AGMA Standard: Surface Durability of Spur Gear Teeth

advertisement

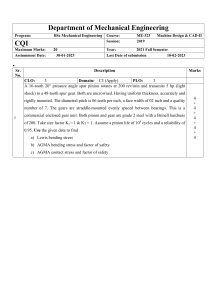

A G M A 210 . 0 2 JAN., 1965 AGMA STANDARD ( for r I < Surface Durability (Pitting) of Spur Ciear Teeth MA .02 5 Put/;s�eJ t�: AMERICAN 1330 Massachusetts Avenue, N. W. • GEAR MANUFACTURERS Washington, D. C. 20005 ASSOCIATION (. ) ) FOREWORD This standard is for rating the surface durability of spur gear teeth. It contains the following: Basic Rating Formula This section enumerates the factors known to affect surface durability. Numerical values are presented for those factors which have been evaluated by analytical means, test results or field experience. Suggestions are made for the factors which are not now capable of being expressed accurately. New knowledge and more definite measurement of these parameters will continually necessitate revisions and improvements, In addition to the above, it is contemplated to publish design practices such as AGMA 2 1 1.0 2A, having specific application under the heading of: Design Practices for Specialized Applications It is recognized that it is sometimes desirable to provide simplified design practice data applicable to a specialized field of application. These individual design practices will enable enclosed speed reducer, mill gear, aircraft or other specialized product designers to record the modifications and limitations they wish to use. Information on references, derivations, explanations and examples are contained in AGMA 229.06. Basic data illustrating the coordination of rating for all types of gears is contained in Tentative Information Sheet AGMA 215 .01, "Surface Durability ( Pitting) of Spur, Helical, Herringbone and Bevel Gear Teeth," The first draft of this standard was prepared rn October, 196 1. membership as of June 13, 1964. It was approved by the AGMA Tables or other self-supporting sections may be quoted or extracted in their entirety. lines should read:. Teeth (AGMA Credit "Extracted from AGMA Standard for S urface Durability (Pitting) of Spur Gear 210.02), with the permission of the publi sher, the American Gea r Manufacturers Assoc iation 1330 Massachusetts Avenue, N. W., Washington, D. C. 20005." COPYRIGHT, 1965, BY AMERICAN GEAR MANUFACTURERS ASSOCIATION - 2 - Personnel of Gear Rating Committee Technical Division January, 1965 E. ] Wellauer, Chairman, The Falk Corp., Milwaukee, Wis. • D. L. Borden, Jr., The Falk Corp., Milwaukee, Wis. Wells Coleman, Gleason Works, Rochester, New York D. W. Dudley, Mechanical Technology, Inc., Latham, New York ] . H. Glover, Ford Motor Co., Dearborn, Michigan I. Koenig, Hewitt-Robbins, Inc., Chicago, Illinois C. F. Schwan, Reliance Electric & Engineering Co., Cleveland, Ohio ] . C. Straub, Wheelabrator Corp., Mishawaka, Indiana F. A. Thoma, Warner & Swa sey Co., Cleveland, Ohio N. A. Wilson, Morgan Construction Co., Worcester, Mass. G. L. Scott, AGMA, Washington, D. C. AGMA Standards are subject to constant improvement, revlSlon or withdrawal as dictated by experience. Any person who refers to AGMA technical publications should satisfy himself that he has the latest information available from the Association on the subject matter. - 3 - AGMA STANDARD SURFACE DURABILITY (PITTING) OF SPUR GEAR TEETH 1. Scope The symbols used, wherever applicable, con­ 1.5 form to Standard AGMA 112.04, "Gear Nomenclature­ Terms, This standard presents the fundamental fo7mula 1.1 Abbreviations" and, "Letter Symbols for Mechanics of Solid Bod­ for rating the surface