lOMoARcPSD|3535879

Basic- Machine- Design- Situational- Problem-BY- Alcorcon-1

Mechanical Engineering (University of Rizal System)

StuDocu is not sponsored or endorsed by any college or university

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

lOMoARcPSD|3535879

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

lOMoARcPSD|3535879

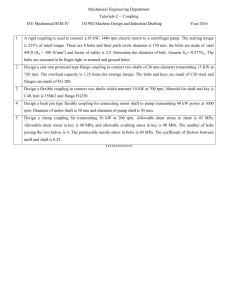

Table of Contents

P.A.R.T •

MACHINE DESIGN SHORT PROBLEMS

I would like to dedicate this work to:

My wife gemma Rosa!5lIcorcon

To our children,

Jolin Cristophet and 5?l[e~andr

For their support

.

1. Strength of Materials

1

2. Mechanics

20

3. Machine Shop

40

4. Machine Elements

53

5. Stresses

58

. 6. Shaft

88

7. Keys

119

8. Coupling

130

9. Pressure Vessel

136

10. Bolts and Power Screw

149

11. Flywheel

162

12. Spring

172

13. Gears

187

14. Bearing

211

15. Belts

219

16. Brake

227

17. Clutch

231

18. Machineries

239

P.A R."'T'" ••

SITllATIONAL PROBLEMS

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

274

lOMoARcPSD|3535879

Strength 0/ MClteriaLs ~ Beams

1

STRENGTH C)F

IIVIA.TE R:J:A.LS

~

PARTl

S;;HO!RT

PRO:BLEM1S

... ~

..

.•... ..

..

' . . . ..

..

...•

'0'

.. ,

",

"" CANTILEVER BEAMS

1. Couple

~

With Fo;rmulas

a

~

Maximum Shear =

Maximum Moment = Mo

8 = maximum slope

~

~

~

~

L

M

e= M L

EI

Y = maximum deflection

~

M L2

y= 2Et

2. Concentrated load at free end

~

~

~ e= 2EI

v

~

>

t

P

P L3

3E I

3. Concentrated load at the mid­span

~

Shear = P

~

Moment =. -~.

PL

2

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

~

*-pL

lOMoARcPSD|3535879

51 reTlCjth

2

~e=PL2

or Materials ­ Beams

St r enqt l i

or Materials ­ Hewns

P L3

3

~

v> 48E I

8El

2. Uniform load

5P L3

~

y= 48E:1

~ Shear « wL

2

~

4. Uniform distributed load

Moment= w ~

wL

8

3

~ e:;; 24Et

~

4

~Y:; 384El

~

5wL

3. Varying load

~

5. Uniformly varying load

wL

~

2

Moment

~

L

~

~.

RESTRAINED BEAMS

~

1. Concentrated load at mid­span.

~

c SIMPLY SUPPORTED BEAMS

~

1. Concentrated load at mid­span

.J!i~:

~

­­­Lk

2:F

Moment", ~

PL

8

3

PL

P

~

Shear",

A

~ Y"'192EI

2. Uniform distributed load

wL

~

Shear", -

2

~

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

t :

~

lOMoARcPSD|3535879

4

~

St r en.qtl: of MClteriClls

Beams

,", For Rectangular Beams:

2

Moment:;:;··WL

12

1. SI = flexural stress

SI = ,6M

bh 2

Where: M = maximum moment

3. Uniform varying load

~

5

St icnqt t: (if l\,l(l(crials ­ Beams

2. Ss = shearing stress

3V

Ss = ­­.

2bh

.

Moment

Where: V = maximum shear

2

wL

20

Momem at B = ­­~

L

PROBLEM 1 (Apr. 1999)

A horizontal cantilever beam, 16 ft long is subjected to a load of 500 Ib located to its

center. The

dimension of the beam is 2 x 4 inches respectively. W = 100 Iblft, find

its flexural stress.

C 4510 pSI

A. 3150 psi

D. 5663 psi

B. 2912 psi

Y = deflection at mid­span

~

wl4

y == 768

,

SOLUTION

PROPPED BEAMS

roller at right end.

y = mid­span deflection

~

~

~p

IJ

For a cantilever beam:

1. Concentrated load at mid­span with fixed at left end and

F = total load at the center

•.

L

F = 500 + 100(16) = 2100lbs

Hl-.r~1i

500lbs

~ w =100 'b/..

L = 16 ft

'""""

M = maximum moment

2. Uniform distributed load with fixed at left end and pin at

right end

M

F x (U2)

M

2100(16/2) = 16,800in­lb

S = M_c_= ~2/4(0 8,61

I

= 3150 psi

(2)(4)3

12

~

~

PROBLEM 2

A 12 m simply supported beam with

30 KN load at the center has a maximum

2

deflection of: (EI = 6000 KN.m )

A. 150 mm

B. 160 mm

~

Under simply supported beam table.

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

C. 170 mm

D. 180 mm

lOMoARcPSD|3535879

6

St r cn at ! of Materials -Beams

SI rcn qtli o] Mat erials ­ Beams

4­

R 1 (10) = (4 x 2)(8) + 10(2)

R 1 = 8.4 KN

y = maximum deflection

3

PL

y = 48E I

where:

P = 30 KN

L = 12 m

2

EI = 6000 KN.m

...­

*30KN

ti.

12 m

10 KN

I'T1

~2rn

:2 kN/rT1l

10 rn

2:M 1 = 0

::6

7

R2 (10) = (4 x 2)(2) + 10(8)

t

R2

R1

R2 = 9.6 KN

By cutting at 10 KN section, and consider the right side of the section:

3

(30)(12)

y = 48(6000)

=0.180m=180mm

MA = R2 (2) = 9.6 (2) = 19.2 KN.m

PROBLEM 3

A 10m simply supported beam with 25 KN load 3 m from the left end has a

2

maximum slope at the left end: (IE = 8000 KN.m )

A. 00056 rad

C. 0.0186 rad

B. 0.0765 rad

D. 0.1823 rad

PROBLEM 5

A 10m simply supported beam with uniform load of 3 KN/m from right end to left end

2

has a maximum deflection of: (EI = 12,000 KN.m )

A. 43.23 mm

C. 54.23 mm

B. 32.55 mm

D. 36.45 mm

SOLUTION

14-" li it­U'

2

125 KN

3m...

2

Pb(L _b )

fk­ ­­­'­­­­­­­­'-

A

6 (E I) L

10m

y = maximum deflection

7rn

KN/nl

5 w L4

384

EI

Y=

~

where:

where:

w = 3 KN/m

L = 10 m

2

EI = 12,000 KN.m

P = 25 KN

b =7 m

L = 10 m

2

EI = 8000 KN.m

25 (7) (10 2 ­ 7 2 )

fk ­ ­':­­­'­­'­,­­­­­­'­

6 (8000) (1 0)

4

5 (3) (10)

= 0.03255 m = 3255 mm

y = 384 (12,000)

0.0186 radians

PROBLEM 4

A 10m simply supported beam has a uniform load of 2 KN/m extended from left end

to 4 m and has a concentrated load of 10 KN, 2 m from the right end. Find the

2

maximum moment at the 10 KN concentrated load. (EI = 10,000 KN.m )

A. 19.20 KN.m

C. 23.45 KN.m

B. 26.34 KN.m

D. 12.34 KN.m

..1-]lIO[-U'

Solving for the reactions at both ends:

LM2 = 0

'W = 3

PROBLEM 6

An 8 m simply supported beam has a uniform load of 2 KN/m from left end to right

end and concentrated load of 10 KN at the center has a maximum deflection of: (EI =

2

5,000 KN.m )

A. 12.34 mm

C. 21.33 mm

D. 34.34 mm

B. 42.66 mm

~1-]'·"Im

Considering the 10 KN concentrated load at the center.

3

PL

yl = 48E I

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

lOMoARcPSD|3535879

St r c-iunl: of MUlerials -Beam s

St r enqt ii o] Materials ~ Beams

8

--

8EI

(10)(8)_ '" 0.021333 m

yl '" 48(5000)

Considering the effect of uniform distributed load of 2 KN/m.

5(2 )(8)4

­­­­­

384(5,000)

25 (14)2

8

'" 0.021333 m = 21.333 mm

8(9000)

iP

=25 KN

L= 14 m

0.068 radians

PROBLEM 9

A 10m cantilever beam has a uniform load of 2.5 KN/m from left to right end. Find

2

•

the maximum deflection of the beam. (EI = 11,000 KN.m )

A. 423. 45 mm

C. 323.45 mm

B. 198.23 mm

D. 284.10 mm

y = y1 + y2

y = 21.333 + 21.333

~

where:

P = 25 KN

L", 14 m

2

EI '" 9,000 KN.m

y1 '" 21.333 mm

5wL4

Y2 '" 384 EI

P L2

()=

3

9

42.66 mm

PROBLEM 7

A 10m cantilever beam has a concentrated load of 10 KN at the free end. Find the

2

maximum deflection of the beam.(EI = 7,000 KN.m )

A. 476.20 mm

C. 544.34 mm

B. 342.34 mm

D. 764.44 mm

EI!!IIl'!13I

W

L4

v SET

>

~+.J' "[.J"

y = maximum deflection

y",

P L3

t

~

3EI

P.10 KN

10 m

where:

w '" 2.5 KN/m

L = 10 m

2

EI '" 11,000 KN.m

4

­ ~L

= 0.2841 m = 284.10 mm

y - 8 (11,000)

where:

P = 10 KN

L = 10 m

2

EI '" 7000 KN.m

PROBLEM 10

A 10m cantilever beam has a uniform load of 2 KN/m from left to right end and with

concentrated load of 8 KN at the center. Find the maximum slope of the beam. (EI =

2

13,000 KN.m )

A. 0.011 rad

C. 0.033 rad

B. 0.022 rad

D. 0.044 rad

10(10)3

Y = ­ ­ ­ ­ = 0.47619 m = 476.20 mm

3(7000)

PROBLEM 8

A 14 m cantilever beam has a concentrated load of 25 KN at the mid­span. Find the

2

maximum slope of the beam. (EI = 9,000 KN.m )

A. 0.00234 rad

C. 1.23 rad

B. 0.068 rad

D. 0.123 rad

EI!!IIl'!13I

Considering the effect of the uniform load of 2 KN/m using beam table,

81

EI!!IIl'!13I

Using beam table, for a cantilever beam with concentrated load at mid­span,

"'~-

6EI

2 (10)3

fl l

'"

6(13.000)

'" 0.0256 rad

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

lOMoARcPSD|3535879

St renqili of MateriClls . Becuns

10

Strength of MCllcliu[s

Considering the effect of concentrated load at the mid-span,

2

fh = P L

8EI

_8 (10)2

8 (13,000)

O2 =

= 81 + 82

8 = 0.002564 + 0.007692 = 0.0333 radians

PROBLEM 11

A 14 m cantilever beam has a load of 16 KN 6 m from the fixed end.

