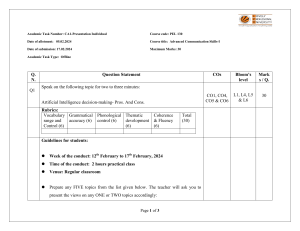

08/25/2022 rP os Version: ED0023 t Case: op yo ISSN 2594-116X Case AEInnova: From Science to Business Raúl Aragonés, the founder of a heat-recuperating start-up called AEInnova, was standing in front of his office in Terrassa (Barcelona), looking at a parked bicycle. It was a sunny summer morning of 2020 and he wondered how someone, centuries ago, had decided which use of the wheel would be the most interesting to try first. These strange thoughts came into his mind because at the moment, he needed to decide which application would be the most interesting for the innovative tC technology of his start-up. The time of only conducting research was coming to an end and they needed to commercialize if they wanted to keep their investors’ support. By next month’s Board meeting, AEInnova’s investors asked for a full launch and development plan of a first product. However, their possible product applications were only in a pilot stage and there was almost no financial information available. How could he decide which of the possible applications would be the most promising one to commercialize first? Which factors should he take into account to No decide this? He urgently needed to choose a path to take or his start-up would fail. The Entrepreneurial Journey Raúl Aragonés obtained a degree in Electronics Engineering from the Universitat Autònoma de Barcelona (UAB), where he also obtained an MS in computer architecture research and a PhD in Computer Science and Microelectronics1. After his PhD, he joined the Design of Integrated Circuits Do and Systems (DCIS) group, led by professors Dr. Carles Ferrer and Dr. Joan Oliver. Aragonés’ reAUTHORSHIP CREDITS This case was prepared by Professor Jordi Vinaixa and Research Assistant Winnie Vanrespaille from ESADE Business School. Teaching cases are developed solely as the basis for class discussion and are not intended to serve as endorsements, sources of primary data, or illustrations of effective or ineffective management. The case was made based on primary data and published sources. To order copies or request permission to reproduce materials, contact coleccion.cladea@gmail.com. Copyright © 2022 ESADE Business School. No part of this publication may be reproduced, stored in a retrieval system, used in a spreadsheet, or transmitted in any form or by any means --electronic, mechanical, photocopying, recording, or otherwise-- without the permission of the copyright holder. Acknowledgment: The development and writing of this case study was supported by the EIT InnoEnergy, funded by the European Union (Specific Agreement No. SGA GA2021 EIT IE). This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 t ED0023 rP os Case: search about wireless sensing networks and space technologies (energy harvesting) was fruitful; he published more than 30 papers in international conferences and journals and, in relation to the research, he supervised the first stage of Roger Malet’s PhD project about power maximization of thermoelectric converters. Aragonés inherited his creativity from his father, who obtained two patents by working on inventions in his free time. However, while his father was a mechanical inventor, Aragonés referred to himself as a “Climate Change Evangelist”. Following his dream and convinced that his op yo research could be converted into a business opportunity, he decided in 2012 to step down from his teaching position at the UAB to begin the challenging process of creating his own company to harvest energy. The next two years were sometimes difficult for Aragonés since he worked many hours without salary and had two young daughters at home. Aragonés could not have taken on the entrepreneurial journey without the help of his wife, who provided most of the family income during those years. Therefore, he decided, in 2013, to search for different sources of funds. To comply with funding requisites, Aragonés recruited five more engineers and PhD’s from his trusted network to complete the founders’ team. In 2014, Aragonés’ hard work finally paid off when they obtained backing from the Repsol Foundation Entrepreneurs Fund2. tC Finally, on October 17th, 2014, Alternative Energy Innovations S.L., or AEInnova, was born with the following mission: To develop thermoelectric energy generation systems that recover residual industrial heat to improve energy efficiency and reduce environmental impact. Aragonés valued his company at EUR 11,000, which was exactly the sum of money the founders No invested from their own pockets. He kept one third of the shares and was appointed CEO. From CEO to President In July 2015, Aragonés presented his company to ESADE BAN investors to obtain EUR 150,000 and got the attention of several Business Angels, particularly from David Comellas3 who was en- Do thusiastic about AEInnova and described Aragonés as a “scientist who likes to sell”. p. 2 The enthusiasm of Comellas delighted Aragonés, and the next day at work, when he saw the somewhat chaotic office, he thought that AEInnova could use someone with business expertise, so he invited Comellas to visit the