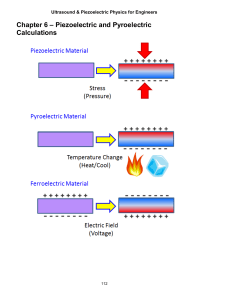

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/346579536 Recent trends in piezoelectric actuators for precision motion and their applications: a review Article in Smart Materials and Structures · December 2020 DOI: 10.1088/1361-665X/abc6b9 CITATIONS READS 140 2,297 5 authors, including: Mohith Santhya Adithya R Upadhya Aita Bio Inc ZF Group 10 PUBLICATIONS 360 CITATIONS 6 PUBLICATIONS 162 CITATIONS SEE PROFILE SEE PROFILE Navin Karanth P. S. M. Kulkarni National Institute of Technology Karnataka National Institute of Technology Karnataka 19 PUBLICATIONS 426 CITATIONS 143 PUBLICATIONS 2,310 CITATIONS SEE PROFILE All content following this page was uploaded by Mohith Santhya on 20 June 2022. The user has requested enhancement of the downloaded file. SEE PROFILE Smart Materials and Structures TOPICAL REVIEW Recent trends in piezoelectric actuators for precision motion and their applications: a review To cite this article: S Mohith et al 2021 Smart Mater. Struct. 30 013002 View the article online for updates and enhancements. This content was downloaded from IP address 117.202.126.39 on 02/12/2020 at 01:14 Smart Materials and Structures Smart Mater. Struct. 30 (2021) 013002 (36pp) https://doi.org/10.1088/1361-665X/abc6b9 Topical review Recent trends in piezoelectric actuators for precision motion and their applications: a review S Mohith1, Adithya R Upadhya1, Karanth P Navin1, S M Kulkarni1 and Muralidhara Rao2 1 Department of Mechanical Engineering, National Institute of Technology Karnataka, Surathkal, Mangalore 575025, India 2 Department of Mechanical Engineering, NMAMIT, Karkala, Nitte 574110, India E-mail: mohith.sdattanagar@yahoo.com Received 23 June 2020, revised 29 August 2020 Accepted for publication 1 November 2020 Published 1 December 2020 Abstract The need for precision positioning applications has enormously influenced the research and development towards the growth of precision actuators. Over the years, piezoelectric actuators have significantly satisfied the requirement of precision positioning to a greater extent with the capability of broad working stroke, high-accuracy, and resolution (micro/nano range) coupled with the advantage of faster response, higher stiffness, and actuation force. The present review intends to bring out the latest advancement in the field of piezoelectric actuator technology. This review brings out the specifics associated with the development of materials/actuators, the working principles with different actuation modes, and classifications of the piezoelectric actuators and their applications. The present article throws light on the design, geometrical features, and the performance parameters of various piezoelectric actuators right from unimorph, bimorph, and multilayer to the large displacement range actuators such as amplified actuators, stepping actuators with relevant schematic representations and the quantitative data. A comparative study has been presented to evaluate the pros and cons of different piezoelectric actuators along with quantitative graphical comparisons. An attempt is also made to highlight the application domains, commercial and future prospects of technology development towards piezoelectric actuators for precision motion applications. The organization of the paper also assists in understanding the piezoelectric materials applicable to precision actuators. Furthermore, this paper is of great assistance for determining the appropriate design, application domains and future directions of piezoelectric actuator technology. Keywords: piezoelectric actuators, unimorph, bimorph, amplified piezoelectric actuators, inchworm actuator, inertial actuator, ultrasonic actuator (Some figures may appear in colour only in the online journal) 1. Introduction fulfilling the need for miniaturized systems has paved the way for the growth of Micro/Nanotechnology [1–4]. The concept of micro/nano system engineering mainly deals with design, manufacturing, and packaging of micro/nano systems with their applications extending to fields such as biomedical, Automobile, Aerospace, Micro Electronics, Micro-optical The technological advancement in the field of science and engineering has fascinated the researchers towards the development of miniaturized devices and systems with high accuracy and precision. The development of technology for 1361-665X/21/013002+36$33.00 1 © 2020 IOP Publishing Ltd Printed in the UK Smart Mater. Struct. 30 (2021) 013002 Topical Review Systems, microfluidics systems, etc [5–8]. The precision manipulation and positioning have been the primary concern among the research community to fulfil the need for micro/nano system development and manufacturing. The critical functionality of such precision manipulation systems aims at generation of precise, stable motion in the micrometre/nanometre range with the capability of quick response, wide range and speed of motion, sufficient load carrying capacity [9–11]. The actuator serves the purpose of precision manipulation and positioning of miniaturized systems. Conventional actuators such as stepper motors, gear drives, sliders, etc may serve the purpose of micromanipulation and position to some extent with the benefits of higher stiffer stiffness, load carrying capacity and positioning accuracy. However, critical factors such as friction, wear, fatigue, etc limit their application, which severely affects positioning accuracy [11–15]. Over the past few years, the industrial and academic research communities have realized and conceptualized the utilization of smart materials as actuators, which could overcome the drawbacks associated with the conventional actuator to a greater extent. In general smart materials refer to the group of materials which respond to external stimuli to perform a predetermined task. The active materials such as piezoelectric [16], shape memory alloy [17], magnetostrictive [18], electrostrictive [19], electro/magnetorheological fluids (ERF/MRF) [20, 21] exhibit direct coupling which can take either mechanical or non-mechanical field as the input while other as the output [22]. Implementation of smart materials as actuator will have a non-mechanical field (i.e. electrical field) as the input and mechanical deformation as the output. The source of actuation occurs from the deformation produced due to the electrostriction .i.e. application of electric field across the polarized smart materials leading to mechanical deformation, thus the actuation [23, 24]. Among the different class of smart materials available, piezoelectric materials have gained significant consideration as precision actuators due to their ability to produce precision motion coupled with other advantageous features such as quick response, high output force, high stiffness, high accuracy and precision, insensitive to magnetic effect [25, 26]. The additional features such as the compactness, availability of different shapes and sizes, biocompatibility (lead-free piezoelectric materials) make them best suited for many commercial applications. Though the utilization of piezoelectric materials as actuator offers numerous advantages, the small range of motion achieved creates a significant hurdle in many practical applications. The range of motion generated by a single layer of piezoelectric material may not fulfil the commercial need of large stroke applications. Thus the development of piezo actuators with broad working range has been the topic of interest among the researchers for quite an extended period. The development and application of multilayered piezo stack actuators have been the source of achieving large stroke actuation [25, 27]. Also, different amplification mechanisms such as lever [28], bridge [29], stepping [30] mechanisms have been proposed for amplifying the displacement of the piezo actuator from tens to hundreds of micrometre range. Considering the potential of the piezoelectric actuator in precision manipulation and positioning, the present review provides a detailed description of advancements in the field of piezoelectric actuators technology. The organization of the current review is as follows. Section 2 aims at presenting the concept of piezoelectricity, history of the development of piezoelectric effect as a source of precision actuation, advancement in the field of piezoelectric materials, and the different modes of application of piezoelectric materials as precision actuators. Section 3 throws light on the classification of piezoelectric actuators. Sections 4–6 illustrates working principles of different piezoelectric actuators like unimorph actuators, bimorph actuators, stepping actuators and multi-degree actuators with relevant features and specification reported by the various researchers over the past decade. Further, a comparison of the performance of different types of piezoelectric actuators has been presented in section 7. Section 8 presents the various application domains and commercial aspects of the piezoelectric actuators. Section 9 provides the summary and the insight into the future directions towards the research in piezoelectric actuators technology. 2. Piezoelectric effect and piezoelectric materials The growth of the concept of the piezoelectric effect and piezoelectric materials has taken a long way starting from the late 19th century. Since the discovery of the piezoelectric effect in 1880 by Pierre Currie and Paul-Jacques Curie performance piezoelectric materials and application of piezoelectric materials in sensor and actuator applications [31]. Figure 1 represents the different time phases of the development of piezoelectric actuators. The concept of piezoelectricity employs the electromechanical interaction of a specific group of materials between the elastic and electrical behaviour. The polarization of the piezoelectric materials at high-temperature through the application of high electric field in a particular direction results in an ordered arrangement of randomly oriented electric diploes. This, in turn, induces piezoelectric effect (figure 2). The application of external stimuli in the form of mechanical stress or electrical potential across the polarized piezoelectric materials results in the development of electrical charge (direct piezoelectric effect, figure 3(a)) or mechanical strain (inverse piezoelectric effect figure 3(b)) respectively due to the ordered arrangement of electric dipoles along the poling direction [31]. Si = cij σj + dki Ek (1) Dm = dmj σj + εmk Ek (2) Equations (1) and (2) represent the electromechanical coupling of the piezoelectric materials in the form of constitutive expressions [32]. Where D and E represent the electric displacement vector and electric field vector, S and σ represent strain vector and stress vector, c is the compliance matrix, d is the piezoelectric material constant, ε is the dielectric 2 Smart Mater. Struct. 30 (2021) 013002 Topical Review Figure 1. Roadmap of development of piezoelectric technology and its application. Figure 2. Mechanism of Piezoelectric effect (a) Before polarization (b) During polarization (c) After polarization. constant matrix. m, k = 1, 2, 3 and i, j = 1, 2, 3, 4, 5, 6 represents different direction in Cartesian coordinates. Application of piezoelectric materials as precision actuators employs converse piezoelectric effect where the mechanical strain developed due to the application of electric field results deformation of the piezoelectric material leading to precision motion. Early applications with piezoelectric materials employed naturally occurring materials such as quartz and Rochelle salt. The advancement in the field of material technology has led to the development of synthetic, high-performance piezoelectric materials with single crystal or polycrystalline structure having higher electromechanical coupling factor. Some of the synthetic piezoelectric materials are ferroelectric which are subjected to external poling mechanism to have spontaneous electric polarization while non-ferroelectric materials do not require any polling mechanism. Figure 4 represents the classification of piezoelectric materials. The precision actuators with piezoelectric materials extensively employ ceramicbased Lead Zirconium Titanate (PZT) (Pb[Zr(x) Ti(1-x) ]O3 ) as the piezoelectric materials. The complications associated with PZT in the disposal and the environmental hazards due to the presence of lead has led to the adoption of lead-free ceramic materials such as Barium Titanate (BaTiO3 ), Sodium Niobate 3 Smart Mater. Struct. 30 (2021) 013002 Topical Review one end of the piezo actuator is fixed (figure 5(e)). The utilization of different modes of actuation majorly depends on the type of precision motion required in the concerned application where piezoelectric materials are used as the source of actuation. Table 2 represents the expression for displacement in different modes of piezoelectric materials. Figure 3. Schematic of (a) Direct piezoelectric effect (b) Inverse piezoelectric effect. 3. Piezoelectric actuators Over the past few years, piezoelectric actuators turned out to be a significant contributor in the precision applications due to their ability to generate precision motion and flexibility to integrate with the other subsystems. Various types of piezoelectric actuators have been proposed for different kinds of applications which require precision motion. Based on the design and functionality, the piezo actuators are classified as traditional actuators, piezoelectric stepping actuators and multi-degree freedom actuators. Figure 6 represents the classification of the piezo actuators. Traditional actuators typically consist of unimorph actuators, bimorph actuators, tube actuators, multilayer actuators and amplified actuators. The traditional piezoelectric actuators are with simple construction and provide a small range of motion analogous to the applied voltage. The needs for large range precision motion lead to the development of piezoelectric motors which typically consists of traditional actuators as the driving source, which induces a broad range of motion through complex driving mechanisms. Based on the functionality and mode of operation, the piezoelectric motors are classified as clamping and feeding actuators, inertial actuators and resonant ultrasonic actuators [33, 40]. Further, the functionality of piezoelectric actuators can be enhanced by the integration of multiple piezoelectric stages to achieve multiple degrees of freedom motion either through direct actuation from traditional actuators or through stepping piezoelectric actuators. The assessment of traditional piezoelectric actuators performance is usually done in terms of the range of free deflection (∆) and the blocked force (F b ) achieved. The range of deflection produced when the actuator is free to move and excited at maximum actuation voltage refers to the free deflection of the actuator. The blocked force of the actuator corresponds to the maximum force exerted by the actuator when the excited at maximum actuation voltage and the motion is completely blocked. Figure 7 represents the relationship between the free deflections and the blocked forced developed by the piezo actuator. The piezo actuators are intended to generate precision motion together with the consistent force for actuation purpose, which represents the optimal performance of the piezo actuator. The ideal optimal performance of the piezo actuator corresponds to the point where the blocked force is one half of the piezo actuator deflection on force vs. deflection plot. Further, the performances of stepping piezoelectric actuators are assessed in terms of the speed of motion, force/torque developed and the motion resolution. The inherent system nonlinearity occurring during the dynamic operation leads to significant hurdle in the application of the piezoelectric actuators. The inherent hysteresis Figure 4. Classification of piezoelectric materials. (NaNbO3 ), Potassium Niobate (KNbO3 ), Lithium Niobate (LiNbO3 ), Lithium Tantalate (LiTaO3 ), Zinc Oxide (Zno) etc. Also polymer-based materials such as PVDF and copolymers [33], Naffion, Carbon Nanotubes, Cellulose and their derivative and piezo composites such as PZT: PDMS, PZT: Zno, Cellulose: BaTiO3 etc have been effectively employed in piezo actuators [34–39]. Further, the piezoelectric materials can exist as single crystal constituent of polycrystalline constituent [31]. Table 1 highlights the range of piezoelectric properties of some of the commonly used materials in precision actuators. The typical application of piezoelectric materials as a precision actuator depends on the direction of application of the electric field (E) and the direction of polarization (P). Thus the piezoelectric materials can be used as an actuator in four modes, namely longitudinal extension/contraction, transverse extension/contraction, shear mode [39]. Figure 5 represents the schematic of the different modes of actuation in piezoelectric materials. The longitudinal extension/contraction (∆T) and the transverse extension/contraction occur (∆L) when the applied electric field aligns with the polarization direction (figures 5(b) and (c)). Linear actuation through the piezoelectric actuator significantly employs longitudinal mode (∆T) due to the significant deformation along longitudinal compared to the transverse deformation (∆L). When the applied electric field and the polarization are perpendicular to each other, the shear mode of deformation occurs (∆x), as shown in figure 5(d). The bending mode of actuation occurs when the 4 Smart Mater. Struct. 