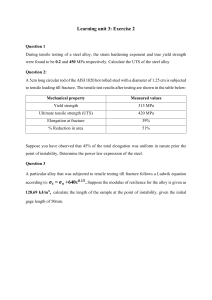

School of Biomedical Engineering International University – Vietnam National Universities HCMC Machine Design Engineering Materials and their Properties Contents 1 Classification of Engineering Materials 2 Physical properties 3 Mechanical properties 4 Chemical properties Materials Science and Engineering structure • arrangement of internal components • subatomic • atomic • microscopic • macroscopic (bulk) characterization properties processing • method of preparing material performance • behavior in a particular application • material characteristic • response to external stimulus • mechanical, electrical, thermal, magnetic, optical, deteriorative Classification of Materials Metals Ceramics & Glasses Polymers • good conductors of electricity and heat • lustrous appearance • susceptible to corrosion • strong, but deformable • thermally and electrically insulating • resistant to high temperatures and harsh environments • hard, but brittle • very large molecules • low density, low weight • maybe extremely flexible Classification of Materials: A Few Additional Catagories Biomaterials Semiconductors Composites • implanted in human body • compatible with body tissues • electrical properties between conductors and insulators • electrical properties can be precisely controlled • consist of more than one material type • designed to display a combination of properties of each component Intel Pentium 4 fiberglass surfboards Why study materials? ❖ applied scientists or engineers must make material choices ❖ materials selection ▪ in-service performance ▪ deterioration ▪ economics BUT…really, everyone makes material choices! aluminum glass plastic Classification of Materials Classification of Engineering Materials The engineering materials are mainly classified as : 1. Metals and their alloys, such as iron, steel, copper, aluminium, etc. 2. Non-metals, such as glass, rubber, plastic, etc. The metals may be further classified as : (a) Ferrous metals, (b) Non-ferrous metals. Selection of Materials for Engineering Purposes The following factors should be considered while selecting the material : 1. Availability of the materials, 2. Suitability of the materials for the working conditions in service. 3. The cost of the materials. Classification of Engineering Materials Metals Semiconductor Steel reinforced concrete Polymers Ceramics Concrete Physical properties ❖colour –light wave length ❖specific heat – the heat required to raise the temperature of one gram of a substance by one degree centigrade (J/kg K) Physical properties ❖density – mass per unit volume expressed in such units as kg/cm 3 ❖thermal conductivity – rate at which heat flows through a given material (W/m K) Physical properties ❖melting point – a temperature at which a solid begins to liquefy ❖electrical conductivity – a measure of how strongly a material allows the flow of electric current (Ω⋅m) Physical properties ❖Optical properties – response to light ▪ index of refraction – bending of light ▪ transparent – light passes through ▪ translucent – some light passes through but no distinct image ▪ opaque – no light passes through Physical properties ❖coefficient of thermal expansion – degree of expansion divided by the change in temperature (m/°C) Mechanical properties ❖tensile strength – measures the force required to pull something such as rope, wire, or a structural beam to the point where it breaks ❖ductility – a measure of how much strain a material can take before rupturing Mechanical properties ❖malleability – the property of a material that can be worked or hammered or shaped without breaking ❖brittleness –breaking or shattering of a material when subjected to stress (when force is applied to it) Mechanical properties ❖elasticity – the property of a material that returns to its original shape after stress (e.g. external forces) that made it deform or distort is removed ❖plasticity - the deformation of a material undergoing non-reversible changes of shape in response to applied forces Mechanical properties ❖toughness – the ability of a material to absorb energy and plastically deform without fracturing ❖hardness – the property of being rigid and resistant to pressure; not easily scratched Mechanical properties ❖machinability – the property of a material that can be shaped by hammering, pressing, rolling Chemical properties ❖corrosion resistance - a material's ability to resist deterioration caused by exposure to an environment Properties of Materials Which properties do the following materials possess? Material Properties Aluminium lightness; strength Rubber elasticity; insulation Ceramics thermal resistivity Steel strength Copper conductivity; corrosion resistance Lead high density; ductility Nylon strength; toughness Cast iron damping capacity Wood insulation; environmental friendliness Properties of Materials Find application for the following engineering materials: Material Applications Aluminium foil; aircraft; window frame Rubber tyres; seal; gasket Ceramics furnace; brick Steel section; pipe Copper pipe; cables Lead storage battery; radiation protection ballast; bullets Nylon rope; clothing Cast iron engine block; valves Wood furniture; deck Physical Properties of Metals Physical properties of metals Material with greatest density Tungsten - 19300 kg/m3 Uranium - 19100 kg/m3 Lead - 11340 kg/m3 Steel - 7800 kg/m3 The strongest material Material Tensile Strength UTS (Ultimate Tensile Strength) Carbon nantotubes 62000 MPa (theoretical 300000 MPa) 48000 kNm/kg Carbon fiber 5650 MPa 3200 kNm/kg Glass fiber 4700 MPa 1340 kNm/kg Spider web 1000 MPa 900 kNm/kg high-strength steel 1200 MPa 154 kNm/kg The best conductor Material Silver Conductivity 63 x 106 S/m (1/ohm) Copper 59.6 x 106 S/m (1/ohm) Gold 45.2 x 106 S/m (1/ohm) Aluminium 37.8 x 106 S/m (1/ohm) The best insulator Material Specific resistance Polyethylene terephthalate (PET) 1020 ohm Glass 1014 ohm Rubber 1013 ohm Material Strength and Stiffness The standard tensile test is used to obtain a variety of material characteristics and strengths that are used in design. The load is converted to stress by the calculation Material Strength and Stiffness The deflection, or extension of the gauge length, is given by l − l0 where l is the gauge length corresponding to the load P. The normal strain is calculated from Stress-strain diagram obtained from the standard tensile test (a) Ductile material; (b) brittle material. Material Strength and Stiffness Material Strength and Stiffness Hooke’s law where E is called Young’s modulus or the modulus of elasticity True strain is the sum of the incremental elongations divided by the current gauge length at load P, Classification of Engineering Materials The maximum shear stress τmax is related to the angle of twist θ by where θ is in radians, r is the radius of the specimen, l0 is the gauge length, G is the material stiffness property called the shear modulus or the modulus of rigidity. Classification of Engineering Materials The maximum shear stress is also related to the applied torque T as where J = ½ πr4 is the polar second moment of area of the cross section. Processes Forging - a manufacturing process where metal is shaped by plastic deformation under great pressure into high strength parts. Casting – pouring or injecting molten metal into a mold containing a cavity with the desired shape Processes Hot-Working Processes Hot working: such processes as rolling, forging, hot extrusion, and hot pressing, in which the metal is heated above its recrystallation temperature. Cold-Working Processes Cold working: the forming of the metal while at a low temperature (usually room temperature). In contrast to parts produced by hot working, cold-worked parts have a bright new finish, are more accurate, and require less machining. Cold-Working Processes General Classes of Materials Young’s modulus E versus density ρ for various materials. School of Biomedical Engineering Thank You !