API Standard 682: Pumps-Shaft Sealing Systems

advertisement

Pumps-Shaft Sealing Systems for

Gentrifugal and Rotary Pumps

API STANDARD 682

FOURTH EDITION , MAY 2014

AMER I CAN P ETROLEUM INSTITUTE

Reproduced undar licer,se of the American Petroleum Institute No psrt of the electronic flre may be reproduced or Iransmitted in any

form. lncluding Iransmittal by e-mail, by !ile Iranster pratocol (FTP ), or by being part of a network accessible system except under lice nse.

Special Notes

API publications necessari\y ad.dress problems of a general nature. With respect to particular circumstances, local,

stale, and federallaws and regulations should be reviewed.

Neither API nor any of API's employees, subcontractors, consultants, commiltees, or other assignees make any

warranty or representa!ion, eilher express or impl ied, wilh respect to the accu racy, completeness, or usefulness of the

information contained herein, or assume any liability or responsibility for any use, or the results of such use, of any

informat\oo or process disclosed in tilis publication. Neither API nor any of API's employees, subconlractors,

consultants. or olher ass1gnees represent that use of this publication would not infringe upon privately owned rights.

API publications may be used by anyone desiring to da so. Every effort has been made by the Institute to assure the

accuracy and reliability of the data contained in them; however, the Institute makes no representalion, warranty, or

guarantee in connection with this publication and hereby expressly disclaims any liability or responsibility for \oss or

darnage resulting from its use or for tile violation of any authorities having jurisdiction with wilicil this publication may

conflict.

API publications are published to facililate the broad availability of proven. sound engineering and operating

practices. These publications are not intended to obviate the need for applying sound engineering judgment

regarding when and where these publications should be utilized_ The formulation and pub\\cation of API publ!cations

is not intended in any way lo inhibit anyone from using any other practices.

Any manufacturer marking equipment or materials in conformance with the marking requirements of an APJ standard

is solely responsib!e for comp!ying with alt the applicable requirements of that standard_ API does not represent,

Warrant, or guarantee !hat such products da 1n fact conform to the applicable API standard.

Usersofthis Standard should not rely exclusively on the information ccntained in this document. Sound business, scientific, engineering. and safety judgment should be used in employing the Information contained herein.

All rights reserved No part of this work may be reproduced, translated, stored in a retrieval system, or Iransmitted by any means,

eleclronic, mechanical, photocopying, recording, or otherwise, without prior writlen permission from the publisher. Contact the

Publisher, API Publishing Services, 1220 L S\reet, NW, Washington, DC 20005

Copyright© 2014 American Petroleum Institute

Foreword

Nothing conlalned in any API publication is to be construed as granting any right, by implication or otherwise, for the

manufacture, sale, or use of any method, apparatus, or product covered by letters patent. Neither should anything

contained in ttle publication be oonstrued as insuring anyone against liability for infringement of Jetters patent.

Shall: As used in a standard, "shall» denotes a minimum requirernent in order to conform to the specification.

Should: As used in a standard, "should" denotes a recommendation orthat which is advised but not required in order

to conform to the specification.

This docllment was produced under API standardization procedures lhat ensure appropriate nolification and

participation in the developrnental process and is designated as an API standard. Questions concerning the

interpretation of the content of this publieation or comments and questions concerning the procedures under which

this publication was developed should be directed in writing to the Director of Standards. American Petroleum

Institute, 1220 L Street, NW, Washington, DC 20005. Requests for permission to reproduce or translate all or any part

of the material published herein should also be addressed to the director.

Generally, API standards are reviewed and revised, reaffirmed, or withdrawn at least every five years. A one-time

extension of up to two years may be added to this review cycle. status of the publication can be ascertained from lhe

API Standards Department, telephone (202) 682-8000. A catalog of APl publications and materials is published

annually by API, 1220 L Street, NW, Washlngton. DC 20005.

Suggested revisions are invited and should be submitted to the Standards Department. API, 1220 L Street, NW,

Washington, DC 20005, standards@api.org.

Contents

Page

1

Scope . .. .. .... . . ... . ....... . .. . .................. . ..... . ........ . .... . ................. 1

2

Normative References... . .......... . .. .. . . .... . ......... . .......... . ... . .................. 1

3

3.1

3.2

Terms, Definitions, and Symbols ..... . ........ . . . .. . .. . ... . ....... . .... . ............ .. ...... 3

Terms and Definitions ........ . .. . ............... .. ... .. . . .............. . ... . .... . .... . .. . . 3

Symbols ... ...• . ... . ... . . . . . ......... . . . . . . . . . ........ . .... . .. ... ..... . ... . . . . . ....... . 12

4

4.1

4.2

4.3

Sealing Systems ........•. .. . .. . . . • ........ . . . .... . ........... . .....•.... .. . . ......... . . 13

Seal Categories, Types, and Arrangements . . . ............. . ... .. ... . . . . . ....... .... ......... 13

Objectives .. .. ...... . ...... . .. . ...... . . .. ......... . .. .. .. . . . ............ .. ........... . .. 15

Specifying andlor Purchasing a Sealing System . . . . ...... . . . .. . . . ...... . . . .. . ... . ....... . .... 15

5

5.1

5.2

General ....... . .. . ....... . .. . ......... . ... . . . . .. . . . . ........... . .. . .............. .. ... . 23

Unit Responsibility .......... . . .. .................... .. ......... ... ........ . .. . . . ... . .... 23

Dimensions . .. . ..... . ... . . . .......... .. ... . . .. .... . ..... . ..... . . . .. . ..... . .. . .•...... . . 23

6

6.1

6.2

Design Requirements .....•. . ............. . ... .. .... . ....... .. ...•..... . .. .. .... . . . ...... 23

Common Design Requirements (All Categories) ........... .. ..... . . . .. . ...................... 23

Design Requirements (Category-specific) ....•. . . .. .. . ..... . . . ... . .......... . ....... . .... . .. 45

1

·7.1

7.2

7.3

Specific Seal Configurations . . ... . ..... ... .. . . .... .. .. ... ...... .. .. . ...... . .. . ............ 48

Arrangement 1 Seals .. . .......... . . .. . .. . . ......... . ... . ... . ............................ . 48

Arrangement 2 Seals .. • ... . . ... . .. ... . ............... . ........ . . .. ......... . ...... . . . .. . . 49

Arrangement 3 Seals ........ . . . ......... . ... . ................................. ... ........ 52

8

Accessories .......... . . . .• . ..... . .......... . ............... . ... . ......... . .... . . . ...... 54

lt 1 General .. ....... .. ............ . .. . ....... . .... . .. ...... . .... . .. . .... . ............ . .. . . ,. . . '54

6.2 Pipi ng f o:r S.eall AuxiiUary Systems ........•. . ..•. .. ........•... .. .. . . .......... . ............... 56

8.3 rCo:m:ponents of Seal Au.xilia~ry Sy.ste.ms (1if Specified in Anrn ex G) .... ,. .. ,. ... .... . .. . ....... • .• . . 59

9

9.1

~ nsi!rumentailiion .. .. . .... . . .. ....... . .. . . . ...•...... .. .. . ....... . ...... . .. . .... .. .. .• ..... . 72

G·ene•.r.a~ ... ,. .... ,. .. . ................... .. .............. ,. .......... . . ,. . .. .................. 72

~9.2

T.emperature-irndicating Gauges ... . ....... . .... . . . ....... . .. . ,. ......... . .•.........•... ,. .. 72

Tiher:mowe.l ls... .............. . . . .. . .... . ...... . . . .. . ... . . . .... . . ,. ......... . ... . .. .. •...... 73

'Pr:essure lndicators ....... . .••. • . " ..........•.•....•........ . .... .. ..... . .. • .. . ....•...... 73

Transmitlets a1rnd Swi~ches • ... ,. .... • ........ .. •...... . ............. . ........ . .............. 73

Level ~ rndicato.rs ............ . .... • ..... . .. . ,. •................... . ... . .......... . ......... 74

Fl-o w h11·s lllrumemits ...... . .... . .. . .................. . .. . . . ..... . ......................... . ... 74

Relief'Valve.s .. .. . .. ..... . .......... . .... . ....... .. ....................... .. . . . . . . .......... 74

IP,ress,vJr.e C·o.mtro' ·val-v.es . . . . . . . . . . . . . . . . . . . . . • . . . . .. . . . . .. . . . . . . . . . . . . . . . • . . . . . . . . . . . . . .. . . . . 7.5

'9.:~.11 !Pressure Am;plifiers.... .. ... . .. .. .. .......... ..................... .. ........... . .... .. ......... 75

9.3

9.4

9.5

:9.6

9.7

9.8

9 :9

10

~nspecti:on, Te'Sli.n,g, a!Jfd Preparati.Gn ifor :Sl'il'i~prnent .. • ~ ........................ . . .. .............. 75

·~ 0; 1 .ß ·e.ll'e'mll . . . . . . . . .. . . . -. . .. . . .. . . . . . . . .. -. . . .. • . . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . .. . . . • . . . . . . '15

-~ 0.·2

lnspe:ction . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . .. • .. . • . . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • .. . ...• 7 5

........ . ............................. .. ................................ .. .......... .7r6

tG A IP1eparati o.n .fQ'r :st.riliJ.m·en.t . . . • . . . . .. . . . . . . . . . . . • . . . . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • • . . . . . . fßß

·~,0. 3 Testl1

n:g

·11 lllata irmn·s'fe:r . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . .. . . . . . . . . . . . . . • . . . . . . . • . . . . . . ·-a·1

11.1 :&eme.r.al ....... . .................. . ................................ .. ......... .. ........ . . ·8·1

·11...:2 Da'ta Requlre:rneot lf.o~m.s ................................................ . .................. 1'82

11.3 i[)a;tasfheet . .. . . . . . . . . . . .. . . . . . . . . . .. . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . .•... • .. ·82

·n1.4 1nspe.ctor CQh:eo'klli.s:t . • . • . . • . . • • . • . . . . • . . • . .. . . • . . • . . . . . . . . • • . . . . • . . . . . . . . . • • • . • . . . . • • • . . • •• <82

V

Contents

Page

Annex A (informative) Recommended Seal Seiaction Procedure .............. .. ................. ... . 83

Annex B (informative) Typical Materialsand Material Specifications for Seal Chamber and Mechanical

Seal Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Annex C (informative) Mechanical Seals Datasheets . . .......................... . .... .. . . ......... 127

Annex D (informative) Seal Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

AnnexE (nonnative) Mechanical Seals Data Requirement Forms . ........ . . . ... ... . . ... .. ......•... 137

Annex F (in·formative) Technical Tutorials and Illustrative Calculations ....................... . •..•... 140

Annex G (normative) Standard Piping Plansand Auxiliary Hardware .. ... ............... ..... . ...... 183

Annex H (infonnative) lnspectors' Checklist for All Seals .......................................... 230

Annex I (normative) Seal Qualification Testing Protocol ........ . ............. . ........ . ......... .. 231

Bibliography ......................... ....•. . .......... . .................................• . . 254

Figures

Seal Configurations .................................. . . . •....... . ....... .. ............... 16.