30 (2021) 013002 Topical Review Table 1. Properties of commonly used piezoelectric materials [31, 32, 34–39]. Strain developed/Electric field (10–12 m V−1 ) Electric field per applied stress (10–3 V-m N−1 ) Material d33 d31 d15 g33 g31 g15 PZT PZ BaTiO3 PVDF ≈152–593 ≈46–640 ≈85–191 ≈-33 ≈-37 to −274 ≈-5 to −259 ≈-34 to −79 ≈18–24 ≈330–741 ≈43–724 ≈270–392 — ≈19–39 ≈15–40 ≈11–58 ≈330–340 ≈ −9 to −16 ≈-2 to −16 ≈-4 to −23 ≈216 ≈26–51 ≈26–39 ≈15–19 — Figure 5. (a) Representation of the piezoelectric materials with corresponding coordinate systems, the direction of polarization/electric field (b) Longitudinal expansion/Contraction mode (c) Transverse expansion/Contraction mode (d) Parallel shear mode (e) Bending mode. Table 2. Different actuation modes of piezoelectric materials. Mode Coupling Coefficient Linear Expression Longitudinal expansion/Contraction mode d33 ∆T = E3 d33 Transverse expansion/Contraction mode d31 E3 d31 ∆L ∆W L = W = T Parallel shear mode d15 ∆x = E3 d15 existing in the piezoelectric actuator is one of the major contributors to the occurrence of nonlinearity. Ideally, the precision positioning applications require linear characteristics of the actuator during the increasing and decreasing cycles of the input voltage to achieve higher accuracy. However, the memory-based hysteresis effect between the applied voltage and the output deflection in the piezoelectric actuators leads to deviation in the deflection curve during the increasing and decreasing cycle of the input voltage. The deviation of the output deflection depends on the amplitude and frequency of excitation resulting in positioning errors. Apart from hysteresis, other factors such as the creep and vibration in the piezoelectric actuators also contribute significantly in inducing system nonlinearity. Creep corresponds to drift in the output displacement of the piezoelectric actuator when there is a sudden change in the input voltage. The creep phenomenon 5 Smart Mater. Struct. 30 (2021) 013002 Topical Review Figure 6. Classification of the piezo actuators. occurs due to the interaction between the applied electric field and the residual polarization in the piezoelectric actuator. The vibration in piezoelectric actuator results in non-uniformity in output response leading to system nonlinearity. Thus there is a need for appropriate modelling and control approaches along with the physical implementation in various applications to address the issues of nonlinearity in piezoelectric actuators. Implementation of well-defined modelling and control methods which takes account of nonlinearity due to hysteresis, creep, and vibration can lead to almost a linear response which is a major requirement in precision positioning applications [31, 32]. The scope of the present review is limited to understand the latest advancement, classification, functioning and utilization of piezoelectric actuator technology. 4. Traditional piezoelectric actuators Figure 7. Piezoelectric actuator performance parameters. The following section highlights design/working principle and performance feature of different types of traditional piezoelectric actuators like the unimorph actuator, bimorph actuator, tube actuator, multi-layered actuator and amplified actuator. contraction/expansion (d33 ), transverse contraction/expansion (d31 ) or bending mode as shown in figures 8(b) and (c). Since the length of the piezo layer is considerably large when compared with the thickness, significant deformation occurs along the transverse direction (∆L) when compared with the longitudinal direction (∆T). The cantilever configuration of the unimorph actuator can induce significant bending motion when subjected external electric field [44, 45]. Unimorph piezoelectric materials are most commonly employed as sensor elements in various applications. But the integration of monolayer piezoelectric actuator with the structural members can impart stretching or bending, thus providing precision motion. Table 3 represents the details of unimorph piezoelectric actuators implemented by some of the researchers in recent years for different applications. 4.1. Unimorph piezoelectric actuator Unimorph piezoelectric actuators are characterized by the single layer of piezoelectric materials sandwiched between layers of thin electrically conductive metal electrodes [41–43]. Figure 8(a) represents the different configuration of the monolayer piezo actuator. The unimorph piezoelectric actuators are used as precision actuators in different shapes such as square/rectangular, circular, ring shaped or cantilever type. Based on the direction of electric field and direction of the polarization, the unimorph actuators can undergo longitudinal 6 Smart Mater. Struct. 30 (2021) 013002 Topical Review Table 3. Details of unimorph piezoelectric actuators reported in recent years. Author Year D O Lee 2011 M W Ashraf 2012 J Ma 2012 W Liu 2013 J Choi 2014 C H Cheng 2015 H K Ma 2015 W Parinya 2016 T Ozaki 2018 N Chen A Gunda 2020 2020 Ref. Type of Actuator/ No Mode of Actuation Material Dimension (mm) Actuation Voltage (V) Deflection Range (µm) Blocked Force (N) [46] Rectangular (Bending) [47] Disc type (Bending) [48] Ring Type (Bending) [49] Cantilever Type (Bending) [50] Cantilever Type (Bending) [51] Square Plate (Bending) [52] Disc type (Bending) [53] Cantilever Type (Bending) [54] Cantilever Type (Bending) [55] Rectangular [56] Disc type (Bending) 38.1 × 12.7 × 0.254 ∅ = 3.00 600 700–900 0.2–0.4 160 16–20 — 100 12.9 — PZT ∅ = 3.00, t = 0.04 _ ×_ × 0.28 ±5 V −15.00–18.00 — PZT _ ×_ × 0.10 140 172.2–182 — PZT 5.5 × 5.5 × 0.15 200 2.5–3.5 — PZT t = 0.2 ±70 190 — PMN-PT 4 × 15 × 1 ±30 5.343 — PIN-PMN-PT — 30 120–145 — PZT PZT 11.3 × 2.5 × 0.1 ±100 ∅ = 4, t = 0.127 ±70 +23.1/–26.7 7.00–8.00 — — PZT PZT PZT Figure 8. (a) Different configurations and actuation modes of the unimorph piezoelectric actuator (b) Linear expansion/Contraction mode of the unimorph piezo actuator (c) Bending mode of the unimorph piezo actuator. in precision motion. The application of electric field across bimorph actuator results in contraction of one of the layer and expansion of the other, thus achieving a curvature on the surface. Typically this type of actuator can generate micrometre level (tens to thousands of microns) motion with a small force of actuation (tens to hundreds of grams). The piezoelectric layers are polarized either in the same direction or in the opposite direction. The wiring of piezoelectric layers in the bimorph actuator is of either the antiparallel or the parallel configuration. The anti-parallel configuration (figure 9(c)) of the bilayer piezo actuator attribute to the instantaneous application of the electric field across 4.2. Bimorph piezoelectric actuators A bimorph piezoelectric actuator typically consists of two layers of piezoelectric materials bonded with or without metal shim. Figure 9 represents the schematic of the poling configuration, wiring configuration, actuator configurations, and actuation modes of the bimorph piezo actuator. The bimorph piezoelectric actuators can undergo extension/contraction (figure 9(a)) or bending motion (figure 9(b)) depending on the direction of the polarization and the wiring of piezoelectric layers across which electric field is applied [57]. The bending mode of bimorph finds extensive application 7 Smart Mater. Struct. 30 (2021) 013002 Topical Review Figure 9. Schematic of (a) Linear expansion/Contraction actuation mode of bimorph piezoelectric actuator (b) Bending mode of bimorph piezoelectric actuator (c) Anti-parallel wiring configurations of bimorph piezoelectric actuators (d) Parallel wiring configurations of bimorph piezoelectric actuators (e) Different design configurations of bimorph piezoelectric actuators. the actuator layer. Thus the electrical potential across each layer will be equal to the total applied electric potential divided by the number of piezoelectric layers. Parallel configuration (figure 9(d)) of the bi-layered piezo actuator refers to the case where the electric potential is applied to each layer individually; thus, electrical potential across each layer of piezoelectric material equals the applied electric potential [57–59]. Bimorph piezoelectric actuators are available as extenders or benders in different forms such as rectangular, square, circular, and cantilever configuration implemented in different applications (figure 9(e)). Table 4 represents the details of bi-layered piezoelectric actuators implemented by some of the researchers for various applications in recent years. Figure 10. Schematic of piezoelectric tube type actuator (a) axial Mode and radial mode (b) Lateral (Bending) mode. 4.3. Piezoelectric tube actuators Piezoelectric tube actuators typically consist of piezoelectric materials in the form of thin cylinder polarized along the radial direction along with electrode layers. Figure 10 represents the schematic representation of the piezoelectric tube actuators. Precision actuation through piezoelectric tube actuators could be achieved either in the axial/radial mode (figure 10(a)) or in the lateral mode (figure 10(b)) [70, 71]. The axial/radial mode piezoelectric tube typically consists of continuous layers of piezoelectric material and electrode which elongates or contracts along the length simultaneously generating elongation or contraction along the radius of the tube. The lateral mode of actuation involves bending of the piezoelectric tube with the application of an electric potential of different polarity across segmented layers of the electrode on the tube surface as represented in figure 10(b). The piezoelectric tube under bending is capable of producing multi-axis motion due to the flexibility of bending in different directions. The more segmented arrangement of external electrode layer helps to achieve accurate control of motion without undesirable bending or tilting motion [72]. Table 5 represents the details of the recently reported piezoelectric tube actuators. 8 Smart Mater. Struct. 30 (2021) 013002 Topical Review Table 4. Details of bimorph piezoelectric actuators reported in recent years. Type of ActuatRef. No or/Mode Author Year Asha J 2012 [60] El Sayed 2013 [61] Y Yuan 2013 [62] R K Jain 2015 [63] B Ghosh 2017 [64] Y Z Liu 2019 [65] A Almeida 2019 [66] R M Dasjerdi 2019 P Shahabi 2020 [67] [68] A Ali [69] 2020 Cantilever Type (Bending) Cantilever Type (Bending) Cantilever Type (Bending) Cantilever Type (Bending) Cantilever Type (Bending) Cantilever Type (Bending) Cantilever Type (Bending) Square Plate Cantilever Type (Bending) Cantilever Type (Bending) Dimension (mm) Actuation Voltage (V) Deflection Range (µm) Blocked Force (N) Material PZT 36 × 6.5 × 0.75 ±36 11 000 — PZT 50 1150 0.1–0.15 ZnO 57.2 × 31.8 × 0.38 1 × 0.5 × 0.001 10 0.122 — PZT 40 × 11 × 0.6 ±60 −1500–1500 0.230 PZT 31 × 9 × 0.65 ±30 −500–500 0.104 PVDF 60 × 20 ×– 800 V 10 000 — PZT 40 × 10 × 0.5 ±45 V −1000–1000 — Zn0 PZT 10 × 10 × 0.1 24.53 × 6.4 × 0.63 100 × 30 × 20 200√2 4 −2.00 to + 2.00 — 60–80 — 40 3.5 PZT — Table 5. Details of h piezoelectric tube actuators reported in recent years. Dimension (mm) Actuation Voltage (V) Deflection Range(µm) PZT PZT PZT PZT — — — — 30 60 160 ±200 Lateral Mode PZT ±250 [78] Lateral Mode PZT ±250 ±35.00 [79] [80] Lateral Mode Lateral Mode PZT PZT OD = 3.2, ID = 2.2, L = 30 OD = 3.2, ID = 2.2, L = 30 — OD = 5, ID = 3, L = 27 1.5–2.0 0.8–1.0 10.00 ±20.00 – ± 30.00 ±35.00 — ±250 100 × 100 × 10 ±35.00 Author Year Ref. No Type of Actuator/Mode Material B Bhikkaji M Mohammadzaheri H Lu D Habineza 2007 2012 2014 2015 [73] [74] [75] [76] Lateral Mode Lateral Mode Lateral Mode Lateral Mode D Habineza, 2015 [77] O Aljanaideh 2016 L Li M Al Janaideh 2019 2020 direction of the piezoelectric layer, the piezo stack actuators can execute either longitudinal or shear mode of actuation [46, 85]. Figures 11(a) and (b) represents the schematic of longitudinal and shears piezo stack actuators with the polarization directions. The constructional features longitudinal and shear stacks are similar except for the direction of polarization of each layer as represented in figure 11. The expression for the output displacement corresponding to the longitudinal mode (∆L) and shear mode (∆S) of the piezo stack actuator having n number of layers is represented by ∆L = nE3 d33 , ∆S = nE3 d15 respectively. Depending on the type application, the piezo stack actuators are available in square, circular, and ring configurations [86–88] (figures 11(c)–(e)). In addition, the dynamic performance of longitudinal piezo stack actuators can be enhanced by incorporating a pre-stress 4.4. Multilayer piezoelectric stack actuator The multilayer piezoelectric actuators also termed as piezo stack actuators typically consist of multiple layers of piezoelectric materials stacked one over the other with suitable adhesives. The piezo stack actuators are beneficial in terms of generating a higher range of motion ranging from few microns to tens of microns and the actuation force from few hundreds to thousands of newton [81, 82]. Each layer of the piezo stack actuator consists of piezoelectric materials with electrodes separated by suitable insulation. The electrode layers having the same polarity are connected to an external electrode [83, 84]. The combined effect of displacement achieved through the application of the electric field across the different piezoelectric layers results in a broader range of motion. Depending on the construction and poling 9 Smart Mater. Struct. 30 (2021) 013002 Topical Review Table 6. Details of multi-layer/stacked piezoelectric actuators reported in recent years. Author Year Ref. No. Type of ActuatMaterial or/ Mode Actuation Voltage Deflection Dimension (mm) (V) Range (µm) Blocked Force (N) S H Choy 2010 [93] 10 × 10 ×— 0.06 — D D Jang 2011 [94] — 2011 [95] ∅O = 35, 150 ∅I = 14, L = 71 — 200 50 D H Wang 62.5 — S B Choi 2012 [96] ∅ = 13, L = 36 160 3.4 220 B Sahoo 2012 [97] ∅ = 8.7, L = 36 175 10 1427 M Meftah 2013 [98] 5 × 5 × 10 150 48.5 950 L Wang 2013 [99] 7 × 7 × 32.5 200 45 — J H Park 2013 [100] 2×3×9 150 13 300 J Jeon 2014 [101] ∅ = 25, L = 100 150 100 — Z Xuan 2014 [102] ∅ = 25, L = 100 1000 80 20 000 Y L Yang 2015 [103] 5 × 5 × 20 150 20 — Muralidhara 2015 [104] 10 × 10 × 20 150 11.5 — C Zhou 2016 [105] 7 × 7 × 36 120 38 1850 W Dong 2016 [106] 10 × 10 ×— 100 0.021 Z Bu 2018 [107] 7 × 7 × 32.5 200 45 — X Gao 2018 [108] ∅ = 40, L = 5 400 6.5 18 H S Hwang 2019 [109] ∅ = 25, L = 114 1000 110 — H Huang [110] Parallel PreBNKLBT stressed (Square) Longitudinal PZT Stack (Ring) Parallel PrePZT stressed (Square) Longitudinal PZT Stack (Circular) Longitudinal PZT Stack (Ring) Parallel PrePZT stressed (Square) Longitudinal PZT Stack (Square) Longitudinal PZT Stack (Square) Longitudinal PZT Stack (Circular) Longitudinal PZT Stack (Circular) Longitudinal PZT Stack (Square) Longitudinal PZT Stack (Square) Longitudinal PZT Stack (Square) Shear Stack PZT (Square) Longitudinal PZT Stack (Square) Shear Stack PZT (Circular) Longitudinal PZT Stack (Circular) Shear Stack PZT (Square) 12 × 10 × 8 4.9 — 2019 on to the piezo stack through elastic mechanism. Such prestressed actuators are termed as parallel pre-stressed actuators [89–91]. Typically such actuator consists of elastic springs integrated parallel to piezo longitudinal actuators as shown in figure 11(f ). In general, the piezo stack actuators can sustain compression to some extent but cannot withstand tension. Thus introducing the pre-stress springs ensures the stack actuator bear enough tension, thus improving its life and dynamic characteristics [92]. Table 6 represents the details of multi-layer/stacked piezoelectric actuators reported in recent years. 20 300 (APA) which generates a larger range of motion with moderate force. Typically amplified piezo actuator consists of an external structural amplifier which amplifies the displacement of the multi-layered piezo actuator [85, 111]. The early phase of amplified piezo actuator started with the growth of Moonie actuator type (figure 12(a)), rainbow type actuator (figure 12(b)) and cymbal actuator type (figure 12(c)) which consisting of end caps attached to piezo disks or multilayer piezo actuator [112–115]. The mechanical strain developed due to the piezo actuator deforms the external end caps, thus producing the amplified motion as represented in figure 12. The later development of amplified piezo actuators incorporated flexural hinged and compliant mechanisms made of a single elastic structural member. The elastic deformation of the mechanisms induced due to the force exerted by the multilayer piezo actuator generates the amplified motion 4.5. Amplified piezoelectric actuators The displacement limitation associated with the piezo stack actuator can be overcome with amplified piezo actuators 10 Smart Mater. Struct. 30 (2021) 013002 Topical Review Figure 11. Schematic of (a) Longitudinal Stack (b) Shear Stack (c) Square section piezo stack actuators (d) circular section piezo stack actuators (e) ring type piezo stack actuators (f ) parallel pre-stressed piezo stack actuators actuator (PPA). Figure 12. (a) Moonie type actuator (b) Rainbow type actuator (c) Cymbal type actuator. [116, 117]. Figure 13 represents the commonly adopted flexural based amplified piezo actuators. One of the simplest forms of amplification approach for multi-layered piezo actuators is the use of the lever principle through flexural hinges, as shown in figure 13(a). The lever amplified motion achieved through the lever mechanism is parallel to the direction of motion of the piezo stack actuator [118, 119]. Another amplification strategy is the Scott-Russell (S-R) mechanism (figure 13(b)), which involves a flexural hinged framework that produces amplified straight-line motion in the right angle direction [120, 121]. The tensural displacement type mechanism (figure 13(c)) is also known for generating amplified motion through symmetrical compliant mechanism configuration. The flexural hinges of the tensural amplifier is loaded in tension and bending when the primary multilayered piezo stack actuator deforms due to applied electric potential [122, 123]. In addition, honeycomb type [124] (figure 13(d)), symmetric five bar type [125, 126] (figure 13(e)), bridgetype [127, 128] (figure 13(f )) and rhombus/elliptical type [129, 130] (figures 13(g) and (h)) flexural amplification mechanisms are also incorporated effectively for enhancing the performance of the piezo actuator. All these actuators adopt a similar approach towards the amplification. Among the different amplification configurations mentioned above, the lever type and Tensural type produces amplified motion parallel to the direction of motion of the piezo stack actuator. All other types of actuators have their output perpendicular to the direction of motion of the piezo actuator. The rhombus type and elliptical type amplifiers are found to effective in amplifying the displacement of the piezo multilayer actuator due to the absence of flexural hinges which avoids the risk of fatigue failure and improves the dynamic performance of the actuator as a whole thus enhancing the life of the actuator. Table 7 highlight the 11 Smart Mater. Struct. 