durability (pitting) of spur gear teeth. Definitions, Symbols, and ies," ( ASA Zl0.3-1948) (Rl953). It contains all of the factors which are known to affect the resistance of gear teeth to pit­ ting. This formula is not applicable to other types of gear tooth surface deterioration such as plastic yielding, scoring, wel ding, etc. 2. This standard is Fundamental Pitting Durability Formula based on AGMA Information Sheet 215.0 1, "Informa­ tion Sheet for Surface Durability ( Pitting) of Spur, The fundamental pitting durability formula for 2.1 Helical, Herringbone and Bevel Gear Teeth" and is gear teeth is as follows: coordinated with the durability ratings for helical, herringbone, and bevel gears. 1.2 Pitting of gear teeth is considered a fatigue phenomenon. The two kinds of pitting - 1) initial, and 2) destructive - are illustrated in Standard AGMA 110.03, "Gear-Tooth Wear and Failure." Corrective and non-progressive initial pitting is not deemed serious. The aim of this standard is to de­ sign the gear teeth so that destructive pitting does Where: not occur. sc 1.3 Surface durability rating practices for a particu­ elastic coefficient (see Section 16) lar field of gearing may be established by selecting the proper factors for this general formula. calculated contact stress number Proper evaluation of the various factors in the basic for­ mula will produce suitable ratings for any applica­ transmitted tion. tangen tial load 10 pounds at operating pitch diameter (See Section 4) 1.4 Load Where no applicable specific AGMA standard overload factor exists, numerical values may be estimated for the factors in this general formula and an approximate (See Section 10) dynamic faccor (See Section 9) surface durability rating calculated. -4- AGMA STANDARD SURFACE DURABILITY (PITTING) OF SPUR GEAR TEETH d = pinion operating pitch diameter, in. NOTE: (or to account for differences in material properties, outside diameter minus two addendums when applicable) Size Both pinion and gear teeth must be checked and number of tooth contact cycles under load. net f�c;e_ width of the narrowest of the mating gears, in. Cs = size factor (see Section 7) 3. cm = load factor (See Dis- The following formula may be used to calculate 3 .1 Section 6) S tress the power directly: geometry factor (See Section 5) tribution distribution cl surface Surface Durability Power Formula condition factor np p ac (See F 126,000 Section 8) Where: NOTE: p ac The above equation is divided into three allowable power, hp groups of terms; the first is concerned with load, pinion speed, rpm. the second with gear size, and the third with stress distribution. 2.2 The relation of calculated contact stress num­ ber to allowable contact stress number is: 4. 4.1 Transmitted Tangential Load - W1 The transmitted tangential load is calculated directly from the power transmitted by the gear set. (When operating near a critical speed of the drive, a Where: careful analysil? of conditions must be made.) When allowable contact stress number Section 15) the transmitted load is not uniform, consideration (See should be given not only to the· peak load and its anticipated number of cycles, but also to intermedi­ ate loads and their number of cycles. life factor (See Section 12) 4.1.1 hardness ratio factor (See Section 14) Frequently a gear set is required to carry a peak load for a limited number of cycles, and then a much smaller load for a much larger number of cycles. temperature factor (See Section 13) In such