2

Arrangement 1: One Seal per Cartridge Assembly ..... ........................... .......... .. 17

3

Arrangement 2: Two Sealsper Cartridge Assembly with a Liquid Buffer Fluid .... . . .. ............ 18

4

Arrangement 2: Two Sealsper Cartridge Assembly with orWithout a Gas Buffer Fluid .. . .. ........ 19

5

Arrangement 3: Two Seals per Cartridge Assembly with a Liquid Barrier Fluid . . .•............... . 20

6

Arrangement 3: Two Seals per Cartridge Assembly with a Gas Barrier Fluid ... .. ................. 21

7

Arrangem:e nt 1 lype A S ·eaas ... .. ............ ..................... .......... ... .... ........ .. 22

B

Arrarng·e ment ·1 Jype IB 'Se:a[s .................................. .. .. ... .. .. ..... .... ..... ... ... 22

·9

Alrr:angem.e nt 1 iyiPe C Seals ............... .. ......... . .................................... .22

10 Retentiorn of Seal Com,pone:nts in Vacl!lum Serv~ces a!f11d Arrangemernt 3 Inner Seal . . ..•..•••••••.• 25

11 Se:a'l Chamber Types ..... . . . .. . .. . ............... .. .. ... ................ . .. ... . . ....... ... 26

12 Sea'l C lhamb'er Register Concentricity.... ...... ............... . ............ .......... , ...... 29

13 Seollio:n Show,ing Seall Gtantil Plate Shoulde.r ..................... ............................ 29

14 'Seal Chamber Face Run.o ut ............................. .. . .. ....................... , .. , • , •.

15 Mechanicai.SeaUPip:ing Co:rnnectio:ns .................. ... .. ..... . . . ........ . .. . .... . ......... 34

16 PJ,a.stic P1lug with Center irab and Example of War;ning lag ........ • ............................ 34

17 Seal ClilamiberlGiand Plate for Verticat Pumps ..... ............. .. . .. . . . ........ ..... ...... ... 34

'118 Matirng Joint Gasket ...•••.•..•••.•••••. -. ... ...... .. ....... ................ .. . .. .......... .. '3·5

'11·9 SeaJI .SJe:e ve Rt~tloud ................. .. ........... .. ............ . ....................... .. ... 3ti

2D AuxHiacy :&leev-e Arrane~e.r.nemit .......................................... ................. .. .. .3B

21 .Seafl Sleev'e ~ttac}'!lllflt~fil:t by Shrinlk Ois_k .... .. ......................................... . . ...... :! 9

2.l

~Sea'l Sleev.e Atta:olllmeAt by SJl)l:it Rh~g ....•..•..••.•.•..•.......•.••.... • .......•..•....•...• -4G

23 1CJam:~ed lface.s ........•............... . • ........ -. ............................. .. ........ ..1,1: 0

~4

lllis:tdb!.det!l Flush Sy.stems .•..•..•.••.........•....•.••. .. ...... • ..•.••..•.••.............• '47

25 .Alttaobnrernt of Key Onl:v-es to S.baft ... .. ...... . .. .. .......•...•. .. .. .•• .. ......• • ............... • ,47

'26 Saation Stnowing •Conlalinm:en;t.:SeaJ Cbamlber Bus'h~_mg fo·r 2CW..ZC'S alitt!L~NC..iCß Co:nftguratior.ls..... 'S1

27 ~s.eall ifestin.g Seql!le:nce •• .............. .. , . " ...............•....•. .. ............. , .......... Tl

A.·j :s'e:a1 :s:e~lel!tion ~og·ic .......................... .. ... -. .. .............. .. . " ......... .. ...... .. .. 1<07

A.l Group fil S:e:ai .Arramgem:ent 'Se:lectiDill Charit, . •..• ...............•.......... , •.............. , "iiiß:S

1

:;ro

vi

Contents

Page

Gonversion of mg/m3 to ppmv at 25 oc (77 °F} and Atmospheric Pressure ...................... 109

Tamperature Gorreetion Factor for Figure A.3 ...... . .... . ... .. . .. ....... ... . ................ 11 0

Relative PV Comparisons for Seal Face Combinations .................... ... ..... .... ....... 121

Estimated Gas Leakage for 50 mm Shaft at 0.7 bar, Expressed in Normal Litersper Minute ........ 142

Estimated Liquid (Water} Leakage for 50 mm Shaft at 2.75 bar, Expressed in Cubic

Cantimetersper Minute......................•........................................... 143

F.3 Illustration of Alternative Vapor Pressure Margin Calculation Options ............... .. ... . ....• 145

F.4 Illustration ofVapor Pressure Margin Calculation Methods as Applied to Propane ................ 145

F.5 Illustration of Balance Ratio Measurement Points .......... . ............... . ................ 149

F.6 Gland Plate Model .. .. ............................................................... . . . 156

F.7 System Model. .................................................................. .. ...•. 156

F.8 Pipe System Friction Curves .....•........... ..... ....................................... 157

F.9 Tubing System Friction Curves ............... . ........................................... 158

F.10 Circulating Device Performance and System Resistance in Tubing System Curves •••.•.•.•••••.• 160

F.11 Circulating Device Performance and System Resistance in Pipe System Curves .... ... .......... 160

F.12 Typical Required Flush Flow for Arrangement 3 CW Seals Without Heat Soak Considered and a

Pumped Fluid Temperature of 54 oc (130 "F) ................................................ 161

F.13 Typical Required Flush Flow for Arrangement 3 CW Seals with Heat Soak Considered and a

Pumped Fluid Temperature of 176 .. c {350 °F) . .. ........................... . ................ 161

F.14 Typlcal Required Flush Flow for Arrangement 3 CW Seals with Heat Soak Considered and a

Pumped Fluid Tamperature of 260 oc (500 °F) ....................... . .... . ....... .... ....... 162

F.15 Typical Required Flush Flow for Arrangement 3CW Seals with Heat Soak Considered and a

Pumped Fluid Tamperature of 371 oc (700 °F) ............................................... 162

F.16 Calculation Points for Piping Plan 53A Systems ..•.......................................... 165

F.17 Pressure Alarm Without Temperature Bias ................................................. 169

F.18 Barrier Liquid Pressure versus Accumulator Gas Volume .................................... 170

F.19 Barrier Liquid Pressure Against Barrier Liquid Volume ... . .................... . .............. 171

F.20 Drive Collar Holding Capab!lity ................................ .... ....................... 178

G. 1 Instrument Symbols ... . ..... . ..... .. ......... . . ............................. . . .. . . ..... 184

G.2 E.quipment Symbols ......... . ....... •.. ..... . ............ • ................ . . . . .. ....... 185

G.3 Standard Seal Piping Plan 01 ............................................................ . 186

G.4 Standard Seal Piping Plan 02 .... ............. . . .... ..................... ... .............. 187

G.5 Standard Seal Piping Plan 03 .................................................... .. ....... 188

G.6 Standard Seal Piping Plan 11 ............................................................. 189

G.7 Standard Seal Piping Plan 12 ...................... . ...................................... 190

G.B Standard Seal Piping Plan 13 ........................ . .. .. . .... ........................... 191

G.9 Standard Seal Piping Plan 14 ............................................................. 192

G.10 Standard Seal Piping Plan 21 ... . ................................................ . .......• 193

G.11 Standard Seal Piping Plan 22 .............. ..... ....... . . ... .. .. . .. . . ..................... 194

G.12 Standard Seal Piping Plan 23 ............................................................. 195

G.13 Standard Seal Piping Plan 31 . ...................•...•.................................... 197

G.14 Standard Seal Piping Plan 32 .. . ............................... . .. .... ...... . ............. 198

G.15 Standard Seal Piping Plan 41 .......................... . . . ................................ 199

G.16 Standard Seal Piping Plan 51 ............................................................. 200

G.17 Standard Seal Piping Plan 52 .............. . ...................... . ...... . ................ 201

A.3

A.4

B.1

F.1

F.2

vi1

Contents

Page

G.18 Standard Seal Piping Plan 53A ... ....... .......... ... ............ .. ....... ............... 203

G. 19 Standard Seal Piping Plan 538 ...................... . . . ........ . .... .. . . ...... . .. ...... .. 205

G.20 Standard Seal Piping Plan 53C ........................ .. ................................. 207

G.21 Standard Seal Piping Plan 54 .... ...... ....... ............... . ....... ..................... 209

G.22 Standard Seal Piping Plan 55 .................... ..................... .. .. ..... . .......... 210