30 (2021) 013002 Topical Review Figure 13. (a) Lever type atuator (b) Scott-Russell type atuator (c) Tensural displacement type atuator (d) Honey comb type atuator (e) Symmetric five bar type atuator (f ) Bridge type atuator (g) Rhombus type atuator (h) Elleptical type atuator. performance of the different amplified piezo actuators reported in recent years. The selection of suitable amplification mechanism majorly depends on the range of motion and force required for the particular application. Though amplified piezo actuators can enhance the performer of the piezo stack actuator, the reduction in the effective blocked force and stiffness is inevitable. principles of the different modes of stepping piezoelectric motors. 5.1. Clamping and feeding mode (inchworm type) stepping piezoelectric motor The clamping and feeding mode stepping piezoelectric motor are also known as inchworm motors type piezoelectric motors since the nature of motion execution resembles the motion principle adopted by the inchworm in nature. The piezoelectric actuators either in the form of multi-layered piezo stacks or amplified piezo actuators are used to execute the motion mimicking the inchworm [164]. The inchworm type-piezoelectric motors incorporate the alternative clamping and driving mechanism to achieve the precision stepping motion. Further, the inchworm type piezoelectric motors can be classified as the pusher type with fixed actuators, walker type with the moving actuators [165, 166]. These actuators have a similar working principle except for the mounting of the clamping and driving actuators. Figure 14(a) represents the working principle of the inchworm pusher type actuators. (1) In the initial position, the clamping actuator 1 (right side represented in red), clamping actuator 2 (left side represented in green) and the driving actuator (centre represented in blue) will be un-actuated. (2) During the operation, the clamping actuator 2 gets energized, which hold the slider firmly. (3) Application of the electric potential across the driving actuator pushes the slider towards the right, thus achieving a small range of motion. (4) The clamping actuator 1 holds the slider firmly (5) the clamping actuator 2 de-energizes losing the clamping force. (6) The driving actuator returns to its initial position. Continuous execution of the cycle of operation leads to large range linear motion. The walker type inchworm motor also has the same working principle as the pusher configuration. The fixed position 5. Piezoelectric stepping motors The stepping piezoelectric actuators have been proposed in different forms for satisfying the requirement of a broader range of motion in micromanipulator applications with greater accuracy and precision. Such stepping piezoelectric actuators are also termed as piezo motors because of their ability to generate continuous motion. The stepping piezo motors can generate either linear or rotational motion depending on the design of the actuator configuration [40, 160, 161]. The clamping and feeding mode piezoelectric motors are inchworm type whose working principle resembles the biological motion which integrates simultaneous clamping and feeding mechanism through piezoelectric actuator as the active source. The inchworm type piezo actuators are either walker type or pusher type [162].The frictional type and impactdriven stepping actuators are categorized under inertial mode piezo stepping actuator, which typically involves faster stepping motion through inertial principles [163]. The resonant type stepping piezoelectric motors involve ultrasonic range piezoelectric actuators which induce resonant wave motion on to an elastic substrate. Depending on the type of motioninduced, the ultrasonic piezo stepping actuator can be categorized as standing wave type and travelling type stepping motors [33, 40]. The following section describes the working 12 Year 2006 2008 2009 2010 2011 2011 2012 2013 2013 2014 2014 2015 2015 2016 2016 2016 2017 2017 2017 2017 2018 2018 2018 2018 2018 2019 2019 2019 2019 Author X X Wang P R Ouyang Y B Ham M Muraoka D Haller K W Chae T Yeom X Sun Q Xu Wenji Ai S Lu J Chen Q S Pan Y Liu T W Na R D Dsouza J W Sohn H Wei S Yang L J Lai Y Fujimura R D Dsouza G Deng F Chen W L Zhu J Liang S Mohith M Ling Y Ding [131] [132] [133] [134] [135] [136] [137] [138] [139] [140] [141] [142] [143] [144] [145] [146] [147] [148] [149] [150] [151] [152] [153] [154] [155] [156] [157] [158] [159] Cymbal Five Bar Lever Honey Comb Cymbal S-R Elliptical S-R Bridge S-R Rhombus Rhombus Rhombus S-R Bridge Rhombus Lever Bridge S-R Tensural Moonie Lever Lever Bridge S-R Lever Rhombus Rhombus S-R, Bridge Type of Ref. No. Mechanism PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT PZT — — Steel Aluminium Silicone Polymer Spring Steel Aluminium Aluminium Aluminium Steel — Steel Aluminium Stainless Steel Spring Steel Stainless Steel — — Aluminium Si Aluminium — Aluminium Aluminium Aluminium Spring Steel Aluminium Aluminium Mechanism Piezo Material Material Actuation Voltage (V) — — 6.5 × 6.5 × 20 16 2 × 3 × 40 100 5 × 5 × 40 150 — 150 2×3×9 100 ∅ = 15, L = 46 100 6.5 × 6.5 × 20 100 10 × 10 × 18 10 ∅ = 12, L = 68 100 ∅ = 10, L = 64 150 5 × 5 × 36 120 18 × 18 × 10 1400 L = 68 100 5 × 5 × 18 150 5 × 5 × 10 160 5 × 5 × 40 150 5 × 5 × 20 — 6.5 × 6.5 × 20 150 — 10 3 × 0.4 ×– — 5 × 5 × 20 160 7 × 7 × 36 120 — 150 ∅ = 12, L = 19 10 ∅ = 12, L = 64 100 5 × 5 × 20 150 10 × 10 × 36 120 — 120 Dimension of Stack (mm) — 16 26 41 — 6 9.00 8.62 1.45 45 60 30 34.6 45 20 10 42 13.5 15.25 10.48 — 30 32 122.2 5.83 60 20 38 19.51 Range of Stack (µm) Table 7. Details of amplified piezoelectric actuators reported in recent years. — 16.2 ≈26 ≈10 — ≈2.46 ≈177 ≈15.5 ≈193 ≈22.2 ≈8.33 ≈3.33 ≈4.62 ≈16.13 ≈11 ≈7.8 ≈9.28 ≈12.44 ≈9.81 ≈27.5 — ≈8.00 ≈9.7 ≈38.43 ≈5.4 ≈2.72 ≈6.35 ≈31.84 ≈3.51 Amplification Ratio 0.23 259.2 683 410 65 14.74 1612 134 280 1000 500 100 160 720 220 78.00 390 168 149.73 288.3 239.5 240.53 310 4688 31.4 163 127 1209.92 68.55 Range of APA (µm) — — — 20 — — — — — — — — — — — 16.54 — — — — — 36.8 — — — — — — — Blocked Force of APA (N) Smart Mater. Struct. 30 (2021) 013002 Topical Review 13 Smart Mater. Struct. 30 (2021) 013002 Topical Review Figure 14. Schematic of working principle of the Inchworm type piezoelectric stepping motor (a) Pusher type (fixed actuator) (b) Walker type (Moving Actuator). and continuous motion of the clamping actuator and the driving actuator differentiate the pusher type and the walker type stepping actuator. Figure 14(b) represents the working principle of the walker type actuator. (1) Initial position none of the clamping and driving actuators are not energized. (2) The actuation of clamping actuator 1 holds the base firmly. (3) The driving actuator gets energized and extends linearly. (4) The clamping actuator 2 clamps the actuator assembly along with the clamping actuator 1. (5) The clamping actuator 1 released. (6) The driving actuator comes to its original position, and the process repeats. Thus the entire actuators assembly, i.e. clamping, and driving actuator undergoes stepping motion which interns lead to the movement of the slider connected to it. In general, the walking type stepping motor employs piezoelectric stack or amplified piezoelectric actuators. The concept of walking type piezoelectric motor can also be extended to produce rotary motion by replacing the linear slide module with the rotary module. The clamping system can be either through intermittent clamping mechanisms such as piezoelectric [162], electromagnetic [167], inertial type [168], or wedge type [169]. A continuous clamping mechanism such as spring type [170], permanent magnet type [171], gravity type and contact wheel type [40] has also been proposed. Selection of suitable clamping mechanism depends on the clamping force requirements and the design considerations. Table 8 represents the recently reported walking type (inchworm actuator) in the recent year. 5.2. Inertial mode stepping piezoelectric motors The inertial type of stepping piezoelectric motors works on the principle of the utilization of the inertial force and frictional force developed due to the deformation of the piezo actuators. Conventionally, the inertial type piezoelectric motors are actuated through sawtooth waveform to generate either linear or rotary range with large stroke [186]. The cyclic transition of the frictional force and the inertial force between the driver and the stator delivers the stepping motion with higher resolution through stick-slip principle. Thus inertial piezoelectric motors are also termed as 14 Year 2010 2013 2013 2013 2014 2014 2015 2016 2018 2018 2019 2019 2019 2019 Author C H oh J Li H Zhao L Ma L Ma J Li S Wang X Xue S Song S Wang Y Gao X Tian S Shao Y Wang [172] [173] [174] [175] [176] [177] [178] [179] [180] [181] [182] [183] [184] [185] Ref. No. Pusher Pusher Pusher Pusher Pusher Walker Pusher Pusher Pusher Pusher Pusher Pusher Pusher Pusher Type Linear Rotary Rotary Linear Linear Rotary Linear Linear Rotary Rotary Linear Linear Rotary Linear 10 000 — — 2040 1259 — 248 445 — — 13.5 273.4 — 216.3 Linear Speed Type of Motion (µm s−1 ) — 6508.5 77 488 — — 71 300 — — 26 740 511.7–42 930 — — 43 500 — Rotational Speed (µrad s−1 ) 5000 — 50 000 50 000 25 000 — 4000 —— — — — — — Stroke Length (µm) — — — 21 11 — — 15 — — 8.7 189.7 — — Output Force (N) Table 8. Details of recently reported inchworm stepping piezoelectric motor. — 931 37 — — 19.6 — —245–882 — — — 112 — Output Torque (N-mm) 10 — — 60 0.06 — 0.0315 0.04 — — 0.006–0.225 27.6 — 0.038 Linear Resolution (µm) — 4.95 0.25 — — 25 — — 4.79 0.567 — — 320 — Angular Resolution (µrad) Smart Mater. Struct. 30 (2021) 013002 Topical Review 15 Smart Mater. Struct. 30 (2021) 013002 Topical Review stick-slip actuators [187, 188]. The inertial type stepping motors have two types of configurations, i.e. as impact-driven piezoelectric motors and the friction driven piezoelectric motors. The friction type inertial piezoelectric motors consist of a fixed piezoelectric multi-layered actuator which drives the slider through a friction element [189, 190]. The stepping motion is produced by stick-slip motion between the slider and the friction element of the piezo actuator. The working principle of the friction type piezoelectric motors is represented in figure 15(a). (1) In the initial position, the driving actuator attached with the friction element remains in the unactuated state; thus, no deformation or motion is generated. (2) When the piezo actuator is driven through an external signal, the driving actuator undergoes deformation. Since the friction element remains in contact with the slider, i.e. stick state, deformation of the actuator stimulates the slider to produce the stepping motion. (3) When the applied potential decreases, the driving actuator returns to its initial position rapidly. At this stage, the inertial effect prevents the slider from following the motion of the driving actuator; thus, there exists a slipping motion causing the slider to remain in the extended position. The impact-driven inertial piezoelectric motors typically consist of a driving actuator which drives the inertial block and sliding block through the impact generated through the inertial force [191]. Figure 15(b) represents the working principle of the impact-driven inertial actuator. (1) The initial state of the actuator without any actuation signal retains the slider block and inertial block in the initial position. (2) During the actuation, the excitation voltage across the driving actuator increases gradually leading to the displacement of the inertial block. The static frictional force acting between the slider block and the interface retains or sticks the slider block in the initial position. (3) The rapid drop in the excitation brings the driving actuator to its initial position. The rapid retraction of the driving actuator pulls the inertial block. In addition to this, the driving actuator induces an inertial force which overcomes the static friction force of the slider block, causing it to slip from its initial position. The sudden impact displaces the slider block to undergo stepping motion. The inertial type stepping piezoelectric motors can generate a continuous range of stepping with high-resolution motion by repeating the cycle of operation over a specific time interval. The reversal of the operating cycle of the inertial actuator can also generate backward motion, thus providing the advantage of two-way motion. Also, the replacement of the linear slide mechanism with the rotational can generate rotational stepping motion with adequate precision. Table 9 represents performance features of recently reported inertial type stepping piezo actuators. operate at lower frequency range while ultrasonic actuators use ultrasonic resonant vibration to produce continuous motion [209, 210]. Typically ultrasonic piezoelectric motors are characterized by a piezoelectric actuator operated at resonance which imparts a driving force on to a stator which in turn drives a slider or a rotor. Based on the propagation of ultrasonic wave generated by the piezoelectric material, the ultrasonic piezoelectric motors are classified as standing wave and travelling wave actuator [211]. Figures 16(a) and (b) represents the schematic of the working principle of the travelling wave type and standing wave type ultrasonic piezoelectric motors, respectively. The travelling wave ultrasonic piezoelectric motors work similar to the movement of the surfing board on the sea waves [212, 213]. The high-frequency excitation of the thin piezoelectric layer transfers the ultrasonic wave on to an elastic stator bonded on to its surface. The particles on the stator surface generate an elliptical trajectory due to the travelling ultrasonic waves across its surface. As a result of the elliptical path, the point of contact between the stator and the slider/rotor shift dynamically, leading to the linear/rational motion of the slider/rotor. Unlike the stepping piezo actuator which generates stepping motion, the travelling wave ultrasonic actuators are known to generate continuous movement of the slider/rotor. The standing wave stepping piezo motor typically consists of a piezoelectric stator which induces standing wave with orthogonal vibration on to an elastic substrate when subjected sinusoidal voltage at the resonance frequency [214, 215, 216]. Figure 16(b) represents the schematic of a standing wave type piezo stepping actuator. As observed in figure 16(b), the excitation of the stator causes the generation of an elliptical trajectory which drives the slider/rotor. The driving foot of the standing wave motor is typically oriented between the wave node and the wave loop. The vibration of the stator allows the tip of the driving foot unit to be in contact with the slider/rotor which generates the driving motion through friction. Thus the standing wave type ultrasonic piezo actuator generates stepping motion with the higher speed as compared with the conventional steeping piezo actuators. Table 10 describes the critical performance features of recently reported ultrasonic piezo stepping actuators. The driving source for achieving precision actuation in standing wave ultrasonic motors is typically achieved through the longitudinal-longitudinal [237, 238, 239], bendingbending mode [240, 241] of vibration of the pies-ceramics. In recent years, the composite ultrasonic motors with the hybrid mode of vibration such as longitudinal-bending mode [242, 243], longitudinal-torsional mode [244, 245] ultrasonic motors configurations are reported extensively. Figures 17(a)–(d) represent the schematic, working principle of longitudinal-longitudinal, bending-bending, longitudinalbending mode, and longitudinal-torsional mode, respectively. Table 11 highlights the performance features of the recently reported hybrid mode ultrasonic motors. The piezoelectric actuators in ultrasonic hybrid motors are excited at an appropriate frequency which let them resonate at a suitable mode of vibration to generate elliptical path which in turn generate precision motion by driving the slider or rotor. In the 5.3. Resonant type (ultrasonic) piezoelectric motors The ultrasonic piezoelectric motors are resonant type actuators known for generating higher velocity and the broad range of motion in micromanipulation applications. Multilayered/amplified piezo actuators and stepping actuators often 16 Year 2011 2013 2015 2015 2015 2015 2016 2017 2017 2017 2017 2018 2018 2018 2019 2019 2019 Author Q S Zhang T Morita J Li J Li J Li Y Peng X Chu S Wang T Cheng S Wang H Li Y Zhang X H Nguyen Q Shen F Qin B Zhong Q Gao [192] [193] [194] [195] [196] [197] [198] [199] [200] [201] [202] [203] [204] [205] [206] [207] [208] Ref. No. Friction Friction Friction Friction Friction Impact Friction Friction Impact Friction Impact Friction Friction Friction Friction Impact Friction Type Linear Linear Linear Rotary Linear Linear Linear Rotary Linear Rotary Linear Linear Linear Linear Linear Linear Linear Type of Motion 3–16 40 000 142 500 — 3086 5400 34 000 — 410 — 390–410 46 670 19 000 720.65 2010–2340 18 000–20 000 15 040 Linear Speed (µm s−1 ) 17 — — — — — — 32 000 — — — 7000–8000 — 1029.3–153 650 — — — Rotational Speed (µrad s−1 ) 0.475 0.27 3.43 11.76 0.98 —0.4 — — — 0.882–1.42 40 0.1 15 3.724 0.13 4.312 Output Force (N) Table 9. Details of recently reported inertial stepping piezoelectric motor. — — — — — — — — — — 158 — 70.6–76.4 — Output Torque (N-mm) — — 0.04 — 11.65 — 0.25 — 0.130–1.522 — — 0.04 0.520–0.716 0.05 0.89 2.56–7.73 30.69 Linear Resolution (µm) — — — 1.54 — 0.04 — 0.24 — 1.83–2.31 — — — — Angular Resolution (µrad) Smart Mater. Struct. 