office. During that visit, Comellas saw that AEInnova was still much more a university spin-off than an industrial company. Moreover, he noticed that not all the co-founders were as diligent as Aragonés. Nevertheless, he saw potential in the company and accepted Aragonés’ proposal to become an investor of AEInnova and simultaneously offered his services as a business associate, to organize accounting, finance and other business issues. This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 t ED0023 rP os Case: After some fruitful months working together, Comellas helped Aragonés see that most of the co-founders were not committed enough to the development of AEInnova, mostly because they were still working other jobs and could not dedicate enough time to AEInnova. However, Aragonés had known them for so long that he did not feel comfortable firing any of them or even quarrelling with them. In fact, he felt that it was the right moment to step down from his position as CEO. AEInnova was getting bigger and an external CEO, with a sound business experience, could manage the start-up better and help it grow more and faster. He thought that Comellas was the perfect person to take on this role. Comellas, convinced of AEInnova’s potential, accept- op yo ed Aragonés’ proposal and by the summer of 2016 he stepped in as AEInnova’s new CEO. Raúl Aragonés kept the position of President of the Board and became the new Business Development Officer. Comellas was glad about this decision and thought that their personalities were very compatible, as he described: Raul is a dreamer who is in love with his technology. I, on the contrary, am more a “Mister No” who keeps his feet on the ground. Together we can make AEInnova big. Immediately after taking office as CEO, Comellas restructured the company: some of the co-founders stepped down from their jobs at AEInnova, while others continued to collaborate, but under a contract agreement with their universities. All of them remained as shareholders. tC The Technological Breakthrough Back in the days that Aragonés was researching energy harvesting technologies at the UAB’s DCIS group, he was especially inspired by the technology of Radioisotope Thermoelectric Generators (RTGs). RTGs used the Seebeck effecti to convert waste heat of radioactive decay into electricity.4 He was convinced that this technology could also have useful applications to reuse waste No heat from industrial processes. To figure out the scale of the waste heat problem, Aragonés carried out market research. The results were both appalling and promising: appalling because there was a huge problem of waste heat and promising because this opened an interesting business opportunity. According to a 2015 study in EU-28, some 304 Terawatt-hours of industrial waste heat per year could potentially be recovered (see Exhibit 1). The technology to convert industrial waste heat into electricity with Do “inverted Peltier cells” already existed. However, it was only capable of recuperating one or two p. 3 Watts for a 100 ℃ thermal gradient. This particularly low yield was due to the interferences that appear when trying to build up electricity by adding up Peltier cells. Their research led them to design a new electronic component, based on System-on-Chip technology,ii that allowed hundreds of those inverted Peltier cells to work together without the interferences mentioned above (see Exhibit 2).5 This new electronic component allowed them to i The Seebeck effect is a phenomena of a differential in temperature between two ends that generates an electric voltage and vice-versa. ii System-on-chip (SoC) is an integrated circuit that includes a processor, a bus, and other elements on a single monolithic substrate. This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 t ED0023 rP os Case: recuperate up to 20% of the wasted heat and they realized that they had something unique and very valuable on their hands. Thus, in 2016, to protect their invention, AEInnova filed a patent for this newly developed technology, for application in the United States (US), Canada and in the four European countries with the most heat intensive industries (Germany, the United Kingdom, Spain and Italy). The patent (Pub. No. US 2018/0138701 A1) was finally published in 2020. When Aragonés created AEInnova, the UAB also wanted their piece of the pie. However, the Repsol Foundation had pre- op yo viously recommended them to leave out any political or educational organisation if they wanted the company to grow quickly. Following this advice, instead of shares, Aragonés gave 3% of royalties on the sales of their patented technology to the UAB. Moreover, AEInnova would be defined as a UAB spin-off, and the University provided them with a working space in its research park. The Search for a Thriving Application Although Aragonés was convinced that their technology had an important industrial potential, he was not sure which application could deliver the most value and help the company thrive. tC PV-panel Performance Improvement Aragonés, Malet and Oliver discovered a potential first application in a