cases the gear rating should be adjusted so that each load and number of cycles carried by the factor of safety (See Section 11) gear set is within allowable stress limits. - 5- AGMA 210.02- Jan., 1965 fr. AGMA STANDARD SURFACE DURABILITY (PITTING) OF SPUR GEAR TEETH 11:.Z The transmitted tangential load is : p x 33,000 D operating inches me gear ratio zc distance (inches) measured along the line of action from the pitch point to the lowest point of single tooth contact. (See Figure A-1) Values for Zc for one diametral pitch are shown in Figures A-2 and A-3 for standard operating center distances. Values for Zc for any dia­ metral pitch can be obtained by dividing these values by the diametral pitch. 126,000 p 2T d Where: p transmitted power, hp T pinion torque, lb-in pitch line velocity, fpm 5. - Geometry Factor pitch diameter of gear - Geometry factors for standard center distances are shown in Figure 1. For non-standard centers or special tooth geometry, see Appendix B. 5.2 I 5.1 The greatest contact stress oc curs at the lowest point of single tooth contact of the pinion. The geometry factor for this position of loading is as follows. The derivation is presented in Appendix A. For an external gear : 6, (; � (- � ( � ) me 2 cot¢ sin¢ Zc -+ - me + 2 D sin¢ Zc -- · - Distribution - Cm 6.1 The load distribution factor Cm, evaluates the effects of non-uniform distribution of load, and depends upon : d 2 Load For an internal gear : 2 cot¢ ( )( me me ) (-- ) sin¢ Zc ---- 1 2 D 1. cutting errors sin¢ - 2 Zc 2. errors m rotating axis m mounting due to bore tolerances - d 3. internal bearing clearance Where: d operating pressure angle - degrees 4. parallelism operating pitch diameter of prn10n inches 5. tooth stiffness of shafts carrying each gear (includes runout) - 6- AGMA STANDARD SURFACE DURABILITY (PITTING) OF SPUR GEAR TEETH 6. 4 When gears. are hardened after cutting, and the profiles are not ground or otherwise processed to insure high accuracy, the tooth distortion will affect the load distribution. When Cm is selected from Figure 5 then: 6. blank stiffness 7. shaft stiffness 8. housing stiffness 9. bearing deflection 6. 4. 1 Multiply cm by 1.05 if one element lS hard­ ened after cutting. 10. Hertz deflection 11. thermal expansion and distortion due to operating temperatures. This is especially important for wide face gears. Multiply Cm by 1.10 if both elements are hardened after cutting. 6. 4.2 6.1. 1 Figures 2 and 3 illustrate misalignment and its effect on load distribution. The effect of different rates of misalignment is shown in Figure 4. Fm represents the face width having 100 per cent contact for a given tangential load and misalignment error. Generally, Fm should exceed F. The amount of misalignment shown in Figure 4 must consider all factors shown in para­ graph 6. 1. 6.1.2 7. Size Factor - Cs 7 .1 The size factor reflects the effect of dimens1ons on the uniformity of material properties. It depends primarily on: 1. tooth size 2. gear diameter Manufacturers of wide-face gears generally find it necessary to c ontrol misalignment by other means than by allowed rates of misalignment. To handle such cases, Table 1 shows appropriate values of 6.2 3. face width 4. ratio of tooth size to gear diameter cm. 5. area of contact pattern 6. ratio of case depth to tooth size For spur gears equivalent to those used in commercial gear units in accuracy and mounting rigidity, the load distribution factor , cm, shown in Figure 5 can be used as a guide. The load distri­ bution factor shown inc l udes other factors affecting gear durability such as size effect, alignment errors, 6.3 7. hardenability and heat treatment of materials. 