30 (2021) 013002 Topical Review 2010 2011 Y Liu S He 2015 2016 2017 2017 2017 2018 2018 2018 2019 Y Liu I Grybas L Wang L Wang X Zhou H Hariri J Liu C M Weng F Qin 2014 X Zhou 2015 2013 S S Jeong S Yuan 2013 X Yang 2014 2013 P Ci Y J Wang 2012 S Park P Smithmaitrie 2012 2010 D Sun [217] Travelling Wave [218] Standing Wave [219] Standing Wave [220] Travelling Wave [221] Standing Wave [222] Standing Wave [223] Travelling Wave [224] Standing Wave [225] Travelling Wave [226] Standing Wave [227] Standing Wave [228] Standing Wave [229] Standing Wave [230] Travelling Wave [231] Travelling Wave [232] Travelling Wave [233] Travelling Wave [234] Resonant Type [235] Travelling Wave [236] Travelling Wave Year Ref. No. Type Author 18 Rotary Linear Linear Linear Linear Linear Linear Rotary Linear Linear Linear Rotary Rotary Linear Linear Rotary Linear — 4500 827 500 133 000 114 600 115 000 72 000 — 891 300 106 000 — — 560 000 165 000 — 175 900 — — Rotary Rotary 40 000 Linear Speed (µm s−1 ) Linear Type of Motion — — 1036.72 × 106 — — — — — — — — 10.10 — — — — — — 6702.6 — — — — — 43.71 × 106 233 525.05 — — — — — 104.71 × 106 — 41.88 × 106 — — 17.28 × 106 — 3.5 — — 1.5 27 — 3.33 0.25 — — 39.2 1.2 0.119 — — 55 3 — 0.29–3.99 — — 0.006 Rotational Speed Stroke Length Output (µrad s−1 ) (mm) Force (N) Table 10. Details of recently reported ultrasonic piezoelectric motors. 0.037 —- — — — — — — — — — 1.47 0.186 — — 0.370 — 0.30 450 — — — 0.21 — — — — — — — — — — — — — — — — — Output Torque Linear Resolution (N-mm) (µm) — — — — — — — 8 — — — — — — — — — — — — Angular Resolution (µrad) Smart Mater. Struct. 30 (2021) 013002 Topical Review Smart Mater. Struct. 30 (2021) 013002 Topical Review Figure 15. Schematic of working principle of the (a) Friction (stick-slip) inertial piezoelectric motors (fixed actuator) (b) Impact driven inertial piezoelectric motors (moving Actuator). Figure 16. Schematic of working principle of the (a) Travelling wave type ultrasonic piezo actuator (b) Standing wave type ultrasonic motors. case of longitudinal-longitudinal mode ultrasonic motor, the horizontal and the vertical piezo transducer are excited at a frequency corresponding to the longitudinal mode of vibration along horizontal and vertical directions. The vertical displacement of the vertical transducers pushes (phase shift of π) the driving feet against the slider/rotor, alternatively. At the same time, the horizontal transducer drives the slider. Thus, the superimposition of the longitudinal mode of vibration of the horizontal and vertical transducer (phase shift of π/2) at right angle generates elliptical motion which delivers precision motion of the slider/rotor [237–239]. The bendingbending mode of the ultrasonic motor (figure 17(b)) operates under the bending resonance condition of the piezo transducer. Application of excitation voltage across the piezo transducers at a frequency corresponding to bending resonance causes the motor driver to achieve bending motion along two orthogonal directions. The superimposition of the orthogonal bending mode of the piezo transducer generates elliptical motion which in turn drives the slider/rotor through the driving feet [240, 241]. In recent years, hybrid ultrasonic motors with the composite mode of vibration are extensively reported. The composite mode of ultrasonic motors combines two different modes of resonant vibration of the piezo transducer to generate the precision motion. The longitudinal-bending mode of the ultrasonic motor (figure 17(c)) integrates the longitudinal and bending vibration modes to generate the elliptical path for generating precision motion. The longitudinal mode of vibration effectively overcomes the preload exerted by the rotor/slider; the bending mode causes the necessary pushing motion for driving the slider/rotor through friction element attached to the driving feet [243–255]. The longitudinal-torsional mode 19 Smart Mater. Struct. 30 (2021) 013002 Topical Review Table 11. Recently reported hybrid mode ultrasonic motors. Author Year Ref. No. Type Type of Motion Linear Speed (µm s−1 ) Rotational Speed (µrad s−1 ) Output Force (N) Output Torque (N-mm) L Yang 2014 [246] Rotary — 2000 × 106 — — X Yang 2015 [247] Linear 487 000 — 2.3 — Z Chen 2015 [248] Linear 310 000 — 2.35 — X Zhou 2016 [249] Linear 63 870 — 3.14 — L Yang 2016 [250] Rotary — 107 861.35 — 48.00 Y Ma 2016 [251] Rotary — 84 823.00 L Yang 2017 [252] Rotary — 146 607.66 — 8.00 V Dabbagh 2017 [253] Rotary — 25 551.62 — 0.32 X Chu 2017 [254] Linear 4900 — 5.0 — Y Liu 2018 [255] Linear 244 000 — 9.8 — H Yu 2018 [256] Linear 416 000 — 21 — L Wang 2018 [257] Linear 127 310 — 2.8 — P Fan 2019 [258] Linear 168 500 — 0.9 — L Wang 2019 [259] Linear 11 730 — 18 — Z Yin 2020 [260] Linear 200 000 — 10 — R Niu 2020 [261] Linear 135 000 — 3.6 — LongitudinalTorsional LongitudinalLongitudinal LongitudinalBending LongitudinalLongitudinal LongitudinalTorsional BendingBending LongitudinalTorsional BendingBending BendingBending LongitudinalBending LongitudinalLongitudinal LongitudinalLongitudinal LongitudinalBending LongitudinalBending LongitudinalBending LongitudinalLongitudinal 0.8 motion with higher resolution and speed could be achieved with the integration of multiple stages of the piezoelectric actuators [262, 263]. The classification of piezoelectric based multi-DOF actuation systems is based on the type and structural arrangement of the piezo driving unit. Based on the type of piezo driving unit, the multi-DOF actuation systems adopt either multiple stages of single piezo actuation stage producing single-DOF motion or a single actuation unit producing multi-DOF motion through a friction element [39]. The most commonly implemented form of multi-DOF actuators adopts single-DOF piezo driving units which are arranged either in series or parallel configuration to achieve multi-DOF motion. The series configuration typically adopts single-DOF piezo actuation unit mounted vertically over the second unit. The vertical mounting of the different piesdriven stages depends on the number of degrees of motion required from multi-DOF actuator as a whole. The parallel configuration of multi-DOF actuators consists of a number of a single-DOF actuator mounted on the same plane, driving a single platform [264, 265]. The characteristics of the motion generated by the multi-DOF stage majorly depend on the type of piezoelectric actuator implemented. Based on of ultrasonic motor consists of linear and torsional piezo transducer for generating the precision motion. The driving source of the slider/rotor originates from the longitudinal and the torsional mode of vibration generated by the respective transducers when externally excited [243–245]. Application of a sinusoidal voltage across the piezo transducer in the stator results in the generation of the longitudinal mode of vibration. Simultaneously torsional mode of vibration is generated from the torsional transducer, which intakes excitation voltage out of phase with that of the longitudinal transducer. Thus an orthogonal propagation of the wave is generated which consist of first longitudinal mode and secondary torsional mode which in turn develops an elliptical motion which drives the slider/rotor [245, 250, 252]. 6. Multi degree freedom piezoelectric actuators The advancement and application of precision motion with multiple degrees of freedom in several commercial applications has led to the development of multi-degree of freedom actuators. The requirement of large stroke multi-degree 20 Smart Mater. Struct. 30 (2021) 013002 Topical Review configuration also adopts a similar approach with the multiple piezo stepping drivers connected in parallel across the driven platform (figure 18(d)) [264, 268]. The series and parallel configurations of the actuator can be assembled together to have higher degrees of freedom of motion as the output [269, 270]. Such multi-DOF actuators are classified under series-parallel type actuators. Figure 19(a) represents the schematic of a series-parallel configuration of the multi-DOF piezoelectric actuators. Typically the series-parallel configuration of the multi-DOF piezo actuators produces linear motion/rotational along three mutually perpendicular directions as represented in figure 19(a). Direct actuation principle or stepping actuation principle can be effectively adopted to produce precision motion with series-parallel configuration. Apart from multiple actuators, the multi-DOF motion can be also achieved through single actuator arrangements which are operated either under quasistatic or under resonance actuation mode. Figure 19(b) represents the schematic of the single actuator type Rotary-Linear (X-θ) multi DOF actuator. The linear-rotary multi-DOF actuator consists of a stator integrated with piezo actuator excited at distinct vibration modes corresponding to the natural frequency. The vibration generated by the start is in turn transferred to a moving output shaft which undergoes linear/rotational motion. The driving platform follows the motion of the moving shaft, thus delivering required motion for precision applications. Typically linear-rotary multi-DOF actuator configuration of the multi-DOF actuator employs either piezoelectric tube, piezoring stack actuator as the primary source of motion. The single bending actuator configuration for multi-DOF adopts a bending actuator configuration which drives a positioning platform as represented in figure 19(c). The bending motion generated by the piezoelectric actuator drives the positioning platform through a friction element similar to that of an inertial actuator. The single bending actuator configuration is able to generate linear or rotary motion along two mutually perpendicular directions [271, 272]. Table 12 highlights the performance parameters of the multi-DOF piezoelectric actuator with different actuation principles. The single actuator configurations have the advantage of less number of actuators when compared with other configuration to achieve multi-degree motion. However, accurate control of motion along different coordinates is relatively complex when compared with multi actuator configuration. Figure 17. Schematic of principle of actutaion in (a) Londitudenal mode (b) Bending mode (c) Longitudenal-Bending mode (d) Longitudenal-Torsional model. the type of piezoelectric actuator adopted, the multi-DOF piezo actuation stage can be classified as direct actuated type or stepping type multi-DOF actuator. The direct actuation method includes conventional piezoelectric actuators in the form of multi-layered piezo stack actuators or amplified piezo actuators together with flexural mechanisms to achieve high precision linear or rotational motion of multiple degrees [264, 266]. The direct-acting actuators are either arranged in series or parallel configuration. Figures 18(a) and (b) represents the schematic of series and parallel configuration of the direct-acting multi-DOF stage. The direct actuation mode employs a simple operating principle which involves the application of an electric potential across the piezo actuator, thus developing mechanical strain which in turn drives the movable platform. Implementation of a flexural amplification mechanism, along with the piezo actuator, can enhance the range of motion associated with direct driven multi-DOF actuator. The direct driven multi-DOF actuator stage can deliver higher resolution motion; however, the range of motion is limited due to the limited range of motion developed by the multilayer piezo actuator. The second class of multi-DOF piezoelectric actuators involve stepping motion through multiple stages of piezo stepping actuators which can effectively overcome the short range of motion associated with direct actuation mode [265, 267]. The conventional stepping actuators such as the inchworm, inertial and ultrasonic actuators are effectively utilized to generate multi-DOF linear or rotational motion. Similar to direct actuated multi-DOF actuators, the driving and structural arrangement of multi-degree stepping piezo actuators are either arranged in series or parallel configuration [46]. Figures 18(c) and (d) represents the schematic of multi-DOF stepping piezo actuators. The series configuration typically consists of a stepping stage with its output coupled with to the second stage connected in series. The number of degrees of freedom achieved with the actuator configuration depends on the number of stages interconnected. The parallel 7. Discussion and comparison on different types of piezoelectric actuators Over the past few years, the piezoelectric actuators technology has seen tremendous growth in terms of design and performance. The year-long research and development towards the development of piezoelectric actuator technology have made them critical players in precision applications due to the ability to offer high precision motion with resolution micrometre to nanometre range. Also, the piezoelectric actuators provide the 21 2014 [276] 2015 [270] Z Chen J Li 22 2018 [280] 2018 [281] 2019 [282] 2019 [283] 2019 [272] 2019 2019 2019 2019 2019 2020 2020 J Deng C Lin Y Tian Y Liu S Zhang Y Liu J Deng C Liang M Ling Q Zhang C Liao Y J Wang [284] [285] [286] [287] [288] [289] [290] 2017 [278] 2017 [266] 2017 [279] J Li X Zhang C Tang [267] [265] [268] [277] 2014 [269] S Hua X Sun 2015 C H Cheng 2015 K Cai 2016 Y T Liu 2016 2013 [275] M Guo L J Lai 2012 [264] W M Chen 2013 [274] 2012 [273] C H Yun Driver Single Piezo actuation Tube Parallel Direct Single Inertial Actuation Single Piezo Tube Actuation SeriesInchworm Parallel Single Ultrasonic Actuation SeriesInchworm Parallel Series Inchworm Parallel Inertial Parallel Ultrasonic SeriesDirect Parallel Series Direct Parallel Direct SeriesDirect Parallel Parallel Direct SeriesDirect Parallel SeriesDirect Parallel Parallel Inertial Single Inertial Actuation Parallel Ultrasonic Parallel Direct Parallel Direct Parallel Direct Parallel Direct Series Direct Parallel Inertial Year Ref. No. Type Author X,Y X,Y θX θy X,Y X,Y X,Y X,Y X,Y θX θy X, θX X,Y,Z,θX , θy ,θz X,Y,Z X,Y X,Y X,Y,Z — — — 138/138 346.1/357.2 128.775 6000 — — 128.1/131.3/17.9 15.45/17.65 127 10.39/15.43/ 15.55 — 111.38/260.06 2040/2012 — — — — — 4.58 × 103 / 2.71 × 103 — — — —– 154 000 — 266 000 — — — — 34 270 — — 3521.7 — 92.36/ 136.97 10 000 — 3.72 × 106 2 0.016 —– — — 0.010 0.1 0.1–0.2 — 10 0.016 — — 0.02 — — 0.1 0.005 0.01 — — 0.2 — 0.003 — — 600 × 106 — — 5 — — —— — 2.49/2.52 — 0.198 — — — — — 698.1317 1.25 — — 0.3 — — — — Linear Angular Resolution Resolution (µm) (µrad) Rotational Speed (µrad s−1 ) 543 000/572 000— 300 — — — — — — — — —18 000/16 000 — 101.7/124.2 — — 19 800 — 6250–7450 — — 1450 — — — — 8.5/6.5 6.35/6.61/10.12 X, θX X, θX X, Y, θz X,Y,Z — — 289 105.31 — — 482 X, θX — — — 21 000 — Linear Speed (µm s−1 ) 35 000 20 000 X, θX — — — — Angular Deflection (µrad) X,Y — θX θy θz θX θy θz 40/40 22.2 × 103 — DOF X,Y X, θX Stroke Length (µm) Table 12. Details of recently reported multi-DOF piezoelectric actuators. Torque (N-mm) 22/24 350 — — — —— — — — — — — — — — — —— — — — — — — — — — — 9.80 — — 73.5 294 — 1.8 × 10−3 / 3.6 × 10−3 380 11.8 4.9 0.25 39.22 — 70 — 2.3 × 10−3 — 0.76 × 10−3 1.6 × 10−6 Force (N) Smart Mater. Struct. 30 (2021) 013002 Topical Review Smart Mater. Struct. 30 (2021) 013002 Topical Review Figure 18. Schematic of (a) Direct actuation mode series multi-DOF piezo actuator (b) Direct actuation mode parallel multi-DOF piezo actuator (c) Series type multi-DOF stepping piezo actuator stage (d) Parallel type multi-DOF stepping piezo actuator stage. the dynamic operation of the piezoelectric actuators over a long period leads to internal heat generation, which affects the electromechanical coupling which in turn affects the actuator performance. Also, the performances of piezoelectric actuators are affected due to the environmental humidity and rise in temperature [291–293]. The different designs of the piezoelectric actuators provide a broad range of performance feature, and the selection of a particular actuator is application-specific. The free deflection and the blocked force developed by the piezo actuator can be considered as one of the critical features for a selection of the piezo actuator for a specific application. Other factors include stiffness, actuation voltage, resonant frequency, and capacitance. Figure 20 represents the comparison of different types of the piezoelectric actuator based on the free deflection and the blocked force developed. The following comparison plot includes data from the different actuators reported in the literature by various researchers and commercially available actuators whose details are provided in the appendix. As observed in figure 20, the unimorph/bimorph cantilever types actuators and plate benders typically offer a higher range of motion but develop a lower range of blocked force. Also, these actuators are less stiffer, which makes it flexible enough to be easily bonded on to the structural members. The stacked piezo actuators offer higher blocked for, but lack in terms of free deflection. The range of motion can be enhanced by stacking multiple stack actuators on over the other, but this creates hurdle in the application, which involves miniaturization and Figure 19. (a) Series-parallel configuration of the multi-DOF actuator (b) Single actuator type Rotary-Linear (X-θ) multi DOF actuator (C) Single Bending actuator type multi-DOF actuator. advantage of compact device development, low voltage actuation, quick response time, vacuum compatibility, and nonmagnetic actuation, less wear, and high life cycle. However, 23 Smart Mater. Struct. 