scientific article about the efficiency of photovoltaic (PV) panels. The article explained that the efficiency depended a lot on the temperature of the panel and that efficiency could decrease more than 30% during hot summer months. Panels were often cooled by applying cold water on them with pumps and sprinklers, wasting huge amounts of water and energy. Aragonés’ team saw an opportunity for his patented No technology: cooling PV-panels, and additionally, converting the heat transferred into extra electricity, and thus greatly increasing their efficiency. He worked on this idea, together with a team of students from the EIT InnoEnergy6 Master program in Renewable Energy (MSc RENE) for six months, checking the prices of PV-panels and calculating the efficiency they could obtain by using their technology (see Exhibit 3). The results of this analysis were that the performance of the PV-panels could increase by more than 40% during summer months. However, the PV-panel cost was constantly decreasing, making it unclear if customers would prefer buying more panels, Do or if they would prefer increasing the performance of their existing ones. However, the PV-pan- p. 4 el industry was booming worldwide,7 making it an interesting application in Aragonés’ opinion. Industrial Waste Heat Recovery Another obvious and immediate application of their technology was the large-scale industrial waste heat recovery from boilers, chimneys, pipes, etc. With their technology, lost heat could be converted into electricity, and put to use in different processes. Since the energy could come from This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 t ED0023 rP os Case: a continuous heat source, it could also become an important energy source for processes that need to be working continuously, even during power outages. The first thing they did to verify the viability of their technology for industrial heat recovery, was to develop a prototype consisting of six Peltier cells, a heat source, and a water circuit to create a cool side. This construction, together with the electric chip, operated as an electricity source to supply a 220 Volt pump (see Exhibit 4). The cost of this prototype was around EUR 3,100, paid with the Repsol Foundation grant. Nevertheless, Aragonés estimated that in recurrent production they could lower the production cost op yo to some EUR 500 per unit. At the time, the system was only capable of recuperating on average 120 Watts per square meter (W/m2) of contact surface, which would not give enough energy savings when compared to the low electricity prices that industrial plants around Europe were paying (see Exhibit 5). Therefore, they first needed to obtain higher heat recovery potentials before they could commercialize this application. This would require some five more years of research and development. Once their prototype worked at lab scale and showed its capability of converting almost any heat source into electricity, Aragonés decided to name it the “Waste Heat Recovery Unit” (WHRU).8 The first industrial test of the prototype in real conditions was done on a boiler in the Engineering school of the UAB. A Spanish newspaper, La Vanguardia, published an article about that pilot project, which got into the hands of a manager of the car manufacturer company SEAT (Volkswagen Group). The next day the manager presented the article to his boss, who showed immediate interest and offered AEInnova a pilot project in their plant in Martorell, tC Catalunya (see Exhibit 6). This second pilot project not only provided them with EUR 30,000, but also with important media impact and a valuable professional image. While analysing the performance of the installed WHRU in the chimney of the factory, their contact person at SEAT asked them to use the recuperated heat to supply electricity to a critical sensor close to the chimney. That provided great insight: Aragonés realized that they could easi- No ly convert small heat sources into electricity supplies for Internet of Things (IoT) applications. 9 IoT Monitoring Applications The energy supply for IoT-devices was usually complex and especially burdensome in chemical plants, where the maintenance of both the cabled and the battery versions was very labour intensive and costly. Although cabled devices were relatively cheap (EUR 50-100), they required ex- Do pensive cabling (according to Aragonés’ own analysis between EUR 50-70 per meter) and could not be used everywhere. On the other hand, battery powered devices could cost EUR 200-300/ year for battery replacement. Additionally, these devices often needed costly repeaters (up to EUR 5,000/each) every 50-200 meters. Moreover, in Explosive Atmospheres (AtEx-zones), the costs increased because the lithium batteries used for wireless sensors needed to be very large and very well protected, since lithium is potentially explosive. Aragonés became fully aware of the real need for a sustainable and secure source of electricity for IoT-monitoring devices. p. 5 This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 t ED0023 rP os Case: At the same time, AEInnova was contacted