2

maximum slope of the beam. (EI = 6,000 KN.m )

A. 0.183 rad

C. 0863 rad

B. 0.048 rad

D. 0.064 rad

IHN"imD

I

Pa 2

2EI

16 (6)2

2(6,000)

Find the

6m

IP

=16KN

T

.

PROBLEM 13

A 10m simply supported beam has a triangular load from zero at left end to a

maximum of 10 KN/m at the right end. Find the maximum deflection of the beam. (EI

2

= 10,000 KN.m )

C. 84.67 mm

A. 5424 mm

B. 65.10 mm

D. 76.56 mm

where: w = 10 KN/m

L = 10 m

2

EI = 10,000 KN.m

0.048 radians

PL 2

81 = 2EI

8 (12)2

0.054 radians

4

Considering the effect of concentrated load at free end:

2(8,000)

1.5(12)3

6 (8,000)

2.5 W L

Y= 384EI

L = 14 m

Em!!miD

­­­­

6EI

For a triangular load with simply supported beam,

PROBLEM 12

A 12 m cantilever beam has a uniform load of 1.5 KN/m extended from fixed end up

to 4 m and a concentrated load of 8 KN at the free end. Find the maximum slope of

the beam. (EI = 8,000)

A. 0.126 rad

C 0.654 rad

B. 0.234 rad

D. 0.345 rad

81

L

Em!!miD

where:

P = 16 KN

a=6m

2

EI = 6,000 KN.m

8

l

W

8 = 81 + 82

8 = 0.072 + 0.054 = 0.126 radians

For a cantilever beam with a concentrated load at a distance from fixed end:

8

11

= 0.007692 rad

tl 2

8

lkwns

P = 8 KN/m

W =1.5 KN/m

0.072 radians

Considering the effect of uniform load of 1.5 KN/m.

L

=12 m

4

y

2.5(10.li1.QL = 0.06510 m

­384(10,000)

65.10mm

PROBLEM 14A 8 m cantilever beam has a triangular load from left end to a maximum of 12 KN/m

2

at the fixed end. What is the maximum deflection of the beam? (EI = 12,000 KN.m )

A. 136.53 mm

C. 165.34 mm

B. 145.34 mm

D. 15434 mm

.1e ] , I " [ e 1S'

For a triangular load of cantilever beam,

4

W L

y = 30EI

where:

w = 12 KN/m

j

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

lOMoARcPSD|3535879

Sf rCllgt h of Materials - Beams

12

SlrcIII/II, ojl\lul('riuls

L=8m

2

EI = 12,000 KN.m

y=

_2(8)~

13

I'I<OULJ:-:M 17

A vertical load of 400 N acts at the end of a horizontal rectangular cantilever beam 2

m long and 25 mm wide. If the allowable bending stress is 130 Mpa, find the depth of

the beam.

A. 23.45 mm

C. 56.34 mm

B. 38.43 mm

D. 45.34 mm

__

30 (12,000) - 0 13653 m = 136.53 mm

PROBLEM 15

A 12 m restrained beams with two end fixed has a concentrated load of 15 KN at the

2

center. Find the maximum deflection of the beam. (EI = 7,000 KN.m )

A. 8.45 mm

C. 19.28 mm

B. 34.23 mm

D. 24.67 mm

E::1!!iirmI

E::1!!iirmI

For a cantilever beam with load act at the free end:

P = 400 N = 0.40 KN

M=PL

M = (0.40)(2)

M = 0.80 KN.m

For restrained beam with concentrated load at the center,

P = 15 KN

PL3

Y = 192EI

~

where: P = 15 KN

L = 12 m

2

EI = 7,000 KN.m

15(12)3

Y = 192-(7,000)

Beams

L:12m

~

Using the formula of flexural stress,

6M

s= --.2

bh

PROBLEM 16

A 15 m restrained beam with two end fixed has a uniform load of 3 KN/m, find the

2

maximum deflection of the beam. (EI = 9000KN-m )

A. 56.34 mm

C. 34.56 mm

B 23.56 mm

D. 43.94 mm

130000 = 6 (0.80)

,

(0.025) h2

h

PROBLEM 18

A simply supported beam is 50 mm by 200 mm in

25 mm

cross section and 4 m long. If the flexural stress is not to exceed 8.3 Mpa, find the

maximum mid-span concentrated load.

A. 2.77 KN

C. 3.45 KN

B. 6.34 KN

D. 4.34 KN

E::1!!iirmI

SOLUTION

For restrained beam with uniform distributed load,

where: w = 3 KN/m

L = 15 m

2

EI = 9000 KNm

400 N

2m

h = 0.03843 m = 38.43 mm

0.01928 m = 19.28 mm

wL4

Y = 384EI

t. p :::

~

~

For a simply supported beam with load at the center,

M = maximum moment

M = PU4

M=~

~p

4

A

M=P

L = 15 m

4m

­:.a

Using the shearing stress formula for beam

s= §~

3 (15)4

Y = - - - - - - = 0.043945 m = 43.945 mm

384(9000)

bh 2

Where:

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

200 mm

lOMoARcPSD|3535879

SI r ctiqt.t: of Materials - Beams

]4

Sln'T/fl/l,

b = 0.050 m

h = 0.20 m

2.77 KN

PROBLEM 19

A simple wooden beam, 50 mm wide by 250 mm deep and 7.5 m long has a

maximum deflection of 102 mm under a uniform load "w". E = 12,411 Mpa

a. What is the uniform load, w.

b. What is the slope?

c. What is the maximum moment?

d. What is the maximum shear?

e. What is the flexural stress?

f. What is the shearing stress?

Em!!'.iIrSmI

bh 3

1=12

f.

S =

2.'­". = _3J7.5l~

2bh

= 900 K a

2(0.05)(0.25)

9

(0.050)(0.250 )3 = 0.0000651 m 4

12

4

5w(7.5)

384(12411 x 103 )(0.0000651)

50 mm

2m

6m

~P2m

~

e

PROBLEM 21

A cantilever beam having a span of 6 m, carries a triangular load of 20 KN/m at its

fixed end to zero at the free end of the beam. Determine the deflection at the free

12

2

end of the beam if EI = 50 x 10 N.mm .

A. 17.28 mm

C. 15.62 mm

B. 16.48 mm

D. 12.63 mm

Em!!'.iIrSmI

3

wL

24EI

2 (7.5)3

24 (12411 x 10 3 )(0.0000651)

0.0435 rad

For triangular load of cantilever beam:

w = 20 KN/m = 20 N/mm

wL4

M = maximum moment

y = 30 EI

M=wL 2/8= 2(7.5)2

8

1

a

2mP~

648 (30,760 x 10 )

w = 2 KN/m

d.

P

PROBLEM 20

A simply supported beam having a span of 6 m carries two concentrated loads of 80

KN at its middle thirds. Compute the deflection at the mid­span due to this load. Let

9

EI = 30,670 x 10 N .rnrn".

A. 18 mm

C. 24 mm

B. 20 mm

D. 30 mm

Y= 23(80,000)(6,000)3 = 20 mm

250 mm

c.

6(14)

= ~= 26,880 Kpa = 26.880 Mpa

S = ­­

b h2

(0.05)(0.25)2

3

y = 23PL

648EI

y = 384EI

b.

6M

e.

4-i-]'lin-gl

a. For a uniform loading beam under simply supported:

5wL4

0.102=

]5

Beams

V = 2(7.5L = 7.5 KN

2

6P

._­­ ­ 2

8,300 = (0.05) (0.20)

1=

III j\!1u/eriols

= 14KN.m

Y=

20 (6,000)4

12

30 (50 x 10 )

= 17.28 mm

V = maximum shear = w U2

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

lOMoARcPSD|3535879

"1­]lliit­a

PROBLEM 22

A simply supported rectangular beam 50 mm wide by 100 mm deep carries a uniform

load of 1200 N/m over its entire length. What is the maximum length of the beam If

the flexural stress is limited to 20 Mpa.