G.23 Standard Seal Piping Plan 61 .................................. .. ...•..................... 211

G.24 Standard Seal Plping Plan 62 ..........•.......... ... . . . •. . •. ... . .... ..................... 212

G.25 Standard Seal Piping Plan 65A ................ .......... . .. ... ..... ..................•... 213

G.26 Standard Seal Piping Plan 658 ..............•......... . . ..... . ... ......... . .•............ 214

G.27 Standard Seal Piping Plan 66A •........................ . . ..... ... ...... . .. . ... ....... . ... 215

G.28 Standard Seal Piping Plan 668 ........................ ......... . .... ..................... 216

G.29 Standard Seal Piplng Plan 71 ...... . .... . ..•............... .. ......... . .. . ....... .. . ... ... 217

G.30 Standard Seal Piping Plan 72 ............. . .. . .. . ........................ .. ... . .. . . .. ..... 218

G.31 Standard Seal Piping Plan 74 . . . .. . ....... . .. . .. . ....................... .................. 219

G.32 Standar'd Seal Piping Plan 75 . . ... •. . . ....... ..... .. ...................... .......... ..... . 221

G.33 Standard Seal Piping Plan 76 ....... .. ...... . .............. ... ...................... . ..... 223

G.35 Standard External 8arrier/Buffer Fluid Reservoir ................................... ..... .... 225

G.36 Alternative External 8arrier/Buffer Fluid Reservoir................................ . . . ........ 226

G.37 Typicallnstallation of a Piping Plan 23 Circulation System ..... .. ............... . . . ..... . .... . 227

G.38 Typicallnstallation of a Barrier/Buffer Fluid Reservoir . .. ........ . .... . . . . .. . .... . .. . ... ...... 228

H.1 lnspectors' Checklist. ................................... .... . .. .. . ...............•...... 230

1.1 Water Test Parameters . ...... . ... ..... .. ... ................. . .. . . .. .. . ........ . .. ...... . 244

t2 Propane 1est Parameters ......... • .............. . .. ...... . . ... . .. ... . .... ........... .. ... 245

1.3 Caustlc (iNaO:HI) 'fest Parameter s ................... ......... .. .. . ........... .............. .24'6

lA Mine.r al Oi~ test Parrameters for Applications Between s oc a•rnd 17·6 oc -(23 °F and 348..:8 o,F) . .•••••. 247

1.5 M~ newa1 Oi~ Te st P.arrameterrs for A!PP I~catio ns IBetween '116

and 400 °C (348•.8 "'F and 750 °F) ..... 246

t 6 .Seal Manufacturer Qualdfication Test Pr.ocedu111e .............. .. .. . . .. ..... . ...............•.. 249

11.7 Se.al M a:nufacturer QuallificaHo:n Test !Procedure for 'Con:taijnment Seals ........ ............ , . , .. 250

11.8 Seal Mamllfacturer Qualijificatlion 'Test IProcedure fo:r Gas Barrie·r .Seal s ............. , .. ........... 251

t9 IMec!hanica~ Seal Qualiftication Test Form '(1CW, 2:CW-CW, 3CWJFB, 3CW-if1F, and '3 CW-BB) ......... 252

1.10 Mechaniical Seal .Q l!lalification Test Form o(2CW-CS, 2NC-CS, 3NC·Ff, 3NC -E!8, and 3NC-FBJ ....... '2:53

oc

Tab'l es

1

Clearances Between Rotary and Stationary Components ...................... .. ...... . .. . .. . . 28

2

Symbü~s aod Size for Sea'I .Cnamber awo Gland Plate Connections . . ............ . . . •. ....•. . ... . 3'3

3

!Minimi!Jm 'Sieeve Th id~mess i11 tll:e Area of Componen1·drive SetScrews ...... .......... , . . ... . .. 37

4

Min:im~r~m Requirer:nen1s for .Auxili ary Piping ................................... . .. . .... .. .... 57

'5

Fl1Unimum Pi pe WaU Thickness • . . . . . . .. . .. . . . ............. . ................ . . . .. ... .. . .... . '58

6

Mjnimum Tubing Wall ihickmess . . . .... . .. . ............... ..... ...... . . .. . . ........ . , ..... . SB

'Conditiolils Af:fecting Codling WaterSystem Design . .. ........... .. ............. . .. . ... . . . ... CG1

:8

Approxi1,n ate Denstt1es of Materlalls Foumß jn Proc ess Streams ...... .. . ... . .. . . ... ........ . .. . . :63

9

;sj~Jng of BI adeder Acoumulators ........... . .. . . . .............. . . . .. . .. . ..... .. .... . ....... 66

10 Nameplate for Bladder ·A ccumli'lato.r . .... . .......... . ... ....... ...... . .......... . • . ......... ·69

A.1 RiPhrase Grouplng irial!llle ......... .... ... . ........... . . . ... .. . . ...... ... ....... ........ ... 1 (!}:5

A/2. H :Staltemant GroU>p.ing 'Table .. .. .. . . ...... .. . .. . .. . ..... . . . ............. . ...... . .. ..... ... 1t(!H~

7

viii

Contents

Page

8.1 Materials Standards ..................................................................... 112

8.2 Miscellaneous Materials Specifications ....... .. . ................. ... ....... . . . . ...... ..... 117

8.3 Typical Temperature Limits for Seal Face Materials .......................................... 118

8.4 Typical Tamperature Limits for Secondary Seals ........•.•................................. 122

8.5 Typical Hardness Range for Selected Secondary Seals ....................................... 125

0.1 Example of an Arrangement 1 Mechanical Seal Code ........................................ 132

0.2 API 610 Mechanical Seal Code (Obsolete) .................................................. 135

F.1 Pipe and Tube Dimensions for System Loss Calculations .................................... 157

F.2 Typical Hardness Ranges for Set Screw Materials ......•.•.................................. 179

F.3 Typical Hardness Ranges for PumpShaft Materials ..... ..................................... 179

F.4 Estimated Sleeve Axial Loads ............................................................ 179

1.1 Organization of Qualification Testing ...................................................... 233

1.2 Qualification Test Fluid and Pumped Fluid Selection Chart...... . ................ ...... ....... 237

1.3 Seal Qualification Test Parameters ................................................. ....... 241

ix

Pumps-Shaft Sealing Systems for Gentrifugal and Rotary Pumps

1

Scope

This standard specifies requirements and gives recommendations for sealing systems forcentrifugal and

rotary pumps used in the petroleum, natural gas. and chemical industries. See A.1.1 and A.1.2. lt is the

responsibility of the purchaser or seal vendor to ensure that the selected seal and auxiliaries are suitable

for the intended service condition. lt is applicable mainly for hazardous. flammable, and/or toxic services

where a greater degree of reliability is required for the improvement of equipment availability and the

reduction of both emissions to the atmosphere and life-cycle sealing costs. lt covers seals for pump shaft

diameters from 20 mm {0. 75 m.) to 11 0 mm (4.3 in.).

This standard is also applicable to seal spare parts and can be referred to for the upgrading of existing

equipment A classification system for the seal configurations covered by this standard into categaries,

types, arrangements, and orientations is provided.

This standard is referenced normatively in API 610. lt is applicable to both new and retrofitted pumps and

to pumps other than API 610 pumps (e.g. ASME 873.1, ASME 873.2, and API 676 pumps).

This standard might also be referenced by other machinery standards suctl as other purnps, compressors,

and agitators. Users are cautioned that this standard is not specifically written to address all of the

potential applications lhat a purchaser may specify. This is especially true for the size envelope specified

for API 682 seals. The purchaser and seal vendor shall mutually agree on the features taken from this

standard and used in the application.

2

Normative References

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendmenls) applies.

API Recommended Practice 520 (al! parts), Sizing, Selection, and Installation of Pressure-relieving

Devices in Renneries

API Standard 526, Flanged Stee! Pressure Relief Valves

API Standard 610, Gentrifugal Pumps for Petroleum, Petroc/1emica/ and Natural Gas lndustries

API Standard 614 Lubrication, Shaft-seaHng and Control-oil Systemsand Auxiliarfes for Petroleum.

Chemical, and Gas /ndustry Services

ASME V 1 , ASME Boiler and Pressure Vesse/ Code, Section V, Non-destructive Examination

ASME VIII, ASME Boilor and Pressure Vesse/ Code, Section VIII, Ru/es for the Constraction of Pressure

vessels

ASME IX, ASME Boiler and Pressure Vessel Code, Seclion IX, Welding and Brazing QIJalificalions

ASME 81.1, Unified lncfl Screw T!?reads (UN and UNR Thread Form)

ASME 81.20.1 , Pipe Threads, General Purpose, Inch

ASME 816.11 , Forged Fittings, Socket-welding and Threaded

ASME 816.20, Metallic Gaskets for Pipe Flanges-Ring Joint, Spiral-wound, and Jacketed

: ASME International, 3 Park Avenue. New York, New York 10016-5990, www.asme.org.