by Soul-Fi, an accelerator focused on SME’s developing innovative web-based solutions for smarter urban life for European citizens.10 Soul-Fi offered AEInnova to partner with the University of Coimbra (Portugal) in an application for EC funds to study the application of heat harvesting for IoT. As they had done with the WHRU, they developed a prototype to test the potential of their technology for IoT-devices. Malet assembled their system-on-chip, containing the proprietary microelectronic technology, with the Peltier-cells and other electronic and mechanical pieces and added all this to the IoT-device. By the end of 2016, they were ready to start testing the prototype. They called it “Indu-Eye”, because their IoT-devices op yo were supposed to become the “eyes” of the industry.11 Once the product was fully developed, they could use it with almost any type of sensor. This, together with the battery-less characteristic, made it an interesting device with low maintenance costs and a minimal environmental impact. Considering the whole cycle of manufacturing and usage, the Indu-Eyes could entail a reduction of up to 95% in CO2, energy, heat and water use, in comparison with batteries. Moreover, due to the great amount of energy that the device could produce, Indu-Eye would be able to use long-range wireless protocols with big bandwidth. To connect the Indu-Eye devices to the internet, a Low-Power Wide-Area Network (LPWAN) was necessary. Exhibit 7 shows a comparison of two of the most important technologies of the LPWAN-family: Long-Range Wide-Area Network (LoRaWAN) and Narrowband IoT (NB-IoT). tC Nevertheless, Aragonés was worried that their technology could be copied once they started using the prototype in pilot projects since their patent of the thermoelectric power generating system was only covering the WHRU application. Although Indu-Eye used the know-how of thermoelectric equipment design gained during the WHRU development, it did not incorporate the patented technology, and they needed to find an appropriate way to protect their development. He had heard many horror stories about companies that spend a lot of money on patents, but that were still copied through small changes in products or technologies. Trying to sort out this dilemma, No Comellas came up with the idea of covering the microchip, containing the encrypted information, with a hard resin, embedding the whole generation unit. It was a great idea to protect the technology since the device could not be hacked without destroying the microelectronic cell, and it was a lot cheaper and less burdensome than patenting. To test the first prototype of the Indu-Eye device, Aragonés convinced Repsol to perform a pilot with a prototype that included a sensor to monitor vibrations at their factory in Puertollano (Castilla-La Mancha). By the summer of 2017, they already had the pilot project confirmed and the IoT-device installed on an oil refrigerant Do pipeline. The communication technology used for this pilot was LoRaWAN for internet connec- p. 6 tion (see Exhibit 7.1). The pilot was a success and the Indu-Eye LoRa Vibro sensor still worked perfectly after more than two years of operation. As it had happened with the WHRU, AEInnova was now winning awards for the Indu-Eye product, including the Best Solution for Innovative Technology at the IoT Solutions World Congress of 2017. This award got the immediate attention of Vodafone, who as a telecommunications company was interested in AEInnova’s technology for their IoT data exchanges. They proposed to partner with AEInnova to develop Indu-Eye powered sensors with NB-IoT communication infrastruc- This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 t ED0023 rP os Case: ture, an alternative technology for LoRaWAN that worked with SIM cards (as in cell phones) to connect devices to the Internet (see Exhibit 7.2). Vodafone invited AEInnova to present their IoT technology, using Vodafone SIM-cards, in their stand at the Mobile World Congress of 2018 in Barcelona. At the congress, oil company Cepsa discovered the Indu-Eye products and offered AEInnova a paid pilot in some of the AtEx-zones of their plant in Huelva (Andalusia), again to monitor vibrations, but this time with NB-IoT communication infrastructure. This pilot was also a success and the Indu-Eye NB-IoT Vibro was technically validated. At the time, other big telecom companies were also developing their NB-IoT infrastructure solutions for IoT. Some of them op yo tested the Indu-Eye with their SIM-cards, showed interest to invest in AEInnova, and even foresaw possibilities to become AEInnova’s official technology partner for NB-IoT industrial sensors. For telecom companies, it was essential to enter the market of industrial IoT-devices because there was a huge data transfer market that was just opening. Additionally, they had to get in it very fast to gain the largest possible market share, because by becoming the suppliers of the entire infrastructure of an industrial company, they would create a very high entry barrier for other telecom companies. An Indu-Eye based business seemed very promising (see Exhibit 8). Nevertheless, to be able to sell it in the European Economic Area, a separate CE-certification for every new component (thermoelectric generator, wireless node, and sensor) was needed. This was a very costly and tC slow process, normally performed by an external company. Moreover, to sell sensors for installation in AtEx-zones, every component also needed an AtEx certification, including for manufacturing, making it even more costly.There was only one Spanish company that could do this: Laboratorios Madariaga.12 No The Competitive Landscape There were many companies researching and selling cooling panel solutions, using different tech- nologies. However, most of those solutions were unable to achieve the efficiency increases that AEInnova could with its technology. Moreover, the option of buying new PV-panels rather than having more efficient panels could be seen as a competitive solution in many cases. AEInnova was also not the only player in the market for heat harvesting. There were many com- Do panies that converted different energy sources (solar, thermal, vibration, etc.) into electricity. For example, Matrix Industries13 a company based in Silicon Valley, was even using body-heat to supply energy for watches. Luckily for AEInnova, not many of those companies were selling or developing industrial solutions, although there were some companies, such as II-VI Incorporated,14 that were recuperating heat to supply small industrial equipment. Nevertheless, a real competitor of the WHRU, capable of generating the same amount of energy per square meter, did not exist yet. This was of course a good thing, but it also meant that Aragonés had to evangelise to convince some early adopters to start using their technology. p. 7 This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 t ED0023 rP os Case: One of AEInnova’s main competitors in wireless, battery-less sensors was Everactive,15 an American company that used different energy sources (solar, thermal, vibration, etc.) for IoT devices. However, the thermal batteries developed with their technology were less efficient than Indu-Eye. The energy generation they produced was so low that they could not use long-range communications, and had to use short-range wireless communication technologies, like Bluetooth, incapable of sending data over very long distances. Regarding the battery powered IoT-devices, their main disadvantage was that they could not use long-range communication without having to change the batteries constantly. Moreover, they were costlier (around EUR 2,000/unit) than Indu-Eye op yo (estimated price of EUR 1,000-1,300). Next steps Exhibit 9 shows AEInnova’s sources of funding since its inception. Comellas and Aragonés were satisfied with the funding received, and even more so with the fact that almost half of it came from public sources, which meant that it did not generate dilution of the founders’ equity. Moreover, they knew that many big technology competitors were not yet evolving to the industry 4.0iii paradigm.16 That could allow AEInnova to become the disrupter triggering a wave of creative destruction of the last century industry incumbents. This idea was aligned with Aragonés’ dream: tC We want to become the industrial processes digitalization stakeholder of reference. We want AEInnova to become the Apple of the IoT business. They had never thought of selling the company to make money, but as an exit strategy for their investors, they were already planning to go public. However, before they could realise their dream, they had to prove the viability of their technology by commercializing a first product. No The results of the pilots were very promising and AEInnova was earning many accolades and prizes (see Exhibit 10). Aragonés considered these awards, grants and funds as a validation of the attractiveness of their technology. However, although they had already considered ways of marketing (through engineering offices, commercial agents, key account managers, etc), Aragonés could not entirely celebrate those achievements before having sold their first product. AEInnova’s investors were becoming especially impatient since they wanted to see some com- Do mercial results from their investments. Aragonés was having sleepless nights. He only had one p. 8 month to develop a plan to launch a first product, and they did not have the resources (money, people, etc.) to commercialize more than one product at the time. He urgently had to decide which of their technology applications they should concentrate on and which go-to market strategy they should use to make AEInnova thrive. iii Industry 4.0 represents the fourth revolution in manufacturing, enhancing the third revolution (adoption of automation) with smart and autonomous systems fuelled by data, machine learning and IoT. This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 rP os 500 Te x til e & Ot he r at he r Le tru ct io n uc ts ns d Co d Qu & 300-400 °C 200-300 °C 100-200 °C <100 °C Non-ferrous metal Chemical Non-metallic - Food, drink & tobacco mineral Paper & printing Other industries an d in W oo Fo o in 