7. 2 The size factor may be taken as unity for most gears, provided a proper choice of steel is made for the size of the parts, hardness pattern or the total case depth agrees with Figure 6. F etc. When-d ratio exceeds 2 , a more detailed analysis is suggested. -7 - AGMA 210.0 2 - ] an., 1 96 5 V» Md � V AGMA STANDARD SURFACE DURABILITY (PITTING) OF SPUR GEAR TEETH Table 1 Load Distribution Factor for Precision Wide-Face Spur Gears - Cm - F Contact cm 95% face w idth contact obtained at one-third torque 95% face width contact obtained at full torque 1.4 at 1/3 torque 1.1 at full �0:que 75% face width contact obtained at one-third torque 9 5% face w idth contact obtained at full torque 1 .8 at 1 /3 torque 1 .3 at full torque· 35% face width contact obtained at one-third torque 95% face width contact obtained at full torque 2. 5 at 1/3 torque 1. 9 at full torque 20% face width contact obtained at one-third torque 75% face w idth contact obtained at full torque 4.0 at 1 /3 tcrgue 2.5 at full torque Ratio ofd 1 .0 or less --- T eeth are crowned 35% face width contact obtained at one-third torque 85% face w idth contact obtained at full torque 2. 5 at 1 /3 torque 1 .7 at full torque Calculated combined twist and bending of pinion not over . 001 in. over entire face Pinion not over 250 Bhn hardness 7 5% contact obtained at one-third torque 95% contact obtained at full torque 2.0 at 1/3 torque 1 .4 at full torque Calculated combined twist and binding of pinion not over .0007 in. over entire face Over 1 but Pinion not over 350 Bhn hardness 75% contact obtained at one-third torque 95% contact obtained at full torque 2.0 at l/3 torque 1 .4 at fu]J torque l ess than 2 30% contact obtained at one-third torque 75% contact obtained at full torque 4.0 at 1 /3 torque 3.0 a t full torque Calculate effects of deflection and in- Twist and bending exceeds .001 in. over entire face crease c to allow m for misalignment errors -8 - AGMA STANDARD SURF ACE DURABILITY (PITTING) OF SPUR GEAR TEETH 7 .3 Standard size factors have not yet been estab­ 9.2 lished for cases where there is a detrimental size effect. Figure 7 shows some of the dynamic factors that are commonly used: In such cases a size factor greater than unity should be used. Curve # 1 - Should be used for shaved or ground 8, Surface Condition Factor 8.1 spur gears where the factors listed in paragraph Cf - 9. 1 result in no appreciable dyna1r.ic load. The surface condition factor Cf, depends on: 1 . surface finish shaving, as lapping, affected grinding, by Curve # 2 - Should be used for shaved or ground spur gears when the factors listed in paragraph cutting, 9. 1 can develop a light dynamic load. shot peening, etc. 2. residual stress Curve # 3 3. plasticicy effects (work hardening). Should be used for shaved or ground 9. 1 can develop a moderate dynamic load. This curve 8.2 - spur gears when the factors listed in paragraph is recommended for commercial spur gears. The surface condition factor Cf' may be taken as unity when a good surface is developed by either processing or run-in. 9.3 When milling cutters are used to cut the teeth or when inaccurate teeth are generated, lower dy­ namic factors than shown by these curves are re­ 9, 9.1 Dynamic Factor - quired. Cv The dynamic factor, Cv, depends on: 9.4 1. effects of tooth spacing and profile error With numerical knowledge of the factors listed in paragraph 9. 