API SrANDARt:>682

2

ASME 831.3, Process Piping

ASM E 873.1, Specification for Horizontal End Suction Centrifugal Pumps for Chemical Process

ASME 873.2, Specification for Vertical In-fine Gentrifugal Pumps for Chemical Process

ASME PTC 8.2, Gentrifugal Pumps, Perfotmance Test Codes

AWS D1.1 2, Structural Welding Code-Steel

EN 287 (all parts) 3 , Approval testing of welders-fusion welding

EN 288 (all parts). Specification and approval ofwelding procedwes formeta/Jic materials

EN 13445 (all parts). Unfired pressure vessels

EPA Method 21 \ Appendix A of Title 40, Part 60 of the U.S. Code of Federal Regulations, Environmentaf

Protection Agency, United Slates, Determination of Vofatile Organic Compound Leaks

IEC 60079 (all parts) 5 , Electrical apparatus for explosive gas atmospf1eres

IEC 60529. Degrees of protection provided by enclosures (/P code)

ISO 7 (all parts) 6 , Pipe threads where pressure-tight Jointsaremade on the threads

ISO 261 JSO general-purpose metric screw threads-Genera! plan

I

ISO 262, /SO general-purpose metric screw threads-Selected sizes for screws. bolts, and nuts

ISO 286-2, ISOsystem of Iimits and fits-Part 2: Tab/es of standard tolerance grades and Iimit deviations

for flOles and shatts

ISO 724, ISOgeneral-purpose metric screw threads-basic dimensions

ISO 965 (all parts), ISO genera/-purpose metric screw threads-Tolerances

ISO 7005-1 Metallic flanges-Part 1: Sieel tlanges

I

ISO 15649, Petroleum and natu.ral gas industries-Piping

NEMA 250 1 , Enclosures forElectrical Equipment {1,000 Volts Maximum)

NFPA 7·0 8 , National Eleotrical Code

T1ilae 1, Part A, Section 112. U. S, National Emission Standards for Hazardous Air Poilufants (NESHAPs)

.( Clean Air Act Amendment, AirPollution Preventlon and Cantf(O/, AirQuaJ;ty .and Emissions Umitationsl

Hazardous Air Poflutants)

1

.AIIT'lerican Weläim_

g Society, 550 NW LeJe.une fRoalil, Miami. Flonda (3.3126,, WW1iv.aws..·o:rg.

~ IEu·r.opean C0mmittee f0r Standardizatio.rnl Avem.1 e ~Jiarni~ 17. B-1GOD Brussels, Belgium. www...:::ern.-eu.

• 'U ,S Envk.onmentai iRrGie.otion Agencyl .Ariel Rios Bullding, 1200 Penrn>y.lltariia Avenue, Wasmingtom, DC 2.0460.

wwtw.J e,pa.:gov_.

" lnJcmnationai iEiectrotedhn'ical Conmnission., 3, rue de Varem;;~e. P •O.IBox 1'31, CH-1211 Hene·va 20. SwirzerJamd,

www.iec,.o~.

e hnlerna(mmal Grganizatjon for Stanüarc;iization. 1, :eh. de .Ia Voia-Cr:euse, Case postale 56, C HI-1211 Geneva 20.

1

'Switzrerl amd, .lf\/W1!J.iso.·or-g,

NatiGilla'l El.ectricar Manufacturers Ass:oc.iationl 1300 _N.orth 17th S.tr.e:et, Suite 1752, Rosslyo. Virg1nia 22209..

·www.1m·ema.:or:g.

u !National Fir-e Pr.otedlion AssGo:atio.n,. 1 B .a tteryman:'h Park, ·Qu'inoy, MHssach.l!Jsetts 02169-747 1, www.n(pa.org.

PI!!Mrs- •SH,\FT SEALIK3 SYST5MS FöR GENTRIFUGAL AND ROTAR" PUMPS

3

'T erms, !De·l ini\tlons, .amd Symb:Gl s

For tlile purposes of this ,docu.mel'lt, if he follow.ing terrms and def,imHions .apply.

3.1

TemilS .atrild [!)efthnlti:O!ns

3.1.d

.a:nlir:.otati:am device

Devioe ·wsed ito prevent lfo'tatron of C!lfle componerlt ~relative to an a'djacent compGrn-emt in .a seal assennbly,

EXAMPLES

Key., pin.

3.1.2

Arrarngernen;f 1 sea:l

'See4.1.4.

3.1.3

Arrangement 2 s:e al

See4.1.4.

3.t. 4

Arrangement 3 ·s eall

See4.1.4.

3.1.5

a•tmospheric ~ eakage ·coUector

Extema!J reservoir arranged to ·capture liquid seail leakage from an Arrangement 1 seal.

3.1.6

auxiliary sleeve

Separate sleeve mounted on the outer diameter of the seal shaft sleeve that facilltates assembly of seal

components,

3.1.7

back-to-back configuration

Dualseal in which both of the flexible elements are mounled between the mating rings, the sealed fluid is

on the ID of the inner seal, and the barrier or buffer fluid is on the OD of lhe inner and outer seal.

3.1.8

balanced seal

Mechanical seal in which the fluid closing forces have been modified through seal design.

NOTE

l.n this standard the seal balance ratio is less than 1 {see balance ratio calculation in Annex F).

3.1.9

barrier fluid

Extemally supplied fluid at a pressure above the pump seal chamber pressure, introduced into an

Arrangement 3 seal to completely isolate the process liquid from the environment.

3.1.10

barrierlbuffer seal chamber

Component or aggregate of components that form the cavity into which the outer seal of a pressurized or

unpressurized dual seal is installed and in which a barrier or buffer fluid is circulated.

4

API STANDARD 682

3.L11

bellows seal

Type of mechanical seal that uses a flexible metal bellows to provide secondary sealing and spring

loading.

3.1.12

buffer fluid

Externally supplied fluid, at a pressure lower than the pump seal chamber pressure, used as a lubricant

and/or to provide a diluent in an Arrangement 2 seal.

3.1.13

cartridge seal

Completely self-conlained unit (including seal/rings, mating ring/s, flexible elements, secondary seal, seal

gland plate, and sleeve) that is preassembled and preset before Installation.

3.1.14

Category 1 seal

See 4.1.2.

3.1.15

Category 2 seal

See 4.1.2.

3.1.16

Category 3 se-al

See 4.1.2.

3 .1. 17

connection

Threaded or f langed joint that rnates a port to a pipe or to a piece of tubing.

3.1.18

co:ntacting seal

Seal design in which ltfile mating faces are not designed to intentionallly create aerodyrnamic or

hyd:rodynamic "Vorces lo sustain a specific separatiorn g.ap.

NOTE Conlactijng seals can aotually develop a fu11 1illlid film, but this is not typical. Contacting seals dc not

incorporate ,geometry {e.'g. gr-ooves, pads, face waviness) to ens'l!lre •thlat ~rne ffa ces do not .t ollcl!'n . Ttfue amou 1'11 of contact

is goenerally very low arnd permits treliaöle operatlon wi!\1 low leal'<age.

3,1.19

containment device

Se.a l or bushing ~nat is fntended 1

to man1age Jeakage from ~h.e inliler or Ol.!ller seal and divert it to a locatior~

determined by tfhe user.

See AriHilHX F for ~~uJ rther description.

3.1.20

coiJ'ilitaii nmernt sea~

Special ve.rsion of ,an outer seal used in Arrangement 2 and that normally ope~ates j(j) a vapor (gas buffer

or no bu:tfer) lbut will S'eal tihe prooess !fluid ti'OJ .a lfumite(jj time in the ·event of an inr:Jer seal faüure. See 4.1:4

3.'L21

'C·orn'rtainmernt seal :dmam'I'Der

GGlmpornent Gr .agg~egCile ·of oonnpoments tl'lat form the caviity 1nto whid.h the con~aimm ent 'Se.al :is •installed.

PH!ifi>S-SH-,..Fir SEALING SYSTEMS FOR CENl'RIFUGA<_ ANI"l ROT!'\9V P..Jr.IPS

3.1.22

containnmerni: :seal cihambe.r 'leakage cd1lector

Reservoir con,lilected tby- -p1pewor'k lo lhe cGn.tainment sea'l char:mber for .tMe

c('lmdenseä leaka~e trolilil the in111er sea\ of an Armnger.nemt 2.

p\l~p>ose

of collecting

3.~.23

·crystalilizing tlu·id

F,luid ithait is in the process Glf focming solids ·or that may f0rm ·soUds lb>ecause of ·dlehydration or c.li1emical

reao1i0n a111d •ca11 .a'Jso be .cause·cl by ,f! change of state swchl a.s C02 .

3.1.24

distribuite:d llush sys1'em

Arrangoeme11t Gf lhdles, passages, baffles, etc. designed to promote an even distro'buliion of flush flu1id

around the drcumference of ~he sea~ taces.

Theseare normally required whe7n piping ~lans provide flu.sh ·;,r~'to the s·e al chamber.

NOTE

3:1.25

drive ·coUar

External part of the seal cartr~idge thal transm'i'ts torqure to the seal sleeve arnd pre1.1ents axäal movement of

~he sea1sleeve relative lo ~he s'haft

1

3.1 ..26

du.al m.eclhanical seal

Arrangement 2 or Arrangemeliltt 3 seal of any type.

3.1.27

dynamic sealing pressure rating

Highest pressure differential that the seal assembly can conlinuously withstand at the maximum allowable

temperature while the shaft is rotating.

NOTE

Thereafter, the seal retains its static sealing pressure rating.

3.1.28

dynamic secondary seal

Secondary seal that is designed to slide or rnove relative to other cornponents to allow axial movement of

the flexible element

3.1.29

engineered seal

Mechanical seal for applications with service conditions outside the scope of this standard.

NOTE Engineered seals are not required to meet any of the design or testing requirements of this standard. See

4.1.3 and A1.2.

3.1.30

external circulating device

Device located outside of ttle seal/buffer/barrier chamber to circulate seal chamber fluid through a cooler

ot through a dual mechanical seal.

3.1.31

face-ta-back configuration

Dual seal in which one mating ring is mounted between the two flexible elements and one flexible element

is rnounted between the ~No mating rings and the pump process fluid is on the 00 of the inner seal and

barrier or buffer fluid is on the I D of the inner seal and OD of the outer seal.

API STANDARD682

3.1.32

tace-to-face configuration

Dual seal in which both of the mating rings are mounted belween the flexible elements.

3.1.33

fixed bushing

Cylindrical device with a close clearance to the shaft or s!eeve that restricts flow between two regions and

that does not have a clearance an the ouler diameler relative to the housing in which il is mounted.

