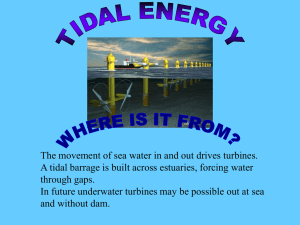

Biogas Energy Bio gas, also known as renewable natural gas (RNG) or biogas, is produced through a process called anaerobic digestion. Here's how it works: 1. Feedstock Collection: Organic materials such as agricultural residues (like crop waste and animal manure), food waste, sewage sludge, and other biomass sources are collected. 2. Anaerobic Digestion: These organic materials are then put into a sealed container called a digester, where bacteria break them down in the absence of oxygen. This process produces bio gas, which is a mixture of methane (CH4) and carbon dioxide (CO2), along with trace amounts of other gases like hydrogen sulphide (H2S). 3. Gas Purification: The bio gas is purified to remove impurities such as moisture, hydrogen sulphide, and other contaminants. This purification process improves the quality of the gas and makes it suitable for various applications. 4. Gas Utilization: The purified bio gas can be used in several ways: Electricity Generation: Bio gas can be used in generators to produce electricity. Heating: It can be used as a direct source of heat for cooking, space heating, and water heating. Vehicle Fuel: Bio gas can be compressed and used as a fuel for vehicles, known as compressed natural gas (CNG) or renewable natural gas (RNG). 5. Digestate Handling: The solid and liquid residues left after anaerobic digestion, called digestate, can be used as nutrient-rich fertilizer for crops or processed further for other agricultural purposes. Bio gas is considered a renewable energy source because the organic materials used to produce it can be continuously replenished through agricultural practices, waste management systems, and sustainable forestry. It's also environmentally friendly, as it reduces greenhouse gas emissions compared to traditional fossil fuels when used for energy generation and transportation. Types of Bio Gas Plants There are several types of biogas plants, each with its own design and functionality. Here are the main two types: Fixed Dome Biogas Plant A Fixed Dome Biogas Plant is a type of biogas system that utilizes a dome-shaped digester for the anaerobic digestion of organic waste to produce biogas. Here's a brief overview: Design: The Fixed Dome Biogas Plant typically consists of a dome-shaped digester made of concrete or brick. It has an inlet for introducing organic waste and an outlet for the digested material (digestate). Function: Organic waste, such as animal manure, crop residues, or kitchen waste, is loaded into the digester. Inside the digester, anaerobic bacteria break down the organic matter in the absence of oxygen, producing biogas as a by-product. Gas Collection: The biogas, primarily composed of methane and carbon dioxide, collects in the dome of the digester due to its lighter nature compared to air. A gas outlet is used to collect and store the biogas for various applications. Floating Drum Biogas Plant A Floating Drum Biogas Plant is a type of biogas system that uses a floating drum or gas holder to collect and store biogas produced during the anaerobic digestion of organic waste. Here's a brief overview: Design: The Floating Drum Biogas Plant typically consists of a digester tank and a gas holder or floating drum. The digester tank is where organic waste is loaded for anaerobic digestion, while the gas holder is a floating structure that rises and falls based on the volume of biogas produced. 2 Function: Organic waste, such as agricultural residues, animal manure, or food waste, is fed into the digester tank. Anaerobic bacteria break down the waste, producing biogas as a by-product. The biogas, primarily methane and carbon dioxide, rises and displaces the water inside the gas holder, causing it to float upward. Gas Collection: As biogas production continues, the floating drum rises to its highest point, indicating the maximum gas storage capacity. A gas outlet is connected to the gas holder, allowing for the collection and utilization of biogas for various purposes. Tidal Energy Tidal energy is a type of renewable energy that harnesses the power of the tides, which are caused by the gravitational forces of the moon and sun acting on the Earth's oceans. This energy is generated by converting the kinetic energy of tidal currents or the potential energy of tidal height variations into electricity. Tidal energy can be harnessed through various technologies such as tidal barrages, tidal stream generators, and tidal turbines. Here's how it works: 1. Tidal Range: Tidal energy relies on the difference in water levels between high tide and low tide, known as the tidal range. This difference creates a potential energy source that can be converted into usable electricity. 2. Tidal Barrages: One common method of harnessing tidal energy is through tidal barrages. A tidal barrage is a dam-like structure built across an estuary or bay. It has sluice gates or turbines that allow water to flow in and out as the tides change. 