered ered tto o its reset p posiosition. The puller pin solenoid is energized when the puller pin is in this position. When this this command command is selected selected the tu tucker cker is ra raised ised to its its res reset et pos position. ition. The tucker solenoid is de-energized when the tucker is in this position. LIFT IN INDEXER PI PIN • Command Selection When this this command command is is selected selected th the e inde indexer xer pin pin is raised raised tto o its reset position (above the top surface of the boat). The index pin solenoid is de-energized when the indexer pin is in this position. (Select One) Activate Selected Function Function Exit Dialog Box Exit Dialog Box Fi g ure 5-17 5-17 Pi n Utilit Utilities ies Di alo logg B ox (Manua (Manuall Mod Mode) e) Maintenance 98888-0000-JB3-01 5-19 IConn High Performance Wire Bonder 5.5 MHS Errors 5. 5.5 5.1 Er Erro rorr In Indi dic cat atio ions ns 5. 5.5. 5.1. 1.1 1 Erro Errorr Reco Recove very ry Opt Optio ions ns Dia Dialo log g Box Box When the machine detects an error in MHS operation, it displays a dialog box on the monitor screen. The error may also light one of the signal lights on the light tower and sound the audible alarm (depending upon signal light/alarm programming), and stop machine operation if necessary. Figure 5-18 illustrates the dialog flow for a typical error event. Dialog Box ‘A’, which appears as soon as the error is detected, displays error information plus gives the user up to five error recovery options from which to choose. Depending upon the error event that is reported, certain options may be inactive (grayed). One of the error recovery options ( MORE) supplies the user with additional information related to the error event (Dialog box ‘B’ in Figure 5-18 5-18.) .) Selecting DONE in this dialog box will display Dialog box ’A’. Error messages are listed in paragraph 5.5.2. The options found in most error dialog boxes are: • CONTINUE • • RETRY • • When tthis his option option is selected selected,, the operati operation on being being perform performed ed when when the the err error or was detected is continued or restarted. If the error indication is not repeated, machine operation will continue and no other user action is required. If it is repeated, the user should select the ABORT button and troubleshoot for the cause of the error. ABORT • • Ret Retrie ries s the operat operation ion.. Checks Checks if error error condit condition ion still still e exis xists. ts. RECOVER • • Ign Ignore ore the the er error ror and and proce proceed ed with with th the e current current ope operati ration. on. When tthis his option option is selected selected,, the operati operation on being being perform performed ed when when the the err error or was detected is stopped and not retried. The user must manually restart the operation or troubleshoot for the cause of the error before proceeding. MORE • When tthis his option option is selected selected,, a second dialog box a appears ppears that shows shows the error number, a more detailed error message than the one in the recovery options dialog box, and additional information that may be helpful when trying to correct the error (see Figure 5-18 , Dialog Box ‘B’). When done reading the dialog box text, the DONE button is selected to return to the error recovery options dialog box. 5. 5.5. 5.1. 1.2 2 Si Sign gnal al Ligh Lights ts and and Aud Audib ible le Al Alar arm m The signal light tower at the top of the machine has three colored lamps: Red, Amber, and Green. The green lamp is usually lit to indicate normal automatic operation. The red and amber lamps are lit to indicate machine errors, material requirements, or changes in machine status, accompanied by an audible alarm. Machine software allows the users to program the conditions under which the signal lamps light and the alarm sounds. Refer to Section 1 of this manual and IConn Operation Manual for more information. information. 5-20 Maintenance 98888-0000-JB3-01 Material Handling System Manual Select MORE to display next dialog box (B) Dialog Box A Select DONE to display options dialog box (A) Dialog Box B Fig ure 55-18 18 E rror Recovery Recovery Opt Options Dialo Dialogg B oxe oxess 5.5. 5.5.2 2 Er Erro rorr a and nd St Stat atus us Me Mess ssag ages es 5. 5.5. 5.2. 2.1 1 ”H ”Hom ome e Not Not Foun Found” d” or ””No Nott Out Out of of Home Home”” Erro Errors rs [SUBSYSTEM] HOME NOT FOUND [SUBSYSTEM] IS NOT OUT OF HOME MAGAZINE HANDLER MOTOR Y, Z, OR G HOME ERROR [Subsystem] may be Puller, Index/Tucker, Heat Block, Puller Pin or Index Pin. P in. • Error Re Recovery • 5. 5.5. 5.2. 2.2 2 Select CONTINUE in the dialog box. If the error is repeated, use the options in the error recovery dialog box to try to identify the cause of the error: • Chec Check k ffor or mecha mechanic nical al pr prob oble lem. m. • Chec Check k sen senso sorr o ope pera rati tion on.. • Check Check motor motor or actuato actuatorr electri electrical cal connec connection tions s and wi wirin ring. g. • Chec Check k mo moto torr or act actuat uator or ope opera rati tion on.. Mate Materi rial al Cond Condit itio ion n Erro Errors rs MATERIAL IN WORKHOLDER WORKHOLDER NOT EMPTY DEVICE OVERHEATED EYEPOINT TEACH FAILURE MATERIAL CANNOT BE PULLED IN - ALREADY PRESENT NO MATERIAL IN SLOT MAGAZINE HANDLER FAILED ON GET MAGAZINE REMOVE BOAT FROM RAILS BOAT IS NOT PRESENT IN WORKHOLDER LOAD TRAY EMPTY (INPUT MAG OR OUTPUT MAG) UNLOAD TRAY FULL (INPUT MAG OR OUTPUT MAG) • Error Re Recovery • Supply MHS with with material material or remove material material as indicated, indicated, tthen hen re restart start operation. Maintenance 98888-0000-JB3-01 5-21 IConn High Performance Wire Bonder 5.5.2 .2..3 Statu tus s Messages WHL WANTS BOND HEAD MOVED WHL WANTS BOND HEAD POSITIONED MHS INDEX TERMINATED INDEX SEQUENCE ABORTED MHS DEVICE INDEXED MHS DEVICE SKIPPED MHS CARRIER PULLED IN MHS CARRIER EJECTED MHS INITIALIZATION EXECUTED MHS PWRFAIL (POWER FAILURE) RECOVERY EXECUTED MHS JAMMED CARRIER REMOVED MH TEACH OPERATION WORKED MH CAL SLOT OPERATION WORKED MH CAL TRAY OPERATION WORKED MHS MAG LOADED MHS MAG LOADED_O MHS MAG UNLOADED MHS MAG UNLOADED_O • 5.5 .5.2 .2.4 .4 No error error recov recovery ery actio action n require required d from the the us user er.. Select Select OK to remove the message message.. Cal Calib ibra rati tio on Mess Messag age es MHS [ANY DEVICE] CALIBRATION SUCCESSFUL WORKHOLDER CALIBRATION TERMINATED HEAT BLOCK CALIBRATION TERMINATED TUCKER EJECT CALIBRATION TERMINATED SLOT CALIBRATION TERMINATED TRAY CALIBRATION TERMINATED • Er Errror Recovery • 5.5 .5.2 .2.5 .5 Select OK to remove message. Repeat calibration procedure if error message indicated that the calibration was terminated before successful completion. Mag Magazin zine Han Handli ling ng Err Error ors s [INPUT/OUTPUT]] MAG HANDLER DETECTED SLOT SENSOR BLOCKED [INPUT/OUTPUT • Er Errror Recovery • Che Check ck whether whether there there is is a boat exten extended ded betwe between en the magaz magazine ine an and d the workholder rails. If so, move the boat into the magazine and select CONTINUE. If there is no boat at the slot sensor fiber optic, set up the J Boat present sensor amplifier (refer to Section 4 for procedure.) [INPUT/OUTPUT] [INPUT/OUTPUT] MAGAZINE HANDLER WILL ALSO HOME Y • Er Errror Recovery • Select CONTINUE to resume operation. No other action is required. [INPUT/OUTPUT] [INPUT/OUTPUT] MAGAZINE HANDLER G HOME WILL ALSO HOME [Y OR Z] • Er Errror Recovery • Select CONTINUE to resume operation. No other action is required. [INPUT/OUTPUT] MAGAZINE HANDLER G HOME WILL DROP MAGAZINE [INPUT/OUTPUT] • Er Errror Recovery • Grasp magazine magazine held held by the gripper gripper of indicate indicated d mag magazine azine handler handler,, then then select CONTINUE . Gripper will release magazine. 