3.1.34

fixed throttla bushing

One-piece cylindrical device that is fitted to the stationary part of the containment seal chamber and has a

radial clearance to a rotating component; it is used to help isolate one region frorn another and assist in

channeling liquid leakage to an exit port, and the design is intended to maintain a fixed radial clearance

over the operating life of the seal, these devices have a low LID ratio 0.2 or lower.

3.1.35

flashing

Rapid change in fluid state frorn liquid to gas.

NOTE ln a dynamic seal, this can occur when f1ictional energy is added to !he fluid as it passes between lhe primary

seal faces, or when fluid pressure is reduced below the fluid's vapar pressure because of a pressure drop across lhe

seal faces.

3.1.36

flashing hydrocarbon

flashing fluid

Liquid hydrocarbon or other fluid with an absolute vapor pressure greater than 0.1 MPa (1 bar) (14.7 psi)

at the pumping temperature, or a fluid !hat will readily boil at ambient conditions.

3.1.37

flexible element

Combination of elernenits that accomnnodale axial movement between ;rotating and statiornary parts.

3.1 ..38

fllexiilble graphlte

ExfiO:Ii·a ted and recompressed graphitematerial used ~or static (secondary seal) -gaskets rirnmechanical se.a'l

design, ~rom cry0genic to ho1 seNtioe.

3:1.39

~loatin:g buslhing

Gylindnical dev~ce with a close clearance to the slhaft o1r 51eeve that r.esltriicts flow be·t ween two regions and

thet has a cleararnce on the outer diarneter rrel.ativ<e 1!0 ~he lhousing in which it is mounted to allow radnal

motion ("floating") of the b.ushing shou1d it corne in contact with the rnotating s!haft or sleeve.

3.·1 .40

filu~ rpßla.stom er

FKM

Satma.ted pdlymer in vJrhich hydrogen a'toms have been rreJPiaced wi~h 'rrluorine; rit is ch.aracterizeGt by

e:x.cel\\ent nydrocarbc:m arKl ~enera\ ch:emicel resistance

3;~ .4~

fJIJI-stil, nown

Fluid fhal is rrntroduced ~nto rthe seal ·cl'ilamber ·On the pnocess if:hiitl siele rin dose proximity to the seal face.s

a:nd typically us·ed for coOiing .and lubricating the seal ~ace$ arndlor to keep .t hem o!earn.

PUMPS-SHAFI SE.ALING SYSTEMS FC" Ct:NBIFUGAL ANO Rou,~Y P J MPS

7

3.1 .42

gland plate

gil:llld eno plate

Pressur e--retain in.g componenL(s) sim ilar to a flange, w hic h connects Lhe statio nary assembly of a

mechanical seal to the seal cham ber.

NOTE A gla.nd plate may con sist of mme t111an one press•.sre-conlahing component, for ex.a mple the two gland

plates often used in a dual seal. .

'3.~ .43

lhook sl:eevt!

Slecve, wittl .a step ar hook at the product end, p!aced over the ·shaft to pmtect it from wear and corrosiam.

INJOTE The step ls ~Jsually abutted ~gainst l·he im.p·efler ·tQl ho.IJ!l ~t ifi'I IPiace with a gasket betweefil the sha'ft and thle

slep (hook}.

3.1 .44

lnmer seal

(A rrangement 2 arnd A rrangement 3} ifhe seal closes~ to the pump impeller or process fluid.

3. 1.45

i nt em al ci.rculating dev i ce

Device located in t he seal/bufferfbarrier ch amber to circulate fluid through a cooler or through a dual

mcchanical seal.

NO T E There are various designs to amieve radial or axial flow. Tlhe internal circulating devir.e can be integral with

other SE)al parts or a separate part. (This device was fonncrly kno\•m as a "pumping ring.")

3 .1 .46

intemally mounted seal

Sea l conflguration in wt1ich the seal is mounted within the boundaries of the seal cham ber or containment

sea l chamber or gland plate.

3.1-47

leakage concentration

Measure of the concentralion of a volatile organic compound or other regulated emission in the

environment immediately surrounding the seal.

3.1.48

leakage rate

Valurne or rnass of fluid passing through a seal in a given length of time.

3.1-49

light hydrocarbon

Hydrocerbon liq uid that will readily boil at ambient conditions.

NOT E

Typically lhis definition inciudes p ure and mixed streams of pentane (C 5) and lighter liquids .

3 .1.50

mat ing ring

Dis k- or toroida l-shaped member, mounted either on a sleeve or in a housing such that it does not move

axially relative to the sleeve or the housing on or in which it is mounted a nd that provides the mating seal

face for the seal ring face, the mating seal face is perpen dicular to ttle axis of the shaft.

3.1.51

maximum allowable temperature

Maximum continuous temperature for which the manufacturer has designed the equipment (or any part to

which t he terrn is referred) when handling thc specified fluid at the specifled m aximum operating pressure.

API S TANDARD 682

8

NOTE 1 This Information is supplied by the seal manufacturer.

NOTE 2 The maximum allowa ble te mperature is usually set by material considerations. This may be the material of

the casing or a temperature Iimit imposed by a gasket or ü-ring. The yield slrenglh and ultimate strength are

temperature dependent. A component's stress Ievei can depend on operating pressure. Thus, the margin between the

strength Iimit of the material and the operafing stress depends on both the material's operating temperature and the

component's stress Ievei. lf the temperature is lowered, the matenal's strength increases and the stress Ievei of the

component may lncrease. Tilis is the reason for associating the maximum allowable temperature to the maximum

specified operatlng pressure.

3.1.52

maxlmum allowable working pressure

MAWP

Maximum continuous pressure for which the manufacturer has dQsign ed the equiprnent (or any part to

which the term is referred) when handfing the specified fluid at the specified maximum operating

temperature [cf. static sealing pressure rating (3.1.84), dynamic sealing pressure rating (3.1.27)].

3.1.53

maximum dynamic sealing pressure

MDSP

Highest pressure expected at the seal (or seals) during any specified operating condition and during

start-up and shutdown.

NOTE ln determining this pressure, con~ideration is given to the maximum suclion pressure. the flush pressure, and

the effect of clearance changes viiihin the pump. This is a process c ondition and is specified by the purchaser.

3.1.54

maximum operating temperature

Maximum tempcrature to which the seal (or seals) can be subjccted.

NOTE

This is a process condition and is specified by the purchaser.

3.1.55

maximum .static se-alirng p ressure

MSSiP

Highest [pres·sure, ~excl u d ing pressur·es encountered du ring lhydrostatic testing, to w:hich the seal (or seals)

can lbe subjected w ,hile the ,pump is shut down.

1

NOTE

ifhis 1is a process cmndition and is specified by ithe 1

pun;rnaser.

3.1.56

noncontacting ·seal

self-acting seal

Seal desigril in which title faces are designed to intentionally .cH~·a te aerodynamic or hyd rodynamic

separ:ating forces to sustain a specific separation gap lbetween the saal ring and the mating ring.

1'\JOTE Noncon1acting seals are specifically designed so that there is always a n operating gap between 'the

stationary and rotating face.

3.1 .57

nonfla·sh\ng h.ydrocarbon

nonflashing fluid

Liquid hydruca rbon or other fluid wlilo.se vapor pressure al any specified operating temperature is Jess than

an absolute pressure of 0.1 1\!lPa (1 1bar) (1-4.7 psi), or a rluid tlilat will nct readily boil at ambien t conditions.

f~.U.MPS- 'SHAFT SEALING 'SYSTEMS FOR .Co'Jc Rff"jGAL.AND !ROT,01<V RJ.:MPS

9

3;rt.·5:8

,uanihydrocartborl ;senlice

Servtice 1in wt,lit.:h ·the 'fluid, such .as sour water, I:Joiler feed water, ·sC!ldium lhydroxide, acids, and amines,

contains nG hydr.ocarbons or the fluid tilas rslative•ly small qua1~tities cif entrained !hly dmcarboms.

zu .s9

.obs:enr~a-cl

te:st

Prodl!ldt iteS:! ,flila't is observed at the diiscret10n ·of the pt1rchaser, w:JnG has beem f)ive.n Mtice df ithe te.st by

lthe manwfadu·r:er, but d.oes not consmwte a manufacl'..rring lroold point

3.'1.60

orifke nippl·e

Pipe nipple made ,of solid bar stodk with an .arriflce ho!e dnlled thr.a:l!lgtl it l o restriet leakage 1in ~he event of

an auxiliary syst·em pipe or ·compornent failur~e.

NOTE

Orifice nipples are commonlyfound on Pip~ng Plan 11 :systems.

3.1 ..61

0 -:ring

B astomeric sea'l ing rinQI w'ithl an 0-shaped (circular) cross-section, which may lbe ~Jsed as eilh~r a stalic or

dy11amic secmndary .sea'l.

3.L 62

oute-r seall

{A nrangement 2 and Anr-angennernt 3) Trhe seallocated farthest from tlhe pump 1impeller or process fluid.

3.1.63

perfluoroelastomer

FFKM

Fully fluorinated fluorocarbon elastomer commonly used as a secondary seal in high-temperature and/or

corrosive service.

3.1.64

piping plan

Gonfiguration of accessories, instruments, controls, and/or fluids designed to manage or control the

environment araund the seal.

NOTE

Auxiliary piping plan.s vary with the. app!ication, seal type, and arrangem ent.

3.1.65

polymerizing fluid

Fluid that is in the process of changing, or is capable of changing, from one chemical composition to

another with Ionger-ehain components and different properties, usually becoming significantly more

viscous and/or tacky.

3.1.66

port

Fluid passageway, typically located in the gland plate.

3.1.67

pressure casing

Composite of all the statio nary pressure-l'.ontain ing parts of the seal. including seal chamber barrier or

buffer fluid chamber, conlainment seal chamber, and seal gland plate, and excluding seal ring, mating ring,

bellows, sleeves, miscellaneous internal seal parts, and atmospheric side gland connections, which

cannot be isolated from atmospheric pressure.