3. Tidal Turbines: Another approach is using tidal turbines, which are similar to wind turbines but are placed underwater in areas with strong tidal currents. As the tidal currents move, they spin the turbines, generating electricity. 3 4. Tidal Stream Generators: Tidal stream generators work like underwater wind turbines, capturing kinetic energy from the moving water. They are often installed in areas with fast-flowing tidal currents. 5. Benefits: Tidal energy is renewable and predictable; as tidal patterns can be accurately predicted years in advance. It produces clean electricity without greenhouse gas emissions, making it environmentally friendly. Classifications of tidal plants Tidal power plants can be classified based on their design and how they harness tidal energy. Here are the main classifications: 1. Tidal Barrage: This type of tidal power plant uses a dam-like structure, known as a tidal barrage, built across an estuary or bay. The barrage has sluice gates or turbines that allow water to flow in and out as the tides change. The movement of water through the turbines generates electricity. Tidal barrages can be further classified into: Single-Basin Barrage: The simplest form of a tidal barrage, where a single basin is enclosed by the barrage. Water flows in and out of the basin through turbines. Double-Basin Barrage: Consists of two basins separated by the barrage. As one basin fills during high tide, the other empties during low tide, maximizing energy generation. 2. Tidal Stream Generators (TSGs): TSGs are devices similar to underwater wind turbines. They are placed on the seabed in areas with strong tidal currents. As the tidal currents flow past the turbines, they spin and generate electricity. TSGs can be further classified into: Horizontal Axis Tidal Turbines (HATTs): These turbines have blades that rotate around a horizontal axis, similar to traditional wind turbines. Vertical Axis Tidal Turbines (VATTs): These turbines have blades that rotate around a vertical axis. They are often used in areas with complex tidal flow patterns. 4 Geothermal Power Plants Geothermal power plants harness the heat energy stored beneath the Earth's surface to generate electricity. Here's how they work: 1. Heat Source: The Earth's core generates heat continuously through radioactive decay and residual heat from its formation. This heat flows outward towards the Earth's crust, creating geothermal reservoirs of hot water and steam. 2. Geothermal Reservoirs: Geothermal power plants are typically located in areas with high geothermal activity, such as volcanic regions or geologically active zones. These areas have access to hot water or steam reservoirs close to the surface. 3. Geothermal Wells: Wells are drilled into the geothermal reservoirs to access the hot water or steam. The temperature and pressure of the water or steam vary depending on the depth and location of the well. 4. Electricity Generation: The steam or vapour from the geothermal reservoir drives turbines connected to generators, producing electricity. The electricity is then transmitted through power lines for distribution to consumers. 5. Renewable and Sustainable: Geothermal power is considered renewable and sustainable because the heat from the Earth's interior is virtually inexhaustible on human timescales. Unlike fossil fuels, geothermal energy does not produce greenhouse gas emissions or air pollutants during electricity generation. Types of Geothermal Power Plants There are two main types of geothermal power plants based on the type of resource they utilize: Dry Steam Plants: Wells drilled into reservoirs containing steam. The steam is directly used to drive turbines, which are connected to generators to produce electricity. 5 Flash Steam Plants: Wells drilled into reservoirs containing hot water under high pressure. When the hot water is released through a valve into a lower pressure environment (flash tank), it flashes into steam. The steam then drives turbines to generate electricity. Binary Cycle Plants: Used when the geothermal resource has temperatures lower than those required for dry steam or flash steam plants. The hot water or steam is passed through a heat exchanger to heat a secondary fluid with a lower boiling point (e.g., isobutane or isopentane). The vapour from the secondary fluid drives turbines to generate electricity. Ocean Thermal Energy Systems Ocean Thermal Energy Conversion (OTEC) systems harness the temperature difference between warm surface seawater and cold deep seawater to generate electricity. Here are the key components and working principles of OTEC systems: Temperature Gradient: OTEC systems rely on the temperature difference, or thermal gradient, between warm surface water (typically around 25°C to 30°C) and cold deep seawater (around 5°C to 10°C or lower). This temperature