A 3.33 m

C. 5.2 m

B. 4.25 m

D. 6.0

m

P = 50 KN

~

PL3

Y=

3E1

t

29.63 = 50,000 (4,000)3

38­'-

1i'­]lI"t­U'

EI = 35.9996 x 10

wL2

Moo ­­8

s,

6M

20 = ­­­­­­

(50)(100)2

9

N.m

2

= 35,999.6 KN.mm 2 = 36,000 KN.m 2

PROBLEM 25

A restrained beam carries a triangular load which increases from zero to 30 KN/m

from A to B having a span of 4 m. Determine the moment at A

A. 12 KN.m

C. 18 KN.m

B. 24 KN.m

D. 16 KN.m

100 mm

6M

bh 2

50 mm

Emut­U'

3

M = 1,666 x 10 N-mm = 1,666 N-m

w:;; 30 KN/m

2

1 666 = 1200 L

,

8

2

30

\p

PROBLEM 23

A simply supported beam having a span of 20 m carries a concentrated load of 10 KN

at a distance of 5 m from the left support and a counter clockwise couple of 6 KN.m

acting 3 m from the right support. The maximum moment due to this load is:

A. 39 KN.m

C. 36 KN.m

B. 43 KN.m

D. 48 KN.m

..i­]'II1t­a

20 R1 = 10 (15) + 6

R1 = 7.8 KN

wL

MA

L = 3.33 m

LMs = 0

17

Strength of MUlerials - Beams

St rcnot u or Materials - Beams

If)

5

110 KN

6 m+

A

tR'

20 m

f

M

A

= EO) (4)2

36'

B'

16 KN.m

I

I

I

I

I

~/

I

L=4 m

PROBLEM 26

A cantilever beam 3 m long carries a concentrated load of 35 KN at its free end The

material is structural steel and the maximum bending stress is not to exceed 125

Mpa. Determine the required diameter of the bar if it is circular

A. 204.5 mm

C. 164.6 mm

B. 188.6 mm

D. 179.2 mm

6 KN-m

P

SOLUTION

~

3m

(\B

M = 7.8 (5) = 39 KN.m

Moo 35 (3)

M = 105 KN.m

PROBLEM 24

A cantilever beam having a span of 4 m caries a concentrated load of 50 KN at the

free end. What is the flexural rigidity if the beam deflects 29.63 mm at its free end.

2

2

A. 36,000 KN.m

C. 24,800 KN.m

2

2

B. 42,000 KN.m

D. 54,200 KN.m

A

s = ~c

6

105 X 10 N.mm

I

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

=35 KN

t

lOMoARcPSD|3535879

Strength oiMa u-ii at-,

SIII'II9Ih of M(lterials ­ Beams

IS

M

\

\

fJ8 KN.m

1'1\( lllLEM 29

nd

1

\

I' ,

105xlO h (di2)

125

64

d

Ii/,w,,"

= 20450 mm

PROBLEM 27

A steel beam 2 m In length is simply supported at each end and carnes a

concentrated load of 100 KN acting 05 m from one of the supports. Determine the

maximum bending stress set up in the beam if the cross-section is rectangular, 100

mm wide by 150 mm deep.

C. 97 Mpa

A. 100 Mpa

D. 150 Mpa

B. 120 Mpa

Em!!ImD

A restrained beam having a span of 6 m carnes a uniform IOdd 01 O~ Nzrn throughout

6

Its span. If E = 200,000 Mpa, I = 6080 x 10 rnrn" determine the deflection at the midspan.

C. 036 mm

A 0.14mm

D. 0.48 mm

B. 0.25 mm

Em!!ImD

wL

384 EI

50,000 (6) (6,000)3

y­­­­­

6

\

384 (200,000)(6,080 x 10 )

LMB = 0

2 R1 = 100 (1.5)

0.5 m ~

R, = 75 KN

6

M = 37.5 KN.m = 37.5 x 10 N.mm

6M

bh 2

S = ­­­.­ = -~

6(37.5X 10 6 )

S = 100 N/mm

p = 100 KN

.a­­ 2m- - B

M = 75 (0.50)

100(150)2

2

tR1

iI'50mm

= 100 Mpa

100 mm

PROBLEM 28

A beam made of titanium has a yield point of 850 Mpa. The beam has 25 mm x 50

mm rectangular cross-section and bends about an axis parallel to the 25 mm face. If

the maximum bending stress is 650 Mpa, find the corresponding bending moment.

A. 6.8 KN.m

C. 4.5 KN.m

D. 8.4 KN.m

B. 8.4 KN,m

m:mmmI

6M

S = ---.

bh 2

6M

650= ­ ­ ­ (25)(50)2

M = 6.8 X 10" N.mm

~

4

y

f150mm

25mm

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

0.14 mm

L = 15 m

lOMoARcPSD|3535879

20

Mechunics

21

Mccllullics

Note.

If a body is at rest, then initial velocity IS zero.

If a body is moving at constant speed, then acceleration IS zero.

If a body is completely stop after the trip, then velocity is zero

~

~

~

2. Free Falling Body

Vf=O

a. VI = va ± gt

Fr

,

c. S= Vbl ±%gf

•

•••

•

=

I

I

I

I

I

**

" "

,,

••

•

·

I

I

I

I

I

I

5

_BL:r

tN

-

Va

•

(. If speed is uniform:

S = vt

­

s

If speed varies:

Vo

2

± 2aS

~

•

-~

I

vJ

Note:

If a body is dropped freely, then initial velocity is zero

~

If a body is thrown upward, then it reached to a maximum height where the

velocity is zero.

Vf

-----.

14

9=0

H

I~

c.S= Vat ±% a t;l.

R

~

x

where

a = acceleration

a is + if accelerating

a is - if decelerating

V o = initial velocity

VI = final velocity

S = distance traveled

t = time

I

3. Projectile Motion

­­­­­.

2

r,

I

I

~

1. Rectilinear motion

- motion is along a straight path.

b. Vf

·

g = acceleration due to gravity

g is + if a body is moving down

a is - if a body is moving up

Vo = initial velocity

v, = final velocity

S = distance traveled

t = time

~w

=f N

a. Vr = Vo ± at

2

Vl

where:

F = frictional force

f = coefficient of static friction

N = normal force

"

I

± 2g8

b.

IEImm

2

Vo

,

1''''''-

Components of initial velocity, va

vox

=v; cose

Voy = va sine

For Horizontal Displacement:

"The horizontal component of initial velocity will not change throughout the

flight. vox = Vlx contant

=

l

x = horizontal displacement = vox t

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

(v, coss) t

lOMoARcPSD|3535879

22

"

Mcch anic:«

R = maximum range

Vo

2

23

Mechanics

.

(. For uniform speed:

sln28

9

" a

For Vertical Displacement:

,

y = verticaldisplacemeI1t

vay t

1t':igrS v"Sjn8.t - 112 9 t2

nDN

Where:

" Vfy = final velocity along vertical = Vay • g t.= vasih!:l· gt

w = angular velocity, rad/s, rev/sec

2

a = angular acceleration in rad/s", rev/s

t = time

8 = rad or rev

a = acceleration, m/s"

R = radius of rotation, m

N = speed, rev/s

v = velocity, m/s

"

f., Vt == final resultant velocity ==

Vo

c;.. H = maximum

2nRN

" v

Note:

29

Use + if accelerating

Use - if decelerating

Where:

Vox = initial velocity along horizontal

v oy = initial velocity along vertical

Vlx = final velocity along horizontal

Vfy = final velocity along vertical

VI = final velocity

Vo = initial velocity

t = time of flight

"

Polar Moment of Inertia

Using English units:

Note:

~

The horizontal component velocity is constant at any time of flight.

~

At maximum point the value of 8 = O.

~

If Y is below the reference point, then the sign of y is negative.

Where:

J m = polar moments of inertia of masses, It­lb­sec"

2

p = Ib!ft

L = length, It

2

g = 32.2 ft/sec

J = polar moment of inertia of area with constant cross-section, ft4

4. Circular Motion

Radian ­ is a unit of angular measure equal to 57.30°

Angular speed ­ is the angle through which it turns per unit time.

&zgular acceleration ­ is the rate of change of its angular speed with respect to time.

.. '

FORMULAS:

~/

For accelerating object:

c;. WI :: Wa ± a t

r~

'W?=Wa ± 2 a 6

6 == wo t ± 112 a

r

Jm = P L J

\~ "

Where:

2

J m = kg_m

(, Radius of Gyration

:/

­,

Using 51 units:

..........

Wo ••·•

2

"

e­-

­

WI

Using English Units

-:

".

"~

......... __ .::

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

p = kg/m

3

L = length, m

J = m"

lOMoARcPSD|3535879

24

K" = radius of gyration

Ko ==

g~P

(f

J m := Wk o

9

25

Mechu7Iics

Mechu7Iics

= anqular acceleration, rad per sec?