5-22 Maintenance 98888-0000-JB3-01 Material Handling System Manual MH LOSS OF PWRFAIL DATA • Error Re Recovery • Use the the arrow keys to to move the gr gripper ipper to to a location location where it will will not contact any part of the magazine handler during initialization. Initialize the MHS. Y, Y, Z, and Gripper axes must find home position before operation can be resumed. [INPUT/OUTPUT] MAG HANDLER: MAG INTERFERENCE POSSIBLE • Error Re Recovery • Grasp Grasp magaz magazine ine held held b by y the the gri gripper pper,, then then sele select ct CONTINUE . Gripper will release magazine. [INPUT/OUTPUT] MAG HANDLER: OPERATION SUSPENDED [INPUT/OUTPUT] • Error Re Recovery • Use the the arrow keys to to move the gr gripper ipper to to a location location where it will will not contact any part of the magazine handler during initialization. Initialize the MHS. Y, Y, Z, and Gripper axes must find home position before operation can be resumed. [INPUT/OUTPUT] MAG HANDLER TRAY DETECT SENSOR NOT BLOCKED • Error Re Recovery • Select CONTINUE. Gripper will attempt to locate tray again. If it fails to locate tray, check position of gripper when it tries to find the tray. If not good, perform tray calibration. If gripper position is good, then gripper tray sensor is probably defective and should be replaced. [INPUT/OUTPUT] MAG HANDLER TRAY DETECT SENSOR BLOCKED • Error Re Recovery • Select CONTINUE. Gripper will attempt to locate tray again. If gripper is positioned so tray sensor is not blocked and the error is repeated, then gripper tray sensor is probably defective and should be replaced. [INPUT/OUTPUT] MAG HANDLER TRAY DETECT SENSOR STATE ERROR • Error Re Recovery • Select CONTINUE. Gripper will attempt to locate tray again. If it fails to locate tray, check position of gripper when it tries to find the tray. If no good, perform tray calibration. If gripper position is good, then gripper tray sensor is probably defective and should be replaced. [INPUT/OUTPUT] MAG HANDLER GRIPPING SENSORS NOT BLOCKED • Error Re Recovery • Hold magazin magazine e in gripper gripper (if presen present) t) and initialize initialize the M MHS. HS. Gr Gripper ipper axis must find home position before operation can be resumed. If error is repeated, check gripper sensor operation and replace sensor assemblies as needed. Maintenance 98888-0000-JB3-01 5-23 IConn High Performance Wire Bonder [INPUT/OUTPUT [INPUT/OUTPUT]] MAG HANDLER GRIPPING SENSORS BLOCKED • Er Errror Recovery • Hold magazi magazine ne in gripper (if present) present) and initial initialize ize th the e MH MHS. S. Gripper Gripper axis must find home position before operation can be resumed. If error is repeated, check gripper sensor operation and replace sensor assemblies as needed. [INPUT/OUTPUT]] MAG HANDLER GRIPPING SENSOR STATES NOT SAME [INPUT/OUTPUT • Er Errror Recovery • Hold magazi magazine ne in gripper (if present) present) and initial initialize ize th the e MH MHS. S. Gripper Gripper axis must find home position before operation can be resumed. If error is repeated, check gripper sensor operation and replace sensor assemblies as needed. [INPUT/OUTPUT]] MAG HANDLER GRIP SENSOR BLOCKED [INPUT/OUTPUT • Er Errror Recovery • Initia Initialize lize the MHS. MHS. If error is repeated, repeated, check grip sensor operation operation and and replace sensor assembly as needed. MH FAILED TO UNLOAD MAGAZINE [INPUT/OUTPUT]] MAG HANDLER FAILED LOAD [INPUT/OUTPUT [INPUT/OUTPUT]] MAG HANDLER FAILED UNLOAD [INPUT/OUTPUT • Er Errror Recovery • Remove magazines magazines from from unload unload ttray ray at at the input or output output magazin magazine e handler (as indicated). Select CONTINUE to resume operation. [INPUT/OUTPUT] [INPUT/OUTPUT] MAG HANDLER FAILED TO LOAD MAGAZINE • Er Errror Recovery • Mak Make e sur sure e there there are are mag magazi azines nes o on n load load tray tray. Sel Select ect CONTINUE. Gripper will attempt to load magazine again. If it fails, check position of gripper when it tries to find the tray. If not good, perform tray calibration. If gripper actually has loaded magazine, then grip sensor is probably defective and should be replaced. TOO MUCH ROTATION FOUND WHEN TEACHING MAGAZINE • Er Errror Recovery • Select ABORT. Use magazine handler utilities menu (tool bar selection) to place magazine on unload tray t ray.. Move magazine to load tray and select option to move magazine to first slot position. Restart procedure to teach tea ch magazin magazine. e. TEACH OPERATION FAILED • Er Errror Recovery • Select ABORT. Restart procedure to teach magazine handler. 5-24 Maintenance 98888-0000-JB3-01 Material Handling System Manual MHS MOTOR DRIVER ERROR • Error Re Recovery • 5. 5.5. 5.2. 2.6 6 Fault reported reported in driver circui circuitt boar board d that operat operates es one of the steppe stepperr motors in the magazine handler or workholder. Make sure no MHS motor is stalled. If motors are good, then driver circuit board should be replaced. Refer to Section 4 for circuit board locations and replacement procedure. In Inje ject ctio ion, n, Inde Indexi xing ng,, and and Eje Eject ctio ion n Err Error ors s CARRIER X REGISTRATION EDGE NOT FOUND • Error Re Recovery • X–registratio X–registration n sensor sensor did did not not dete detect ct ca carrier rrier leading leading edge during injection. injection. Check: • X–registratio X–registration n sensor sensor while blocking blocking a and nd un unblocki blocking ng se sensor nsor element elements s in the rear rail. Make sure the sensor display (Diagnostic mode) indicates when the sensor is blocked. If not, check sensor electrical connections. If good, the sensor should be replaced. • Carrie Carrierr dimens dimensions ions and other other ind indexi exing ng p param aramete eters. rs. • Puller Puller op opera eratio tion n - make sure sure that that the puller puller ar arm m engages engages a hole hole in the boat and can pull the boat into the workholder input. DEVICE’S EYEPOINT NOT FOUND • Error Re Recovery • PRS coul could d not find find devi device ce ey eyepo epoint int afte afterr ind index. ex. Chec Check: k: • Diffuser Diffuser air air pressure. pressure. Increasing Increasing pressure pressure may enable PRS to find e eyeyepoint. • Mate Materi rial al cond condit itio ion n an and d type type.. • Device illumination illumination.. Make Make sure sure that that ther there e is a high high con contrast trast betwee between n bordering eyepoint features. Make sure that there is no variation in brightness with eyepoint features. Reteach eyepoint after any illumiination adjustment. Refer to eyepoint selection guide in IConn Operation Manual. CARRIER JAMMED DURING INDEX OR EJECTION • Error Re Recovery • Verify Verify tthat hat there there is actual actually ly a jammed jammed carrier in the workholder workholder or or at the the workholder output. If so, clear the jam manually and select CONTINUE. If this error is displayed often with no jammed carrier in the workholder, check: • Condition Condition of of the index overlo overload ad contact contact pins o on n the indexe indexer. r. Increased Increased resistance in the contact pin circuit caused by pin corrosion or contamination may cause false carrier jam signals • Operation Operation of the spring-l spring-loaded oaded bar that that electrical electrically ly co connect nnects s the conta contact ct pins. Except when there is a jam, the bar must be in contact with the pins. • • Electrical Electrical wiring wiring and connections connections from tthe he pins pins to the indexer indexer interface. interface. Any open circuit condition will signal an carrier jam. If actua actuall carrier carrier jam jams s occ occur ur fr freque equentl ntly y, che check: ck: • Rail parallelism parallelism - mak make e sur sure e that gap be between tween rails at output output e end nd of workholder is equal to gap at the input end. Refer to the rail alignment procedure in section 2 for more information. Maintenance 98888-0000-JB3-01 5-25 IConn High Performance Wire Bonder • Rail Heigh Heightt - perform