gradient is found in tropical and subtropical regions, where the surface water is warm due to solar heating. Working Fluid: OTEC systems use a working fluid with a low boiling point, such as ammonia or a similar refrigerant. The working fluid is circulated in a closed-loop system between the warm surface seawater and cold deep seawater. Evaporation and Condensation: The warm surface seawater is used to evaporate the working fluid, turning it into vapour. The vapour then expands through a turbine, driving a generator to produce electricity. After passing through the turbine, the vapour is condensed back into a liquid using cold deep seawater. Environmental Impact: OTEC systems have minimal environmental impact in terms of emissions since they utilize natural temperature differences in seawater. 6 However, they may have localized effects on marine ecosystems due to changes in water temperature and nutrient distribution. Types of Ocean Thermal Energy Systems Closed Cycle OTEC: In a closed-cycle Ocean Thermal Energy Conversion (OTEC) system, a working fluid with a low boiling point, such as ammonia or a similar refrigerant, is used to transfer heat between warm surface seawater and cold deep seawater. Here's how the closed-cycle OTEC process works: 1. Warm Seawater Heat Exchange: Warm surface seawater with temperatures typically ranging from 25°C to 30°C is pumped into a heat exchanger. The heat exchanger transfers heat from the warm seawater to the working fluid (e.g., ammonia) in a closed-loop system. As the working fluid absorbs heat, it vaporizes and turns into a gas. 2. Expansion and Turbine: The vaporized working fluid (gas) is then directed to a turbine. The high-pressure gas expands as it flows through the turbine, driving the turbine's rotation. The rotating turbine is connected to a generator, which converts mechanical energy into electrical energy, generating electricity. 3. Cold Seawater Heat Exchange: After passing through the turbine, the gas exits the turbine at a lower pressure and temperature. Cold deep seawater, typically around 5°C to 10°C or lower, is pumped into another heat exchanger. The heat exchanger transfers heat from the gas to the cold seawater, causing the gas to condense back into liquid form. 4. Pump and Repeating the Cycle: The liquid working fluid (ammonia or refrigerant) is then pumped back to the heat exchanger where it absorbs heat from the warm seawater, starting the cycle again. 5. Discharge and Closed-loop Operation: Throughout this process, the working fluid remains in a closed-loop system and is not in direct contact with seawater. The warm seawater and cold seawater used in the heat 7 exchangers are discharged back into the ocean after heat exchange, without mixing with the working fluid. Open Cycle OTEC: Open-cycle OTEC (Ocean Thermal Energy Conversion) is one of the primary methods used to harness the temperature difference between warm surface seawater and cold deep seawater for electricity generation. Here's how the open-cycle OTEC process works: 1. Warm Seawater Intake: Warm surface seawater with temperatures typically ranging from 25°C to 30°C is pumped into the OTEC system. 2. Evaporation: The warm seawater is directed into a low-pressure chamber called a vacuum chamber or evaporator. Inside the chamber, the pressure is reduced to lower than atmospheric pressure, causing the warm seawater to boil and evaporate at a lower temperature (around 70°C to 80°C). This process extracts heat from the seawater, converting it into steam. 3. Turbine and Generator: The steam produced in the evaporator is then directed to a turbine. As the steam expands and flows through the turbine blades, it drives the turbine's rotation. The rotating turbine is connected to a generator, which converts mechanical energy into electrical energy, generating electricity. 4. Cold Seawater Condensation: After passing through the turbine, the steam exits the turbine at a lower pressure and temperature. Cold deep seawater, typically around 5°C to 10°C or lower, is pumped into the system to condense the steam back into liquid form. This process releases heat from the steam into the cold seawater, causing the steam to condense and return to liquid form. 5. Discharge: The cold seawater, now warmed due to heat exchange with the steam, is discharged back into the ocean. 8 Magneto Hydro Dynamic (MHD) power Magneto Hydro Dynamic (MHD) power generation is a method of generating electricity directly from the movement of electrically conductive fluids (such as seawater or plasma) in the presence of a magnetic field and an electric field. Here's how MHD power generation works: 1. Electrically Conductive Fluid: MHD systems require an electrically conductive fluid, which could be a liquid (such as seawater) or a gas (such as ionized gas or plasma). The fluid is typically ionized to make it conductive. 