2

USing 81 Units:

2

T o:= J m a == mko a

Where:

Where:

J m = polar moments of inertia of masses, It-lb-sec"

To := torque, N-m

Ko = ft

g = 32.2 tt/sec"

W := weight, Ib

J,'l := moment of inertia, kg_m

2

a := angular acceleration, rad per sec

Using 51 Units

Kinetic Energy

(. Kinetic Energv of Translating body

2

1

2

KE:= ­mv

2

KE == Wv

29

2

Where:

J m:= kg_m2

p:= kg/m 3

Ko:= m

m := mass, kg

Where:

"

2

Radius of Oscillation

For isosceles triangle:

For circle:

For parabola:

314 of height

5/8 of diameter

5/7 of the height

KE = kinetic energy, Joules

m:= mass, kg

v = velocity, mls

W:= weight, N

g = acceleration due to gravity, rn/s"

(, Kinetic Energy of Rotating body

"

Center of Percussion

KE == 1fz Jln {t)2

Q := distance from axis of rotation to center of percussion

Where:

J m:= moment of inertia, tt-lb-sec''

(. Total Kinetic Energy

Where:

r := the distance form axis of rotation to center of gravity of body

KE := Y2mv2 + Yz. J m {t)2

(,. Force of a Blow:

(., Formulas relating Torque and Angular Acceleration

Average force of blow :=

Using English units:

To == J m a

ws

d

Where:

8 := total height, It

W := weight of driver in Ibs

o := distance in feet which pile is driven

«:.. Linear Impulse and Momentum

Where:

To := torque in pounds-feet

2

J", := moment of inertia, ft-lb-sec

Ko:= radius of gyration, It

W

'

L Inear rnornentum» m v = - v

9

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

()) = angular velocity, radlsec

lOMoARcPSD|3535879

r,

26

\1-

I

Mechanics

Mcrhultics

Linear impulse » F x t

F :=: forcet = time

~

m = mass

27

\, Unbanked curve

v = velocity

W :=: weight

Angular impulse and Momentum

tan (8 + x) :=:

v2

a

==

~-

9

gR

H

AOQularmornentUfTl :=: J m W

Angular impulse :=: To x t

Where:

f :=: coefficient of friction

R :=: radius of curvature

8 = super elevation angle or banking angle

x :=: side thrust friction angle

H = super elevation

Angular impulse :=: Change in angular momentum

TdX f=,J m{4>f -wo)

.

.

~,

.

Fe

\,. Acceleration

Normal acceleration :=: V'/r

Tangential acceleration :=:dvldt

,

Centrifugal Force

j

Fe :=: rnas, :=: rI1 (l/r)

\

I

Ig',

:=:

wv 2

gr

V

.~

•I

W

FR

I

I

I

FR = .m!l

I R

I

I

I

I

I

tan

~'

v2

noitoM~.,- -

~n

_

• • •

FR

H

9

~._

gR

Where:

m = mass, kg

~

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

.

c.

~.-

-;;::._

.....

..

9

• •

FR

2. If the object is decelerating, the direction of reverse effective force is the

same with the direction of motion.

Banked curve

a

9

.

Banking Curves:

f

~a

1. If the object is accelerating, the direction of reverse effective force is

opposite to the direction of motion.

...

v = velocity, m/s

r :=: radius of curvature, m

f = coefficient of friction

a = acceleration, m/s"

m = mass, kg

W = weight, N

g :=: 9.81 m/s" = 32.2 ft/s 2

\,

=w

Direction of Reverse Effective Force

Where:

"

reverse effective force

W:=: weight, N

Motion

i

a = acceleration, rn/s"

lOMoARcPSD|3535879

:2H

PROllLEM I (OCt. 2000)

A car travels with an initial velocity of 10 m/s or 36 km/hr. If it is decelerating at the

rate of 3 rn/s", how far, in meters does it travel before stopping?

A. 17

C. 19

B. 21

D 15

~

From the ground to a maximum height:

V" = 114km/s==114,000m/s

2==V 2

0

Vt==Vo-gt

-2aS

.:

o == 114,000 - 9.81 t

(0)2 == (10)2 - 2 (3) S

..,.

6 m/s

/ /. £"\

,,'-

VI == 0 at maximum height

PROBLEM

Vt

29

Mecltwlics

!Hech ci nie s

i

:_-------------

­­-

.....

~

~,

l

t = 11620.795 sec == 3.228 hrs

S = 16.67 m

Time of object in going up == time of object in going down

PROBLEM 2 (Oct. 2000)

A block weighing 56 Ibs rest on horizontal surface. The force needed to move along

the surface is 20 Ibs. Determine the coefficient of friction.

C 0.36

A. 0.0

B 0.112

D.028

Em:!!imD

So that total time to go up and back.

== 3.228 + 3.228 == 645 hrs

PROBU':M 5 (ME Bd. Oct. 97)

An occupant moves toward the center of a merry go around at 6 rn/s If the merry go

around rotates at 6 rpm. Compute the acceleration component of the occupant

normal to the radius.

A. 6.79 rn/s"

B. 8.29 m/s"

F==fN==fW

C. 7.54 rn/s"

D. 3.77 rn/s"

20 == f (56)

~

f == 0.357

v == 2rcRN

6 == 2 rt R (6/60)

R == 955 m

PROBLEM 3 (Oct. 2000)

A baseball is thrown straight upward with a velocity of 20 m/s. Compute for the time

elapse for the baseball to return. Assume for a zero drag.

A. 1.84

C. 250

B. 2.21

D. 2.04

a == acceleration

a

Em:!!imD

a

VI = Va - g t

v2

R

62

9.55

3.77 m/s

2

o == 20 - 9.81 t

PROBLEM 6 (ME Bd. Apr. 98)

t == 2.038 sec

PROBLEM 4 (Apr. 1999)

A 114 km/s speed is projected vertically how long will it take to go back to its initial

position.

C. 7.23 hrs

A. 645 hrs

B. 1.23 hrs

D. 845 hrs

,\'

,~

A wheel accelerates from rest with a = 5 rad/sec.sec. Compute how many revolutions

are made in 4 seconds.

A. 5.71 rev

C.700rev

B. 6.36 rev

D. 2000 rev

...-r.JX'ur.1~.

1 rev == 2rc rad

,I';,

..

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

lOMoARcPSD|3535879

30

31

Mechanics

Me(' han i ('.s

e

H c= w.t + 1/2 (f

w, c= 0 (from rest)

o c= 0 + 1/2 (5/2rr)(4)2

e = 6.36 rev

mv~

i

c=

Fe

mg

R

t

9 R

v c= 343 m/s

PROBLEM 7 (ME Bd. Apr. 98)

What minimum distance can a truck slide on a horizontal asphalt road if it is traveling

at 25 m/s. The coefficient of sliding friction between asphalt and rubber is at 0.6 The

weight of the truck is 8500 kg.

A. 44.9

C. 532

B. 58.5

D. 63.8

Solving for N:

v==2rrRN

343 = 2 rr (1.2) N

V

//--1'_.'l~ -.

/ = 9.81(1.2)

I

A.2m),

,,

,

.

,

,

;'

,

···

'

'

·

"~"

,

...... "

N = 0.455 rev/s X 2rr = 2.86 rad/s

SOLUTION

v = 25 m/s

--.

v=o

--.

I..

;1

I

PROBLEM 10 (ME Bd. Apr. 98)

Compute the speed a satellite to orbit the earth at an elevation of 100 km.

radius is at 6400 km. Assume no change of gravity with the elevation

C. 8740 m/s

A. 6320 m/s

B. 7120 rn/s

D. 7920 rn/s

I

Em!!DtmI

Considering the truck:

FR

-----.

IFH = 0

~

Fr c= FR

W

f W = ---a

g

a c= f g = (0.6)(9.81)

c=

5.887 m/s

To maintain the satellite to orbit the earth,

Fe = r,

2

L,<.-X,,l,

I

2

2

981 (6400,000 + 100,000)

v == 7985 m/s

PROBLEM 11 (ME Bd. Apr. 98)

A liquid full is to be rotated in the vertical plane. What minimum angular velocity in

radians/sec is needed to keep the liquid not spilling if the rotating arm is 12 meters?

A. 2.26

C. 3.16

B. 25.6

D. 2.86

To keep the liquid not spilling out,

gR

v

PROBLEM 9 (ME Bd. Apr. 98)

SOLUTION

mv_ == mg

R

i

After the slide it will stop so that V2 = o.

2

2

V2 = V1 + 2aS

o = (25)2 + 2(5.886)S

S = 532 m

An elevator weighing 2000 bs is moving vertically upward with an acceleration of 3

tt/s". A man standing in said elevator weighs 180 lbs. Compute the tension in the

supporting cable under this condition.

C 1820lbs

T

A. 2180lbs

B. 2191 Ibs

D. 23831bs

t

....{.)'i'iMDI

I Fv c- 0

W == total load

00

~

f

Fe = Fg

Earth's

W = 2000 + 180 = 2180 Ibs

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

FRt

lOMoARcPSD|3535879

32

MechcUlics

Mechanics

T

PROBLEM 14 (ME Bd. Apr. 96)

A drop hammer of 1 ton dead weight capacity is propelled downward by a 12 in

diameter cylinder. At 100 psi air pressure, what IS the Impact velocity if the stroke IS

28 inches?

C. 15.8 fps

A. 63.2 fps

o 474 fps

B. 316 fps

W + FH

W

W+ - a

g

T

T

2180

+~-

2180

32.2

3:)

(3) = 23831bs

Em!!ImD

PROBLEM 12 (ME Bd. Apr. 98)

The capsule orbits the earth 180 km above the surface. In what velocity in m/s

necessary for a circular orbit consider the earth radius at 6400 km and at 92 rn/s"?

A. 8864

C. 7780

B. 7016

O. 8058

W = 1 ton = 2000 Ibs

Em!!ImD

Force = Pressure x Area

Solving for the force acting on piston:

Force

= P (2C 0 2 )

4

Fe = F g

Force = 100 [ (rr/4)(12)2]

Force = 11,310 Ibs

~

rnv"

--=mg

R

6400 km

mv 2

--=g

w

R

R = distance from center of

Earth

earth to the capsule

R = (6400 + 180) 1000 = 6,580.000 m

Substitute:

v2

------=9.2

6,580,000

v = 7780 m/s

v} = 0 + 2(214.3)(28/12)

V2 = 31.6 fps

PROBLEM 13 (ME Bd. Apr. 96)

A truck skids to a stop 60 m after the application of the brakes while traveling at 90

Km/hr. What is its acceleration in rn/sec"?

