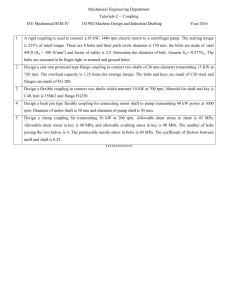

Load & Stress Analysis Tutorial: Mechanical Engineering Design

advertisement

Faculty of Engineering and the Built Environment Mechanical Engineering Design 2: MED260S Load and Stress Analysis, Tut#1 Answer the following problems (Shigley’s Ch3): 2023 / Semester 2 1. For each of the plane stress states listed below, draw a Mohr’s circle diagram properly labelled, find the principal normal and shear stresses, and determine the angle from the x axis to σ1. Draw stress elements in the principal orientation and maximum shear orientation and label all details. a) σx = 12, σy = 6, τxy = 4 cw b) σx = 10, σy = 24, τxy = 6 ccw c) σx = −4, σy = 12, τxy = 7 ccw d) σx = −10, σy = 18, τxy = 9 cw 2. Sketch a free-body diagram of each element in the figure. Compute the magnitude and direction of each force using an algebraic or vector method, as specified. 3. Twin diagonal aluminium alloy tension rods 15 mm in diameter are used in a rectangular frame to prevent collapse. The rods can safely support a tensile stress of 135 MPa. If the rods are initially 3 m in length, how much must they be stretched to develop this stress? 4. Using a maximum allowable shear stress of 60 MPa, find the shaft diameter needed to transmit 35 kw when (a) The shaft speed is 2000 rev/min. (b) The shaft speed is 200 rev/min. 5. A 15-mm-diameter steel bar is to be used as a torsion spring. If the torsional stress in the bar is not to exceed 110 MPa when one end is twisted through an angle of 30°, what must be the length of the bar? 6. A hollow steel shaft is to transmit 5400 N·m of torque and is to be sized so that the torsional stress does not exceed 150 MPa. (a) If the inside diameter is three-fourths of the outside diameter, what size shaft should be used? Use preferred sizes. (b) What is the stress on the inside of the shaft when full torque is applied? 7. The conveyer drive roll in the figure is driven at 8 rev/min by a geared-motor source rated at 1 kW. Find a suitable shaft diameter dC based on an allowable torsional stress of 75 MPa. d c