400-500 °C sp 500-1000 °C dr M g Pr od hi ry ne ry t en ac M in or tE qu Pr & m tin g co ac Pa p & k in er to b in m Tr an tC 120 d, Waste heat potential (TWh/year) >1000 °C 160 lic al et -m on N 200 er al l ic a em et al Ch us rro -fe N on Iro n & St ee l 0 op yo 100 ar 200 W oo 300 in g EU-28 industrial heat consumption: 1820.73 TWh/year 400 m Heat consumption (TWh/year) 600 ip Exhibits Section t Exhibit 1. Heat Consumption and Waste Heat Recovery Potential of Europe in 2015 17 80 40 No 0 Iron & Steel EU-28 Waste Heat Potential per country un 2015 (TWh/year) 80 70 60 50 40 20 10 0 Au st Be ria lg i Bu um lg ar Cr ia oa t C ia Cz ypr ec us h De Rep nm a Es rk to n Fi ia nl an Fr d a Ge nce rm an Gr y ee H ce un ga Ire ry la nd Ita l La y Li tvi a t Lu hua xe n m ia bo ur g N et Ma he lta rla nd Po s la Po nd rt Ro uga m l a Sl nia ov a Sl kia ov en ia Sp Un a ite Sw in d ed Ki en ng do m Do 30 p. 9 This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 Exhibits Section t rP os Exhibit 2. AEInnova’s technology Peltier cells can work as generators when submitted to a thermal gradient (Seebeck effect) or absorb energy to generate a temperature differential between their two faces (Peltier effect). These effects have two problems: 1. Power self-consumption: When connecting more than one Peltier cell either in series or in parallel at different temperatures, a self-consumption effect may take place, meaning that the energy generated by one cell may end up being consumed by another cell. 2. Possible heating of the cold cell side and cooling of the hot cell side decreases the tem- op yo perature gradient, while this gradient is needed for electricity production. The electronics of AEInnova’s products is completely controlled by System on chip technology. This allows reduce of costs, improved reliability and repeatability. AEInnova’s electronics design, together with the System on chip technology, allowed the reduction of the above mentioned heating/cooling and self-consumption effects. Malet was the technology architect of this patent. Exhibit 3. PV-panel cooling study, by Aragonés and MSc RENE students tC Problem The efficiency of a solar panel is reduced by its heating, in a proportion that, depending on the type of cell, is around 0.30% per degree Celsius (ºC). This means that a solar panel at 50 ºC is 6% less efficient than a solar panel at 30 ºC. Solution No The concept of the PV panel cooling study was intended to improve the performance of PV solar panels by passive cooling, using Peltier cells and the patent of Aragonés. For the development, Aragonés and the MS RENE students used a matrix of 4 Peltier cells on a PV panel and managed as such to lower the temperature to 8 °C on a cloudy day in February (worst case scenario), implying an improvement in the performance of the panel by about 8%. However, they calculated that they could increase the efficiency of the panel by 40% during sunny summer days. As such, they estimat- Do ed a mean efficiency increase of 24% every day of the year (during more or less 6 hours per day). p. 10 Cost (2018 data) ≈ Average cost of a 100 Watt (W) solar panel: EUR 40 ≈ Average cost of a Peltier cell for 100 W panel: EUR 600; for 4 cells: EUR 2,400 ≈ Average electricity prices (taxes and levies included) in Spain and the European Union:18 2018 – Second Semester EU (28 countries) Spain 0.21 €/kWh 0.25 €/kWh This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 t rP os Exhibit 4. Prototypes of AEInnova’s Waste Heat Recovery Unit 19 op yo Exhibits Section Exhibit 5. European industrial plants yearly electricity consumption in 2018 and average electricity prices by sector from 185 plants 20 1,000 100 80 60 40 10 20 le Do Pa c Ta b as s Gl w ar ka w e gi ns n tre g G am la ss Al u N m itr in og iu m en Fe rti lis er St ee lE AF Re fin er ie s St Pr ee im l ar BO y Al F um in iu m iu s in um rT ile Al ry da Se c on l& Fl oo Ti le d Ro of W al m 0 s 1 an ks ic Br 140 120 100 No Do 160 Electricity Price €/MWh Electricity consumption (GWh) tC 10,000 Median Electricity Consumption Average Electricity Price €/MWh p. 11 This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 t rP os Exhibit 6. WHRU prototype in SEAT factory of Martorell (Spain) Do No tC op yo Exhibits Section p. 12 This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 Exhibits Section t rP os Exhibit 7. Comparison of LongRange Wide-Area Network and Narrowband IoT 21 LoRaWAN and NB-IoT are both Low-Power Wide-Area Network (LPWAN) technologies that can serve devices in multiple IoT markets (utilities, smart buildings, logistics/asset tracking, industrial/smart manufacturing, smart agriculture, etc.). The table below shows a comparison of the two technologies.22 Technology Parameters LoRaWAN NB-loT 125 kHz 180 kHz Coverage 165 dB 164 dB Battery Life Peak Current Sleep Current Throughput Latency Security Geolocation Cost Efficiency (Device and Network) Technology Comparison Bandwidth op yo Bandwidth 15+ years 10+ years 32 mA 120 mA 1µA 5µA 50 Kbps 60 Kbps Device Class Dependent <10 s AES 128 bit 3GPP (128 a 256 bit) Yes (TDOA) Yes (en 3GPP Rel 14) High Medium