perform rail rail height height adjustment. adjustment. Follow the displayed displayed instructions precisely when using the rail r ail height adjuster. • Carrier Carrier width width - make sure boat width width param parameter eter value value is ac accurate curate for device being processed. • Magazine Magazine di dimensio mensions ns an and d slot slot calibratio calibration n - ifif carriers carriers jam at at magazine magazine slot lead–ins or against sidewall, make sure Slot Pitch, Magazine Width, and Distance from Bottom parameter values are correct. If they are, perform an output slot calibration. • • Magazine Magazine po position sitioning ing - If leadframe leadframes s pass pass par partway tway into magazi magazine ne and then jam, make sure rear magazine wall is in contact with the three (3) magazine stop buttons on the gripper jaws. If not, eject and reload the magazine. Also, perform an output slot calibration and make sure that both wear plates in the lower gripper jaw contact the calibration gauge at the same time. If not, loosen four (4) SHCSs that secure the gripper to the Y axis casting and rotate the gripper until both wear plates are in contact with the gauge. If jam errors are indicate indicated d when when indexer indexer is be being ing dry dry cy cycled cled ((run run without without material), check: • Mechanical Mechanical interference interference - between between the the tuc tucker ker ar arm m or index pin a and nd an any y part of the workholder or output magazine handler. Make sure that the tucker blade is centered between the front workholder rail and the front boat support blade when the tucker arm is down. Make sure tucker blade is not bent or otherwise damaged. CLAMP VACUUM NOT PRESENT • Er Errror Recovery • Vacuum sensor (optional) (optional) has has detected detected low v vacuum acuum at bon bond d site after a device was clamped. Check: • Device defect. defect. Make Make sure sure underside underside of device device has n no o defect defect th that at pre pre-vents a good vacuum seal with the top surface of the heat block insert. • Heat block block conditi condition. on. Make Make sure top of heat b block lock iinsert nsert iis s clean clean so that device can seat properly on the insert. • V accum accumhoses. hoses hoses - make make sure that that there there are no b bloc locked ked,, crac cracked ked,, or kinked • False vacuum error indications. indications. Adjust vacuum sensor. sensor. (R (Refer efer to Section Sectio n 2 for vacuum sensor setup setup procedure). procedure). CARRIER CANNOT BE PULLED IN - ONE ALREADY PRESENT INDEXER AXIS LIMIT ERROR EMPTY INPUT MAGAZINE SLOT • Er Errror Recovery • No ca carrie rrierr was ffoun ound d in a magaz magazine ine sl slot ot wh when en an atte attempt mpt w was as mad made e to inject a carrier into the th e workholder. Select CONTINUE . If the error is repeated, use the Magazine Handler Utilities to load a new input magazine. 5-26 Maintenance 98888-0000-JB3-01 Material Handling System Manual WORKHOL WORKHOLDER DER DETECTED SLOT SENSOR BLOCKED • Erro rror Recove overy • Che Check ck whethe whetherr there there is a boat betwe between en the workh workhold older er and the the inpu inputt or output magazine. If so, move the boat into the magazine and select CONTINUE. If there is no boat under the slot sensor fiber optic, set up the input or output slot sensor amplifier (refer to Section 4 for procedure.) RAIL INDEX MOTION ERROR RAIL CORRECTION MOTION ERROR DEVICE CLAMPED IN WORKHOLDER • Erro rror Recove overy MHS MOTOR DRIVER ERROR • Erro rror Recove overy • Fault reported reported in driver circui circuitt boar board d that operate operates s one of the steppe stepperr motors in the magazine handler or workholder. Make sure no MHS motor is stalled. If motors are good, then driver circuit board should be replaced. Refer to Section 4 for circuit board locations and replacement procedure. 5.5 .5.2 .2.7 .7 Init Initia iallizat izatio ion n Er Error rors MHS INITIALIZATION FAILED • Erro rror Recove overy • Press [MOTOR STOP]. Select OK in the Standby Mode dialog box to restart the initialization. If the error is repeated, check: • Workholder Workholder and magazin magazine e han handler dler home sensors and workholder workholder rail jam sensors. Make sure there are no cuts in the insulation of the rail jam sensor wires that may allow a short to ground through the workholder. • Workholder Workholder and magazin magazine e hand handler ler m motion otion axes. Make sure there is no mechanical interference in any axis of motion. • Electrical Electrical connections connections at indexer indexer flex cable boards and at indexer interface board. Electrical connections at magazine handler wiring harnesses and interface board. • Oper Operati ation on of stepp stepper er motor motors. s. MH MAGAZINE WILL BE DROPPED • Erro rror Recove overy • Gra Grasp sp maga magazin zine e he held ld by the gri grippe pperr, then then se selec lectt CONTINUE. Gripper will release magazine. CLEAR MAGAZINE HANDLER TRAYS OF ANY MAGAZINES • Erro rror Recove overy • Remove allselect magazin magazines es from from. unl unload oad and and loa load d trays trays of the m magazin agazine e handlers, then CONTINUE Maintenance 98888-0000-JB3-01 5-27 IConn High Performance Wire Bonder MAGAZINE HANDLER SETUP ERROR • Er Errror Recovery • 5.5 .5.2 .2.8 .8 Perf Perform orm tray tray and s slot lot calib calibrat ration ions s for both both magazin magazine e hand handler lers. s. Pr Pro ogram ram Ex Exe ecu cuti tion on Err Error ors s UNDEFINED MHS COMMAND DISABLED OR ACTIVE MHS COMMAND RESOURCES FOR EXECUTION OF MHS COMMAND ARE UNAVAILABLE WORKHOLDER SOFTWARE RESET REQUEST CANNOT CREATE SEMAPHORE CANNOT OPEN CHANNEL MAGAZINE HANDLER SOFTWARE LOGIC ERROR MAGAZINE HANDLER SOFTWARE CREATION ERROR MAGAZINE HANDLER ERROR SENDING MESSAGE MAGAZINE HANDLER ERROR RECEIVING MESSAGE UNDEFINED LEADFRAME LOCKING STATUS UNDEFINED INDEX TYPE UNDEFINED INDEX STATUS UNDEFINED CORRECTION STATUS UNDEFINED INDEXING CYCLE UNDEFINED WORKHOLDER STATE UNDEFINED PULLER STATE UNDEFINED PULL TYPE REQUESTED JAM DETECTION CONTROLLER’S COMMAND FAILED JAM DETECTION CONTROLLER’S DIAGNOSTIC FAILED • Er Errror Recovery • If a pro progra gram m exe execut cution ion error error is is indica indicated ted,, always always se selec lectt CONTINUE or RECOVER in the dialog box. If the error is repeated, select ABORT and then perform an MHS initialization. If the error is repeated when operation is resumed, press [MOTOR STOP], then shut down and restart the machine. This will reload machine operating code. 5-28 Maintenance 98888-0000-JB3-01 Material Handling System Manual 5.6 5.6 MH MHS– S–Re Rela late ted d Bond Bondin ing g Prob Proble lems ms Some problems seen in the bonding process or in general machine operation may be caused by errors in operation, calibration, or setup of the MHS. Flow diagrams in the paragraphs that follow were prepared to help correct common MHS– related problems: • EYE POINT FIND FAILURES - See paragraph 5.6.1 • NON–STICK ON PAD ERRORS - See paragraph 5.6.2 • NON–STICK ON LEAD ERRORS - See paragraph 5.6.3 Maintenance 98888-0000-JB3-01 5-29 IConn High Performance Wire Bonder 5. 5.6. 6.1 1 Ey Eye eP Poi oint nt Fi Find nd Fa Fail ilur ures es Test bond several leadframes. leadfra mes. Observe START MHS operat ion. Inspect operation. leadfra leadframes. mes. PRS or optics problems? NO YES Leadframe clamping problem? Check optics focus. Adjust if necessary. Increase diffuser air pressure. Reteach eyepoint. Change lighting or eyepointt scene area. eyepoin Perform PRS Calibration. NO Problem corrected? YES YES Check device thickness. Enter correct thickness if incorrect. Check for vacuum at top of heat block. Check pneumatic system if no vacuum. Perform clamp calibration. NO DONE 5-30 Maintenance 98888-0000-JB3-01 Material Handling System Manual 5.6. 