NOTE

The MAWP of the auxiliary systern is specified in Section 8.

API STANDARD 682

10

3.1.68

product temperature margin

Difference between lhe vaporization temperature of the fluid at the seal chamber pressure and thc actual

temperature of the fluid.

NOTE For pure fluids. lhe vaporization temperature is the Saturation temperature at seal chamber pressure; for

mix.ed fluids, the vaporization temperalure is the bubble poinl temperature at the seal chamber pressure.

3.1.69

pump manufacturer

Agency that designs, manufactures, tests, and prcvides service supporl for t11e pump.

NOTE

The pump manufacturer may also purchase the sealing system and perform the installation.

3.1.70

pumped fluid

process fluid

The process stream designated in the datasheet for the pump service.

3.1.71

purchaser

Agency that issues the order and specifications to thc vcndor .

3.1.72

pusher seal

Seal that incorporates a dynamic secondary seal to allow axial movement of the flexible element: the axial

movement is driven (pushed) by mechanical andfor hydraulic force.

3.1.73

quench,noun

Neutral fluid, usually water, steam, or nitrogen, introduced on lhe atmospheric side of the seal to retard

formation of solids that may interfere wilh seal movement, or for olher purposes such as prevention of

cokfrng, crystallization, er icing.

3.1.74

s .e al

end faoe mecharnica'J seal

Device Vhat prev·ents the leakage of .flulids between a sihaft a:nd .housing ilil relative lliloticm.

NOTE SeaJing 1is accomplished by a stationary seal face lbearing against.a notating s·eal faoe; the seallng faces ar•e

mournted iPerpendic\JIIar to tlile shafit axis.

3.1.'75

se:a~ balance rat:io

Ratio of seal face area exposed to closing force by liydrat!Jiic diifferential pressure .acmss tihle seal face to

the itotal sea'l iace area (see Annex F).

NOTE

1t 1is :sGmetimes expressedas a percentage.

3:1..76

seal clilambet

Oompo.nenl, eiui1er imtegral with or .se,parate frorn ithe JJll!lm:p ,case (ho,UJsingj, wl<lichl for;ms the rregion

lbetween the:shaft and casing iinto whictn tlile;seatl is instaJiad

PUMPS-SHAFT SEALINS SYSTEMS FOR GENTRIFUGAL AND RCTARY PUMPS

11

3.1.77

seal face

seal faces

The lapped surface of a mating ring or seal ring that comes in contact or close proximity to the other ring

and provides the relative rotary motion sealing surface(s)_

3.1.78

seal manufacturer

Agency that designs, manufactures, tests, and provides service support for seals and associated support

sealing systems.

3.1.79

sealring

Disk- or toroidAI-shaped member, mounled eilher on a sleeve or in a housing such that it is able to move

axially relative to the sleeve or the housing on or in which it is mounted and that provides the mating seal

face for the mating ring face, the seal ring face is perpendicular to the axis of the shaft.

3.1.80

seal sleeve

Hollew cylindrical compot1ent that fits an the outer diameter of the shaft with a close tolerance fit,

incmporates a static secondary seal with the shaft and extends beyend the seal gland plate, it is used in

the assembly of the seal components and ensures they rotate with the snaft.

3.1.81

secondary seal

Oevice (such as an 0-ring, flexible graphile ring, flexible graphite filled spiral wound gasket or bellows)

that prevents leakage of the sealed fluid, barrier fluid, buffer fluid, or quench medium through paths other

than the inner or outer seal faces, the containment device, or designatecl drain.

3.1.82

segmented floating bushing

Throat or throttle bushing that is composed of circumferential segments retained by a tensioning device.

3.1.83

service condition

Maximum or m inimum temperature or pressure under static or dynam1c conditions.

3.1.84

static sealing pressure rating

Highest pressure that the seal can continuously withstand at the maximum allowable temperature while

the shaft is not rotating.

NOTE

Thereafter, the seal maintains its dynamic sealing pressure rating_

3.1.85

static secondary seal

Secondary seal between two surfaces that have no relative motion.

3.1.86

strainer

A relatively low pressure drop device designed to remove solid particles from the flush or other fluid.

3.1.87

throat bushing

Device that forms a restrictive close clearance around the sleeve (or shaft) betv~een the seal chamber and

the impeller.

API STANDARD 682

12

3.1.88

throttle bushing

Containment device that forms a restrictively close clearance around the sleeve at the atmospheric end of

a gland plate_

3.1.89

total indicator reading

total indicated runout

TIR

Difference between the maximum and mm1mum readings of a dial indicator or similar device when

monitaring a Face or cylindrical surface during one complete revolution of the monitared surface_

NOTE Fora perfect!y cylindrical surface, the indicator reading implies an ecce11tricity equal to half the reading. Fora

perfectly flat face, the indicator reading gives an out-of-squareness equal to the reading. lf the diameter in question is

not perfectly cylindrical or flat, interpretation of the meaning of TIR is more complex, and may represent ovality or

lobing_

3.1.90

Type A seal

See 4.1.3.

3.1.91

Type 8 seal

See 4.1.3.

3.1.92

Type C seal

See 4.1.3.

3.1.93

vendor

Manufacturer of the equipment, or his/her agent, normally responsible for service support.

NOTE This ,standard :addresses the ,responsibi!ities between twc parties, defined as the purchas-er arnd the venGJor.

T'here are m any par:ties t:hat -are nnv.o!ved in ithe purchase and manufacture of tihe equipmen'i. These parties an~ given

different lities depending on thie.ir order in the chain. Thoey may ioe called buyer, contr.a ctor, manutacturer, ·Or subvendor.

1F0r example, f,li'le [panty supplv,!ng a :Juhricating oil console may be the console vendor of Ihle compressor manufacturer.,

the s-utvendor of the purchaser, and the purchaser of compo.nents within t.he ·console. All of tlilese terms, h owever, can

be reduced to t he purchaser <:md vendo:r. ll is for this reascn !hat o111!y these twc terms .a re defirned_ Attempts to define

these other terms V-lould on'ly cau.se cornfu siorn.

3.1.94

vol.atile hazarrdous aii r pollutant

VHAIP

Any oeompound as defined b>y "fitle 1, Part A, Section 112 of the U. S. NationEJI Emission Standards for

Hazardous Air Rolliutants (NESHAPs) (Clean Air Act Amendment).

3.11.95

Wiflnessed i llSpectiorn

w ilt nessed test

lnSif])e.otton ·or t:est fm Whbch the purclllaser ~s ~~otiJieGl 'Of tih e Um1ng ,amd a holcl is placed un prooucticn wntil

the ,purchlaser or his1her rr:~presentativ:e is in atitendance.

For th.e lßUrposes of flnis doownent, the ~ollow"ing S}lmbols apJ):Ily.

iJ

~lüe area ofthe seal face. e;oqpressed in 'Sq~are miflimelers

13

PUM?S-SHJ\FT SEALING SYSTEMS FOR GENTRIFUGAL AiiJD RoTARY PUM PS

F0

the opening force, expressed in Newtons

f

the effective coefficient of friction

K

the pressure drop coefficient, dimensionless

f/%Ai\

volume percentage of component A in mixture B

!'J..p

the differential pressure. expressed in megapascals

PA

density (specific gravity) of fluid A

PB

density (specific gravity) of fluid B

wAa

mass percentage of component A in mixture B

4

Sealing Systems

4.1

Seal Categories, Types, and Arrangements

4.1.1

General

The seal configurations covered by this standard can be classified into three categories (1, 2, and 3), three

types (A, B, and C) and three arrangements (1, 2, and 3). Further, Arrangement 2 and 3 seals can be in

three orientations: "face-ta-back,'' "back-to-back," and "face-to-face" These categories, types,

arrangements, and orientations are defined below.

See Figure 1, Figure 2, Figure 3, F1gure 4, Figure 5, Figure 6, Figure 7, figure 6, and figure 9 for typical

representations.

4.1.2 Seal Categ·o ries

There are throee seal categori·es, as follows.

Cat~g<}.nJ 1 s.eals a f'e ln•te11~ed ~er use in non-API 610 P'l.'lmp seal chambers, meetimg the dimens\~r~al

reqw;ir.emetilts of Ä'SME IB73, 1, and ASME 8732 seal 'dhambt:r dimenslons alilc!l ·their application "is

rimited ·to sea1 c.lilamber ~emperatwres ~rrom -40 "C (-40 ·QF) lo ~6G 'OC (500 GF) alfld gau9e ·pressmes

up to 2 MPa (ZQ bar) {30Cl psi)

·Catego(Y 2 .seals ~me inteooed tfor .lilse in seal cmarnbers rmee~img the rlismber envelope dlrneP.siOnal

'fequirememts ef AP1 .611 0. lfheir~pplioatioo is lirnited to seal chamber tenlPeratutres.from -40 "C (--40 "Fj

to 400 'C C7:S8 'aF1 alflti·gl'lt'lge p:"Msures up tc 4 .M.Pa (40 bar).(600 IP.Si),.

·catflgl:lr-; ,3 proviEles the rmC!lsl rigorously :teS.ted .aml:t .documemted ·seal des·i!:Jn They r,meet ·the s:eal

cl;1ambler ·envelope reqai~erments Of Äp;l 6 W (or eql!.lal). T;heir -af!>pl1tati0m ris limiled to se.ar chamber

lemperat~res ~rolil'l --40 •Oe (-40 ~F) to 400 "C ,(7.50 °F,) <

and gal'lge pressll!r.es :qp ttil 4 MPa {40 bar)

·(SGO ,psi•}.