1 and by using methods published in the literature, other dynamic factor curves can be 2. effects of pitch line speed and rpm prepared for specific fields of application. 3. inertia and stiffness of all rotating elements 4. transmitted load per inch of face 9.5 When 5. tooth stiffness actual dynamic loads are computed or measured and are added to the tangential load, the 6. lubricant properties. dynamic factor can be unity. - 9- AGMA 210.02- Jan., 1 96 5 AGMA STANDARD SURFACE DURABILITY (PITTING) OF SPUR GEAR TEETH 10. Overload Factor C0 - 10. 4 Service factors have been established where field data is available for specific applications. These service factors include not only the overload The overload factor makes allowance for the factor, but also the life factor and factor of safety. roughness or smoothness of operation of both the Service factors for many applications are listed in driving AGMA 1 0.1 and driven apparatus. Specific overload Standards, and should be used whenever factors can only be established after considerable applicable. field experience is gained in a particular applica­ place of the overload factor C0, use a value of 1.0 tion. for CR and CL. 10. 2 If a specific service factor is used in In determining the overload factor, considera­ tion should be given to the fact that many prime movers develop momentary overload torques appre­ ciably greater than those determined by the name­ plate ratings of either the prime mover or the driven apparatus. 10. 3 11. Factor of Safety - CR In the absence of specific overload factors, the values in Table 2 should be used. 11.1 The equation factor of safety is introduced in this to offer the designer an opportunity to design for high reliability, or in some instances, to Table 2 Overload Factors - design for a calculated risk. Failure does not mean C 0* an immediate failure under the applied load, but rather a shortening of life. gested list of safety factors. Character of Load On Driven Machine Power Source Uniform Table 3 shows a sug­ Moderate Heavy Uniform Shock Shock 1.00 1.25 Light Shock 1.25 1.50 Medium Shock 1.50 1.75 1. 75 o r h igher Table 3 the factors in Table 2. - CR 2.00 or higher Requirements of Application 2.25 or higher *This table 1s for speed decreasing drives only. Fo< >pood inma>ing d<ive> add .01 Factor of Safety t::J High Reliability 1.25 or higher Fewer than One Failure in 100 1.00 Fewer than One Failure in Three 0.80** <o **At this value plastic profile deformation might occur rather than pitting. - 10 - AGMA STANDARD SURFACE DURABILITY (PITTING) OF SPUR GEAR TEETH 12, Life Factor - CL Table 4 Hardness Combinations 12.1 The life factor, C L, adjusts the allowable loading for the required number of cycles. At the present time, there is insufficient data available to present accurate fatigue curves for any type of gear. The data available indicates that the fatigue curves for pitting will have a slope, as in­ dicated in Figure 8. Temperature Factor - Cy 1 3 .1 The temperature factor, Cy, is generally taken as unity when gears operate with oil or gear blank temperatures not exceeding 250 degrees F, In some instances, it is necessary to use a Cy value greater than unity for carburized gears operating at oil temperatures above 180 degrees F. 14. 14.1 Hardness Ratio Factor - Gear Bhn Pinion Bhn 180 210 225 265 210 12.2 1 3. Typical Gear and Pinion 245 245 285 255 300 270 315 285 335 300 350 The hardness ratio factors (CH) given rn Figure 9 may be used as a guide . 