5.6.2 2 No Non– n–St Stic ick ko on n Pa Pad d (N (NSO SOP) P) E Err rror ors s NO START Transducer working Properly? YES Check Transducer cable service loop. Loosen cable any tighten cable. Device thickness correct? YES NO Bond plane height correctly calibrated? Enter correct value for device thickness parameter. parameter. YES NO Preheat and bond site temperature correct? Perform Transducer Alignment calibration to set bond plane height. Check Transducer and USG Board Adjust workholder rail height to OPTIMAL setting in relation to bond plane height. NO Check bond site and preheat temperature set points. Change set points if necessary. YES Correct clamp and heat block insert for L/F used? NO Verify that correct p-parts for L/F installed. Replace p-parts if incorrect. Check actual bond and preheat temperature. Enter Check if tie bar temperature as needed. offsets seated correctly If p-parts are replaced, teach MHS before continuing production. Problem corrected? YES NO There may be a bonder or material problem. Check bond parameters, device, and wire. YES DONE Maintenance 98888-0000-JB3-01 5-31 IConn High Performance Wire Bonder 5. 5.6. 6.3 3 No Non– n–St Stic ick k on Le Lead ad ((NS NSOL OL)) Er Erro rors rs NO START Transducer working Properly? YES Check Transdu Transducer cer cable service loop. Loosen cable any tighten cable. Device thickness correct? NO Enter correct value YES Bond plane height correctly calibrated? YES NO YES for device thickness parameter. Preheat and bond site temperature temperature correct? NO Perform Transducer Alignmentt calibration Alignmen to set bond plane height. Correct clamp and heat block insert for L/F used? NO Check Transducer and USG Board Adjust workholder rail height to OPTIMAL setting in relation to bond plane height. Verify that correct p-parts for L/F installed. installe d. Replace p-parts if incorrect. Check bond site and preheat temperature set points. Set correct set points if necessary necessary.. Check Lead finger vibration, if yes do clamp calibration. -- Adjust c lamp force offset Check Heat block perpendicular Check actual bond and preheat temperature. temperat ure. Enter temperatu temperature re offsets as needed needed.. Problem corrected? NO If p-parts are replaced, teach MHS before continuing production. There may be a bonder or material problem. problem. YES Check bond parame ters, device, and wire. YES DONE 5-32 Maintenance 98888-0000-JB3-01 Material Handling System Manual A Glos Glossar sary y of of Term Terms s & Abbr Abbrevi eviati ation ons s -AALIAS: Area or feature on a die or leadframe which may be mistaken by the PRS for a valid eye point. p oint. ALIGNMENT: Material alignment is the positioning of the material at the bondsite. This positioning may be accomplished by the use of the Pattern Recognition System or by the operator depending on the parameters and settings in the bond program. ALIGNMENT TOLERANCE: Maximum allowable deviation from the programmed distance between the two oper- ator points of a reference system. Valid only for 2-point reference systems. Suggested tolerance should be 10% of the smallest bond pad dimension. For outer leads, it should be referenced to the lead with tolerance and may be somewhat greater to allow for the potentially larger expansion. ALTERNATE EYE POINT: An eye point for an alternate reference. For example: if there are two possible vendors of a particular die that the manufacture uses where the two die are not identical, the program would call out an alternate reference system/eye point. See also "Backup Eye point". AXIS POSITION INDICATORS: X, Y and Z values at the upper right of the monitor screen. X and Y values of the crosshair are relative to the previously entered X-Y zero. Z refers to the bondhead height, again with reference to a previously entered zero location. -BBACKUP EYE POINT: Another eye point on the same die in a different different location. Its purpose is to give the vision system a second chance to find an eye point for alignment purposes. BITS: Bond Integrity Test System. Used to detect non-stick bonds at the die (NSOP), non-stick bonds at the leadframe, or short tails (SHTL) during auto bonding. BIMODAL: Only two primary brightness levels are present. BOND FORCE: The force applied to promote a good bond (capable of providing an electrical connection). It is the contact force, in grams, exerted on the wire during bonding. BOND HEIGHT: The height at which the bonding tool touches the work surface. BOND OFF: A process for forming a gold ball once the wire is loaded through the capillary (with a fraction of an inch extended beyond the capillary). Used when repairing a broken wire or replacing a wire spool. BOND POWER: The ultrasonic energy exerted by the USG during bond time. BOND PROGRAM: see Process Program. BOND TIME: The length of time that the USG is turned ON for each bond. This affects the strength of tthe he bond. If bond time is too low or too high, the bonds will be relatively weak. Experimentation using shear tests will reveal the optimum setting. BONDING: Bonding requires the calculation of bond locations based on the alignment data and the control of all the subsystems necessary to accomplish the bonding. BOOT/BOOTING: The initial activity of the machine after after a reset or power up to re-load the machine’s software and prepare it for processing. BUTTON: A button may be square, rectangular, or triangular in shape. When clicked on, it starts a process, brings up a dialog box, steps through a list of choices, increases/decreases a value, or opens an edit field. Glossary of Terms & Abbreviations 98888-0000-JB3-01 IConn High Performance Wire Bonder -CC/V: see Constant Velocity Value. th e machine CALIBRATION MODE: A mode of the machine that allows the operator to calibrate parameters of the to ensure valid measurements. For example: to set the distance between the tool and the optics (crosshair offset),find limits, set the pixels to pulse ratio in the PRS. CAMERA IMAGE: The window that displays the image from the camera on the machine’s screen. CAMERA LINEARITY: Alignment of the video camera CCD image element with the machine axes of motion. This is accomplished by rotating the camera body. CHESSING: Moving the work table (in the X and Y directions) corresponding to manual controls by using the mouse and mouse button [B2]. Holding the Arrow button down will cause the auto repeat function to take effect and the image will move at a continuous rate. Chessing only applies to the graphics and video image window. There are three forms of chessing available to the operator: • JUMPING - Position the cursor at the desired location and press B2. • DRAGGING - Press and hold B2 then drag the image. • INCHING - Use the cursor keys on the keyboard to move a single pixel at a time (depending upon the zoom factor). COMPONENT FILES: The other files used with the Process Program File to create a process program. The process program file has the .BND extension and may have a filename of up to 80 characters. A component file has a REF., .PRM, OPR, .CHG, .CHG, .WIR, .PDL, or a .EYE extension and may have a filename of up to 40 characters. CONFIGURE MODE: A mode of the machine that allows the operator to configure or style the machine to meet the factory’s needs. work surface after TIP and, CONSTANT VELOCITY VALUE (C/V): The speed of the capillary descending to the work therefore, the constant velocity of the capillary against the work. If set too high, bonds may be squashed. If set too low, low, the operating times may be unacceptably high. Value is expressed in microns/msec or mmps. CROSSHAIR: On-screen horizontal and vertical cross image which are used with tthe he X, Y Y,, and Z directional buttons to locate eye points, operator points, etc. for the process program. The large yellow crosshair appears initially in the center of the graphics and the video image windows. The two windows and their crosshair are handled slightly differently. The crosshair on the video image window is always