30 (2021) 013002 Topical Review Figure 20. Comparison of the performance of monolayer piezoelectric actuator, bilayer piezoelectric actuator, multilayer piezoelectric actuator and amplified piezoelectric actuator. space constraints. The integration of flexural amplifier with the piezo stack actuator can enhance the performance in terms of free deflection but reduces the blocked force, stiffness, and response time of the actuator as a whole. Besides, the flexural amplifier and the interfacing structural members can add to the cost of the actuator in terms of manufacturing and materials involved. Table 13 highlights the comparison of key features of the different piezo actuators. The need for a broad range of motion coupled with better resolution and speed led to the development of stepping piezo actuators. Typically stepping piezoelectric motors use either bimorph/multilayer or amplified piezo actuators as the source to drive either the slider or the rotor with higher resolution. The inchworm motors, inertial motors, and ultrasonic motors extended the application of piezo generated motion to large range precision motion. The major advantage of such stepping motors involves broad range bidirectional motion with better travel speed and output force. The parameter such as the linear/rotary speed and output force/torque are critical in performance evaluation of the stepping actuators. Figures 20(a) and (b) compares the performance of both linear and rotary type inchworm, inertial and ultrasonic actuators in terms of the linear/rotary speed and the force/torque developed. The inchworm and inertial type stepping actuators are typically quasi-static which operate at a lower range of frequency. The loading capacity of inchworm motors majorly depends on the static friction between the slider/rotor and the clamping mechanism. Thus inchworm motors are capable of generating higher force/torque as observed from figures 21(a) and (b). Also, these motors offer higher resolution motion with a compact design. The complex motion configuration of the clamping and driving actuator leads to the lower speed of motion. The slider/rotor is prone to vibration if there exists an unsynchronized operation of clamping and driving actuator. The constant motion of the moving actuator configuration of the inchworm actuator may create an inconvenient situation in handling the power cables of the moving actuator. The inertial type stepping motors relatively have less structural complexity when compared with the inchworm actuators due to the absence of clamping systems. The inertial motors can develop moderate force/torque and reasonably better driving velocity than the inchworm actuator as evident from figures 21(a) and (b). During the operation of the inertial motors, a certain amount of rollback motion of the slider/rotor is inevitable which majorly depends on the preload between the slider/rotor and friction element. This rollback can cause some degree of loss of motion, which intern affect the performance as a whole. Further, the constant movement of the actuator in impact-driven inertial actuator can lead to uneasiness in handling power cables which move along with the actuator. The ultrasonic piezoelectric motors belongs to a non-quasistatic group of actuators which generate precision motion at very high frequency. The ultrasonic motors offer the advantage of high-speed linear/rotary motion relatively a lower force/torque. Also, ultrasonic actuators have the benefit of lightweight, simple construction, noiseless operation, and self-braking. The ultrasonic motors operate at a specific frequency, phase, and amplitude of the actuation signal and the complexity involved in controlling these signals adds to the demerits of such actuators. Table 14 summarizes the performance of the different motors based on the accumulated data from tables 8–11. The multi-degree of actuators can operate in a different mode with different types of actuation principles to generate either linear or rotational precision motion in different directions. The performance of the multi-DOF actuators in terms of degrees of motion, range of motion and the resolution of motion majorly depend on the type of actuator configuration, the arrangement of actuators in different directions and the structural configurations. Implementation of direct actuation mode in multi-DOF actuators leads to a limited range of motion. The traditional actuators such as the multi-layered piezo stack actuators, amplified piezo actuators, tube actuators can generate a limited range of motion which limits 24 Smart Mater. Struct. 30 (2021) 013002 Topical Review Table 13. Comparison of unimorph/bimorph, multilayer and amplified piezo actuator. Parameter Unimorph/Bimorph Actuator Piezo Tube Actuator Piezo Multilayer Actuator Amplified Piezo Actuator Deflection (µm) Large (≤11 000) Blocked Force (N) Low (≤0.4) Small (≤35) N/A Small (≤100) High (≤20 000) Moderate (≤4688) Moderate (≤36.5) Table 14. Comparison of stepping piezoelectric actuators. Parameter Inchworm Motor Inertial Motor Ultrasonic Motor Stroke (µm) Linear Speed (µm s−1 ) Linear Resolution (µm) Rotational Speed (µrad s−1 ) Rotational Resolution (µrad) Force (N) Torque (N-mm) Control System Large Low (≤10 000) Good (≥0.038) Low (≤77 488) Good (≥0.25) High (≤189.7) High (≤882) Complex Large Moderate (≤40 000) Good (≥0.04) Moderate (≤153 650) Moderate (≥0.04) Moderate (≤40) Moderate (≤158) Simple Large High (≤827 500) Moderate (≥0.21) High (≤1036.72 × 106 ) Moderate (≥8) Moderate (≤39.2) Moderate (≤450) Complex the actuation range achieved with direct actuation mode of multi-DOF actuators. However, the improved resolution of motion can be ensured with the direct actuation mode of multiDOF actuators. The limitations of a short range of motion associated with the direct actuation principle can be overcome with the stepping mode of actuation. The stepping mode of actuation such as the clamping and feeding mode, inertial mode or resonant mode of actuation can effectively enhance the range of multiDOF actuator stage. The selection of appropriate stepping mode of actuation depends on different factors such as the resolution of motion, speed of actuation, force/torque. Among the different stepping mode, the ultrasonic mode of actuation develops a higher speed of motion with lower resolution and moderate force/torque. The inertial mode of actuation for multi-DOF actuator stage imparts precision motion with higher force/torque with inferior resolution and speed. The direct mode of actuation has a simple structural arrangement with easily integrated and controllable piezoelectric actuation stage, which adds to the advantage of the direct mode of actuation. Unlike the stepping mode of actuation which involves complicated structural arrangements in addition to the limitation in terms of wear and tear, nonlinearity and complex control strategies. The parallel configuration of the piezoelectric multi-DOF stage incorporates a compact design which occupies less space. The different axes motions possess the same dynamic characteristics since the piezoelectric actuators for achieving motion along different direction are directly acting on a single platform. This, in turn, benefits in the reduction of overall moving mass, considering the entire piezoelectric multi-DOF system as a whole, thus reducing the mass inertia effect. Since the parallel configuration significantly employs direct actuation principle, the direct parallel metrology can be conveniently adopted for the measurement of degrees of freedom of a moving platform in different directions with respect to a fixed reference point. With the implementation of close loop sensor-based position control, a highly reliable accurate precision motion is achievable with the parallel configuration in real-time, thus enhancing the dynamic characteristics. Also, the parallel configuration has the advantage of higher stiffness and higher load-carrying capability. The series configuration of the piezoelectric multi-DOF actuation does not possess dynamic characteristics as good as that of the parallel configuration of the piezoelectric multi-DOF stage. The series configuration of the piezoelectric multi-DOF actuator stage finds commercial application in low cost, highly reliable, easy control systems with small coupling errors where the superior dynamic characteristics are not the major concerns. The series configuration occupies larger space since multiple stages of single-DOF systems are stacked one over the other results in increased bulkiness. The cumulative effect of errors of different stages in series can affect the accuracy of the system. In addition, the series configuration possesses other shortcomings such as parasitic movements of different stacked stages, reduction in natural frequencies due to increased mass, different dynamic characteristics in different DOF motion directions and large cross-couplings. 8. Applications and commercial aspects of piezoelectric actuators Over the past few years, the piezoelectric actuator technology has gained significant consideration as a source of the precision actuation system. The need of maximum position accuracy with improved resolution and repeatability in the micro/nanometre range has grabbed the attention of many researchers in the development of different varieties of piezoelectric actuators and the implementation of the same for various commercial applications. The advantage of high-speed motion coupled with high resolution/precision motion, simple design, less moving parts with minimum wear and tear, silent drive and less power consumption makes them suitable for various commercial applications even in extreme cryogenic or vacuum environment. The piezoelectric actuators proved to have widespread applications in precision manufacturing, 25 Smart Mater. Struct. 30 (2021) 013002 Topical Review [100, 129, 157]. The multilayer piezoelectric stack actuators coupled with amplification mechanisms find an application which requires a broader range of motion with higher force. Some of the fluidic devices such as spool valves [101], jet dispensers [105, 107, 147, 153], micro dispensers [141] employ piezoelectric stack actuators for precision motion. The cantilever type monolayer/bilayer piezoelectric actuators find application in micro-gripper [61, 63], micro-tweezers [66] which are intended to grip and hold micro-sized objects. Such micro grippers are effectively used in applications such as fibre optics, end effector in minimal invasive surgery, micro devices and chip fabrication, etc. The micro grippers and micro tweezers can also be realized through compliant flexural mechanisms with multilayer piezo stack actuators as a source of actuation which can generate higher force [103]. Advancement in the medical diagnosis and pharmaceutical therapy requires precision motion systems with compact design, minimum energy consumption, high speed and reliability. Piezoelectric actuators are self-capable of fulfilling precision motion requirement of medical technology. Piezoelectric tube actuators are applicable in endoscopic applications due to their flexibility of multi-degree of motion, particularly for delivery image information, minimally invasive surgical procedures and treatments. The high precision positioning systems for laser beam control and focussing in ophthalmology adopts piezoelectric actuators to a greater extent. Other than these, the fluid delivery system for drug delivery, sample handling, drug discovery and similar other field employs piezo actuators as an active source in the form of micropumps, micro-dosing systems and pipetting systems. Other medical-related applications of piezoelectric actuators involve image stabilization, precision motion in magnetic resonance imaging, 3D bio cellular assembly systems, artificial fertilization systems, implants and prosthetics, etc [176, 183, 275, 278]. Image processing applications are very much evident in applications such as medical and pharmaceutical research, manufacturing and material research for a verity of visualization tasks. Such image processing technology requires fast and accurate drive mechanisms with the compact structure capable of operating under a magnetic field, radiation environment and vacuum conditions. The precision motion coupled with good repeatability and better resolution motion increased the scope of piezoelectric actuators in micro optic applications. Micro scanning mirrors, precision positing and focussing of lens and mirrors are some of the functionalities associated with scanning electron microscope, atomic force microscope, while field interferometry, etc [73, 268, 289]. Piezoelectric tube actuators, multi-DOF piezoelectric stages are commendably employed in such microoptic applications. The precision positioning stages with multiple degrees of freedom find extensive applications in manufacturing and assembly of precision devices. Manufacturing technology and automation sector require miniaturized, energy-saving precision drive systems capable of fulfilling the need of micro/nano device fabrication with dimensional accuracy and precision. Such an advanced manufacturing system also calls for linear/rational multi-axis Figure 21. Comparison of the performance of (a) Linear Inertial, Inchworm and ultrasonic Piezoelectric Motors (b) Rotary Inertial, Inchworm and Ultrasonic piezoelectric motors. fluidic applications, medical technology, microelectronics/semiconductor device, aviation and defence sector, automation, micro-optics, robotics and consumer electronics. Figure 22 highlights some of the application domains of piezoelectric actuation technology. Microfluidic devices such as micropumps [47], micromixers, micro-reactors, micro-separators, microvalves make extensive use of unimorph/bimorph piezoelectric actuators as an active source for actuation [2]. The precision bending motion generated by the flexible piezoelectric actuators controls the flow of the fluid through micro-devices [35, 41–44]. Such microfluidic devices find extensive application in drug delivery, electronic cooling, fuel cells, lab on a chip, micro jet dispensers etc [2]. These microfluidic devices also adopt multilayer piezo stack actuators/amplified piezo actuators as an active source for precision delivery of fluids 26 Smart Mater. Struct. 30 (2021) 013002 Topical Review Figure 22. Application domains of piezoelectric actuation technology. motion drives. The stepping actuators/motors such as the inertial motors, inchworm motors and ultrasonic motor incorporate bilayer or multilayer piezoelectric actuator to deliver significant range stepping motion with better resolution and accuracy. The multi-axis precision motion through stepping position stages are best suitable for precision tool and workpiece feeding [175, 183], microchip fabrication and packaging, semiconductor device fabrication, positioning stages for micro-welding, milling, turning, laser, electric discharge machining [272, 277], 3D additive manufacturing [203]. Piezoelectric actuators are also employed as an active source in the vibration isolation system, which considerably reduces undesirable vibration nonlinearities, reduces the settling, and enhances the measurement/machining accuracy. Besides, the defence, aviation and aerospace sector also employs piezoelectric actuators in different applications. Some of the applications include precision actuation of flaps, winglets in helicopters, trajectory control of missiles/unmanned aerial vehicles, active control of flow on air-foils, active vibration damping, precision motion control of defence cameras, landing gears, optic equipment micro-thrusters for satellites, solar image diameter and surface mappers, precision actuation mechanisms for micro/nano satellites, space interferometers, shape and position control of antennas and mirrors. The increasing demand for compact, high-performance and long cycle precision devices and consumer electronic products has led to the high growth rate of the piezoelectric actuator, and the motor industry. The market for piezoelectric actuators majorly depends on the application and the geographical region. According to technavio market research, the piezoelectric market is estimated to be about from 11.78 Billion in 2016 to USD 25 Billion by 2021 with the compound annual growth rate of 16% with a significant contribution from American countries, European and Asian Pacific countries [294]. Such growth rate and demand call for continuous research and development towards high-performance piezoelectric actuators. Some of the key market participants in the manufacturing and technology development of piezoelectric actuator include Noliac, CTS Corporation (Kvistgard, Denmark), Mide Technology (Massachusetts, USA), APC international Ltd (Pennsylvania, USA), Cedrat Technologies (Meylan Cedex, France), Thorlabs (Newjercy, USA), Physique Instrumente (Karlsruhe, Germany), Piezodrive (New South Wales, Australia), Smart Act (Oldenburg, Germany), Attocube (Haar, Germany), Shinsei Corporation (Tokyo, Japan). 9. Concluding remarks and future prospective The present review aims at presenting a comprehensive survey of technological advancement in piezoelectric actuators, particularly for precision manipulation and positioning applications. An attempt is made to bring out the detailed overview of the development of piezoelectric actuator technology, the concept of piezoelectricity as a source of precision actuation, different piezoelectric materials and modes of actuation. The paper highlights the brief classification of the piezoelectric actuators based on the design, construction and functionality together with the technical specification and the performance features. Among different categories of piezoelectric actuators, the unimorph/bimorph, piezoelectric actuators exhibited a higher range of motion, but lack in terms of the blocked force developed. The multi-layered stacked configuration of the piezoelectric actuator executed 27 Smart Mater. Struct. 