14.3 15, CH Allowable Contact Stress Number - sac The allowable contact stress number, sac' depends on: 15. 1 The hardness ratio factor, CH, depends on: 1. gear ratio 1. material composition 2. hardness of pinion and gear . 2. mechanical properties 3. number of cycles 1 4.2 The gear and pinion hardness combinations shown in Table 4 have been used successfully. 4. temperature - 11 - AGMA 210.0 2 - ] an., 1965 AGMA STANDARD SURFACE DURABILITY (PITTING) OF SPUR GEAR TEETH 5 . size 1 6. residual stress 7. work hardening. Where: 15.2 An allowable contact stress number for 10 million cycles of load application is determined by field experience, for each material and condition of that material. This stress number is designated - Poisson's ratio for pinion and gear respectively Modulus of elasticity for pinion and gear 15.3 The allowable contact stress number for gear materials varies considerably with heat treatment, forging or casting practice, and material composition. 15 .4 The designer should consult other AGMA Rating Standards, and use the contact stress num­ bers given there wherever applicable. If the appli­ cation doe s not fit any of these established classes, then the contact stress numbers" listed in Table 5 may be used as a guide. In Table 5, the lower values are suggested for general design purposes. The upper values may be used when high quality material is used, when 15.5 section size and design allows maximum response to heat treatment and when proper quality control is effected by adequate inspection. 16. Elastic Coefficient - CP 16.1 The elastic coefficient, CP, is defined by the following e quation. Its values for various combina­ tions of gear and pinion materials are shown in Table 6. - 12 - AGMA STANDARD SURFACE DURABILITY (PITTING) OF SPUR GEAR TEETH Table 5 Allowable Contact Stress Number Surface Hard ness, Minimum Material Through Hardened Steel sac Cast Iron 50- 60,000 65-75,000 75 - 85,000 . 180 Blm 85 - 95 ,000 240 Bhn 105 - 115 ,000 AGMA Grade 20 AGMA Grade 30 AGMA Grade 40 3 00 Blm� 120- 135,000 Nodular Iron 360 Bhn 145 -160,000 Annealed 165 Bhn 440 Bhn 170- 190,000 Normalized 210 Bhn Oil Quench and Temper 255 Bhn 90-1003 of the sac value of steel with the same hardness Tensile Strength psi (Min.) Sac 40,000 3 0,000 Case Carburized (see Note 1) 55 RC 180-200,000 Bronze 60 Rc 200-225,000 Tin Bronze AGMA 2C (10123 Tin) Aluminum Bronze ASTM B 148 -5 2 (Alloy 9C-H.T .) Flame or Induction Hardened so RC NOTE 1. sac Surface Hardness, Minimum Material sac - 170- 190,000 - 175 Bhn 200 Bhn .... - 65,000 90,000 For minimum case depths at the pitch diameter as shown rn Figure 6. Table 6 Elastic Coefficient - CP Gear Material and Modulus of Elasticity - E* Pinion Material and Modulus of Elasticity - E* Steel 30 x Cast Iron 106 19 x 106 Aluminum Bronze 17.5 x 106 Tin Bronze 16 x 106 Steel 30 x 106 2300 2000 1950 1900 Cast Iron 19 x 106 2000 1800 1800 1750 Aluminum Bronze 17.5 1950 1800 1750 1700 Tin Bronze 16 1900 1750 1700 1650 Poisson's Ratio *NOTE: = x x 106 106 0.30 When more exact values of E are obtained from roller contact tests, they can be used. - 13 - 0 AGMA 210.02 - Jan., 1965 z � .100 LI: >­ � .080 w � !il <!