centered. Selecting a new position causes the video image to shift and the crosshair is automatically recentered. Hence, it is possible to "work your way" across the bond site. The graphics image crosshair can be moved to any position in the graphics window and depending upon the zoom factor this may include the entire work area or only a very small portion of it. Manipulation of either window will cause an appropriate change in the other window. CROSSHAIR OFFSET: A taught distance which compensates for the fact that the objective lens and the capil- lary are not in line above a device. This adjustment is necessary when the crosshair crossh air is being used to represent the location of the bond tool over the device. CURSOR: The on-screen "+" used to point to and click on menus, menu items, and buttons and to grab and adjust slide bars. A-1 A-2 Glossary of Terms & Abbreviations 98888-0000-JB3-01 Material Handling System Manual -DDE-SELECT:To close or turn off a menu, menu item, function, or state by positioning the cursor on top of the desired item and clicking the B1 (left) mouse button. If a state is de-selected, the highlighting will be turned off to show that the state is no longer active. DEFAULT BUTTON: A square button with a “D” in the center of it. Clicking on this button will set a parameter value to its pre-determined default value. DEFAULT BUTTON DIALOG BOX:A window that appears temporarily to request information or to allow adjustment or selection of settings/parameters. without moving the cursor cursor.. DOUBLE-CLICK: To rapidly press and release the mouse button [B1] twice without DRAG: To move an item on the screen by first positioning the cursor over the item and then pressing and holding the mouse button [B1] while manipulating the mouse to move the cursor. DRY CYCLE: Cycle the MHS workholder with or without material present in the workholder workholder,, without bonding wire. -EEFO: see Electronic Flame-Off. EFO GAP: The vertical distance between the EFO electrode and the tip of the wire on the capillary when the bond head is at its reset position. EFO OPEN: Refers to an error condition that occurs when the wire tail is too short or no wire is at the tip of the capillary or the EFO Gap is too great. EFO TIME: The time that the EFO is turned on. EJECT: This refers to the activity of transferring materials from one mechanical sub-system to another. For example: eject a leadframe refers to the process of moving a leadframe from the output side of the workholder to the output magazine in the output elevator. To eject a magazine means to move it from the elevator to the output platform. ELECTRONIC FLAME-OFF: The hardware that produces the electronic spark to m make ake the gold ball form at the end of the wire exposed at the tip of the capillary. ENTER: Using the MMI keypad or the keyboard to enter and edit information. EYE POINT: A human and machine identifiable feature of the material. The number of o f eye points and their location can be specified in process program. This reference point is learned by the PRS during the teach sequence. For each reference system, the number of eye points must equal the number of operator points. Die eye points make use of the fine detail typically found on die reference systems. Lead eye point looks for long straight edges such as those normally found in an outer lead reference system. EXCEPTION: Failure, fault, or unusual occurrence. Glossary of Terms & Abbreviations 98888-0000-JB3-01 IConn High Performance Wire Bonder -FFACTORY AUTOMATION SERVER/SYSTEM: A computer which can supervise the wire bonder through a commu- nications link using the SEMI SECS protocol. FAS: Factory Automation Server/System. FORCE: see Bond Force. screen. These buttons are FUNCTION BUTTONS: Two rows each containing 10 buttons at the bottom of the screen. used to begin or end an action. The function associated with a button may change when certain types of operations are performed. FUNCTION KEYS: The row of 10 keys at the top of the keypad located on the MMI. These keys perform the same functions as the bottom row of Function buttons. The function associated with a key may change when certain types of operations are performed. -GGUI: An abbreviation for the term Graphical User Interface. -HHOST: A remote computer that can gather or issue process information from/to fr om/to the machine, select pro- cess programs for the equipment, and control the machine. HOST INTERFACE: A technique to exchange information between a host computer and the machine. The host computer may also exert control over the machine using this interface. HOT KEY: The numeric character associated with an item in a menu or dialog box. When working in menus or dialog boxes, pressing the item’s Hot Key selects the that item. By selecting the item, a data entry field may open, an operation may be performed or another menu or dialog box may appear. HOT KEY -IIC: A device with two reference systems: the outer leads or substrate and the die. ICON: A symbol that represents a window or action/s. INDEXING: Indexing moves new material into position for bonding. Indexing may occur after an entire unit has been processed or after a partial unit has been processed. The index may present an entirely new unit to the bond location or a new part of the same unit. INJECT: Generally this term refers to leadframes and usually means a leadframe will be moved from the input magazine into the workholder. A-3 -JJ WIRE: A Kulicke and Soffa technique to lay designed bent w wires. ires. This technique puts a J-shape into the bonding wire by using a parameter called lateral motion. JOG: A term to indicate a vertical index of a mag handler’s handler ’s gripper assembly. assembly. A-4 Glossary of Terms & Abbreviations 98888-0000-JB3-01 Material Handling System Manual -KKEYBOARD:A QWERTY keyboard (keypad) located on the MMI (see MMI). KINK HEIGHT:The vertical distance between the first bond and the position above the first bond where the XY table starts the Reverse Motion. -LL/F: LeadFrame. LEADFRAME:Carrier for IC devices incorporating metal leads to which wires from IC bond pads are attached LIGHT TOWER:A post on which a number of signal lights are mounted to indicate the machine’s state (Motors stopped, operating automatically, error, etc.). LINEARITY: Camera rotation. See Camera Linearity. LOT: A grouping of materials for tracking purposes. LOT ID: A name or number associated with a lot for identification purposes. LOT TRACKING:A technique to monitor the process and collect data for historical purposes. LOW LOOPING:The Kulicke and Soffa process for making very low wire loops. LOWER CONSOLE:The machine’s main card rack, electronics(cards), power supplies, amps for the servos and LTOL: steppers, the disk drives, the chassis, and the fans. An abbreviation for the term “line tolerance”. Line tolerance is used to ensure that the placement of operator points and eye points are valid. -MM/C: Machine. parameter. MACHINE DEPENDENT PARAMETER: A bonder or machine specific parameter. MAN MACHINE INTERFACE (MMI): Means through which the machine operator communicates with the control system. Operator controls via the mouse, buttons, function keys, and keypad on the lower console. MANUAL: Depending upon context this term may refer to the Manual Mode of the machine’s machine’s operation or indicate human intervention is required to complete a process. MANUAL MODE: A machine mode that allows the operator to bond wires in a manual fashion. That is, desig- nate the location of bond sites and lay a single wire. MATERIAL HANDLING SYSTEM: The Material Handling System consists of the electronics, mechanics, and controlling software that is used to move material through the machine. The Material Handling System may be considered as part of the process if the heating elements are controlled by the Material Handling System. MATRIX: An array of chips, devices or device groups that are arranged in columns and