30 (2021) 013002 Topical Review higher stiffness and blocked force coupled with a reasonable range of motion. Integration of flexural based amplifier with piezoelectric stack actuators enhanced the displacement range with moderate blocked force. The stepping piezoelectric actuators/motors can further improve the displacement range by executing bidirectional continuous stepping motion (linear/rotary). The ultrasonic piezoelectric motor outperformed inertial piezoelectric motor and inchworm piezoelectric motor in terms speed of motion but delivered lower force/torque. The inchworm motors delivered high force/torque but are inferior in terms of speed of motion. The performance of inertial piezoelectric motors falls in between that of ultrasonic motor and inchworm motors. The traditional and stepping piezoelectric actuators are effectively implemented in multi-DOF actuation stages to achieve multiple degrees of freedom linear/rotational motion along different axes. The direct actuation mode of the multi-DOF piezoelectric stage executed superior resolution with the limited stroke. Implementation of stepping piezoelectric actuators enhanced the range of motion along the different direction in multi-DOF actuation stages with inferior resolution when compared with direct actuation mode. The series configuration of multi-DOF actuation stage adopts simple and flexible construction feature which can execute a large range of motion. The application of series configuration is limited due to the bulkiness, increased inertia effect, cumulative nonlinearity and the crosscoupling errors. The parallel configuration instead employs a compact structural arrangement with reduced inertial effect and enhanced dynamic characteristics along different axes of motion. Based on the detailed survey of the piezoelectric actuators, the authors observed the following research suggestions. to achieve better resolution and precision, speed of actuation, force/torque with the emphasis on miniaturization and elimination of system nonlinearity due to structural assembly. • Integration of piezoelectric actuator technology with state of the art modelling and control approaches to eliminate system nonlinearity and achieve higher accuracy and precision motion. Appendix The following companies currently fabricate and commercially market different varieties of piezoelectric actuator. Figures 19 and 20 considered some of the data from following websites. (Accessed between 12 January 2020 and 14 January 2020) Noliac, Kvistgård, Denmark, https://www.noliac.com Piezo, Woburn, https://www.piezo.com Micromechatronics, Inc. (MMech), Pennsylvania, United States, https://www.mmech.com Mide Engineering Solutions, Woburn, Massachusetts, United States, https://www.mide.com Thorlabs, Newton, New Jersey, United States, https://www.thorlabs.com Physik Instrumente, Karlsruhe, Germany, https://www. physikinstrumente.com Cedrat Technologies, Meylan, Cedex, France, https://www.cedrat-technologies.com PiezoDrive, Shortland, Newcastle, Australia, https://www.piezodrive.com Smart Act, Oldenburg, Germany, https://www.smaract.com Attocube, Haar, Germany, https://www.attocube.com Shinsei Corporation, Georgia, United States, https://www.shinsei-motor.com • Development and application of pre-stressed multilayer piezo stack actuator for high force applications • Development and optimization of novel flexural based amplification mechanisms for multilayer piezoelectric stack actuators with a higher range of amplification and delivery of higher blocked force. In addition, miniaturization of such amplified piezoelectric actuators for MEMS and NEMS applications. • Miniaturization of existing concepts of stepping piezoelectric motors with superior structural design to have better performance in terms of speed, force/torque, enhancement of reliability and repeatability and overall life of the actuator. • Optimization of the frictional behaviour occurring due to the relative motion between the slider and the driving unit in stepping piezoelectric actuator to minimize wear and tear to enhance the life span of the actuator. Development and application of friction-resistant materials can be the scope of future implementation. • Development of advanced locking/clamping mechanisms which ensures accurate/precision motion by developing appropriate clamping force and instantaneous release to achieve the next step of motion without delay or lag. • Exploration of advanced and novel driving mechanisms through a hybrid approach with the piezoelectric actuator ORCID iD S Mohith https://orcid.org/0000-0001-5232-235X References [1] Cecil J, Kumar M R, Lu Y and Basallali V 2016 A review of micro-devices assembly techniques and technology Int. J. Adv. Manuf. Technol. 83 1569–81 [2] Mohith S, Karanth P N and Kulkarni S M 2019 Recent trends in mechanical micropumps and their applications: A review Mechatronics 60 34–55 [3] Roy J, Chandra S and Maitra S 2019 Nanotechnology in castable refractory Ceram. Int. 45 19–29 [4] Vaezi M, Seitz H and Yang S 2013 A review on 3D micro-additive manufacturing technologies Int. J. Adv. Manuf. Technol. 67 1721–54 [5] Hsu T-R 2004 MEMS and Microsystems: Design and Manufacture (USA: McGraw-Hill) [6] Maluf N and Williams K 2002 An Introduction to Microelectromechanical Systems Engineering (Boston, London: Artech House, Inc) [7] Lin X, Chen H, Ma Y, Fisher J G, Huang S, Zhang D and Cheng X 2017 Investigation of temperature sensitivity of 28 Smart Mater. Struct. 30 (2021) 013002 Topical Review actuation performance for piezoelectric fiber composites Ceram. Int. 43 10590–4 [8] Gardner J W, Varadan V K and Awadelkarim O O 2001 Microsensors MEMS and Smart Devices (West Sussex, England: Wiley) [9] Tzou H S, Lee H J and Arnold S M 2004 Smart materials, precision sensors/actuators, smart structures, and structronic systems Mech. Adv. Mater. Struct. 11 367–93 [10] Liang C, Wang F, Shi B, Huo Z, Zhou K, Tian Y and Zhang D 2018 Design and control of a novel asymmetrical piezoelectric actuated microgripper for micromanipulation Sensors Actuators A 269 227–37 [11] Xiao X, Li Y and Xiao S 2017 Development of a novel large stroke 2-DOF micromanipulator for micro/nano manipulation Microsyst. Technol. 23 2993–3003 [12] Le K M, Van Hoang H and Jeon J W 2017 An advanced closed-loop control to improve the performance of hybrid stepper motors IEEE Trans. Power Electron. 32 7244–55 [13] Henke B, Sawodny O and Neumann R 2015 Distributed parameter modeling of flexible ball screw drives using ritz series discretization IEEE/ASME Trans. Mechatron. 20 1226–35 [14] Altintas Y, Verl A, Brecher C, Uriarte L and Pritschow G 2011 Machine tool feed drives CIRP Ann. Manuf. Technol. 60 779–96 [15] Ouyang P R, Tjiptoprodjo R C, Zhang W J and Yang G S 2008 Micro-motion devices technology: the state of arts review Int. J. Adv. Manuf. Technol. 38 463–78 [16] Wang R, Tang E, Yang G and Han Y 2020 Experimental research on dynamic response of PZT-5H under impact load Ceram. Int. 46 2868–76 [17] Dudek K, Dulski M, Goryczka T and Gerle A 2018 Structural changes of hydroxyapatite coating electrophoretically deposited on NiTi shape memory alloy Ceram. Int. 44 11292–300 [18] Tsay C Y, Lin Y H and Jen S U 2015 Magnetic, magnetostrictive, and AC impedance properties of manganese substituted cobalt ferrites Ceram. Int. 41 5531–6 [19] Feng F and Yan Y 2019 Large electrostrictive effect in Mn-doped BCZT ferroelectric ceramics Ceram. Int. 45 21315–20 [20] Oh J S and Choi S B 2017 State of the art of medical devices featuring smart electro-rheological and magneto-rheological fluids J. King Saud Univ. Sci. 29 390–400 [21] Ma H, Chen B, Qin L and Liao W H 2017 Design and testing of a regenerative magnetorheological actuator for assistive knee braces Smart Mater. Struct. 26 035013 [22] Ghareeb N and Farhat M 2018 Smart materials and structures: state of the art and applications Nano Res. Appl. 1 1–5 [23] Kamila S 2013 Introduction, classification and applications of smart materials: an overview Am. J. Appl. Sci. 10 876–80 [24] Bogue R 2012 Smart materials: A review of recent developments Assem. Autom. 32 3–7 [25] Muralidhara V N J and Makaram S 2009 Investigations on a directly coupled piezoactuated tool feed system for micro-electro-discharge machine Int. J. Mach. Tools Manuf. 49 1197–203 [26] Galvez P S, Paiva S A S, Guillermain E, Butcher M, DI Castro M and Masi A 2019 Gamma and proton irradiation tests on a piezoelectric actuator IEEE Access 7 184398–410 [27] Shin D J, Jeong S J, Seo C E, Cho K H and Koh J H 2015 Multi-layered piezoelectric energy harvesters based on PZT ceramic actuators Ceram. Int. 41 S686–90 [28] Huang H, Li J, Zhao H and Shi C 2016 On the correlation between the structure and one stepping characteristic of a piezo-driven rotary actuator Microsyst. Technol. 22 2821–7 [29] Qi K Q, Xiang Y, Fang C, Zhang Y and Yu C S 2015 Analysis of the displacement amplification ratio of bridge-type mechanism Mech. Mach. Theory 87 45–56 [30] Lobo A F, Raheman A and Muralidhara R R 2016 Design considerations of piezo stepping actuator Int. J. Innov. Res. Sci. Eng. Technol. 5 679–84 [31] Uchino K 2010 Advanced Piezoelectric Materials: Science and Technology (Cambridge, UK: Woodhead Publishing Limited) [32] Gu G Y, Zhu L M, Su C Y, Ding H and Fatikow S 2016 Modeling and control of piezo-actuated nanopositioning stages: A survey IEEE Trans. Autom. Sci. Eng. 13 313–32 [33] Liu Y, Deng J and Su Q 2018 Review on multi-degree-of-freedom piezoelectric motion stage IEEE Access 6 59986–60004 [34] Aksel E and Jones J L 2010 Advances in lead-free piezoelectric materials for sensors and actuators Sensors 10 1935–54 [35] Lee H J, Zhang S, Bar-Cohen Y and Sherrit S 2014 High temperature, high power piezoelectric composite transducers Sensors 14 14526–52 [36] Ramadan K S, Sameoto D and Evoy S 2014 A review of piezoelectric polymers as functional materials for electromechanical transducers Smart Mater. Struct. 23 033001 [37] Gao J, Xue D, Liu W, Zhou C and Ren X 2017 Recent progress on BaTiO3 -based piezoelectric ceramics for actuator applications Actuators 6 1–20 [38] Sappati K K and Bhadra S 2018 Piezoelectric polymer and paper substrates: A review Sensors 18 3605 [39] Liu H, Zhong J, Lee C, Lee S W and Lin L 2018 A comprehensive review on piezoelectric energy harvesting technology: materials, mechanisms, and applications Appl. Phys. Rev. 5 041306 [40] Wang S, Rong W, Wang L, Xie H, Sun L and Mills J K 2019 A survey of piezoelectric actuators with long working stroke in recent years: classifications, principles, connections and distinctions Mech. Syst. Signal Process. 123 591–605 [41] Kang L H and Han J H 2010 Prediction of actuation displacement and the force of a pre-stressed piezoelectric unimorph (PUMPS) considering nonlinear piezoelectric coefficient and elastic modulus Smart Mater. Struct. 19 094006 [42] Zhu Y, Liu W, Jia K, Liao W and Xie H 2011 A piezoelectric unimorph actuator based tip-tilt-piston micromirror with high fill factor and small tilt and lateral shift Sensors Actuators A 167 495–501 [43] Bakhtiari-Shahri M and Moeenfard H 2019 Energy harvesting from unimorph piezoelectric circular plates under random acoustic and base acceleration excitations Mech. Syst. Signal Process. 130 502–23 [44] Chung H C, Kummari K L, Croucher S J, Lawson N J, Guo S,, Whatmore R W and Huang Z 2009 Development of piezoelectric fans for flapping wing application Sensors Actuators A 149 136–42 [45] Yao L Q, Zhang J G, Lu L and Lai M O 2004 Nonlinear static characteristics of piezoelectric bending actuators under strong applied electric field Sensors Actuators A 115 168–75 [46] Lee D O, Kang L H and Han J H 2010 Active vibration isolation demonstration system using the piezoelectric unimorph with mechanically pre-stressed substrate ASME 2010 Conf. Smart Mater. Adapt. Struct. Intell. Syst. SMASIS 2010 2 309–14 29 Smart Mater. Struct. 30 (2021) 013002 Topical Review [47] Ashraf M W, Afzulpurkar N, Nisar A and Tayyaba S 2012 Fabrication and analysis of hollow microneedles and polymeric piezoelectric valveless micropump for transdermal drug-delivery system IET Commun. 6 3248–56 [48] Ma J, Hu Y, Li B, Feng Z and Chu J 2012 Influence of secondary converse piezoelectric effect on deflection of fully covered PZT actuators Sensors Actuators A 175 132–8 [49] Liu W, Zhu Y, Jia K, Liao W, Tang Y, Wang B and Xie H 2013 A tip-tilt-piston micromirror with a double S-shaped unimorph piezoelectric actuator Sensors Actuators A 193 121–8 [50] Choi J, Qiu Z, Rhee C H, Wang T and Oldham K 2014 A three-degree-of-freedom thin-film PZT-actuated microactuator with large out-of-plane displacement J. Micromech. Microeng. 24 075017 [51] Cheng C H, Yang A S, Lin C J and Huang W J 2017 Characteristic studies of a novel piezoelectric impedance micropump Microsyst. Technol. 23 1709–17 [52] Ma H K, Chen R H and Hsu Y H 2015 Development of a piezoelectric-driven miniature pump for biomedical applications Sensors Actuators A 234 23–33 [53] Wattananukulchai P and Isarakorn D 2017 A comparative study based on classical and newer piezoelectric materials based unimorph actuators for hard disk drive IEEE Region 10 Annual Int. Conf., Proc.(TENCON) (IEEE) pp 3464–7 [54] Ozaki T and Hamaguchi K 2018 Performance of direct-driven flapping-wing actuator with piezoelectric single-crystal PIN-PMN-PT J. Micromech. Microeng. 28 025007 [55] Chen N and Yan P 2011 Dynamic modeling and validation of a novel 3-DOF flexible thin sheet nano-manipulator with piezoelectric material bonded Smart Mater. Struct. 29 0–11 [56] Gunda A, Özkayar G, Tichem M and Ghatkesar M K 2020 Proportional microvalve using a unimorph piezoelectric microactuator Micromachines 11 130 [57] Rios S A and Fleming A J 2015 A new electrical configuration for improving the range of piezoelectric bimorph benders Sensors Actuators A 224 106–10 [58] Karpelson M, Wei G Y and Wood R J 2012 Driving high voltage piezoelectric actuators in microrobotic applications Sensors Actuators A 176 78–89 [59] Ngernchuklin P, Ryu J, Eamchotchawalit C and Park D S 2013 Soft/Hard PZT monolithic bi-layer composite actuator Ceram. Int. 39 S541–4 [60] Hall A J and Riddick J C 2012 Micro-electro mechanical flapping wing technology for micro air vehicles Bioinspiration Biomimetics Bioreplication 8339 1–9 [61] El-Sayed A M, Abo-Ismail A, El-Melegy M T, Azah Hamzaid N and Abu Osman N A 2013 Development of a micro-gripper using piezoelectric bimorphs Sensors 13 5826–40 [62] Yuan Y, Shyong Chow K, Du H, Wang P, Zhang M, Yu S and Liu B 2013 A ZnO thin-film driven microcantilever for nanoscale actuation and sensing Int. J. Smart Nano Mater. 4 128–41 [63] Jain R K, Majumder S, Ghosh B and Saha S 2015 Design and manufacturing of mobile micro manipulation system with a compliant piezoelectric actuator based micro gripper J. Manuf. Syst. 35 76–91 [64] Ghosh B, Jain R K, Majumder S, Roy S S and Mukhopadhyay S 2017 Experimental characterizations of bimorph piezoelectric actuator for robotic assembly J. Intell. Mater. Syst. Struct. 28 2095–109 [65] Liu Y Z, Hao Z W, Yu J X, Zhou X R, Lee P S, Sun Y, Mu Z C and Zeng F L 2019 A high-performance soft actuator based on a poly(vinylidene fluoride) piezoelectric bimorph Smart Mater. Struct. 28 055011 [66] Almeida A, Andrews G, Jaiswal D and Hoshino K 2019 The actuation mechanism of 3D printed flexure-based robotic microtweezers Micromachines 10 12 [67] Moradi-Dastjerdi R, Meguid S A and Rashahmadi S 2019 Dynamic behavior of novel micro fuel pump using zinc oxide nanocomposite diaphragm Sensors Actuators A 297 111528 [68] Shahabi P, Ghafarirad H and Taghvaeipour A 2020 High-frequency robust position control of a nonlinear piezoelectric bending actuator JVC/J. Vib. Control 26 1560–73 [69] Ali A, Pasha R A, Elahi H, Sheeraz M A, Bibi S, Hassan Z U, Eugeni M and Gaudenzi P 2019 Investigation of deformation in bimorph piezoelectric actuator: analytical, numerical and experimental approach Integr. Ferroelectr. 201 94–109 [70] Dong S 2012 Review on piezoelectric, ultrasonic, and magnetoelectric actuators J. Adv. Dielectr. 02 1230001 [71] Habineza D, Zouari M, Hammouche M, Le Gorrec Y and Rakotondrabe M 2016 Characterization and modeling of the temperature effect on the piezoelectric tube actuator IFAC-PapersOnLine 49 354–60 [72] Tian Y, Cai K, Zhang D, Liu X, Wang F and Shirinzadeh B 2019 Development of a XYZ scanner for home-made atomic force microscope based on FPAA control Mech. Syst. Signal Process. 131 222–42 [73] Bhikkaji B, Ratnam M, Fleming A J and Moheimani S O R 2007 High-performance control of piezoelectric tube scanners IEEE Trans. Control Syst. Technol. 15 853–66 [74] Mohammadzaheri M, Grainger S, Bazghaleh M and Yaghmaee P 2012 Intelligent modeling of a piezoelectric tube actuator INISTA 2012 - Int. Symp. Innov. Intell. Syst. Appl [75] Lu H, Fang Y, Ren X and Zhang X 2014 An improved direct inverse modeling approach for high-speed feedforward tracking control of a piezoelectric tube actuator Int. Conf. on Manipulation, Manufacturing and Measurement on the Nanoscale (IEEE) pp 341–6 [76] Habineza D, Rakotondrabe M and Le Gorrec Y 2015 Bouc-wen modeling and feedforward control of multivariable hysteresis in piezoelectric systems: application to a 3-DoF piezotube scanner IEEE Trans. Control Syst. Technol. 23 1797–806 [77] Habineza D, Rakotondrabe M and Le Gorrec Y 2015 Simultaneous suppression of badly damped vibrations and cross-couplings in a 2-DoF piezoelectric actuator by using feedforward standard H ∞ approach Next-Generation Robotics II; and Machine Intelligence and Bio-inspired Computation: Theory and Applications IX vol 9494 (USA: SPIE) p 94940L [78] Aljanaideh O, Habineza D, Rakotondrabe M and Al Janaideh M 2016 Experimental comparison of rate-dependent hysteresis models in characterizing and compensating hysteresis of piezoelectric tube actuators Phys. B: Condens. Matter. 486 64–68 [79] Li L, Li C X, Gu G and Zhu L 2019 Modified repetitive control based cross-coupling compensation approach for the piezoelectric tube scanner of atomic force microscopes IEEE/ASME Trans. Mechatron. 24 666–76 [80] Al Janaideh M, Al Saaideh M and Rakotondrabe M 2020 On hysteresis modeling of a piezoelectric precise positioning system under variable temperature Mech. Syst. Signal Process. 145 106880 30 Smart Mater. Struct. 30 (2021) 013002 Topical Review [81] Zhang Y, Tu Z, Lu T F and Al-Sarawi S 2017 A simplified transfer matrix of multi-layer piezoelectric stack J. Intell. Mater. Syst. Struct. 28 595–603 [82] Zhang X, Wang C, Liu J, Yan R, Cao H and Chen X 2019 Robust active control based milling chatter suppression with perturbation model via piezoelectric stack actuators Mech. Syst. Signal Process. 120 808–35 [83] Su H H, Hong C S, Tsai C C and Chu S Y 2018 Domain structure of nonstoichiometric sodium potassium niobate-based ceramics for piezoelectric acoustic actuators Ceram. Int. 44 3787–90 [84] Jeong S J, Lim D H, Saleem M, Koo B G and Kim M S 2018 Properties of CuAg/(BiNaSr)TiO3 multilayer ceramic actuator Ceram. Int. 44 S112–6 [85] Wang L, Chen W, Liu J, Deng J and Liu Y 2019 A review of recent studies on non-resonant piezoelectric actuators Mech. Syst. Signal Process 133 106254 [86] Arda Gozen B and Burak Ozdoganlar O 2012 Characterization of three-dimensional dynamics of piezo-stack actuators Mech. Syst. Signal Process. 