> .060 2 0 3 14t DEGREE (A) 4 6 5 GEAR RATIO 8 7 9 10 PRESSURE ANGLE FULL DEPTH TEETH STANDARD ADDENDUM = .!.. pd H I a: � u rt Np= 50 OR MORE .140 Np= 30 Np= 24 .120 N p= 16 >­ a: l;j .100 � !il (!) .080 .060 0 2 ( B) 20 DEGREE 3 4 5 6 8 7 GEAR RATIO 9 10 PRESSURE ANGLE FULL DEPTH TEETH STAND ARD ADDENDUM:: � d � Np=24 >- Np= 16 rt .1 00 � � .080 0 w (!) .060 0 2 (C ) 20 3 DEGREE 4 5 GEAR RATIO 6 PRESSURE ANGLE STANDARD ADDENDUM = 8 7 9 10 STUB TEETH - � d NOTE: ALL CURVES ARE FOR THE LOWEST POINT OF SINGLE TOOTH CONTACT ON THE PINION. FIG. I EXTERNAL SPUR PINION GEOMETRY FACTOR FOR STANDARD CENTER DISTANCES - 14 - - I PINION GEAR FIG. 2 EXAMPLE OF A PINION AND GEAR MISALIGNMENT UNDER NO LOAD. TEETH CONTACT AT LEFT HAND END AND ARE OPEN AT RIGHT HAND END. w, 0 <X F g FACE WIDTH- F F IG. 3 LOAD DIS T RIBU TION ACROSS FACE WIDTH FOR VARIOUS CONTACT CONDIT IONS -15 - ce - wt - 1000 e ) I Wt = e = TANGENT IAL L O AD - LBS � LIGNME NT E RR O R - INCHES/ INCH I ' 15,000 14,000 5.0 13,000 12,000 Q) 11,000 Iz w 10,000 u u LL LL w 0 u Cl'. 0 Cl'. Cl'. w w u Cl'. 0 LL 4.0 E 3.0 u 9,000 8 ,000 2. 0 7,000 6,000 1.0 0 1.0 Fm - 5,000 F 4,000 F = FAC E WI DTH (INCHES) 3,000 2,000 1 ,000 0 2 FIG. 4 5 SPUR GEAR 6 LOAD - 16 - DISTRIBUTION FA CTOR - Cm 2.0 FOR USE FOURTH THIRD AND AD DITIONAL REDUCT I 0 NS VALUES REDUCTION e (.) I 0:: 0 ...... (.) <( LL ....... ---J I z 0 ...... ::::> m 0:: ...... en 1.8 1.7 1.6 F Cm=.52F + 2.3 1.5 ' 1.4 0 1.3 c <( 0 -' 1.2 Use above formulas when face widths exceed 18'� I. I 1.0 F cm= .55F+ 2.5 0 2 3 4 5 6 8 7 FACE FIG. 5 SPUR GEAR 9 10 II 12 13 14 15 WIDTH (INCHES) LOAD ACRES DISTRIBUTION NITOBA LTD. FACTOR - Cm 16 17 18 20 DP TO TAL CASE DEPTH IS THE DEPTH AT WHICH THE CARBON CONTENT OF THE CASE AND CORE ARE EQUAL. 10 D.P. ::i::: � a:: _. <l g:: w � <l iS SOME HEAVY DU TY GEARS 6 D.P. 4 D.P. - - 2 D.P. I D.P. .5 D.P. .010 .020 • .030 .040 .050 .070 .100 .200 APPROXIMATE M INIMUM DEPTH OF CASE (INCHES) FIG. 6 DEPTH OF CASE - 18 - AT PITCH LINE .300 .500 .700 ' CURVE I n . Cy = I ,-1 .80"' CURVE 2 P Cv = > (.) j 78./Vf + 78 I � .60111111111111i11111mttm11!!!tI!11!I!1111:II!Ii111111:!111111111111i1111i11111111111111111111111111i111111111111111111I1111!111111111I11i1111111111111111111 1-­ (.) \0 I ,_. U � <X z >0 3 CURVE � 40 . t:='.� �:=:;::±-==-�1-L _,_._,�J::i +-1-W- > ' .� � !---- ---- �· ' t� ' . r 'R i-.:i= ....mµ. ' . _::::I ' .. ' . rt rlt1 -I T Cy = ' ' ' H- ++ -r H- 5+0 v +f 50 ""ry- ' - '� ' -H ' ' + - :� ' .'.- -.-i- ' ±it, ...;J_"- ' ...w- L+f-H+ .20EP:lmmmmtmm+Riilillim111111111111111111111111111111111i11111111111111!111111111111111: 1111111rrrrmmrnnr:11111111111111mrn11111111111iii II I I ! I I I I I -1-H�-++-++rl-- � 0 1000 ,. 2000 3000 4000 5000 PITCH LINE VELO CITY - Vt ( fpl"fl) FIG. 7 CR�� DYNAMIC L' FACTOR - Cv 6000 7000 8000 a> 0 <O Q en w ....J Q u >u ,... z w u.. ....J 0 I.Li a:: CD 5 Q 0 w a:: I 0 iri . . ,· 0 � 0 rri <t 0 C\i IO 10 - �010'1.:t - 20 - d 3.:111 Q a:: 0 ..... (.) <( u.. w u.. ...J I <X> (!) LL K = BRINELL OF PINION BRIN ELL OF GEAR WHEN K ( 1.2 USE CH= 1.00 l: 0 0: 0 t­ o <( � 0 � 0: (/) (/) LU z 0 0: <( :c '�f FIG. 9 4 8 SI N GLE REDUCTION GEAR RATIO 12 HARDNESS - RATIO - 21 - 16 FACTOR - CH 20 APPENDIX A DERIVATION OF GEOMETRY FACTOR (I) FOR A PINION AT THE LOWEST POINT OF SINGLE TOOTH CONTACT 1. 