rows. MBD: Missing Ball Detector. MDP: see Machine Dependent Parameter MENU: A list of available commands in a window. window. Menu titles may appear in the banner at the top of the window. The illustration shows the MANUAL mode menu. window. The illustration shows the MANUAL mode menu. MODE BAR MENU MHS: see Material Handling System. Glossary of Terms & Abbreviations 98888-0000-JB3-01 IConn High Performance Wire Bonder MMI: see Man Machine Interface. MODE: A logical grouping of related tasks or functions usually accessed by selecting the “mode” of operation in a dialog box or menu (e.g., “Add” mode when teaching operator points). This term could also be used to refer to an operating state of the machine such su ch as Auto mode, Manual mode, Program mode, etc. MODE BAR: The horizontal bar that contains the names of the program’s major sections or modes. The mode bar is at the top of the display screen. The illustration above shows the leftmost modes in the mode bar. MANUAL mode is the active mode MOTORIZED WIRE SPOOL: Activated by a sensor indicating the wire loop is getting taunt and deactivated by a sensor indicating the wire loop is getting slack. MOUSE: Input device with three buttons and a ball used to position an on-screen cursor and make selections or adjustments (see illustration). MOUSE BUTTONS: The three mouse buttons are located on the mouse and are referred to as B1, B2, and B3 on the screen. The function of each button changes depending on the operations being performed on the screen. Refer to the screen for the current button functions. Some of the possible functions for the three buttons are listed below. Mouse Buttons B1, B2, B3 Mouse • B1 = Left Left Button: Button: Select, Select, Add/Lea Add/Learn, rn, Uns Unsele elect, ct, Nex Next, t, Step • B2 = Cent Center er Butt Button on:: Ches Chess s • B3 = Right Button: Delete, Unselect, Unselect, Auto Learn, Relearn, Relearn, Assign, Assign, Disass Disassociociate, Reverse MTBA: Mean Time Between Assists. Average length of time between bonder-detected errors. MTBF: Mean Time Between Failures. Average length of time between events that require actual repair by a technician. MTTA: Mean Time To To Assist. Average amount of time to fix a bonder program. MTTR: Mean Time To To Repair. Average amount of time needed for a technician to complete the repair. MWS: see Motorized Wire Spool substr ate and one for each MULTI-CHIP: A device with more than 2 reference systems: one for outer leads or substrate die on the device. -NNSOL: No Stick on Lead. BITS error message indicating wedge is lifted from the second bond. A-5 No Stick on Pad. BITS error message indicating ball is lifted from the first bond. NSOP: -OON-LINE HELP:A window is displayed containing text that explains an indicated object for the machine opera- tor. Note: once On-line Help is activated other topics are available for review. ON-LINE PROCEDURE: A window with information for the machine operator that gives step by step instructions for some procedure to be performed on the machine. For example: threading the wire. To display the contents of a file in a window or to enlarge an icon to a window. OPEN: A-6 Glossary of Terms & Abbreviations 98888-0000-JB3-01 Material Handling System Manual OPERATOR POINT: A location on the die or outer lead that a machine operator can identify to ensure the device is properly aligned. This reference point is taught by the operator. Used if the PRS fails. Must be targeted before device can be bonded. Preferred location is on bond pad or streets. OPTICS OFFSET:The displacement between the center of the optical path and the bonding tool. -PPAD FIND: This function uses the PRS to automatically center first bonds on bond pads. Vision System. This term usually refers to the electronics PATTERN RECOGNITION SYSTEM (PRS): A part of the Vision and software that actually recognize patterns at the work site for alignment purposes. The PRS allows the bonder to operate without attention by automatically finding eye points before each device is bonded. Compensates for variations in die location from package package to package. PERFORMANCE LOGGING: Refers to statistical information that can be automatically gathered by the machine and includes such information as MTBA, MTTA, MTBF, MTBF, MTTR, and Utilization time. PFR: see Power Failure Recovery. PIXEL: The smallest graphic unit that can be displayed on the screen, usually a single dot. POINT: Moving the cursor to a specific area on the screen. POWER FAILURE RECOVERY: This routine provides resumption of automatic operation after power failure. PREHEAT: Heating the device before it reaches the bond station. PROCESS PROGRAM (PP): Made up of re-usable modules of ASCII text that can be read, modified, saved, and restored. These modules contain the instructions and p parametric arametric information that the machine will need to process materials. PROCESS PROGRAM FILE:Main file of a process program. Component Files are the other files used with this file to create a process program. The process program file has the .BND extension and may have a filename of up to 80 characters. PROCESS STATISTICS STATISTICS::Refers to information automatically gathered by the machine while the equipment is automatically bonding. Included in this set of statistics would be: number of devices bonded, and number of bonds since capillary was replaced. pr ogram. PROGRAM MODE:A mode that allows the operator to load, edit or teach a process program. PROMPT: A program initiated statement which indicates an operator action is needed. Prompts are normally located in dialog boxes or in the monitor screen’s information boxes, below the Mode bar. PRS: see Pattern Recognition System. PRS CALIBRATION:A procedure to establish the relationship between the vision systems pixels and the machines motion pulses particularly to ensure orthogonality between the two systems. -Q-RRADIO BUTTON:A diamond shaped button. Radio buttons are grouped in sets of two or more. Only one radio button per set can be active at a time. As shown in the example, “Normal Index” is selected. RADIO BUTTONS Glossary of Terms & Abbreviations 98888-0000-JB3-01 IConn High Performance Wire Bonder REFERENCE SYSTEMS:A reference system is a logical grouping of bond sites, typically all the bond sites of a particular object in the work area, always of the same height. Examples of ref reference erence systems are: • al alll tthe he bo bond nd site sites s on on a di die e • all the bond sit sites es on on the the outer outer lead lead (le (lead ad shelf shelf)) The goal of the reference system technique is to allow the mixing and matching of die and outer lead without the necessity of re-teaching. A complete process program would contain the definition of all of the reference systems in the work area in addition to instructions regarding r egarding the wiring of the device. REFERENCE SYSTEM ORIGIN: The origin (0,0) of an instance of a reference system. typically,, when ball bonding, the first REVERSE BONDING: Refers to the reverse sequence of bonding. Where typically (ball) bond is on the die and the second (wedge) bond is on the lead. In reverse bonding the first bond is on the lead and the second bond is on the die pad. REVERSE MOTION: The reverse motion causes the XY table to move a defined distance in the reverse direc- tion (away from the second bond) after the bond head has risen to a preset height (Kink Height) while still above the first bond to achieve a unique wire shape. -SS ING: This term refers to unintentionally curved wires. When viewed from the overhead position these wires take on a slight “S” shape. SCAN CORRIDOR: The area and direction that the VLL will scan when searching for the lead. SCREEN: The display area of the monitor. SCROLL BAR: A horizontal or vertical bar within a dialog box containing a center button which can be moved to show additional text or choices. SELECT: To choose or turn on a menu, menu item, function, or