31 268–83 [87] Deng J, Liu Y, Weishan C and Junkao L 2018 Development and experiment evaluation of an inertial piezoelectric actuator using bending-bending hybrid modes Sensors Actuators A 275 11–18 [88] Likun W, Lei Q, Gang W and Tianxiao D 2011 Analyses for radial vibration of piezoceramic disc stack Ferroelectrics 413 443–51 [89] Heverly D E, Wang K W and Smith E C 2004 Dual-stack piezoelectric device with bidirectional actuation and improved performance J. Intell. Mater. Syst. Struct. 15 565–74 [90] Le L R, Sosnicki O, Barillot F and Claeysssen F 2005 Actuators in adaptronics : piezoelectric actuators Conf. on Smart Structures and Materials pp 18–21 [91] Jiang S and Cheng L 2017 Modeling and design of a pre-stressed piezoelectric stack actuator AIP Adv. 7 075114 [92] Mikułowsk G, Fournier M, Porchez T, Belly C and Claeyssen F 2016 15th Int. Conf. on New Actuators Semi-Passive Vibration Control Technique via Shunting of Amplified Piezoelectric Actuators 13–15 [93] Choy S H, Jiang X P, Kwok K W and Chan H L W 2010 Piezoelectric and dielectric characteristics of lead-free BNKLBT ceramic thick film and multilayered piezoelectric actuators Ceram. Int. 36 2345–50 [94] Jang D D, Jung H J, Shin Y H, Moon S J, Moon Y J and Oh J 2012 Feasibility study on a hybrid mount system with air springs and piezo-stack actuators for microvibration control J. Intell. Mater. Syst. Struct. 23 515–26 [95] Wang D H and Zhu W 2011 A phenomenological model for pre-stressed piezoelectric ceramic stack actuators Smart Mater. Struct. 20 11 [96] Choi S B, Seong M S, Ha S H, Jeon J and Sohn J W 2011 Design of a piezostack-based inertial actuator and application to vibration control: experimental investigation Proc. Inst. Mech. Eng. I 225 1115–24 [97] Sahoo B and Panda P K 2012 Fabrication of simple and ring-type piezo actuators and their characterization Smart Mater. Res. 2012 1–4 [98] Meftah M, Irbah A, Letty R L, Bataille A, Ducourt E, Poiet G and Privat M 2011 The picard/sodism pointing mechanism: from the design to the flight performances 14th European Space Mechanisms and Tribology Symp. pp 11–18 [99] Wang L, Du J, Luo Z, Du X, Li Y, Liu J and Sun D 2013 Design and experiment of a jetting dispenser driven by piezostack actuator IEEE Trans. Compon. Packag. Manuf. Technol. 3 147–56 [100] Park J H, Seo M Y, Ham Y B, Yun S N and Kim D I 2013 A study on high-output piezoelectric micropumps for application in DMFC J. Electroceram. 30 102–7 [101] Jeon J, Han C, Han Y M and Choi S B 2014 A new type of a direct-drive valve system driven by a piezostack actuator and sliding spool Smart Mater. Struct. 23 075002 [102] Xuan Z, Jin T, Ha N S, Goo N S, Kim T H, Bae B W, Ko H S and Yoon K W 2014 Performance of piezo-stacks for a piezoelectric hybrid actuator by experiments J. Intell. Mater. Syst. Struct. 25 2212–20 [103] Yang Y L, Wei Y D, Lou J Q, Tian G, Zhao X W and Fu L 2015 A new piezo-driven microgripper based on the double-rocker mechanism Smart Mater. Struct. 24 11 [104] Muralidhara Rao and Rao R 2015 Displacement characteristics of a piezoactuator-based prototype microactuator with a hydraulic displacement amplification system J. Mech. Sci. Technol. 29 4817–22 [105] Zhou C, Duan J A, Deng G and Li J 2017 A novel high-speed jet dispenser driven by double piezoelectric stacks IEEE Trans. Ind. Electron. 64 412–9 [106] Dong W, Li H and Du Z 2016 A planar nano-positioner driven by shear piezoelectric actuators AIP Adv. 6 085104 [107] Bu Z, Lin S, Huang X, Li A, Wu D, Zhao Y, Luo Z and Wang L 2018 A novel piezostack-driven jetting dispenser with corner-filleted flexure hinge and high-frequency performance J. Micromech. Microeng. 28 075001 [108] Gao X, Xin X, Wu J, Chu Z and Dong S 2018 A multilayered-cylindrical piezoelectric shear actuator operating in shear (d15) mode Appl. Phys. Lett. 112 152902 [109] Hwang H S, Nasser J and Sodano H A 2019 Piezoelectric stack actuator for measurement of interfacial shear strength at high strain rates Exp. Mech. 59 979–90 [110] Huang H, Wang L and Wu Y 2019 Design and experimental research of a rotary micro-actuator based on a shearing piezoelectric stack Micromachines 10 1–14 [111] Claeyssen F, Letty R L, Barillot F and Sosnicki O 2007 Amplified piezoelectric actuators: static dynamic applications Ferroelectrics 351 3–14 [112] Newnham R E, Dogan A, Xu Q C, Onitsuka K, Tressler J and Yoshikawa S 1993 Flextensional ‘moonie’ actuators Proc. of the IEEE Ultrasonics Symp. vol 1 pp 509–13 [113] Sun C L, Guo S S, Li W P, Xing Z B, Liu G C and Zhao X Z 2005 Displacement amplification and resonance characteristics of the cymbal transducers Sensors Actuators A 121 213–20 [114] Goh P H, Li M J and Tsou N T 2017 The design and analysis for low-frequency piezoelectric cymbal transducers Ceram. Int. 43 S49–54 [115] Sitharthan R, Ponnusamy M, Karthikeyan M and Sundar D S 2019 Analysis on smart material suitable for autogenous microelectronic application Mater. Res. Express 6 0–16 [116] Wise S A 1998 Displacement properties of RAINBOW and THUNDER piezoelectric actuators Sensors Actuators A 69 33–38 [117] Ling M, Cao J and Pehrson N 2019 Kinetostatic and dynamic analyses of planar compliant mechanisms via a two-port dynamic stiffness model Precis. Eng. 57 149–61 [118] Hricko J and Havlík Š 2020 Compliant mechanisms for motion/force amplifiers for robotics Adv. Intell. Syst. Comput. 980 26–33 [119] Li Y, Li H, Cheng T, Lu X, Zhao H and Chen P 2018 Note: Lever-type bidirectional stick-slip piezoelectric actuator with flexible hinge Rev. Sci. Instrum. 89 1–4 [120] Chen C M, Hsu Y C and Fung R F 2012 System identification of a Scott-Russell amplifying mechanism with offset driven by a piezoelectric actuator Appl. Math. Model. 36 2788–802 31 Smart Mater. Struct. 30 (2021) 013002 Topical Review [121] Tian Y, Shirinzadeh B, Zhang D and Alici G 2009 Development and dynamic modelling of a flexure-based Scott-Russell mechanism for nano-manipulation Mech. Syst. Signal Process. 23 957–78 [122] Han Q, Jin K, Chen G and Shao X 2017 A novel fully compliant tensural-compresural bistable mechanism Sensors Actuators A 268 72–82 [123] Chen G, Ma Y and Li J 2016 A tensural displacement amplifier employing elliptic-arc flexure hinges Sensors Actuators A 247 307–15 [124] Kim K, Lee J, Ju J and Kim D M 2014 Compliant cellular materials with compliant porous structures: A mechanism based materials design Int. J. Solids Struct. 51 3889–903 [125] Acob J M, Pano V and Ouyang P 2012 Optimization of a compliant mechanical amplifier based on a symmetric five-bar topology Lecture Notes in Computer Science LNAI In International Conference on Intelligent Robotics and Applications vol 7507 ( Berlin: Springer, Heidelberg) 323–332 [126] Ouyang P R, Zhang W J and Gupta M M 2005 Design of a new compliant mechanical amplifier Proc. of the ASME Int. Design Engineering Technical Conf. and Computers and Information in Engineering Conf. - DETC2005 (American Society of Mechanical Engineers Digital Collection) vol 7 pp 15–24 [127] Lin C, Zheng S, Li P, Shen Z and Wang S 2019 Positioning error analysis and control of a piezo-driven 6-DOF micro-positioner Micromachines 10 542 [128] Choi K B, Lee J J, Kim G H, Lim H J and Kwon S G 2018 Amplification ratio analysis of a bridge-type mechanical amplification mechanism based on a fully compliant model Mech. Mach. Theory 121 355–72 [129] Mohith S, Karanth P N and Kulkarni S M 2020 Performance analysis of valveless micropump with disposable chamber actuated through amplified piezo actuator (APA) for biomedical application Mechatronics 67 102347 [130] Mohith S, Muralidhara Rao, Navin Karanth P, S M Kulkarni and Adithya R Upadhya 2020 Development and assessment of large stroke piezo-hydraulic actuator for micro positioning applications Precis. Eng. 67 334–338 [131] Wang X X, Or S W, Lam K H, Chan H L W, Choy P K and Liu P C K 2006 Cymbal actuator fabricated using (Na0.46K0.46Li 0.08)NbO3 lead-free piezoceramic J. Electroceram. 16 385–8 [132] Ouyang P R, Zhang W J and Gupta M M 2008 A new compliant mechanical amplifier based on a symmetric five-bar topology J. Mech. Des. 130 1045011–5 [133] Ham Y B, Seo W S, Cho W Y, Yun D W, Park J H and Yun S N 2009 Development of a piezoelectric pump using hinge-lever amplification mechanism J. Electroceram. 23 346–50 [134] Muraoka M and Sanada S 2010 Displacement amplifier for piezoelectric actuator based on honeycomb link mechanism Sensors Actuators A 157 84–90 [135] Haller D, Paetzold A, Goldin N, Neiss S, Goldschmidtboeing F,, Nitsche W, King R and Woias P 2011 Cymbal type piezo-polymer-composite actuators for active cancellation of flow instabilities on airfoils 16th Int. Solid-State Sensors, Actuators and Microsystems Conf., TRANSDUCERS’11 pp 494–7 [136] Chae K W, Kim W B and Jeong Y H 2011 A transparent polymeric flexure-hinge nanopositioner, actuated by a piezoelectric stack actuator Nanotechnology 22 335501 [137] Yeom T, Simon T W, Zhang M, North M T and Cui T 2012 High frequency, large displacement, and low power consumption piezoelectric translational actuator based on an oval loop shell Sensors Actuators A 176 99–109 [138] Sun X, Chen W, Tian Y, Fatikow S, Zhou R, Zhang J and Mikczinski M 2013 A novel flexure-based microgripper with double amplification mechanisms for micro/nano manipulation Rev. Sci. Instrum. 84 085002 [139] Xu Q 2014 Design and smooth position/force switching control of a miniature gripper for automated microhandling IEEE Trans. Ind. Inform. 10 1023–32 [140] Ai W and Xu Q 2014 New structural design of a compliant gripper based on the scott-russell mechanism Int. J. Adv. Robot. Syst. 11 192 [141] Lu S, Liu Y, Yao Y, Huang B and Sun L 2014 Design and analysis of a piezostack driven jetting dispenser for high viscosity adhesives IEEE/ASME Int. Conf. on Advanced Intelligent Mechatronics pp 227–32 [142] Chen J, Zhang C, Xu M, Zi Y and Zhang X 2015 Rhombic micro-displacement amplifier for piezoelectric actuator and its linear and hybrid model Mech. Syst. Signal Process. 50–51 580–93 [143] Pan Q S, YBin L, Liu Y H, Gong L J, He L G and Feng Z H 2015 Design and fabrication of a large displacement piezoelectric actuator Proc. of the 2015 Symp. on Piezoelectricity, Acoustic Waves and Device Applications (IEEE) pp 261–4 [144] Liu Y and Xu Q 2016 Mechanical design, analysis and testing of a large-range compliant microgripper Mech. Sci. 7 119–26 [145] Na T W, Choi J H, Jung J Y, Kim H G, Han J H, Park K C and Oh I K 2016 Compact piezoelectric tripod manipulator based on a reverse bridge-type amplification mechanism Smart Mater. Struct. 25 1–13 [146] Dsouza R D and Karanth P N 2016 Experimental investigation of amplified piezoelectric stack actuators 50XS, 60S and 120S for the actuation of microgrippers FTC 2016 - Proc. of Future Technologies Conf. pp 1282–9 [147] Sohn J W and Choi S B 2018 Identification of operating parameters most strongly influencing the jetting performance in a piezoelectric actuator-driven dispenser Appl. Sci. 8 243 [148] Wei H, Shirinzadeh B, Li W, Clark L, Pinskier J and Wang Y 2017 Development of piezo-driven compliant bridge mechanisms: general analytical equations and optimization of displacement amplification Micromachines 8 238 [149] Aoki F Y and Hayden F G 2012 Design, analysis and testing of a novel decoupled 2-DOF flexure-based micropositioning stage Journal of Micromechanics and Microengineering 27 1–10 [150] Lai L J and Zhu Z N 2017 Design, modeling and testing of a novel flexure-based displacement amplification mechanism Sensors Actuators A 266 122–9 [151] Fujimura Y, Tsukamoto T and Tanaka S 2018 Piezoelectric moonie-type resonant microactuator Electron. Commun. Jpn. 101 3–10 [152] Dsouza R D, Navin K P, Theodoridis T and Sharma P 2018 Design, fabrication and testing of a 2 DOF compliant flexural microgripper Microsyst. Technol. 24 3867–83 [153] Deng G, Cui W, Zhou C and Li J 2018 A piezoelectric jetting dispenser with a pin joint Optik 175 163–71 [154] Chen F, Du Z, Yang M, Gao F, Dong W and Zhang D 2018 Design and analysis of a three-dimensional bridge-type mechanism based on the stiffness distribution Precis. Eng. 51 48–58 [155] Zhu W, Zhu Z, Guo P and Ju B F 2018 A novel hybrid actuation mechanism based XY nanopositioning stage with totally decoupled kinematics Mech. Syst. Signal Process. 99 747–59 32 Smart Mater. Struct. 30 (2021) 013002 Topical Review [156] Liang J, Zhang X and Zhu B 2019 Nonlinear topology optimization of parallel-grasping microgripper Precis. Eng. 60 152–9 [157] Mohith S, Karanth P N and Kulkarni S M 2019 Experimental investigation on performance of disposable micropump with retrofit piezo stack actuator for biomedical application Microsyst. Technol. 25 4741–52 [158] Ling M, Cao J, Jiang Z, Zeng M and Li Q 2019 Optimal design of a piezo-actuated 2-DOF millimeter-range monolithic flexure mechanism with a pseudo-static model Mech. Syst. Signal Process. 115 120–31 [159] Ding Y and Lai L J 2019 Design and analysis of a displacement amplifier with high load capacity by combining bridge-type and Scott-Russell mechanisms Rev. Sci. Instrum. 90 1–8 [160] Tian X, Liu Y, Chen W, Deng J and Liu J 2018 Development and experiment evaluation of an H-shape linear piezoelectric actuator operated in stepping mode Ceram. Int. 44 S246–9 [161] Mashimo T and Toyama S 2010 Rotary-linear piezoelectric microactuator with a cubic stator of side length 3.5 mm IEEE Trans. Ultrason. Ferroelectr. Freq. Control 57 1825–30 [162] Hunstig M 2017 Piezoelectric inertia motors—a critical review of history, concepts, design, applications, and perspectives Actuators 6 27–33 [163] Silvestri M, Confalonieri M and Ferrario A 2017 Piezoelectric actuators for micro positioning stages in automated machines: experimental characterization of open loop implementations FME Trans. 45 331–8 [164] Li J, Huang H and Morita T 2019 Stepping piezoelectric actuators with large working stroke for nano-positioning systems: A review Sensors Actuators A 292 39–51 [165] Mrad R, Abhari A and Zu J 2003 A control methodology for an inchworm piezomotor Mech. Syst. Signal Process. 17 457–71 [166] Kwon K, Cho N and Jang W 2004 the design and characterization of a piezo-driven inchworm linear motor with a reduction-lever mechanism JSME Int. J. Ser. C 47 803–11 [167] Kato H, Hayakawa K, Torii A and Ueda A 2000 XYΘ Actuators Using Piezoelectric and Electromagnetic Actuators Electr. Eng. Japan. 131 44–51 [168] Wen J, Ma J, Zeng P, Cheng G and Zhang Z 2013 A new inertial piezoelectric rotary actuator based on changing the normal pressure Microsyst. Technol. 19 277–83 [169] Hoffmeister H W, Loeis K and Schuller B C 2010 Piezo actuator and its hysteresis compensation for an active clamping system in wood machining Key Eng. Mater. 447–448 498–502 [170] Chen K, Wen J, Cheng G, Ma J and Zeng P 2016 An asymmetrical inertial piezoelectric rotary actuator with the bias unit Sensors Actuators A 251 179–87 [171] Tjeung R T, Hughes M S, Yeo L Y and Friend J R 2011 Arbitrary axis rotating surface acoustic wave micro motor 6th IEEE Int. Conf. on Nano/Micro Engineered and Molecular Systems pp 180–3 [172] Oh C H, Choi J H, Nam H J, Bu J U and Kim S H 2010 Ultra-compact, zero-power magnetic latching piezoelectric inchworm motor with integrated position sensor Sensors Actuators A 158 306–12 [173] Li J, Zhao H, Qu H, Cui T, Fu L, Huang H, Ren L and Fan Z 2013 A piezoelectric-driven rotary actuator by means of inchworm motion Sensors Actuators A 194 269–76 [174] Zhao H, Fu L, Ren L, Huang H, Fan Z, Li J and Qu H 2013 Design and experimental research of a novel inchworm type piezo-driven rotary actuator with the changeable clamping radius Rev. Sci. Instrum. 84 10 [175] Ma L, Jiang C, Xiao J, Wang K, Xie W and Liu B 2013 A piezoelectric inchworm actuator based on the principle of flexible amplification 2013 Int. Conf. Manip. Manuf. Meas. Nanoscale, 3M-NANO 2013 - Conf. Proc 201–6 [176] Ma L, Xiao J, Zhou S and Sun L 2015 A piezoelectric inchworm actuator of linear type using symmetrical lever amplification Proc. Inst. Mech. Eng. N 229 172–9 [177] Li J, Zhao H, Shao M, Zhou X, Huang H and Fan Z 2014 Design and experiment performances of an inchworm type rotary actuator Rev. Sci. Instrum. 85 015006 [178] Wang S, Zhang Z, Ren L, Zhao H, Liang Y and Zhu B 2015 Design and driving characteristics of a novel ‘pusher’ type piezoelectric actuator Smart Mater. Struct. 25 12 [179] Xue X, Tian X, Zhang D and Liu X 2016 Design of a piezo-driven inchworm flexure stage for precision positioning Int. J. Appl. Electromagn. Mech. 50 569–81 [180] Song S, Shao S, Xu M, Shao Y, Tian Z and Feng B 2018 Piezoelectric inchworm rotary actuator with high driving torque and self-locking ability Sensors Actuators A 282 174–82 [181] Wang S, Rong W, Wang L, Pei Z and Sun L 2018 A novel inchworm type piezoelectric rotary actuator with large output torque: design, analysis and experimental performance Precis. Eng. 51 545–51 [182] Gao Y, Wen J, Ma J, Zhang Y, Wang R, Hu Y and Li J 2019 A self-adapting linear inchworm piezoelectric actuator based on a permanent magnets clamping structure Mech. Syst. Signal Process. 132 429–40 [183] Tian X, Zhang B, Liu Y, Chen S and Yu H 2019 A novel U-shaped stepping linear piezoelectric actuator with two driving feet and low motion coupling: design, modeling and experiments Mech. Syst. Signal Process. 124 679–95 [184] Shao S, Song S, Liu K and Xu M 2019 A piezo-driven rotary inchworm actuator featured with simple structure and high output torque Int. J. Appl. Electromagn. Mech. 59 317–25 [185] Wang Y and Yan P 2019 A novel bidirectional complementary-type inchworm actuator with parasitic motion based clamping Mech. Syst. Signal Process. 134 106360 [186] Qi H Y 2019 Influence of waveform symmetry on output performance of piezoelectric inertia actuator controlled by composite method IOP Conf. Ser. Mater. Sci. Eng 565 [187] Hunstig M, Hemsel T and Sextro W 2013 Stick–slip and slip–slip operation of piezoelectric inertia drives. Part I: ideal excitation Matthias Sensors Actuators A 200 90–100 [188] Hunstig M, Hemsel T and Sextro W 2013 Stick-slip and slip-slip operation of piezoelectric inertia drives - Part II: frequency-limited excitation Sensors Actuators A 200 79–89 [189] Cheng T, He M, Li H, Lu X, Zhao H and Gao H 2017 A novel trapezoid-type stick-slip piezoelectric linear actuator using right circular flexure hinge mechanism IEEE Trans. Ind. Electron. 