Coverage Battery Life Cost Efficiency Throughput Geolocation Security Latency LoRaWAN NB-loT Source: ABI Research tC 7.1. LoRaWAN IoT-protocol and advantages Long-Range Wide-Area Network (LoRaWAN) is an open LPWAN system architecture developed and standardized by the LoRa Alliance, a non-profit association of more than 500 member companies. This technology is patented by Semtech, which charges a fee on each LoRa chipset No in sensors and gateways. LoRaWAN consumes less power than NB-IoT and thus has a longer battery life. Additionally, by using the unlicensed spectrum, it also has a lower total cost of ownership. Moreover, LoRaWAN has better indoor penetration capabilities (higher coverage). LoRaWAN’s is a good solution for enterprise private networks that want complete control over their infrastructure and devices. Lastly, in April 2019 there were more LoRaWAN networks than NB-IoT networks (113 LoRaWAN net- Do works and only 90 NB-IoT networks) worldwide. p. 13 This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 t rP os Exhibits Section 7.2. NB-IoT IoT-protocol and advantages NB-IoT is a radio technology standard that operates in the licensed spectrum, so acquisition of Radio Frequency spectrum from network operators is needed. This technology covers cellular telecommunications technologies, which provide a complete system description for mobile telecommunications. NB-IoT devices are moving towards embedded SIM (eSIM) usage. NB-IoT is a more secure solution than LoRaWAN. Moreover, it has a higher throughput and usually also a lower latency than LoRaWAN. This all makes NB-IoT better suited for commercial and op yo consumer IoT applications requiring connectivity at a great scale. 7.3. Worldwide LPWAN connections by technology from 2017-2023 (estimation) 23 Number of LPWAN connections by technology worldwide from 2017 to 2023 (in millions) 800 tC Number of connections in millions 1000 600 400 No 200 0 2017 2018 Sigfox 2020 NB-loT 2021 LTE-M 2022 2023 Other Source: IHS. Statista Do LoRa 2019 p. 14 This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 rP os Exhibits Section t Exhibit 8. Internet of Things (IoT) as a promising technology 8.1. Global IoT revenue by technology segment from 2018 until 2023 (estimation) 24 Global loT revenue by technology segment ($bn), 2018-2023 350 300 55 op yo USD$(bn) 250 200 37 26 150 100 16 13 50 101 0 31 2018 2019 2020 Software and services 226 190 161 143 127 30 24 20 17 37 44 2021 2022 Connectivity Devices 2023 Source: GlobalData, Technology Intelligence Centre tC Source: GlobalData, Technology Intelligence Centre 8.2. Global share of IoT projects in 2018 25 loT Segment Details Global share of loT projects¹ Americas Europe 1 Smart City 2 Connected Industry 3 Connected Building 4 Connected Car 5 Smart Energy 6 Other 7 Connected Health 6% 8 Smart Supply Chain 5% No Do p. 15 Insights that empower you to understand loT markets 2018 23% 17% 12% 11% 10% 8% 9 Smart Agriculture 4% 10 Smart Retail 4% N=1,600 global, publicly announced loT projects Americas Europe MEA N/A APAC APAC 34% 45% 18% 45% 31% 20% 53% 33% 13% 54% 30% 12% 42% 35% 19% 50% 34% 11% 55% 29% 15% 49% 36% 12% 39% 26% 31% 53% 35% 9% Trend² 1. Based on 1,600 publicly known enterprise loT projects (Not including consumer loT projects e.g., Wearables, Smart Home). 2. Trend based on comparison with % of projects in the 2016 loT Analytics Enterprise loT Projects List. A downward arrow means the relative share of all projects has declined, not the overall number of projects. 3. Not including Consumer Smart Home Solutions. Source: loT Analytics, Jan 2018 Source: loT Analytics, Jan 2018 This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 Name Pre-seed Funding 2014 Seed Funding 2015-16 Valuation: 11,000 1 M* Co-founders 11,000 Awards & prizes (Exhibit 10) 17,500 Repsol Foundation 312,000 11,500 Funding Round 2 2018 Funding Round 3 20182020 2 M** 3.65 M** 4.25 M** Company Shares 2020 14,588 55.4% 1,500 / / Public Grant: SME instrument of Horizon2020 50,000 / Public Grant: FIWARE project of Horizon2020 75,000 / Public Grant: NEOTEC program of CDTI 196,000 Public Grant: LIFE program, HEAT-R / 636,000 / 294,000 / Public Grant: H2020 EIC Pilot Indu-Eye 2.0 507,000 / Public Grant: Nuclis d’economia Circular 130,000 tC Public Grant: H2020 Harvestore Project David Comellas 30,000 3,000 Acceleration fund (InnoEnergy) 160,000*** 33,986 7 ESADE Business Angels / 2.2% 17,865 14.1% 175,411 7.4% 100,000 2.6% CxC Renovables 650,000 13.4% No Sabadell bank Former Vice-president BASF Europe 200,000 4.9% Internal bridge investment round 399,000 included above 1,530,000 100% TOTAL: Do t Funding Round 1 2017 op yo Exhibits Section rP os Exhibit 9. AEInnova’s Public Grants and Private Funding (in EUR) 340,500 326,500 424,485 1,403,865 * Post-money valuation ** Pre-money valuation *** Funding in two tranches: 100,000 with a call option for 10% of founders shares plus EUR 60,000 with a call option for a 5% of founders’ shares. They executed the call option in 2016. p. 16 This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 Exhibits Section Year Name First award Repsol Foundation 