A. -5.21 rn/sec"

C. 6.36

B -7.06

O. 5.76

SOLUTION

V1

90(1000)

= --._.--= 25 rn/s

3600

v/ = V,2 + 2aS

V2 = 0 (stopped)

o = (25)2 + 2a(60)

a = -521 rn/sec"

F = ma

F = (W/g) a

11,310 = (2000/322) a

2

a = 182.1 ft/s

v/ = V,2+ 2aS

v, = 0 (from rest)

a = 1821 + g

2

a = 1821 + 322 = 2143 ft/s

-

v = 90 kph

~

~

......

'4

5 = 60 m

-

v=o

....,

PROBLEM 15 (ME Bd. Apr. 96)

A flywheel rotates at 120 rpm or 12.57 rad/sec slowed down to 102 rpm or 10.68

rad/sec during the punching operation that requires 3/4 second of the punching

portion of the cycle. Compute the angular acceleration of the flywheel in rad/sec".

A. -2.52 rae/sec"

C. 3.15 rae/sec"

0 2.22 rad/sec''

B. -2 75 rae/sec"

...

. :r .~ ji[.l~.

a

ex

u

W2 ="!1

10.68 -12.57

-_.---~----

0.75

-252 rae/sec'

' ,.

\

'~r

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

lOMoARcPSD|3535879

34

Mcciuinics

35

Mechanics

C. 400 m

D. 600 m

A. 350 m

B 500 m

PROBLEM 16

A 2-ton weight is lowered at a constant acceleration of 2 rt/s".

stress?

A 4,344.34 Ib

C. 3,751.55 Ib

B. 5,344.56 Ib

D. 6,356.24Ib

What is the cable

"'.-]",,[-1\-

Solving first the acceleration:

Vr = Vo + at

50=20+a(10)

SOLUTION

Solving for the distance traveled:

2

S =0 Vo t + Y2 a t

S = 20(10) + 1/2 (3)(10)2

S = 350 m

Cable Stress

v =20 m/s

v = 50 m/s

•

•

----+

----+

I.

t = 10 seconds.

~I

When lowering the load:

r

FR = direction of FR is upward since the

direction of load is downward.

W

FR= - a

R

F

g

FR -

Ex20~)

32.2

Em!!ImD

W = 2 tons

(2) = 248.45 Ib

PROBLEM 19

A box sliding on a floor has a frictional resistance of 100 N. If coefficient of friction is

0.3, find the weight of the box.

A. 222.22 N

C. 444.44 N

B. 111.11 N

D. 333.33 N

Fr =0 frictional resistance

l:F v

=0

0

r. = f N

Cable stress = W - FR

Cable stress =0 (2 x 2000) - 248.45

Cable stress =0 3,751.55 Ibs

100 = 0.3 N

N = 333.33 N

PROBLEM 17

The speedometer of a vehicle changes from 20 km/hr to 80 km/hr In 10 seconds.

Find the acceleration for this period in m/s".

A. 1.67

C. 2.34

B. 6.34

0 8.45

W = N =0 333.33 N

PROBLEM 20

An object dropped on a gravity travels 300 m after how many seconds?

A. 5.34 sec

C. 7.82 sec

B. 6.34 sec

D. 10.23 sec

SOLUTION

V1 = 20 (1000/3600)

V1 = 5.55 m/s

V2 = 80 (1000/3600)

V2 =0 22.22 m/s

v =20 kph

v =80 kph

~

•

•

Va

----+

~

----+

t = 10 seconds.

~

S

V2 = V1 + at

22.22 = 5.55 + a(10)

a =0 1.67 rn/s"

=0

=0

0 (dropped)

Vo t

+ '12 g t

2

300 =0 0 + '12 (9.81) t

I

\

Ii

,

PROBLEM 18

A car changes accelerates its speed from 20 m/s to 50 rn/s in 10 sec.

distance traveled during the period of acceleration.

Find the

t =0 7.82 sec

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

5 =300 m

2

lOMoARcPSD|3535879

3G

Mechanics

2

-

v, 2 - 2 g S

s

VI = 0 (at maximum height)

0

2

V =40 m/s

S = 8155 m

­­:­::­­0" -,

IlE!!i.mD

From maximum height to the ground:

'

Va = 0

Vt =

­­-

H = maximum height

PROBLEM 22

A stone is projected upward from the ground travels a maximum height of 50 m. Find

the velocity of stone when it returns to the ground.

A. 31.32 m/s

C. 4323 rn/s

O. 2345 m/s

B. 5434 m/s

2

981

17877 m

R

E:mImD

t

= (40)2 - 2 (9.81) S

(45)2 Sin 2(30)

R

PROBLEM 24

A shot is projected 40° from the horizontal at the rate of 30 m/s will reached the

maximum height of:

C. 32.34 m

A 20.34 m

O. 4534 m

B. 18.95 m

SOLUTION

VI

37

Mechanics

PROBLEM 21

An object IS projected upward at the rate of 40 m/s. How high will the object rise?

C 65.34 m

A. 5434 m

O. 8155 m

B. 7645 m

v/ + 2 g S

'

,

H =

'u

~-_.

2

(~0)2

. 2

sin 0.

2g

.~_,-

sin ~O

2(9.81)

2

H=1895m

,\

,

I

'

'

I

I

•

I

'

'

I

I

'

I

'

'

I

I

S'SOml tv

V? = 02 + 2 (9.81) (50)

H =

V

~

PROBLEM 25

A capsule orbit the earth at the rate of 6000 rn/s. If the radius of earth is 3000 km,

find the height of capsule from the surface of the earth ..

A. 435.66 m

C. 543.23 m

B. 669.72 m

O. 78545 m

.i·"··"·lh"

The capsule will orbit the earth if:

Vf = 31.32 m/s

•

6400 krn

Fe = Fg

PROBLEM 23

An object is projected upward at the rate of 45 m/s at 30° from the horizontal. Find

the maximum range of projectile.

A. 178.77 m

C 18934 m

o 10934m

B. 165.34 m

SOLUTION

~

"r;;.

"

/

/

~<;:

R

R

maximum range

2 sin 28

g

~

30'

,

,

"

(6,000)2 = 9.81 R

,

,

/'7/7/%7777/// ; \

I..

Wv 2

- - ~W

gR

R = distance from center of earth to the

capsule above the earth surface.

2

v = g R

.1

R = 3669724.771 m

R = 3669.724 km

R = r" + H

3669724 = 3000 + H

H = 669.72 m

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

w

Earth

lOMoARcPSD|3535879

38

Mcclwnic!i

PROBLEM 26

A car that travels 100 mph reduces its speed 50 mph in 30 seconds.

distance traveled by the car until it stops.

A 4402.10 m

C. 5434.56 m

B. 3452.34 m

D. 6456.35 m

Find the

v =100 mph

~

e..

I.

V = 50 mph

~

Tan H

Sl

30 sec

~

(40)2

Tan H

8 = 9.26

SOLUTION

-

S2

0

V=O

~I

= 50 (5280/3600) = 73.33 ft/s

VI = va - at

14667 = 73.33 - a (30)

a = 2.44 m/s"

SI

=

Vo t

- Y2 a t

2

S, = 146.67 (30) - Y2 (2.44) (30)2

S, = 3300.10 m

Solving for S2:

VI

2

=

Va

2

-

2a S2

0 2 = (73.33)2 - 2(2.44)S2

S2 = 1102 m

S = total distance traveled

S = 3300.10 + 1102 = 4402.10m

PROBLEM 27

A car traveling at 40 m/s in a radius of 1000 m will have a banking angle of:

0

A. 7.34°

C. 9.26

B. 183.4°

D. 12.3°

SOLUTION

Tan 8

v = 40 m/s BI""'1II

-I iL~

0.1631

..

~u

---

9.81 (1 000)

Va = 100 (5280/3600) = 14667 ftls

VI

39

Mechanic!i

v2

gR

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

...

;'

,

/

/

.....

"' \

I

\

\

I

\

~I

0

R=1000m,

\

I

\

"' ..... .....

/

......

_-- ....

-" /

lOMoARcPSD|3535879

40

Machine Shop Pta ct icc

Mact n n«: Shop Practice

IV~C="':J

3

11'1 E

!:» ..... C» F»

41

m:mmB

Co

Time = Length to be,welcl

Welding rate

(; Volume Consumption of gas. V

V = (Va + Va) L

~

Where:

V = total gas consumption of oxygen and acetylene

Va = volume of oxygen consumed per unit length of seam

Va = volume of acetylene needed per unit length of seam

L = length of seam

Im!!Jm]

(. Cutting Speed, v:

v = 11: 0 N

~

Where:

v = cutting speed

D = diameter of workpiece

N = speed

t.. Time of Milling

"

PH.OBLEM 1 (Oct. 2000)

= Length to be cut

Determine the time in seconds, to saw a rectangular magnesium bar 5 in wide and 2

in thick if the length of cut is 5 in. The power hacksaw does 120 strokes/min and the

feed/stroke is 0.127 mm.

Cutting rate

(; Time»

.~Le_n.-':g,thC0bcu

No. ot teeth x Speed, N x Feed rate

A 189

C. 99

B. 500

D. 20

~1·]'"[B

~

"

Time of Cutting = Length to be cut

Cutting rate

time

Time

= Length to be cut

Cutting rate

'" For a hacksaw, there is only one cut stroke per revolution.

c. Time: .__

Lengthtobe cut

Speed, N x ~trok

rev

x . ~.e F

stroke

Length to be cut

--"- - . - - - - - - -

Cutting rate

For a hacksaw. there is only one cut stroke per revolution.