2. Magnetic Field: A strong magnetic field is applied perpendicular to the direction of fluid flow. This magnetic field interacts with the moving charged particles (ions) in the fluid. 3. Electric Field: An electric field is also applied perpendicular to both the magnetic field and the direction of fluid flow. This electric field causes the charged particles in the fluid to move in a direction perpendicular to both fields (known as the Lorentz force). 4. Induction and Generation: As the electrically conductive fluid flows through the magnetic and electric fields, the Lorentz force induces an electric current in the fluid. This electric current can be harnessed and collected using electrodes placed in the fluid stream. 5. Conversion to Electricity: The electric current generated in the fluid is collected by electrodes and conducted through an external circuit. This current can then be used to power electrical devices, generate electricity, or be converted into other forms of energy as needed. Fuel Cells Fuel cells are electrochemical devices that convert chemical energy directly into electrical energy. They operate like batteries but can continuously produce 9 electricity as long as they are supplied with fuel and oxidant. Here's how fuel cells work: Basic Components: 1. Anode: The fuel cell's anode is where fuel (such as hydrogen, methanol, or natural gas) is oxidized, releasing electrons and protons. 2. Cathode: The cathode is where an oxidant (typically oxygen from the air) reacts with electrons and protons to form water or other by-products. 3. Electrolyte: The electrolyte is a membrane that allows protons to pass through while blocking the flow of electrons. It maintains the separation of the anode and cathode, allowing the fuel cell to generate an electrical current. Electrochemical Reaction: 1. At the anode, fuel molecules (e.g., hydrogen gas) are split into protons (H⁺) and electrons (e⁻) through a process called oxidation. The electrons are released and flow through an external circuit, creating an electric current. 2. The protons generated at the anode pass through the electrolyte to the cathode. 3. At the cathode, the protons combine with oxygen (from air) and electrons that have travelled through the external circuit to produce water (H₂O) or other by-products. Types of Fuel Cells Fuel cells come in various types, each designed for specific applications and operating conditions. Here are the main types of fuel cells: Proton Exchange Membrane Fuel Cells (PEMFCs): 1. Electrolyte: Uses a solid polymer electrolyte (typically a proton-conducting membrane). 10 2. Operating Temperature: Operates at relatively low temperatures (typically below 100°C). 3. Fuel: Hydrogen gas is commonly used as the fuel, although methanol can also be used in direct methanol fuel cells (DMFCs). 4. Applications: PEMFCs are used in transportation applications such as fuel cell vehicles (FCVs), portable electronic devices, and backup power systems. They are known for their fast start-up time and high power density. Solid Oxide Fuel Cells (SOFCs): 1. Electrolyte: Uses a solid ceramic electrolyte (typically yttria-stabilized zirconia, YSZ). 2. Operating Temperature: Operates at high temperatures (typically 6001000°C). 3. Fuel: Can use hydrogen, natural gas, biogas, or syngas as fuel. 4. Applications: SOFCs are suitable for stationary power generation applications, distributed power generation, and combined heat and power (CHP) systems. They are known for their high efficiency but require high operating temperatures and longer start-up times. Molten Carbonate Fuel Cells (MCFCs): 1. Electrolyte: Uses a molten carbonate salt (e.g., lithium potassium carbonate) as the electrolyte. 2. Operating Temperature: Operates at high temperatures (around 6501000°C). 3. Fuel: Can use natural gas, biogas, or syngas as fuel. 4. Applications: MCFCs are suitable for large-scale power generation, such as utility power plants and industrial applications. They offer high efficiency and can utilize a variety of fuel sources. Phosphoric Acid Fuel Cells (PAFCs): 1. Electrolyte: Uses a phosphoric acid solution as the electrolyte. 2. Operating Temperature: Operates at moderate temperatures (around 150220°C). 11 3. Fuel: Typically uses hydrogen gas as the fuel. 4. Applications: PAFCs are used in stationary power generation applications, including combined heat and power (CHP) systems for buildings and industrial processes. They offer good efficiency and reliability. Alkaline Fuel Cells (AFCs): 1. Electrolyte: Uses a liquid alkaline electrolyte (e.g., potassium hydroxide, KOH). 2. Operating Temperature: Operates at moderate temperatures (around 50250°C). 3. Fuel: Typically uses hydrogen gas as the fuel. 4. Applications: AFCs have been used in space applications and some niche applications but are less common in commercial applications due to their sensitivity to CO2 and relatively lower efficiency compared to other types of fuel cells. 12