2014 First award EcoEmprendedor XXI First Award Green Building Council First Award UAB Ideas Program First Finalist United Nations Award Ideas4Change First Finalist Everis Foundation Award 2016 No Do 2018 2019 2020 t 312,000 15,000 Free booth in Construmat 2,500 Start-ups Incubation program 50 hours business consultancy 5,000 First Award Cafè Aventura (Sabadell Municipality) 1,500 First Award Caixa d’Enginyers Emprenedoria 5,000 First Finalist Emprendedor XXI 50 hours business consultancy European Commission Seal of Excellence First Finalist Energy Transition Awards of German Energy Agency DENA Mission to World Energy Forum First Finalist Advanced Factories Fair, category innovation in industry 4.0 - Best innovative technology of IoT World Congress Free marketing campaign First Finalist Spanish corporate awards by EnerTIC - First Award Acció, Best Catalan Startup 150 hours of international commercialization support First Award “The one to watch” of European Business Angel Network (EBAN) 1,500 European Commission Seal of Excellence La SalleDemoDay. BestStartup. - First Award Chamber of commerce of Terrassa. - SECOT “Revelation Entrepreneurs of the Year” - First Award Go!ODS from United Nations, Global compact for SDG-7 (affordable & Clean Energy) - European Commission Seal of Excellence StartupOle: the best European Energy Startup 40,000 € in Amazon Web Services Association of Engineers of Catalonia: First Award Industry 4.0 - European Commission Seal of Excellence First Award G-STIC (Global Sustainable Technology & Innovation Conference) Free booth Chinese tech fair European Commission Innovation Radar: Top EU Key Innovator for autonomous sensors node - tC 2017 First Award Volkswagen Think Blue Money / Prize received (EUR) op yo 2015 rP os Exhibit 10. AEInnova’s Awards and Prizes p. 17 This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860 t NOTES rP os Exhibits Section 1 For more information: https://www.linkedin.com/in/ra%C3%BAl-aragon%C3%A9s-ortiz-phd77bb9a60/?originalSubdomain=es 2 For more information: https://www.fundacionrepsol.com/en/entrepreneurs-fund 3 For more information: https://www.linkedin.com/in/davidcomellas/?originalSubdomain=es Jiang, Mason (March 2013). An Overview of Radioisotope Thermoelectric Generators. Submitted as coursework for PH241, Stanford University. Retrieved from http://large.stanford.edu/courses/2013/ ph241/jiang1/ 4 For more information: https://www.sciencedirect.com/topics/engineering/system-on-chip 5 For more information: https://www.innoenergy.com/for-students-learners/master-school/master-s-in-renewable-energy op yo 6 7 For more information: https://www.alliedmarketresearch.com/solar-photovoltaic-panel-market 8 For more information: https://aeinnova.com/wrhu/ For more information https://www.forbes.com/sites/jacobmorgan/2014/05/13/simple-explanation-internet-things-that-anyone-can-understand/#1ce2e61d1d09 9 For more information: https://www.fiware.org/about-us/ 11 For more information: https://aeinnova.com/indu-eye/ 12 For more information: http://www.lom.upm.es/ 13 For more information: https://www.matrixindustries.com/ 14 For more information: https://ii-vi.com/product-category/products/thermoelectrics/power-generators/ 15 For more information: https://everactive.com/ tC 10 Marr, B (2018). What is industry 4.0? Here’s a super easy explanation for anyone. Retrieved from https://www.forbes.com/sites/bernardmarr/2018/09/02/what-is-industry-4-0-heres-a-super-easy-explanation-for-anyone/#2d4e412b9788 16 Papapetrou, M. et al. (June 2018). Industrial waste heat: Estimation of the technically available resources in the EU per industrial sector, temperature level and country. Retrieved from https://www.sciencedirect. com/science/article/pii/S1359431117347919 17 Eurostat (2020). Electricity prices for household consumers - bi-annual data (from 2007 onwards). Retrieved from https://ec.europa.eu/eurostat/databrowser/view/nrg_pc_204/default/table?lang=en No 18 For more information: https://www.technologyreview.es/s/4779/aeinnova-podria-convertir-hasta-el-20-del-calor-residual-industrial-en-electricidad 19 CEPS and Ecofys (October 2018). Composition and Drivers of Energy Prices and Costs: Case Studies in Selected Energy Intensive Industries – 2018: Final Report. Retrieved from https://www.ceps.eu/wp-content/uploads/2019/01/ET0318091ENN.en_.pdf 20 21 For more information: https://ubidots.com/blog/lorawan-vs-nb-iot/ ABIresearch (June 2019). LoRaWAN and NB-IoT: Competitors or complementary? Retrieved from https://lora-alliance.org/resource-hub/lorawan-and-nb-iot-competitors-or-complementary Do 22 23 For more information: https://ubidots.com/blog/lorawan-vs-nb-iot/ For more information: https://www.windpowerengineering.com/global-iot-market-to-reach-318-billion-by-2023-says-globaldata/ 24 25 For more information: https://iot-analytics.com/top-10-iot-segments-2018-real-iot-projects/ p. 18 This document is authorized for educator review use only by Shahbaz Abbas, NUST - National University of Science and Technology until Mar 2024. Copying or posting is an infringement of copyright. Permissions@hbsp.harvard.edu or 617.783.7860