1

A sumu1a~y of 'the 'finain dififere:mces in ·seaJ.categaries •is:g''ivemlin Amnex A

"Termper-alures and JXessures-.o utsiäeltherangcs of:.these•cate.gGries, or.wlnich invdlvr;:'fll)l"i\!Js'r.Jot. ineluded .in

Am nex :A, ·may reql!lire engineenirm.an<l ·seal •sEileetion :gJ.ii.ä ance ·dth_er than providc'ä in !his stancilar.d.

4..:1..3 S:eallype-s

API STANDARD 682

14

Type A seal is a balanced, internally-mounted, cartridge design, pusher seal with multiple springs.

Secondary sealing elements are elastomeric 0-rings.

Materials are specified in Section 6. Guidance on equivalent materials standards is given ill Annex B.

Figure 7 depicts a Type A seal.

Type B seal is a balanced, internally-mounted. cartridge design (metal bellows) seal. Secondary

sealing elemants ar6 elastorneric O·rings.

Materialsare specified in Section 6. Guidance an equivalent materials standards is given in Annex B.

Figure 8 depicts a Type B seal. A metal bellows seal offers the advantage of having only static

secondary seals. lt may be specified instead ofthedefau lt Type A seal for low-temperature service.

Type C seal is a balanced, internally-mounted, cartridge design (metal bellows) seal. Secondary

sealing elementsareflexible graphite.

Materialsare specified in Section 6. Guidance on equivalent materials standards is given in Annex B.

Figure 9 depicts a Type C seal. Bellows seals are inherently balanoed. Stationary meta! bellows seals

are the primary choice for high-temperature Arrangement 1 seals.

Type A and T ype B seals are sultable for temperatures up to 176 oc (350 'F). Type C seals a re for high

temperatures up to 400 oc (750 °F). Seals outside the scope of Type A, B, and C are termed engineered

seals and referred to as ES.

NOTE

For Seal Arrangement 2 and Arrangemenl 3 the seal types can be rnixed across configurations.

4.1.4 Seal Arrangements

4.1.4.1 Arrangement 1, 2, and 3 Seals

There are three seal arrangements, as follows.

Arrangement 1-Seal configurations having one seal per cartridge assembly.

Arrangement 2-Seal configuralion having two seais per cartridge assernbly, with the space between

the seals at a pressure less than the seal chamber pressure.

Arrangement 3-Seai configurations having two seals per cartridge assembly. utilizing an externally

supplied barrier fluid at a pressure greater than the seal chamber pressure.

NOTE 1 The principal diffierence between Arrangement 2 and Arrangement 3 configurations is the concept of

containment of leakage versus the elim ination of process fluid l eakage. Refer to the associated definitions and

Annex G piping plan descriptions.

NOTE 2 ln Arrangement 2, the outer seal can be a wet seal or a dry-running seal. The inner seal utilizes a piping

plan typical of Arrangement 1 seals. lf the outer seal is a wet seal design, an unpressur·ized liquid b uffer fluid is

supplied to the outer seal chamber. lf the outer seal is a dry-running seal it is defined as a containmenl seal (3.1.2.0); a

gas buffer may be used.

4.1.4.2 Alternate Technology Designsand Sealing Methods

Alternative technology designs and sealing methods are also considered, as follows.

Contacting wel (CW) seals-Seal design where the seal faces arenot designed to inlentionally create

aerooynamic or hydrodynamic forces to sustain a specific Separation gap (refer to 3.1.18).

Noncontacting (NC) seals (whether wet or dry)-Seal design wl1ere the seal faces are designed to

intentionally create aerodynamic or hydrodynamic separating forces to sustain a specific separation

gap (refer to 3. 1.56).

Containment sea/s (CS). wherher contacting or noncontacting--Seal design with one flexible element.

seal ring and mating ring mounted in the containment seal chamber (refer to 3.1.20).

IPLIM"B-SI-IAFT SEALNC SYSTEMS FOR GSNTRIFUG,A!_-A ND ~OTARY PUMPS

Fi~we 1 ;places '·all tlnt.:-se ·conaepts rim rQT1e

?.5

diagram, pmv-idimg ,-a oonr]preher:Jsi.v e way 1(!) llndk at !Hrteir

riOtBTrel:ationsh1ips.

4. \.:5 ~Se:al ·Config.ur:a:tians

Arrangalili1ent.2 anCI ArranQJelinen't -3 sealis can ,be hrtbe fdllowin,g three con'figurations:

.f:ace1t0-back H~fer :to 3.1._3n;

back-to4ba_ck: f-eTer .to 3. ~ . 7;

face-to-=

'faGe: r efer to 3. ~ .32;

Refer t0 fiigi!Jre 1,

Othler Gon'fi_glllratlon sudli1 ras concemtric s·eaLs rmay be agreed lby t he purrchaser an.d vemdor arnd are

·consldered a111 engimesred seat

4:2 Objeötive;s

S:haft sealing s.ystems conl[Orlining to tt~ls standard are intend€d [o meet the following objectives:

a) all seals stnouJd operate contimmusly for 25,000 t1 wii1out nsed for replacement;

b)

Arrangement 2 ,_outer seals should operate for .at least 25,000 h without need for rreplacement (wet or

dry seals) at a~y containment seall chamber or huffer f luid ctuarnber pressure .equal to or less than the

seallea'kage IPressure switch setting [not to exceed .a gaug-e pressure of (l07 MPa (0.7 1bar) (10 ps'i)1

and fo.r at ~east 8 h at the seal chamber CO'ndiNons;

c)

-

all seals should operate for 25,000 h without need for replacement while either complying with local

emissions regulations, or extlibiting a maximum scre~mi ng value of 1,000 ml/m3 (1 ,000 ppm vol) as

measured by the EPA Method 21, whichever is more stringent.

4.3

Specifying and/or Purchasing a Sealing System

The datasheet (Annex C) shall be used to convey purchasing requirements. Default requlrements are

identified therein that allow the purchaser to specify a seal "vith minimum Information. The minimum data

required on the datasheet to obtain budgetary prlc!ng on a sealing system ls expressed in the seal code,

Typical seal codes !hat can be used are given in Annex D. This assumes all standard defaults

(construction features and materials). The minimum Information required on the datasheet to purchase a

seal with assurance thal the selectlon will satisfy the objectives of 4.2 is the pump data, fluid data, and seal

specification.

API Srt.NDARD 682

16

Arrangement 1

Arrangement 2

Arrangement 3

One s~l per c<~r1rioge

Two seals per cartridge assembly with a

containme11t seal chamber that is at a

pressure less than the seaJ chamber pressure

Two seals per cartridge assembly

thal utilize an exlernally supplied

barrier fluid

assembly

I

Liquid buffe r fluid

Gas buffer fluid or

no buffer fluid

I

I

Contacting

single wet seal

with a fixed

th rottle bushing

Dual t:ontacting

wet seals

Gonfiguration

l

Liquid barrier fluid

Gas barrier fluid

I

I

Contacting wet

inner seal with a

containme nt

seal

Contacting wet

seals in a

face-to-back

configuration

Noncontacting

seals in a

back -to-back

configuration

Genfig uration

Configuration

Caniiguration

Gonfiguration

1CW-FX

2CW-CW

2CW-CS

JCW-FB

3NC-BB

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

1

I

Gontacting

single wet seal

with a floating

throttle bushing

Noncontacting

inner seal wilh a

'-containment

seal

Contacting wet

seals in a

back-la-back

configuration

Noncontacling

seals in a

face-to-face

conflguration

Gonfiguration

1CW-FL

Configuration

2NC-CS

Gonfiguration

3CW-BB

Figure 2

Figure 4

Figure 5

Gonfiguration

3NC-FF

Fi gure 6

Contacting wet

sea!s in a

face-to-face

configuration

Noncontacting

seals in a

face-to-back

configuration

Gonfiguration

3CW-FF

Figure 5

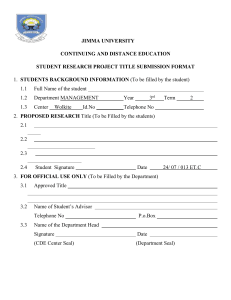

IFigur.e 1-Seal Confi:gu rations

I

Gonfiguration

3NC-F'B

I

Fi gure6

P !ll\ll?s:-swAFT"S-= AuNG.SI'STEMS FOR C 8 NrRin!IGAL AXIf"J R.OT.O.RY PUMPS

a) 1CW-FX_,(Contaoting Stngle :We'l S.ea~ w'jth ·.a lfhted ilit:rr.o'Mie Bl!lshlrng

b) 1CW-FL, Contactin!] Single Wet Seal with a Floating Throttla Bushing

c) Typical Gland Plate Connection Orientation

NOTE

For connection designations, see Table 2.

Figure 2-Arrangement 1: One Seal per Cartridg e Assembly

17

18

API STANDA~O 682

a) 2CW-CW, Dual Contacting Wet Seal

b} Typical Gland P~alte Connection Odentation

NOT E

For connection designat ions, s ee Table 2_

Figure 3-Arrangement 2: Tw,o Seals per Cartridge Assembly with a Liquid Buffer Fh.iid

19

a) 2CW-CS, Contacting Wet lnrner Seal with ;a Contaii nmtmit Seal[

b) 2NC-CS, Noncontacting Inner Seal with a Containment Seal

NOTE

c) Typical Gland Plate Connection

d) Typical Gland Plate Connection

Orientation for 2CW-CS

Orientation for 2NC-CS

For connection designations, see Table 2.

Fi gure 4-Arrangement 2: Two Seals per Cartridge Assembly with or Without a Gas Buffer Fluid

20

API STANDARD 682

a) 3GW-FB, Gontacting Wet Seals in a Face-to-Back Gonfiguration

b) 3GW-BB, Gontactlng Wet Seals in a Back-to-Back Configuration

c) 3GW-FF, Gontacting Wet Seals in a Face-to-Face Gonfiguration

G~

~

0\f

._

.. ,

'\.