Feed per stroke = 0.127 mm = 0.005 in

time =

5

--_._--_..- - - - - - - - = 8.33 min

strokes

in

120-.

(0.005---)

min

stroke

500 sec

PROBLEM 2 (Oct. 2000)

In an Oxy-Acetylene manual welding method. to weld a 3 1/2 ft long seam in a 0.375"

thick steel plate at a consumption rate of 9 ft3/ft for oxygen and 7 ft31ft for acetylene.

Compute for the total combined gas consumption in ft3

A 48

C. 56

B 24.5

D. 31.50

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

lOMoARcPSD|3535879

42

Machine Shop Practice

SOLUTION

Machine Shop Prcut ic«:

43

Cutting time- 10.42 min

v = total gas consumption

PROBLEM 6 (Oct. 1998)

Compute the cutting speed in fpm of a workpiece with 2 inches diameter and running

at 100 rpm.

A. 52

C. 25

D. 26

B. 62

v = (Vo + Va) L

= 56 ft3

V = (9 + 7) (35)

PROBLEM 3 (Oct. 1998)

Compute for the drill penetration in in/min when a drill turns at 1200 rpm and the feed

of 0.005 inlrev. Material is steel.

A. 1.8

C. 12

B. 3.6

D. 6

ED:!ImI:I

V=ITDN

V = IT (2/12) (100)

52.35 ftlmin

SOLUTION

PROBLEM 7 (ME Bd. Apr. 98)

Drill Penetration = (Feed rate) N

Drill Penetration = (0.005 - ' ~

)(1200 rev)

rev

min

6 in/min

PROBLEM 4 (Oct. 1998)

What is the value in degrees of 1 radian?

C. 57.29°

A. 5749°

B. 57.94°

D. 57.92°

Compute the cutting speed in fpm of a workpiece with 2 inches diameter and turning

at 100 rpm?

A. 72

C. 62

B. 102

D. 52

ED:!ImI:I

v=rrDN

v = IT (2/12)(100)

SOLUTION

1 rad x] 80°

IT rad

57.29°

PROBLEM 8 (Oct. 2000)

PROBLEM 5 (Oct. 1998)

Compute the manual cutting time in minutes, of a steel plate 4 ft by 8 ft by 2.5 cm

thick with a hand cutting speed of 3.8 to 4 mm/sec, cutting lengthwise.

A. 10

C. 0.38

B. 1.81

D. 8.16

-=~.

.

TIme =

Considering the average value:

Length

Determine the average time to cut by automatic oxygen-acetylene (machine)

crosswise a 4 ft x 8 ft x 4 in thick steel plate.

A. 6.85 min

C. 10 min

B. 318 sec

D. 360 sec

Using the average cutting rate of 9 in/min for oxygen-acetylene cutter.

SOLUTION

Cutting speed

= 52 ftlmin

~8+4

2

=3.9 mm/sec

Time

Length to be cut

cutting rate

4(12)

---

9

-r-

.

5333 min

= 5333(60)

320 sec

= 8 ft (12) (25.4) = 2438.40 mm

Length

Cutting time = ·Cuttingspeed

, PROBLEM 9 (ME Bd. Apr. 96)

2438.40 = 625.23 sec

3.9

Calculate the rpm for machining a cast iron workpiece 6 inches in diameter.

lowest cutting speed for cast Iron is 50 fpm.

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

The

lOMoARcPSD|3535879

44

Machine Shop Practice

A. 35.3

C. 43.3

l\!Jachine Shop Pra ct icc

C. 33.3

O. 53.32

45

I'~O()LEM

12 (ME Bd. Oct. 95)

How long Will it take to saw a rectangular piece of aluminum plate 8 in wide and 1 1/2

In. thick if the length of the cut is 8 in, the power hacksaw makes 120 rev/min and

average feed per stroke is 0.0060 in?

A.13.11

C.11.11

B 14.01

O. 12.03

SOLUTION

v=nON

50 = rr(6/12)N

E1':'m!immI

N = 31.83 rpm

The answer is: C (nearest)

time

Length of cut

------------

Cutting Rate

PROBLEM 10 (ME Bd. Oct. 95)

With the arc welding rate of 18 in/min, how long will It take to weld 1/2 in thick plate by

3 feet long seam?

A. 3 min

C. 2 min

B. 1.5 min

O. 4 min

11

A1

J1

1/2"

SOLUTION

Length to be weld

time

- ' " - - - - - -

Welding rate

L = J'

time = (3 x 12)/18 = 2 min

V

V

For a hacksaw. there is only 1 cut stroke per revolution.

.

&n

.

time = - - - -.--- -------..- - - . - - = 11.11 min

120 ev x~troke

xO.0060

In

min

rev

stroke

.r.

PROBLEM 13 (ME BD. Oct. 95)

Using oxyacetylene welding method to weld a 3 ft long seam in a 3/8 in thick plate at

a consumption rate of 9 ft31ft of weld for oxygen and 7 felft for acetylene. What is the

total combined gas consumption in ft3?

A. 51

B. 48

C. 45

O. 55

E1':'m!immI

PROBLEM 1 1 (ME Bd. Apr. 95)

How long will it take to mill a 3/4" by 2" long keyway in a 3" diameter shafting with a

24 tooth cutter turning at 100 rpm and 0.005" feed/tooth?

A. 0.136 min

C. 0.196 min

B. 0.166 min

O. 0.106 min

v

total gas consumption of oxygen and acetylene

v

ft3

(9 + 7 ) - - - (3) ft length = 48 ft3

ft length

SOLUTION

PROBLEM 14

time

A grinding wheel rotates 1750 rpm and has a surface speed of 2290 ft/min.

diameter of the wheel in inches.

A. 3 in

C. 4 in

B. 5 in

O. 6 in

Length to be cut

-----_.

- . -

Cutting rate

time

2in

24 te~

x1 o~e_v

rev

time

0.167 min

"-N !Ii it-D

x~.O-

min

tooth

v=rrON

2290 = rr (0) (1750)

0=5 in

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

Find the

lOMoARcPSD|3535879

46

PROBLEM 15 (ME Bd. Apr. 96)

To facilitate the milling (roughing) work of a cast steel material using a 1 1/2 inch

diameter cutter choose between the two available stock. Find the

speed of the

cutter in rpm. -high speed steel cutter with a cutting speed of 50 fpm - carbide tipped

cutter with a cutting speed of 200 fpm

A. 389

C. 572

B. 509

O. 412

SOLUTION

47

MUc!liTI<' Shop Practice

Mcicttinc Shop Practice

o = 0.955 ft (12) == 11.461n

PROBLEM 18

A workpiece turning at 20 rad/s has a diameter of 4 in. Find the peripheral speed of

workpiece

C. 5.23 fps

A. 1.23 fps

O. 7.34 fps

B. 3.33 fps

EmmmD

v=nON

High speed steel cutter (slower)

50(12) = n(1.5)N

N

20 ( 1rev)

N

3.183 rev/s

2n

v == nON = IT (4/12) (3.183) = 3.33 fps

N = 127 rpm

PROBLEM 19

Carbide tipped cutter (faster)

Two plates 4 ft x 8 It plate % in thick is to be joined lengthwise. A welding machine to

be used has a welding rate of 20 in/min. How long will it take to join the plates?

.

A. 7.34 min

C. 4.80 min

B. 1.23 min

O. 6.45 min

200(12) = n(1.5)N

N = 509 rpm

EmmmD

PROBLEM 16

A piston reciprocates 100 times per minute (single stroke). The length of the stroke is

6 in. What is the average wristpin velocity in ft/min?

A. 50 ft/min

C. 75 ftimin

B.100ft/min

0.125ft/min

SOLUTION

\

Time

--------._--

Time

8 x 12' = 4.8 min

20

Welding rate

,

v == LN

ft

stroke

.

v == (6/12) _ . - (100) ---.- = 50 ft/rnin

rrun

stroke

4"

Length to be weld

~

(

8"

PROBLEM 17

A workpiece turninq at 300 rpm has a tangential speed of 15 ft/s. Find the diameter. PROBLEM 20

I A 10 It long seam can be weld in 10 min. The welding rate is:

of the workpiece.

A. 8 in/min

C 10 in min

C. 13.23 in

A. 11.46 in

B. 12 in/min

O. 14 in/min

O. 17.34 in

B. 15.23 in

EmmmD

V=nON

EmmmD

.

Length to be weld

Time = . - - - ----.--Welding rate

15 == IT (0) (300/60)

~."fi _

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

I

8''''

lOMoARcPSD|3535879

i'vlachirlc ShoJi )'/rl( I ice

48

Machine Shop Prartire

1l4·I l!mm

10(12)

10

--

- - --- -----

Welding Rate

Length to be cut

time =

A seam can be weld in 3 min. If welding rate is 15 in/min, find the length of seam.

A. 20 in

C. 25 in

D. 45 in

B. 30 in

SOLUTION

time

5

0.2

25 sec

PROBLEM 24

Length to be weld

-------~--

Welding rate

L

Length to be weld

It takes 1 min to mill a 3;'/ x 4" keyway of a hub by means of a cutter having 30 teeth

at 120 rpm. Find the equivalent feed per tooth, In/tooth

A 000222

C 0.00333

B 000444

D. 0.00111

EI!!ImD

---------~

15

Length to be weld

= 45 in

time

PROBLEM 22

How long will it take to mill %" by 1.5" long keyway by means of 25 teeth cutter turning

at 120 rpm and 0.008" feed/tooth.