64 5545–52 [190] Wang S, Rong W, Wang L, Pei Z and Sun L 2017 Design, analysis and experimental performance of a novel stick-slip type piezoelectric rotary actuator based on variable force couple driving Smart Mater. Struct. 26 055005 [191] Spanner K and Koc B 2016 Piezoelectric motors, an overview Actuators 5 6 [192] Zhang Q S, Chen X B, Yang Q and Zhang W J 2012 Development and characterization of a novel piezoelectric-driven stick-slip actuator with anisotropic-friction surfaces Int. J. Adv. Manuf. Technol. 61 1029–34 [193] Morita T, Nishimura T, Yoshida R and Hosaka H 2013 Resonant-type smooth impact drive mechanism actuator 33 Smart Mater. Struct. 30 (2021) 013002 Topical Review operating at lower input voltages Jpn. J. Appl. Phys. 52 3–8 [194] Li J, Zhou X, Zhao H, Shao M, Hou P and Xu X 2015 Design and experimental performances of a piezoelectric linear actuator by means of lateral motion Smart Mater. Struct. 24 1–5 [195] Li J, Zhou X, Zhao H, Shao M, Fan Z and Liu H 2015 Design and experimental tests of a dual-servo piezoelectric nanopositioning stage for rotary motion Rev. Sci. Instrum. 86 1–7 [196] Li J, Zhao H, Shao M, Zhou X and Fan Z 2015 Design and experimental research of an improved stick-slip type piezo-driven linear actuator Adv. Mech. Eng. 7 1–8 [197] Peng Y, Cao J, Guo Z and Yu H 2015 A linear actuator for precision positioning of dual objects Smart Mater. Struct. 24 125039 [198] Chu X, Zhong Z, Zhu C, Zhao Y and Li L 2016 A novel low-voltage non-resonant piezoelectric linear actuator based on two alternative principles Ferroelectrics 505 147–58 [199] Wang S, Rong W, Wang L, Pei Z and Sun L 2017 Design, analysis and experimental performance of a piezoelectric rotary actuator based on compliant foot driving Microsyst. Technol. 23 3765–73 [200] Cheng T, Li H, He M, Zhao H, Lu X and Gao H 2017 Investigation on driving characteristics of a piezoelectric stick–slip actuator based on resonant/off-resonant hybrid excitation Smart Mater. Struct. 26 9 [201] Wang S, Rong W, Wang L, Pei Z and Sun L 2017 Design, analysis and experimental performance of a bionic piezoelectric rotary actuator J. Bionic Eng. 14 348–55 [202] Li H, Li Y, Cheng T, Lu X, Zhao H and Gao H 2017 A symmetrical hybrid driving waveform for a linear piezoelectric stick-slip actuator IEEE Access 5 16885–94 [203] Zhang Y, Peng Y, Sun Z and Yu H 2019 A novel stick–slip piezoelectric actuator based on a triangular compliant driving mechanism IEEE Trans. Ind. Electron. 66 5374–82 [204] Nguyen X H, Mau T H, Meyer I, Dang B L and Pham H P 2018 Improvements of piezo-actuated stick-slip micro-drives: modeling and driving waveform Coatings 8 1–16 [205] Shen Q, Liu Y, Wang L, Liu J and Li K 2018 A long stroke linear stepping piezoelectric actuator using two longitudinal-bending hybrid transducers Ceram. Int. 44 S104–7 [206] Qin F, Huang H, Wang J, Tian L, Liang T and Zhao H 2019 Design and stepping characteristics of novel stick–slip piezo-driven linear actuator Smart Mater. Struct. 28 075026 [207] Zhong B, Zhu J, Jin Z, He H, Sun L and Wang Z 2019 Improved inertial stick-slip movement performance via driving waveform optimization Precis. Eng. 55 260–7 [208] Gao Q, He M, Lu X, Zhang C and Cheng T 2019 Simple and high-performance stick-slip piezoelectric actuator based on an asymmetrical flexure hinge driving mechanism J. Intell. Mater. Syst. Struct. 30 2125–34 [209] Yang C P, Xie K J and Chang J Y 2019 Design and simulation of an ultrasonic linear motor with dual piezoelectric actuators Microsyst. Technol. 6 71–78 [210] Doshida Y, Shimizu H, Mizuno Y and Tamura H 2013 High-power properties and miniature ultrasonic motor of (Sr,Ca)2NaNb5O15 piezoelectric ceramics Ceram. Int. 39 S721–7 [211] Chu X, Meng X and Li L 2010 The design and test of a new kind of piezoelectric motor based on standing wave and multilayer Ferroelectrics 409 168–74 [212] Richter A, Pustka M, Rydlo P and Kolář M 2004 Ultrasonic piezoceramic motor: the computation of traveling-wave velocity on the stator surface and excitation by PWM modulation with higher harmonic suppression Ceram. Int. 30 1857–61 [213] Jingzhuo S and Dongmei Y 2014 Characteristic model of travelling wave ultrasonic motor Ultrasonics 54 725–30 [214] Shi Y and Zhao C 2011 A new standing-wave-type linear ultrasonic motor based on in-plane modes Ultrasonics 51 397–404 [215] Hou X, Lee H P, Ong C J and Lim S P 2013 Development and numerical characterization of a new standing wave ultrasonic motor operating in the 30–40 kHz frequency range Ultrasonics 53 928–34 [216] Martinez T, Pillonnet G, Vasic D, Costa F and Hata S 2019 A transverse traveling wave piezoelectric transformer Smart Mater. Struct. 28 075012 [217] Sun D, Wang S, Sakurai J, Choi K B, Shimokohbe A and Hata S 2010 A piezoelectric linear ultrasonic motor with the structure of a circular cylindrical stator and slider Smart Mater. Struct. 19 045008 [218] Liu Y, Chen W, Liu J and Shi S 2011 A cylindrical standing wave ultrasonic motor using bending vibration transducer Ultrasonics 51 527–31 [219] He S, Chiarot P R and Park S S 2011 A single vibration mode tubular piezoelectric ultrasonic motor IEEE Trans. Ultrason. Ferroelectr. Freq. Control 58 1049–1061 [220] Smithmaitrie P, Suybangdum P and Muensit N 2012 Design and performance testing of an ultrasonic linear motor with dual piezoelectric actuators IEEE Trans. Ultrason. Ferroelectr. Freq. Control 59 1033–42 [221] Park S and He S 2012 Standing wave brass-PZT square tubular ultrasonic motor Ultrasonics 52 880–9 [222] Ci P, Liu G, Chen Z and Dong S 2013 Longitudinal and bending hybrid linear ultrasonic motor using bending PZT elements Appl. Phys. Lett. 1 103 102904 [223] Yang X, Liu Y, Chen W and Liu J 2013 Longitudinal and bending hybrid linear ultrasonic motor using bending PZT elements Ceram. Int. 39 S691–4 [224] Jeong S S, Cheon S K, Kim M H and Park T G 2013 Motional characteristics of ultrasonic motor using Λ(lambda)-shaped stator Ceram. Int. 39 S715–9 [225] Zhou X, Chen W and Liu J 2014 A novel traveling wave ultrasonic motor using sandwich-type ring stator Joint IEEE Int. Symp. on the Applications of Ferroelectric, Int. Workshop on Acoustic Transduction Materials and Devices and Workshop on Piezoresponse Force Microscopy 26 5–8 [226] Wang Y J, Chen Y C and Shen S C 2015 Design and analysis of a standing-wave trapezoidal ultrasonic linear motor J. Intell. Mater. Syst. Struct. 26 2295–303 [227] Yuan S, Zhu C, Chu X, Zhao Y, Amin M and Fan Y 2015 A novel linear piezoelectric actuator with two working principles of standing and traveling wave vibration mode AIP Adv. 5 107213 [228] Liu Y, Shi S, Li C, Chen W and Liu J 2016 A novel standing wave linear piezoelectric actuator using the longitudinal-bending coupling mode Sensors and Actuators A 251 119-25 [229] Grybas I, Bansevicius R, Jurenas V, Bubulis A, Janutenaite J and Kulvietis G 2016 Ultrasonic standing waves-driven high resolution rotary table Precis. Eng 45 396-402 [230] Wang L, Shu C, Zhang Q and Jin J 2017 A novel sandwich-type traveling wave piezoelectric tracked mobile system Smart Mater. Struct. 75 28–35 [231] Wang L, Wielert T, Twiefel J, Jin J and Wallaschek J 2017 A rod type linear ultrasonic motor utilizing longitudinal traveling waves: proof of concept Smart Mater. Struct. 26 085013 34 Smart Mater. Struct. 30 (2021) 013002 Topical Review [232] Zhou X, Zhang Y and Zhang Q 2017 A novel linear ultrasonic motor with characteristic of variable mode excitation Ceram. Int. 43 S64–9 [233] Hariri H, Bernard Y and Razek A 2018 2-D traveling wave driven piezoelectric plate robot for planar motion IEEE/ASME Trans. Mechatron. 23 242–51 [234] Liu J, Liu Y, Zhao L, Xu D, Chen W, Deng J 2018 Design and experiments of a single-foot linear piezoelectric actuator operated in a stepping mode IEEE Trans. Ind. Electron. 65 8063–71 [235] Weng C M, Tsai C C, Hong C S, Chiang C H, Chu S Y, Lin C C and Sheen J 2018 Effects of post-annealing on electrical properties of CuF2·xH2O-doped KNN ceramics for rotary-linear ultrasonic motors Ceram. Int. 48 16173–80 [236] Qin F, Chen Y, Sun X, Wang Y, Dai G and Du Y 2019 An adjustable magnetic preloading and stepping controlled piezoelectric traveling-wave ultrasonic micromotor J. Microelectromech. 28 264–70 [237] Liu Y, Chen W, Liu J and Shi S 2013 A Rectangle-Type Linear Ultrasonic Motor Using Longitudinal Vibration Transducers With Four Driving Feet IEEE Trans. Ultrason. Ferroelectr. Freq. Control 60 1860–7 [238] Liu Y, Liu J, Chen W and Shi S 2010 A high-power linear ultrasonic motor using longitudinal vibration transducers with single foot IEEE Trans. Ultrason. Ferroelectr. Freq. Control 57 1860–7 [239] Xu D, Zhang X, Zhaou L and Yu S 2019 A novel rotary ultrasonic motor using the longitudinal vibration mode IEEE Access 7 135650–5 [240] Liu Y, Chen W, Liu J and Yang X 2012 A high-power linear ultrasonic motor using bending vibration transducer IEEE Trans. Ind. Electron. 60 5160–6 [241] Liu Y, Xu D, Yang X and Chen W 2015 Miniaturized piezoelectric actuator operating in bending hybrid modes Sensors Actuators A 235 158–64 [242] Shi S, Liu J, Chen W and Liu Y 2010 A novel L-B hybrid langevin transducer type linear ultrasonic motor with modal coupling reducing configuration Ferroelectrics 408 71–77 [243] Liu Y, Yang X, Chen W and Liu J 2012 A rotary piezoelectric actuator using longitudinal and bending hybrid transducer Ultrasonics 2 042136 [244] Park T G, Jeong D S, Kim M H and Song T K 2006 A study on the rotary-type ultrasonic motor using a longitudinal-torsional vibration converter Mater. Chem. Phys. 98 1–4 [245] Al-Budairi H, Lucas M and Harkness P 2013 A design approach for longitudinal-torsional ultrasonic transducers Sensors Actuators A 198 99–106 [246] Yang L and Zhao C 2014 Flexible supporting and fixing method for hybrid ultrasonic motor using longitudinal and torsional vibration modes J. Vibroeng. 16 2854–61 [247] Yang X, Liu Y, Chen W and Liu J 2015 Miniaturization of a longitudinal-bending hybrid linear ultrasonic motor Ceram. Int. 41 S607–11 [248] Chen Z, Li X, Ci P, Liu G and Dong S 2015 A standing wave linear ultrasonic motor operating in in-plane expanding and bending modes Rev. Sci. Instrum. 86 1–7 [249] Zhou X and Zhang Y 2016 A new linear ultrasonic motor using hybrid longitudinal vibration mode IEEE Access 4 10158–65 [250] Yang L, Zhu X and Chen X 2016 A novel type of hybrid ultrasonic motor using longitudinal and torsional vibration modes with side panels J. Vibroeng. 18 759–67 [251] Ma Y, Choi M and Uchino K 2016 Single-phase driven ultrasonic motor using two orthogonal bending modes of sandwiching piezo-ceramic plates Rev. Sci. Instrum. 87 115004 [252] Yang L, Zhu X and Di S 2017 A type of dual-rotor hybrid ultrasonic motor based on vibration of four side panels J. Intell. Mater. Syst. Struct. 28 1916–24 [253] Dabbagh V, Sarhan A A D, Akbari J and Mardi N A 2017 Design and manufacturing of ultrasonic motor with in-plane and out-of-plane bending vibration modes of rectangular plate with large contact area Meas. J. Int. Meas. Confed 109 425–31 [254] Chu X, Zhang M, Yuan S and Zheng X 2019 An eight-zonal piezoelectric tube-type threaded ultrasonic motor based on second-order bending mode Appl. Sci. 9 10 [255] Liu Y, Shi S, Li C, Chen W, Wang L and Liu J 2018 Development of a bi-directional standing wave linear piezoelectric actuator with four driving feet Ultrasonics 84 81–86 [256] Yu H, Quan Q, Tian X and Li H 2018 Optimization and analysis of a U-shaped linear piezoelectric ultrasonic motor using longitudinal transducers Sensors 18 12 [257] Wang L, Liu J, Liu Y and Yan J 2018 A novel single-mode linear piezoelectric ultrasonic motor based on asymmetric structure Ultrasonics 89 137-42 [258] Fan P and Li C 2019 Simple bidirectional linear ultrasonic motor driven by single-phase signal J. Braz. Soc. Mech. Sci. Eng. 41 1-12 [259] Wang L, Liu Y, Li K, Cheng S and Tian X 2019 Development of a resonant type piezoelectric stepping motor using longitudinal and bending hybrid bolt-clamped transducer Sensors Actuators A 285 182-9 [260] Yin Z, Dai C, Cao ZC, Li W, Chen Z and Li C 2020 Modal analysis and moving performance of a single-mode linear ultrasonic motor Ultrasonics 108 106216 [261] Niu R, Zhu H and Zhao C 2020 A four-legged linear ultrasonic motor: design and experiments Rev. Sci. Instrum. 91 076107 [262] Zhang M, Guo W and Sun L 2008 A multi-degree-of-freedom ultrasonic motor using in-plane deformation of planar piezoelectric elements Sensors Actuators A 148 193–200 [263] Shen S C, Tsai P C, Wang Y J and Huang H J 2012 A new type of multi-degree-of-freedom miniaturization actuator using symmetric piezoelectric pusher element for a pocket sun-tracking system Sensors Actuators A 182 114–21 [264] Lai L J, Gu G Y and Zhu L M 2012 Design and control of a decoupled two degree of freedom translational parallel micro-positioning stage Rev. Sci. Instrum. 83 045105 [265] Cheng C H and Hung S K 2016 A piezoelectric 2-degree-of-freedom nano-stepping motor with parallel design IEEE/ASME Trans. Mechatron. 21 2197–9 [266] Zhang X, Zhang Y and Xu Q 2017 Design and control of a novel piezo-driven XY parallel nanopositioning stage Microsyst. Technol. 23 1067–80 [267] Sun X, Chen W, Zhang J, Zhou R and Chen W 2015 A novel piezo-driven linear-rotary inchworm actuator Sensors Actuators A 224 78–86 [268] Cai K, Tian Y, Wang F, Zhang D and Shirinzadeh B 2016 Development of a piezo-driven 3-DOF stage with T-shape flexible hinge mechanism Robot. Comput. Integr. Manuf. 37 125–38 [269] Hua S, Liu G, Lou Y, Li Z and Meng Y 2014 A 2-DOF piezoelectric inchworm actuator for precise positioning Adv. Mech. Eng. 2014 8 [270] Li J, Zhao H, Qu X, Qu H, Zhou X, Fan Z, Ma Z and Fu H 2015 Development of a compact 2-DOF precision piezoelectric positioning platform based on inchworm principle Sensors Actuators A 222 87–95 [271] Rakotondrabe M, Haddab Y and Lutz P 2009 Development, modeling, and control of a micro-/nanopositioning 2-DOF 35 Smart Mater. Struct. 30 (2021) 013002 Topical Review stick–slip device IEEE/ASME Trans. Mechatron. 14 733–45 [272] Zhang S, Liu J, Deng J and Liu Y 2019 Development of a novel two-DOF pointing mechanism using a bending-bending hybrid piezoelectric actuator IEEE Trans. Ind. Electron. 66 7861–72 [273] Yun C H, Yeo L Y, Friend J R and Yan B 2012 Multi-degree-of-freedom ultrasonic micromotor for guidewire and catheter navigation: the NeuroGlide actuator Appl. Phys. Lett. 100 164101 [274] Chen W M and Liu T S 2013 Modeling and experimental validation of new two degree-of-freedom piezoelectric actuators Mechatronics 23 1163–70 [275] Guo M, Hu J, Zhu H, Zhao C and Dong S 2013 Three-degree-of-freedom ultrasonic motor using a 5-mm-diameter piezoelectric ceramic tube IEEE Trans. Ultrason. Ferroelectr. Freq. Control 60 1446–52 [276] Chen Z, Li X, Liu G and Dong S 2014 A two degrees-of-freedom piezoelectric single-crystal micromotor J. Appl. Phys. 224101 1–6 [277] Liu Y T and Li B J 2016 A 3-axis precision positioning device using PZT actuators with low interference motions Precis. Eng. 46 118–28 [278] Li J, Liu H and Zhao H 2017 A compact 2-DOF piezoelectric-driven platform based on ‘Z-shaped’ flexure hinges Micromachines 8 1–14 [279] Tang C, Zhang M and Cao G 2017 Design and testing of a novel flexure-based 3-degree-of-freedom elliptical micro/nano-positioning motion stage Adv. Mech. Eng. 9 1–10 [280] Deng J, Liu Y, Li K, Su Q and Yu H 2018 A novel planar piezoelectric actuator with nano-positioning ability operating in bending-bending hybrid modes Ceram. Int. 44 S164–7 [281] Lin C, Shen Z, Wu Z and Yu J 2018 Kinematic characteristic analysis of a micro-/nano positioning stage based on bridge-type amplifier Sensors Actuators A 271 230–42 [282] Tian Y, Ma Y, Wang F, Lu K and Zhang D 2020 A novel XYZ micro/nano positioner with an amplifier based on L-shape levers and half-bridge structure Sensors Actuators A 302 111777 [283] Liu Y, Wang L, Gu Z, Quan Q and Deng J 2019 Development of a two-dimensional linear piezoelectric stepping platform using longitudinal-bending hybrid actuators IEEE Trans. Ind. Electron. 66 3030–40 [284] Liu Y, Yan J, Wang L and Chen W 2019 A Two-DOF ultrasonic motor using a longitudinal-bending hybrid sandwich transducer IEEE Trans. Ind. Electron. 66 3041–50 [285] Deng J, Liu Y, Liu J, Xu D and Wang Y 2019 Development of a planar piezoelectric actuator using bending–bending hybrid transducers IEEE Trans. Ind. Electron. 66 6141–9 [286] Liang C, Wang F, Huo Z, Shi B, Tian Y, Zhao X and Zhang D 2019 A 2-DOF monolithic compliant rotation platform driven by piezoelectric actuators IEEE Trans. Ind. Electron. 67 6963–74 [287] Ling M 2019 International Conference on Intelligent Robotics and Applications A Flexure-Based XY Precision Positioning Stage with Integrated Displacement PVDF Sensor vol 11740 LNAI (Springer International Publishing) [288] Zhang Q, Zhao J, Shen X, Xiao Q, Huang J and Wang Y 2019 Design, modeling, and testing of a novel XY piezo-actuated compliant micro-positioning stage Micromachines 10 19 [289] Liao C, Xu M, Xiao R and Han W 2020 Integrated design of piezo-actuated 2-DOF submillimeter-range super-resolution platform with self-sensing unit Mech. Syst. Signal Process. 139 106569 [290] Wang Y J, Yang C, Sue C Y and Wang Y T 2019 Analysis of a 0.1-µm stepping bi-axis piezoelectric stage using a 2-DOF lumped model Microsyst. Technol. 2 12 [291] Liu Y, Shi S, Wang D, Chen W and Xu D 2017 Research on the thermal characteristics of bending hybrid piezoelectric actuators under different exciting methods Ceram. Int. 43 S15–20 [292] Lipscomb I P, Weaver P M, Swingler J and McBride J W 2009 The effect of relative humidity, temperature and electrical field on leakage currents in piezo-ceramic actuators under dc bias Sensors Actuators A 151 179–86 [293] Weaver P M, Cain M G, Stewart M, Anson A, Franks J, Lipscomb I P, McBride J W, Zheng D and Swingler J 2012 The effects of porosity, electrode and barrier materials on the conductivity of piezoelectric ceramics in high humidity and dc electric field Smart Mater. Struct. 21 045012 [294] Technavio Research 2017 Global piezoelectric actuators and motors market drivers and forecast from technavio (available at: (https://www.businesswire.com/news/home/ 20170418005275/en/Global-Piezoelectric-ActuatorsMotors-Market—Drivers) (Accessed 25 December 2019) 36 View publication stats