state by positioning the cursor on top t op of the desired item and clicking mouse button B1. If a state is selected, the selection will be highlighted to show that it is active. Items in dialog boxes and menus may also be selected by pressing the item’s “Hot Key” if a number is to the left of the item. SEQUENCE STOP MODE: A mode the machine enters when the operator presses the sequence Stop Button while the machine is in automatic mode. Its effect is to pause the action at the earliest safe place in the process. For example: at the end of a wire or at the end of an index. While in Sequence Stop mode the operator may operate the machine as if it were in Manual Manu al mode. While generally it is assumed the operator will release the sequence stop button and continue processing materiSHTL: als, it is possible to escape automatic operation entirely from this mode of the machine Short Tail. Tail. BITS error message indicating that the wire tail formed after the second bon bond d is too short. SITE: Depending on context it can mean a bonding site (a die pad or lead bonding site), a die, a die and outer lead, device group, or all the area accessible by the bond head. SKIP: An index where the materials that will be moved away from the work site have not been processed. SLIDE BAR: A horizontal or vertical bar with a center button used to make sliding adjustments to a setting such as illumination or focus. As shown, the illuminators can be increased by moving the center button to the right or decreased by moving it to the left. A-7 SLIDE BAR SOIC: Small Outline IC. SPC: see Statistical Process Control. A-8 Glossary of Terms & Abbreviations 98888-0000-JB3-01 Material Handling System Manual STANDBY: This mode is entered by pressing the [Motor Stop] control button on the MMI. In Standby mode, power to the electric motors and solenoids is interrupted. STATISTICAL PROCESS CONTROL: A technique to improve manufacturing yield by gathering and analyzing data, and then altering the process while in progress to improve or keep the product consistent. STEP AND REPEAT: A machine feature to process a number of identical devices (device groups) without an index. For example, if several identical die are in the same work site instead of teaching each die individually the operator would teach the process once and then teach only the locations of successive die. SWAP: To move the images in the screen’s display windows so that they change place (swap). The image in the large window moves to the small window and the image in the small window moves to the large window. Initiated by the pressing F1 function key. -T--T [TAB]: A key used to move from one edit field or selection to the next. TABLE MAPPING:A method of correcting any precision errors in the XY table positioning. TABLE ORIGIN:The absolute origin (0,0) of the table. Reference System Origins are located within with in (mapped on top of) this reference system. TAIL LENGTH:Tail length is the length of the wire “tail” left hanging below the capillary after the second bond is TIP: made. This parameter effects the size of the ball that will be formed by the EFO. see Tool Inflection Point. ( or constant) velocity. TIP HEIGHT: The height above the work surface to start search (or TOL CORRECTION: Top of Loop correction equalizes wire payout and adjusts trajectory during part of the cycle to help loop height consistency in some applications. TOOL INFLECTION POINT: The distance above the bond surface at which the speed of the descending capillary changes from controlled deceleration to constant velocity. velocity. TIPs are learned for all wires. Subtracting the programmed TIP offset value from the learned bonding height gives the TIP offset. TRANSDUCER:A device that converts electrical into vibration energy to weld the wire. -Utransduce r as part of the bonding ULTRASONICS GENERATOR: The mechanics and electronics that vibrate the transducer process. monitor, man machine interface, keyboard, light tower tower,, UPPER CONSOLE: Bonder subassemblies including: monitor, audio alarm, wire feed, pneumatic controls and cabling. UPH: UNITS PER HOUR. HOUR. The number of units bonded per hour. UPS: Uninterruptible Power Supply S upply.. USG: see Ultrasonics Generator. UTILITIES MODE: A mode of the machine that allows the operator to make adjustments that are typically not related to the process. For example: copying disks, deleting files, etc. -V--V VIDEO LEAD LOCATOR: Finds exact taught location of bond positions on the outer leads to each device to ensure accurate placement. Maintains information about position, angle, width, and illumination levels. Notifies bonder of any lead displacements to ensure correct bond placement. Takes video image directly from the monitor. VISION SYSTEM: There are two aspects of the vision system: the optics and the electronics. The Vision Sys- tem provides information for the proper alignment of die bond sites and leads within the work site. VLL: see Video Lead Locator. Vision ision System from one position of VLL ASSOCIATION: A contiguous group of leads that can be viewed by the V the table. 98888-0000-JB3-01 Glossary of Terms & Abbreviations IConn High Performance Wire Bonder -WW/C: Wire clamp. W/H: Workholder. WIRE FEED: A system for taking wire from a wire spool and delivering it to the bonding tool. A wire feed mech- anism including: mechanics, electronics, sensors, and controlling software. WIRE GROUP:A group of wires that reside in the same reference system that have the same bond parameters applied to them. WIRE PATH: The mechanics including: possibly compressed air, supports, etc. that is the bonding wire’s route from the spool to the capillary. WIRE SAG: Refers to a wire whose loop tends to dip down u unintentionally nintentionally.. -XX AXIS: The side to side motion of the bond head (see XY table). X-Y ZERO: Primary alignment point for a package. Used as point from which all other X and Y coordinates are calculated. Suggested location is at bottom left-hand corner of package on a lead. XY TABLE: A positioning system for moving a load (a bond head in the case of wire bonders) in XY X Y (horizontal) space. -Y--Y Y AXIS: The front to back motion of the bond head (see XY table). YIELD: The percentage of good bonded devices processed by the machine vs. the number of unbonded devices that enter the machine. -ZZ APEX: The highest point achieved by the Z axis between bonds of a single wire. Z AXIS: The up and down motion of the bond head. A-9 A-10 Glossary of Terms & Abbreviations 98888-0000-JB3-01 Material Handling System Manual B ICon IConn n J Boat Boat Wire Wire Bond Bonder er MHS MHS Wir Wirin ing g Di Diagr agram ams s See below for IConn J Boat MHS Wiring Diagram. 98888-0000-JB3-01 IConn J Boat Wire Bonder MHS Wiring Diagrams IConn High Performance Wire Bonder This pa pagg e is le left ft inte intentiona ntionall llyy bla blank nk B-1 B-2 IConn J Boat Wire Bonder MHS Wiring Diagrams 98888-0000-JB3-01 Material Handling System Manual Index A Abbreviations A-1 Adjust Puller Gripper Jaw Gap 2-15 B Belt Tension Setup, Magazine Magazine Tray 3-13, 3-15 Bond Site/Preheat Heat Heat Block Assembly Replacement Bond Site Heat Block Block Assembly 2-80 Bond Site Heater Assembly 2-76 Bond Site Motor Motor 2-85 Bond Site Thermocouple Assembly 2-78 Compression Spring 2-71 Preheat Heat Block Assembly 2-79 Preheat Heater Assembly 2-73 Preheat Prehe at Linear Slide Assembly 2-86 Preheat Motor 2-8 2-82 2 Preheat Thermocouple Thermocouple Assembly 2-75 C Cable Assemblies 4-35 Calibration Access to Software Software Options 1-12 General Descriptions 1-12 Workholder 2-40 Clamp 2-44, 2-50 Heat Block 2-51 Tucker Eject 2-52 Workholderr Calibrations 2-53 Workholde Circuit Boards Descriptions 4-8 Indexer Interface Board 4-18 Indexer Intermediate Board 4-21 Locations 4-8 Replace Card Rack Circuit Cards 4-23 Replace Indexer Interface 4-26 Replace Input/Output Interface 4-24 4-24 Roller Jam Detect Board Board 4-20 Stepper