A. 1.23 sec

C. 4.23 sec

D. 375 sec

B 634 sec

SOLUTION

Length to be cut

---.---------_._-

Cutting rate

- - ----

4

,---~

------.

rev

teeth

120 . x 30 -- - x Feed per tooth

min

rev

Feed per tooth

= 0.00111 in/tooth

PROBLEM 25

How long will it take to cut a rectangular plate 4 it wide by means of a saw that has a

speed of 160 rev/min and an average feed per stroke of 0.009 in?

A. 22.22 min

C. 55.55 min

D. 44.44 min

4"

B 3333 min

Length to be cut

time

--

time

------------"

time

,-----'

Cutting rate

time

PROBLEM 21

3

-

12 in/min

Welding rate

Time

-~--

Cutting rate

1.5

120 ~ev

x 25 teeltl x O.OOB

min

4~)

rev

0.0625 min (60)

EI!!ImD

in

tooth

= 3.75 sec

time

Length to be cut

-.---

---

-

Cutting rate

For a hacksaw, there is only one cut stroke per revolution.

PH.OBLEM 23

A 5 in long keyway is 10 be mill at the rate of 0.2 in/min. How long will it take to mill

the keyway?

A. 20 sec

C 25 sec

B. 15 sec

0 30 sec

4 (12)

lime = .'

----.

160 rE3~

x l~trokE3.

x 0.009

in

min

rev

stroke

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

= 33.33 minute

_.~

~

lOMoARcPSD|3535879

,~!uchine

50

PROBLEM 26

A 4ft wide x 8 ft long and 1,12 In thick steel plate is be cut into 4 equal parts crosswise

If cutting rate is 0.02 In/stroke and saw speed is 110 rpm, how long will it take to do

the job?

A. 53.45 min

C. 65.45 min

D. 67.45 min

B. 3423 min

4"

SOLUTION

L

L

~

L

total length of cut

L

4 cuts (4 ftl cut)

time

total length of plate to be cut

3 cuts (4 ft / cut) = 12 ft

Length__to be cut

.._--

time

time

--

Cutting rate

4"

= 16 ft

---,

..- - - - - - - - -

Cutting rate

16 (12)

10

19.20 min

USing oxyacetylene welding method to weld 10ft long seam In a 1,12 In thick plate at a

3

3

consumption rate of 10ft /ft oxygen and 8 ft /ft for acetylene. What is the total gas

consumption?

C,160fe

A 150 ft3

o 180 fe

B. 170 ft'!

PHOBLEM 27

1/2"

~

It takes 5 min to cut a plate 20 ft long by means of a saw having a speed of 250 rpm.

What is the average feed per stroke 01 the saw, in/stroke?

A 0.534

C. 0.745

B. 0.192

D 0.342

v

Total gas consumption

~

v

Volume ()f~9

(Length to be weld)

length to be weld

V

(10+8)(10)

V

180 ft'!

Length to be cut

-_.__

- - - - - _ ~ .

Cutting rate

20

20 (12)

-.---- .----.--.----.---

250

rev

stroke

.-- x 1 -- - x Feed per stroke

min

rev

Feed per stroke

EW'M~:sazc

11

For a hacksaw, there is only one cut stroke per revolution.

5=-

8"

Length to be cut

PROBLEM 29

For a hacksaw, there is only one cut stroke per revolution.

12(12)

.

time = -.~_c

= 65.45 min

rev

stroke

In

110- x 1 - --- x 0.02

min

rev

stroke

time

51

r\i!uchinc Shop Prac t icc

Shop Piact icc

PROBLEM 30

A 24 ft2 lateral surface for a cylindrical tank is to be made by joining 2 ft by 2 ft steel

3/lt

plate to form 6 It x 4 ft. The consumption rate for both oxygen and nitrogen is 20 ft

using oxyacetylene welding method. Find total gas consumption needed, fe.

A, 250 fe

C. 440 fe

3

B. 470 ft3

D. 280lt

~

o 192 in/stroke

PROBLEM 28

4"

2"

An oxyacetylene cutter IS use to cut a 4 ft x 8 ft steel plate crosswise and divided the

whole plate into five equal parts. If the cutting rate is 10 in per minute, how long Will It

take to cut the plates.

A 19.20 min

C. 21.23 min

D 1734 min

B. 13.45 min

2"

L = total length to be weld

L = 6+4+4 = 14ft

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

~

6"

~

lOMoARcPSD|3535879

52

Total gas consumption

Total gas consumption

Mac n in« Shop Practice

·

..

4.

(20) (14)

280 ft3

PROBLEM 31

.

A 10ft X 20 ft plate is to be divided into 8 pieces 5 ft x 5 ft steel plate by means of an .

oxyacetylene cutter that has a cutting rate of 10 in per minute. How long will it takes

to do the Job?

C. 60 min

A. 50 min

B 70 min

O. 80 min

SOLUTION

10"

L = 20 + 10 + 10 + 10

L = 50 ft

.

Length to be cut

time = - - - . - - Cutting rate

M1ACHINE

ELEIVIEN-r!:»

-

5"

5"

L = total length to be cut

53

Mach inc Elcrncli t s

1. Cylinders Rolling in opposite direction:

20"

50 (12)

10

= 60 min

~

Tangential speed

V2

V1 = V2 = TI 01 N1 = TI 02 N2

(.

Relation of diameter and speed

D1 N1 = D2 N2

to Speed Ratio ==

".

Center Distance

Speed of Driver

Speedof the Driven

R + R

1

2

c

= D 1 +~2

2

2. Cylinders Rolling in the same direction

4L.

Tangential speed

V1 = V2 = TI D1 N1 = TI D2 N2

\.

Relation of diameter and speed

01 N1 = D2 N2

(.

Speed Ratio

Speed of Driver

= Speed of the Driven

I

I

(.

Center Distance

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

R z - R1

l:)?=_l:)l

2

101(

.

C

..

I

lOMoARcPSD|3535879

54

Mach.irie Elements

PROBLEM 1 (ME Bd. Apr. 97)

Two parallel shafts connected by pure rolling turn in the same direction having a

speed ratio of 2.75. What is the distance of the shafts if the smaller

cylinder is 22

cm in diameter?

A. 16.67 cm

C. 30.25 cm

B. 25.25 cm

O. 19.25 cm

PROBLEM 3

A 5 ft diameter pulley is turning at 200 rpm. Find the speed of the pulley mid-way of

the center and outer surface of the pulley.

A. 20.45 ft/s

C. 24.34 ft/s

B. 30.45 fils

O. 26.18 fils

E'iI!!ImD

SOLUTION

v == 2 IT Im N

Using the relation of 0 and N:

0 1 N1 == O2 N 2

22(2.75) == O2(1)

O2 == 60.5 cm

r == 5/2 == 2.5 ft

rm == 2.5/2 == 1.25 ft

v == 2 t: (1.25) (200/60)

For cylinders in the same direction:

C == O2 _=-P-l

2

v == 26.18 fils

PROBLEM 4

60.5 - 22

C

_ ..

C

19.25 cm

~-

A wheel is turning at 360 rpm.

the radius of the flywheel?

A. 8ft

B. 2ft

2

PROBLEM 2 (ME Bd. Apr. 97)

A lineshaft runs at 360 rpm. An 18" pulley on the shaft is belt connected to a 12"

pulley on the countershaft.

From a 15" pulley on the countershaft, motion is

transmitted to the machine. Compute/check the required diameter of the pulley on the

machine to give a spindle speed of 660 rpm.

A. 16"

B. 121/4"

C. 101/2"

O. 81/2"

12"

SOLUTION

OL N L

55

Mci ci': inc ElcITICf/( S

== Dc Nc

If tangential speed of the wheel is 15080 ft/s, what is

C. 4 ft

O. 10ft

E'iI!!ImD

v==ITON

150.80 == IT 0 (360/60)

o

8ft

R

8/2

4ft

18(360) == 12N c

Nc == 540 rpm (speed of countershaft)

Dc Nc == OMNM

If center distance is

Lineshaft

Countershaft

Machine

15(540) == OM(660)

SOLUTION

OM == 1227

Say 12 1/4"

Speed ratio == - ~ N

-

3

-1-

2

0 1 N 1 == D 2N 2

O2 == (N,/N 2)DI

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

'.

I

C

= 40 in.1"

lOMoARcPSD|3535879

57

Machine Elcmcnt s

5G

Machine Elements

EmmiImI

D2 = DI (3/1)

DA N A = DB NB

DA (6) = DB (4)

DA = 2/3 DB

D2 = 3 D,

For cylinders rolling in opposite direction:

C =~_-+:

40

D,

DB NB = De Ne

DB (4) = De (2)

De = 2 DB

D

Dc

CAe = - A + DB + -2

2

2

3D + D

1

1 _._-,,-

2

20 in (smaller pulley)

PROBLEM 6

Three cylinders A:8:C rolling in external contact has a speed ratio of 4:2:1. If the

diameter of cylinder A is 10 ern, find the center distance between cylinder A and C.

A.40cm

C.45cm

8. 35 cm

D. 50 ern

K-N':JmmI

DA NA

DB NB

10(4)

DB (2)

DB NB

20 (2)

o, (1)

2/3 DB

---- + DB + 2D

--B

2

2

30 = 2.33 DB

DB = 12857 in

DA = 2/3 (12.857) = 8.571 in

Dc = 2 (12.857) = 25.714 in

2

Dc = 40 cm

CAe

=30in

De Ne = Do No

25.714 (2) = Do (1)

Do = 51.428 in

2Do

D

CAO = - A + DB + Dc + - 2

2

8571

51.428

CAO = - - - + 12857 + 25714 + - - -

DB = 20 cm

o, Nc

CAe =

~c

Dc

DA

+ DB+--

2

2

10

40

CAe

-- + 20 + --2

2

CAe

45 cm

PROBLEM 7

Four cylinders A:8:C:D has a speed ratio of 6:4:2:1. If center distance between A and

C is 30 inches, find the center distance A and D.