1.1 STANDARD CENTER DISTANCE The contact stress for a gear mesh at the lowest point of single tooth contact is: s· c 1 cP s C1 C P Where: C1 R1 WI + R2 F cos¢ R1 R2 W I R1 - F cos¢ R1 R2 R2 external gears internal gears coeffici ent dependi ng on the type of stress (contact stress, subsurfa tensile stress, etc.) ce shear stress, radii of curvature of bodies 1 and 2 at the point of contact - inches 1.2 The geometry factor is: Where: R1 R1 R2 D = - 2 D 2 d 2 sin¢ + Zc external gears sin¢ - zc internal gears sin¢ - zc - A-1 - APPENDIX A Where: D operating pitch diameter of gear - inches d operating pitch diameter of pinion - inches Zc distance (inches) measured along the line of action from the pitch point to t he lowest point of single tooth contact, (See Figure A-1). Values for Zc for one diametral pitch are shown in Figures A-2 and A-3. Values for Zc for diametral pitch, Pd canoe obtained by dividing the values from Figures A-2 and A-3 by the diametral pitch. ( 2 sin¢ d D sin¢ 2 2 d (cot ¢) [ d ± 2 . (cos¢) d sin¢ ( 4 sin 2 ¢ - zc Dd . 2 sin¢ D ± d 2 sin¢ ) (D ± d) � sin 2 ¢ 2D cl 4 (cot¢) - sin2 ¢ zc 2 me ± 1 2 cot ¢ ( ) (\ 2 cot ¢ ( )( me sin ¢ me + 1 2 me me ± + 1 _ 2 ± ± \ J Zc _ D sin¢ ( : �) z 2 c l 2 Dd external gears !...::_) (� �) D c z 2 - A-2 - _ cl internal gears DRIVEN DRIVER II _Q_ 2 FIG. A-I Do 2 DIAG RAM FOR THE DISTANCE - A-3 - - Zc -1 . ,, 1 .0 I 14t I 0- PRESSURE ANGLE - DIAMETRAL PITCH _,_ 0.5 ,_ 'r c � 0 CJ) w :I: (.) z I "' I' -0.5 I" I" ' � "' ..... "' " � " .. I' . -1.0 ... "' �.. ' .... ..... "' I' " " .... "' " " r c .... � � ,_ ..,,_ ' ....... ' � " " ' ...... .... ' � � " � III � � I.ii::: � -1. 5 -0.5 .... I r" - 1.0 � .._ i"o I ':I """ � ... ... ,�.. -1.5 I ,J .... ... 20 10 30 NUMBER F IG. .... ll::l -2.0 A-2 40 50 60 " 1" -2.0 ...... ""' ... 70 80 90 100 OF PINI ON TEETH Zc -DISTANCE ALONG THE LINE OF ACTI O N FROM THE PITCH PO INT TO THE LOWEST POINT OF SINGLE TO OTH CONTACT ON THE PINION F O R STA NDARD CENTER DISTANCES. - A-4 - CJ) w :I: (.) z 0 N ' � "" ,....... � " "' "' "' "' 0.5 '""lo.� 0 .. �,... � 0 N 1 .0 n 1n llM II� ' 2.0 1.5 --- -..; .... I'""' .. ""' 0 ""' .... .... .... "" ... ... "" ,..... ""' .... .... 0 � ""' -0.5 .... ... -0.5 -...._ -........_ 20° - PRESS UR'E ANGLE -1.0 I -DI AMETRAL PITCH - 20 1.0 �� ,...,_ 10 30 40 50 60 70 - 80 90 100 NUMBER OF PIN ION TEETH FIG. A-3 Zc - DISTANCE ALONG THE LINE OF ACT I ON FROM THE PITCH POINT TO THE LOWEST POINT OF S INGLE TO OTH CONTACT ON T HE PINION FOR STANDARD CENTER DISTANCES. t . ; . - A-5 - CJ) l.LJ ::I: u z (.) N I .... � i-.. � ... .... ,....., � 1.0 I� 0.5 ,.... (.) N II ... '""' � I -... 1.0 0.5 1.5 ·� - CJ) l.LJ ::I: (.) z 2.0 II� - q APPENDIX B GEOMETRY FACTOR FOR A SPUR GEAR AT THE LOWEST POINT OF SINGLE TOOTH CONTACT 1. NON-STANDARD CENTER D ISTANCES OR SPECIAL TOOTH GEOMETRY 1 .1 The expression for geometry factor is the same for both standard and non-standard center distanc es, however, the value of Zc must be calculated when non -standard centers are used , whereas, for standard ce nters , the value of Zc c an be obtained from Figures A-2 or A-3 . 1.2 The expression for the geometry factor ( I ) 1s : 2 cot¢ 2 cot¢ ( )( ( 1)J ( me sin¢ me + 1 2 me sin ¢ me + 2 J (� } �) �) (� ) Zc D 2 _ D 2 e xternal gears d � internal gears d Where : ¢ operating pressure angle - degrees. me gear ratio D operating pitch diameter of gear d operating pitch diameter of pinion - inches. Zc ·- inches. distance measured along the line of action from the pitch point to the lowest point of single tooth contact - inches. Pb base pitch - inches. Z addendum portion of line of action - inches. a - B- 1 - APPENDIX B Where : d0 outside diameter of pinion - inches. db base circle diamet er of pinion - inches. Other terms shown in Figure A- 1 but not used in any formula are : Where : - �] D0 outside diameter of gear - inches. Db base circle diameter of g ear - inches. D operating pitch diameter of gear - inches. .-:::- · - B-2 -