Controller 4-14 Clamp Calibration 2-44, 2-50 Clear Leadframes from Workholder 1-20 Signal Light 1-9 Video & Graphics Graphics Display 1-10 Video Monitor 1-9 D Declaration of of Exemption S-22 Descriptions Carrier Injection 2-9 Device Indexing 1-5 General 1-3 Magazine Handlers 1-5 Workholder 1-4 Dictionary A-1 E Electronics 4-1 Cable Assemblies 4-35 MHS Sensors 4-28 Overview Overv iew 4-2 Sensor Handling Handling 4-5 Stepper Stepp er Drive 4-4 System Diagram Diagram 4-3 System Organization Organization 4-2 Replace Circuit Boards Replace Indexer Intermediate Board 4-26 Replacing the Input/Output Magazine Handler Intermediate Board 4-24 Replace DMHS Card Rack Circuit Boards 4-23 Subsystem/Board Description 4-8 Circuit Board Locations 4-8 DMHS Hex Half Stepper Driver Circuit Boards 4-15 DMHS Indexer/Solenoid Driver Board 4-14 DMHS Micro/Tri Half Stepper Driver Board 4-18 DMHS Stepper Controller Board 4-17 Indexer Intermediate Board 4-21 Interconnect Boards 4-22 Magazine Handler Intermediate Board 4-20 Emergency Off Switch S-8 Other Safety Features S-9 Configuration Boat/Device Dimensions Boat Dimensions 2-55 Bond Plane Offset 2-57 Overview S-8 Specifications S-8 Testing Operation S-8 Equipment-Specific Warnings S-2 Device Dimensions 2-56 Configuration, MHS 2-54 Controls/Indicators 1-6 Alarm, Audible 1-9 Control Panel Panel 1-6, 1-8 Emergency Eme rgency Off 1-6 Locations 1-7 98888-0000-JB3-01 F Fire Safety S-7 Fire Suppression S-7 Maintenance S-7 Index INDEX-1 IConn High Performance Wire Bonder G General Precautions S-3 Glossary A-1 Grippers MHS utilities 5-18, 5-19 H Heat Block Vacuum Sensor Adjustment 2-38 Heated Material and Equipment S-6 Servicing Heated Equipment S-6 User Responsibilities S-6 I Identification Label Descriptions S-18 EFO Box Odering Notice Label S-18 Equipment Identification Label S-18 Index/Tucker Parts Index Arm andReplacement Pin 2-95 Tucker 2-98 Tucker Solenoid 2-99 Indexer Flex Cable Assembly Replacement Gripper Flex Cable Assembly 2-113 Puller Flex Cable Assembly 2-111 Indexer Intermediate Board 4-21 Indexer Pin/Tucker Eject Setup Indexer Pin Setup Sequence 2-20 Tucker Eject Setup Sequence 2-22 Initial Start-Up 1-18 Introduction S-1 Descriptions 1-3 General Information 1-1 Operating Procedures 1-18 Operator Controls 1-6 Product Conversion 1-22 Software Functions 1-12 Specifications 1-6 L Leadframe Present Sensor Setup 4-34 Load/Unload Magazines 1-20 Calibration 3-7 Input/Output Slot 3-9 Input/Output Tray 3-7 Components 3-2 Description 3-2 Magazine Handler Adjustments 3-13 Magazine Handler Configuration 3-13 Positions 3-3 Removal and Installation 3-15 Input Magazine Handler 3-15 Output Magazine Handler 3-21 Setup 3-6 Maintenance 5-1 MHS Errors 5-21 MHS-Related Bonding Problems 5-30 Preventive Maintenance Schedule 5-2 Special Tools and Gauges 5-5 Troubleshooting 5-5 Manual Mode Utilities 5-16 MHS Utilities 5-14 Motor Diagnostics 5-5 Re-Initialize MHS 5-10 Sensor Diagnostics 5-10 MHS Errors 5-21 Error and Status Messages 5-22 Error Indications 5-21 MHS Information in other Manuals 1-2 MHS Manual Contents 1-1 MHS Manual Mode Utilities Clamp Utilities 5-18 Gripper Utilities 5-18 Index Utilities 5-16 Pin Utilities 5-19 MHS Manual Scope 1-1 MHS-Related Bonding Problems 5-30 Eye Point Find Failures 5-31 Non-Stick on Lead (NSOL) 5-33 Non-Stick on Pad (NSOP) 5-32 Microscope Use S-6 O Operating Procedures 1-18 Bonder/Workholder System Shutdown 1-21 Clear Leadframes from Workholder 1-20 Initial Start-Up 1-18 Load/Unload Magazines 1-20 M Remove Magazines from Magazine Handlers 1-20 Stop Auto Bonding 1-20 Options Heat Block Vacuum Sensor Adjustment 2-38 Machine Emissions S-9 Gases,Vapor,Dust S-9 Ionizing and Non-Ionizing Radiation S-9 Noise S-9 Vibration S-9 Magazine Handler Adjustments Belt Tension Setup 3-13 Tray Adjustment 3-15 Magazine Handlers 3-1 INDEX-2 P Parts Replacement 2-71 Control System Card Rack Circuit Boards 4-23 Index 98888-0000-JB3-01 Material Handling System Manual Indexer Interface 4-26 Input/Output Input/Outp ut In Intterfac erface 4-24 Workholder 2-7 2-71 1 Bond Site/Preheat Heat Block Block Assembly 2-71 Index/Tucker 2-95 Workholder Sensor Locations 4-29 Servicing Electrical Electrical Equipment S-4 Lockout/Tagout Lockou t/Tagout Procedure S-5 Servicing Servici ng the Power Supply S-5 Types of Electrical Electrical Hazards S-4 Indexer Flax Cable Assembly 2-111 Puller 2-88 Rails 2-101 Replace Heat Block Vacuum Solenoid Valve 2-116 Sensor Sensor Assemblies 2-106 Preventive Maintenance Schedule 5-2 Workholder 2-69 Product Conversion 1-22 Conversion Sequence Sequence 1-22 Enter/Edit MHS Parameters 1-24 Load Process Program 1-24 MHS Operation Check 1-25 Replace Clamp/Heat Block Inserts 1-23 Required Requi red Tools/Parts 1-23 Puller Parts Replacement Replacement Puller Finger Finger 2-88 Puller Motor 2-90 2-90 Puller Rack 2-89 Puller Solenoid 2-93 Puller Pin Setup Puller Pin Setup Sequence 2-16 Shutdown and Start-up Start-up Procedures S-23 Shutdown Procedure S-23 Start-up Procedure S-23 Shutdown Bonder/MHS 1-21 Software Functions Functions 1-12 Auto Run Configuration 1-16 Calibration 1-12 MHS Configuration 1-12 MHS Diagnostics 1-17 MHS Magazine Utilities 1-14 MHS Utilities Utilities 1-13 MHS Workholder Utilities 1-15 Specifications Carrier Dimensions 1-6 1-6 Magazine Dimensions Dimensions 1-6 Other 1-6 Stop Auto Bonding 1-20 Symbols and Messages S-1 Caution S-1 Note S-1 Warning Warni ng S-1 T R Rail Calibration 2-40 Rail Parts Replacement Indexer Index er Motor 2-101 Leadscrew Bearing 2-105 X Axis Leadscrew Assembly 2-103 Record of Changes S-2 Remove Magazines from Magazine Handlers 1-20 Remove/Install Input Magazine Handler 3-15 Remove/Install Workholder 2-61 Roller Jam Detect Board 4-20 S Safe Handling Heated Material and Equipment S-6 Terms and Conventions S-1 Tools and Fixtures 5-5 Trained Operators and Service Technicians S-4 Troubleshooting 5-5 Error Indications 5-21 Error Messages 5-22 Initialize MHS 5-10 Maintenance Diagnostics 5-10 MHS Manual Mode Utilities 5-16 MHS Related Bonding Problems 5-30 MHS Toolbar Utility Menus 5-14 MHS Workholder and Motor Cycling Diagnostics 5-5 Temperature Controller Diagnostics 5-8 U Use of This Manual S-1 Safety 1-2 Sensor Assemblies Replacement J Boat Present Sensor Amplifier 2-109 Optical Switch Assemblies Assemblies 2-107 X Registration Sensor 2-106 Sensors 4-28 Magazine Handler Sensor Locations 4-30 Reflective Sensor Setup 4-33 Leadframe Present Sensor 4-34 Sensor Sens or Types 4-28 Status Display 4-34 98888-0000-JB3-01 V Video & Graphics Display 1-10 W Warning and Safety Labels S-10 Berylium Product Warning S-16 Burn Hazard Warning S-14 Index INDEX-3 IConn High Performance Wire Bonder Disconnect Power Label S-15 Electrical Hazard Warning S-15 Emergency Off S-14 Equipment Grounding IEC S-16 General Hazard Warning S-15 Hard Stop Caution S-17 Operator ESD Connection S-16 Pinch Point Hazard Warning S-14 Workholder 2-1 Boat Indexing and Ejection Sequence 2-11 Boat Injection Sequence 2-9 Boat Transfer Sequence 2-11 Calibration 2-40 Heat Block Calibration 2-51 Workholder 2-40 Workholder Calibration 2-53 Components 2-2 Configuration 2-54 Boat/Device Dimensions 2-55 Indexing Options 2-59 Indexing Parameters 2-57 Workholder Configuration 2-59 General Description 2-2 J Boat Indexer Assembly Removal and Installation 2-61 J Boat Slider Assembly Removal and Installation 2-66 Preventive Maintenance 2-69 Setup & Adjustments 2-13 Preheat Heat Block/Bond Site Alignment 2-32 Puller Rack Backlash Adjustment 2-36 Subsystems 2-5 Bond Site Heat Block Assembly 2-7 Front/Rear Rail Assemblies 2-6 Index/Tucker Assembly 2-7 Indexer Intermediate Board 2-8 J Boat MHS Pneumatic System 2-8 Preheat Heat Block Assembly 2-6 Puller Assembly 2-5 Workholder Calibrations 2-53 Workholder Setup & Adjustments 2-13 Bond Site Heat Block Alignment 2-24 Heat Block Vacuum Sensor Setup 2-38 Index Pin/Tucker Eject Setup 2-20 Puller Pin Setup 2-15 Rail Parallelism Adjustment 2-27 Setup Sequence 2-13 Workholder Gauge 2-15