0

..-r-~

't

,.

\ 0/'~~\

~,/

I

I

I

0/

/

oG' -~-­

d) Typical Gland Plate Connection Odentation

NOTE

For connection designations, see Table 2.

Figure 5-Arrangement 3: Two Seals per Cartridge Assembly wlth a Liquid Barrier Fluid

I

PUMPS-SHAFT SEALING SYSTEMS FCR CENTRIFIJGAL liND ROTARY PUMPS

a) 3NC-BB, Noncontacting Seals in a Back-to-Back Configuration

b) 3NC~FF, Noncontacting Seals in a Face-to-Face Gonfiguration

c) 3NC-iF'B , Noncontacting Seals in a Fa.ce-t·o-Bac.k Configuraltiion

·d) lfy:pic,;:j I ·GJancl fAl::a1e :-Co:nnad:tiiam ~Orie'ntafi'olil

i~J(.HE

IFQr .conli\eeti:on uesi~r.atroms see lt~e 2.

21

22

APt STANDARD 682

a) Rotating Flexible Element

b) Stationary Flexible Element

Figure 7-Arrangement 1 TypeASeals

.a) Rotating ,B eUows Assembty

b) Stationary Bellows Assembly

Frigure .8 -Arrangement 11 Type B Seall·s

a~

Stanio1mary Bell ows Assembly

lb} RGtattirn g ,BeHows Assembly

Fri gure 9-ArrangemeJJtl: 'i1 Type C S:e:als

PUMPS- -SHAFT SEALINS SYS1 EMS FORCENTRIFUGAL AND ROTARY PUMPS

5

General

5.1

Unit Responsibility

23

Unless otherwise specified, the pump vendor shall have unit responsibility for the seal system if the seal

system is purchased as pa1rt of a pump system. lf not purchased as part o•f a pump system, the seal vendor

shall have unit responsibility for the seal system. The vendor who has unit responsibility shall ensure that

all subvendors comply with the requirements of this standard. Annex E specifies the interface

responsibilities of the pump and seal vendors.

5.2

•

Dimensions

The purchaser shall specify whether data. drawings, han:Jware (inclu ding fasteners). and equipment

supplied lo this standardshall use SI units (or U.S. Customary units)_

6

Design Requirements

6.1

Common Design Requirements (All Categories)

6.1.1

General Information

6.1.1.1

All mechanical seals, regardless of type or arrangement shall be of the cartridge design, without

hook s!eeves.

API 610 requires that pumps be designed to enable seal removal without disturbing the driver . lf pumps

are being retrofitted that are not back-pullaut design, it should be verified that adequate shaft end spacing

exists by comparing the seal cartridge length to the distance between shaft ends.

•

6.1.1.2

Unless otherwise specified the flexibleelementshall be rotating for Type A and Type 8 seals. lf

specified, or if recommended by the seal manufacturer and agreed by the purchaser, a stationary flexible

elemeot s\ya\1 b:e 'i!.upp\\ed fo.r Type A or Type B sea\s.

NOTE WJtimin the scop!:! of th\s standard, rotating and statior:~ary fte.xible elernents .are c.onsidered to b:e 'technically

equiv-alenl lb1!1t t he optiml!lm choice is linflu.enced by many different lfaotor-s. The defau:ll fo.r rota~ing or stationary

elememts for different .seal types and l·be'ir arrangements ·have been lbas·ed •o!il insta.lled popu1ation arnd reliable

opeva\ic;m.

Tih.e.re .are a rnumber of'fadors rela:t ed to ~he design 1mamufactt1.re, imstalla!fio.n, •amt!.l r.epc:ür 0f the :eguipment

ithat sh.auld be comsidered Whelil lillak1ng the selectton of .a rotatimg or stationary ßexib.lc element. ifhe

:relative liTilerits of rotary .al'i'Jd stationary ·,flexible element seats ar~d the faot~rs 1ir•lfih:~ee~cing rthe choice are

·aarJressed tim,0fher'subsecti0ns in this section a rnd F .5.

•

~s.. 1.':L.3

Unless •dttnerwis:e ·specified "{he iftexible elerner.1t :slilall be ·stalionary ·forTyp.e C ·seals. !hpeciJie~

•oriif mcGmi•Tilenäcd -~y the ·seal trlnnllif~:clu.rer and agrced .by ttile porchas·e r ;a •rotating f!exi~le element shalfl

-b eJJse.dJorilype·C se-al:s.

lNUi.'.E

'See'i\IIDE ·in 6. 1.1 ..2.

'll.~rt ..1-4-

ifhe ~cat'trr<I!.<s€ -'.<>e<=ik;lhall itincorpma:te a -setttn.g ·delllce ' {sULch as s,.emin@ plates) tt.trat1is suffici~:mtl:;

lrobust t::J &lnable~t~e ..assemb_ly to be·pushed or·pulled d~ ri11g installation ,, rclt@r, atJjijstment,' or ·d[sas.S'eml:illy

·.·N:ithodt transferring r.adfal or a·xiall loatl itolthe:s-ea.·,,taces.

~6.1 ..rt.:5

'A ~statiema~y · fl-e.~i9le-'eleme-r1t s_eal "Shall t.t;e ,pr0vided -~f .c$eaJcface .,surfac;::e -sp:eed ' at .the m.e.an

:oliametcr-ciUhe",se·al'faG_e.Bxcee'ds23·.m/s.(•45·oo;ftlmin).

1NOTE As--~peed iincreas:es, the·Jlexible~element:rnf a rotaUr,tg-seaT-'flexes..at; a correF,>pon'dJngly'faster ,f ate to' kt!ep.the

rseal ·.fac:.es; olosed..At very~·hjglrspeeds·. (and' fort.Ja.rge cs~eaU;iz~;;s.), tt:lel'forces ·r:c~uirectao. keep.theifa-ces· closetl~be.come

· s:o: ia[,Cle':that ~ü~v, n.~aalivejv .affa~~. the;seai .life.

24

A"RI STNIDAR:J 682

·Gonsideration .stnould ibe ,giveo ,for,reqjuiring :a siationary ilifexible :olement iff:

'bJ 1;Jurmp case or gtalild p'late .dist0rt!ion :and:i 'misalignmer1t eX~ist due ·to pipe l0aCfs, tlirerrmal disto.r.tiotl,

p~essurre distortio_o, ,etc.;

c) 1tti1e 1 parpe1'1~icularity •ofithe .seal c:haniber rnounting ;surface to the shaft is ..a p.ro.bler:n, .aggtavate.d 'by

toig.h mta'tiGoal :,':1peed; .or

a:) · t~e ·s.ea'l chamber · face rnno.l:.it .requirememts desQribed im 6:1.2. ~ 3 ·Canm.o.t lb"e 'met {a:s Jound 1ir1

ASME 87.3. ~ ar;rd 1ASME IBY3.2 pi.Hmps anl] with sofilile slendl'er~sh.aft, m11ltistage pum~ ,ltfes'igns).

6. ~ .1.6

Tbis &tand:a~d does not cover fhe desigR of the C<DiiYlJDornen1 parts of mec'lilamicar seaJs; ,fuowever,

tl1e c!les·igfl a nd mateJii als -af ~he component parts Shall lbe 'S'J•itabile for1the specified serv~ice comdilions. irhe

maxiir:rilum allow,a'ble workl ng pressure ~MAWP) Sha'll appl,y lo all partts re'feHed ·~o in ithe C!fefinli tium {}f

pr.essure casin,g

NOTE

lt 'is not trnormal pracbioe for ssals tobe raled far the IMA\1\fiP lfor the pump in W1hich bliley are installed.

t6 .1 .1 :7

The sea'l manutact,L.rrer slha'I'J design the ·.seal faces and sea'l balance r.atio to minimize

seal-fa:ce·g.er~·er.ated hea't ootn sistent with o,ptimum liife ex,pectat~orns ~n 4.2 arnd emissions Iimit requ irements.

Balance diameter varlies wi~'h se al desi,gn, but for spring pustlier seals 'it is nonna'Jiy thc diameter of the

sUding contaot surface of lhe dynamic 0-rin.g. For Une inner seal of a dual seal the sliding ·s UJrface c-an vary

depending orn whethe.r tlhe pressUJre 1is internal or extemal. IFor weldled metal beHows-type s-eals., ·t he

balance diameter is normally the mea n diameter of the beJiow.s, but lthis \ivjll vary w,ith pressure. Contact the

see'l vendor for determination of the oalance diameter under varying pressure condi!ions.

NOTE 1 Tetn~etature of th~ environment eround the seal as influenced by se~l face generated heat and heat soak

will have an impact on seal performance. Refer to F.2.1 and F.2.2 for discussion of seal balance diameter, seal

generated heat, and heat soak.

NOTE 2

Starting torque and seal power can be significant issues for small pump drivers, seals at or above the

balance diameter and pressure boundaries of this standard, and for Arrangement 3 seals.

The seal supplied shall be capable of handling normal and transient differential axial movernenl

between the rotor and stator.

6.1.1.8

NOTE Maximum axial movement is of particular concern in hot multistage pumps. During start-up conditions, it is

not unusual for a large amount of differen tial thermal grovll.h to occur between the shaft and casing. This differential

can exceed the capabilities of some seals. Appropriate warm-up procedures r.an minimize this problem. Axial

movement is also a concern in some vertical pump designs !hat rsly on the motor bearing for thn.Jst positioning (i.e.

in-line pumps without pump bearing housings and vertical can pumps). ln certain conditions. process pressure can

result in an upward thrust. Shaft axial movement is only lirnited by motor-bearing axial float in these cases.

6.1 .1.9

Uniass otherwise specified, 0-ring sealing surfaces, including al! grooves and bares, shall have