A. 68.57 m

C. 5634 m

8. 83.45 m

D. 7634 m

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

2

68.57 in

lOMoARcPSD|3535879

58

51 resses

I

5

STRESSES

12. Strain (unit strain) - is the total deformation measured in the direction of the line

of stress.

13. Modulus of Elasticity - is the ratio of stress to the strain.

14. Residual Stress - internal inherent, trapped locked-up body stress that exists

within a material as a result of things other than external loading such as cold

working, heating or cooling, etching, repeated stressing and electroplating.

~

15. Compressive Strength - is the ability of a material to resist being crushed.

16. Bending Strength - is the quality of a material which resists forces from causing

a member to bend or deflect in the direction in which the load is applied.

~

Force

. 2

2

2

1. Stress (S) = -----, lb/in , kg/cm , KN/m

Area

Stress - a total resistance that a material offers to an applied load.

2. Ultimate stress (Su) - is the stress that would cause failure

3. Yield stress(Sy) - maximum stress without causing deformation

4. Allowable stress(Sail)

59

Stresses

~

1. Tensile Stress (S,)

S, = Ft

A

D

For solid circular cross-section: A = 2: 0"

4

= Ultimate stress/Factor of Safety

For hollow circular cross-section: A = ~(Oo

5. Design stress(Sd) - stress used in determining the size of a member.

Based on ultimate stress:

Based on yield stress: ~"i=-c±

where: FS = factor of safety

6. Working stressfSc) = stress actually occurring under operating condition.

7. Endurance limit or fatigue limit = the maximum stress that will not cause failure

when the force is reverse indefinitely.

8. Elastic limit - is the maximum stress to which a standardized test specimen may

10. Strength - is the ability of metal to withstand loads without breaking down.

11. Shear strength - is the ability of metal to withstand forces thus following a

number of twist.

_Oj2)

F

For rectangular cross-section: A "'base x height

2. Compressive Stress(Sc)

Sc =

F

Fe

A

For solid circular cross-section: A = ~

be subjected without a permanent deformation.

9. Proportional Limit - is the stress at which the stress-strain curve deviates from a

straight line.

2

4

4

For hollow circular cross-section: A = ~

02

~D

2

4

(0 0 _Oj2)

For rectangular cross-section: A = base x height

Note: For both compressive and shearing stress, the area is perpendicular to the line

of force.

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

lOMoARcPSD|3535879

Srress es

61

5 I r esses

3. Shearin g Stress( Ss}

A

For single bolt of rivet needed to join to plates together.

Ss

5. Factor of safety( FS}

D

F

a. Based on yield strengt h

F

where:

cross section)

~ircula

(fO~

.il4p~

For single rivet: A

For double riveted joint: A =2(rr74 p2)

F '" applied load

Note: The shearin g area is always parallel

to the line of force.

b. Based on ultimat e strengt h

F

II

where:

B. Shearin g due to punchin g of hole.

Sail ::: allowab le stress

Su = ultimate stress

5 y '" yeild stress

(for punchin g a hole)

(for square hole)

t~

Where: S '" length of side of square

t '" plate thickne ss

6. Torsion al Shear Stress( Ss}

nOs

where:

T '" torque

J '" polar momen t of inertia

Pressur e needed to punch a hole. F:

(focsolipShaft)

F= (fXlx8 0,tons

~£.

c '" distanc e from neutral axis to the farthest fiber

c '" r (for circular cross section)

d = diamete r

d '" hole diameter, in

t '" thicknes s, in

7. Bendin g Stress( Sr}

FROM MACH INERI ES HAND BOOK p. 1149:

W ::: working strength to screwe d up tightly to packed joint

where:

F

P,ojec ted "'ea

..

= DL

+ ""J

g....--L--:a

I

Where: Sj '" working stress, psi

d '" bolt diamete r, in

where: A

F

Sf:= Me

2

W:=iSI (O.55d ;>0;250)

4. Bearing Stress( Sb)

~

16T

o

FROM MACH INERI ES HAND BOOK p. 1924:

Where:

T

~

M '" momen t

c = distanc e of farthest fiber from neutral axis

I '" momen t of inertia about the neutral axis

3/12

(for rectang ular cross section)

I = bh

M

I

Z := section modulu s := - : = -

e

L

1<

D

)j

D

8. Strain and Elonga tion

c

Strain

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

y

Sf

lOMoARcPSD|3535879

62

Stresses

(. Stress ==

Sa=' Smax=.§min

2

Smax == maximum stress

Smm == minimum stress

A

L

"

(., Poisson's Ratio(u) == is the ratio of lateral unit deformation to axial unit

deformation.

(.

where:

~

Y == elongation due to applied load

L == original length

F == force

A == area

S == stress

U=

where:

,I

(t2 - tl)

e.

E

-

E

2G

G == shear modulus of elasticity

E == modulus of elasticity

F

.

F

AE

E == stram ==-.....

9. Thermal Elongation; Stresses

e

63

Stresses

F

U ==

r

~

v

L

h2

q I"""

-J

V/2

Longitudinal Strain

== By.

Ex

~

Ex == L z -L1

L

1At J4UJ.ij

.

Lateral Strain

-----,,___

~.=

Ez

Ex

E == WZ - W1

y

L1

w1

E == t2 - t 1

z

11

k-V/2

PROBLEM I (Apr. 1999)

A steel rod 30 mm & 800 mm long has an allowance elongation not to exceed 1.5

where:

Y == elongation due to temperature difference

k == coefficient of thermal expansion. m/m-oC

t 1 == initial temperature, "C

b == final temperature, °C

mm, find the allowable load in kN.

A. 278

B. 248

C. 316

D. 236

4-t-l i 'i'(,]:'1

(., Relation between shearing and tensile stress based on theory of failure:

For steel:

~y

Ssrnax

1

(., Variable Stress

E == 30 x 10 6 psi

Y _

206,785,714 kpa

FL

FS

AE

FS == factor of safety

Sy == yield point

Sn == endurance limit

Sm == mean stress

0.0015 ==

where:

Smax +Smin

2

Sa == variable component stress

F(0.800)

- - -

~ (0.03)2(206,785,714)

4

F == 274 KN

1'[{OBLf<:M 2 (Oct. 2000)

Compute the induced/compressive stress, In kpa. of a steel solid shafting of 50 mm

diameter and 800 mm in length that is subjected to an increase of temperature by

80"C.

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

lOMoARcPSD|3535879

64

Stresses

Stresses

A. 181,816

B. 242,816

65

SOLUTION

C. 218.182

D. 196,560

Z == Polar section modulus

SOLUTION

Z == TIS

Where:

For steel:

T == torque

S == stress

6

E == 30 X 10 psi == 206,785,714 kpa

6

G == 12 x 10 psi == 82,714,286 kpa

6

a == thermal elongation == 11.7 x 10- m/mDC

Using thermal elongation formula:

S == K E (t2 - t1)

S == 11.7x10

6(206,785,714)(80)

IT d

3

Simplify:

IT d

TIS

3

_ IT (3)3 == 5.30 in3

16

16 -

193,551.43 Kpa

PROBLEM 5 (Apr. 1999)

The answer is: D (nearest)

PROBLEM 3 (Oct. 2000)

Compute for the load in KN on a 3 cm diameter, 100 cm long steel rod if its maximum

elongation exceed 0.12 cm.

C. 148

A. 178

B. 196

D. 287

Em!!ImD

Compute the allowable load in kN on a 20 mm x 120 cm long steel rod with a

maximum elongation must not exceed 1 mrn.

A. 35

C. 66

B. 55

D 76

~

For steel:

E == 30x10 6psi == 206,785,714kpa

For steel:

6

E == 30 x 10 psi

FL

y == - AE

0.0012 ==

16 T

S

206,785,714 kpa

y ==

~

AE

0001 ==

F (1.0)

.._ - - - - - -~

IT (0.03)2 (206,785,714)

F (1

-J (0020)2(206,785,714)

F == 54.1364 KN

4

F == 175.40 KN

PROBLEM 6 (Oct. 2000)

Determine the load in kw on a 25 mm diameter x 1200 mm long steel shaft if its

maximum elongation exceeds 1 mm.

A. 83

C. 103

B. 125

D 234

The answer is: A (nearest)

PROBLEM 4 (Oct. 2000)

Compute for the polar section modulus of a SAE 1060 shafting having a diameter of 3

inches. Use a factor of safety of 2 and design stress at 800 psi.

A. 4.7

C. 4.2

B. 6.1

D. 5.3

Ei-l"imD

For steel:

E == 30 X 10 6 psi zz: 206785,714 kpa

Downloaded by King Nixon Lagrisola (knlagrisola@gmail.com)

lOMoARcPSD|3535879

ast·m1D(.]tI

FL

Y = _.AE

F(120)

.

0.001 = . - - . - . - - .

IT (0.025)2(206,785,714)

4

F = 84.59 KN

S

Em!!mm

3

to fix a lever to a shaft,

Determ ine the minimu m mean diamete r of a taper pin for use

r is 2 inches and

diamete

shaft

The

in-lbs.

700

of

torque

m

if it is transmi t a maximu

2.

of

safety

of

factor

the materia l allowab le stresse s is 15,000 psi. Use

mm