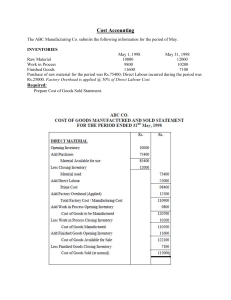

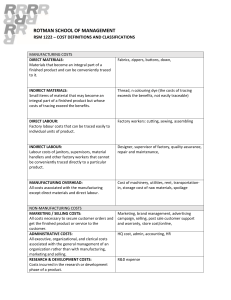

MODULE 13 COST ACCOUNTING (MANUFACTURING) Note to the Teacher: In Grade 10 learners were exposed to cost concepts and then in Grade 11 they drew up manufacturing ledger accounts, calculated costs of manufacturing and were exposed to some ethical and internal control measures. In Grade 12 the focus falls on the Production Cost Statement, costing and ethical and control measures. If you wish to revise the General Ledger accounts then we suggest you refer to the Grade 11 textbook. However, it is not necessary. At this stage you would be better off revising the different cost components and then lead them into the Production Cost Statement. Most learners find this statement a lot easier than the ledger accounts. It is important to note that it has become the norm in examinations to test the two aspects, i.e. the Production Cost Statement and the costing in two different parts of a question. This is because of work-in-progress. If costing includes work-in-progress then the calculations are far more complicated as they are bringing in costs from the previous year. In the examination guideline document it states that for costing calculations there must be no work-in-progress at school level. Further assumptions are also made around factory overheads and administration and selling and distribution costs. In terms of the school curriculum Factory overheads and Administration costs are regarded as fixed costs – in other words the costs remains the same irrespective of the number of units produced. However, Factory overheads will include some items that could be seen as variable, for example electricity. While electricity does have a fixed amount each month the balance will be variable – if you double your production then this will affect the electricity charges. The same can be said for other costs, e.g. consumable stores. At school level we regard Factory overheads and Administration costs as fixed – the majority of the costs will be fixed. However, make learners aware of the fact that this is a bit of an assumption and that at tertiary level they will be involved in more complicated calculations when they will have to split these costs further in to what is fixed and what is variable. TASK 13.1 Matching columns COLUMN A COST CONCEPTS 1. Direct materials 2. Indirect materials 3. 4. Direct labour Indirect labour 5. 6. 7. 8. 9. 10. 11. 12. Prime cost Factory overheads Fixed costs Variable costs Total cost of production Unit cost Mark-up Selling price COLUMN B DEFINITION J Material that forms a part of the item produced. F Materials that are used in the manufacturing process but do not form part of the item produced. L Labour directly involved in the manufacture of the goods. A Labour used in the factory but are not involved in the manufacture of the goods. H Total direct costs (raw materials + direct labour). B Other expenses incurred by the factory other than direct expenses. K Costs that remain constant irrespective of the amount produced. D Costs that vary in proportion to the amount of goods produced. I Includes all costs involved in the production. C Cost of one item produced. G The profit made on the goods produced. E The price that the items are sold for. TASK 13.2 Ralley Bike Manufacturers: Statement Production Cost 13.2.1 NAME OF MANUFACTURER: RALLEY BIKE MANUFACTURERS PRODUCTION COST STATEMENT FOR THE PERIOD ENDED 28 FEBRUARY 20.8 Note Direct / Prime costs 430 000 Direct material costs Direct labour costs Factory overhead costs Total manufacturing costs Work-in-process at beginning of the year 1 2 3 Work-in-process at end of the year Cost of production of finished goods 13.2.2 NOTES TO THE FINANCIAL STATEMENTS 1. Direct material costs Opening stock Net purchases (200 000 + 60 000) Carriage on purchases Closing stock Direct material cost 80 000 260 000 30 000 370 000 *(40 000) 330 000 *Balancing figure 2. Direct labour costs Factory wages (210 000 – 110 000) Direct labour cost 100 000 100 000 3. Factory overhead costs Consumable stores (24 000 – 6 000) Salaries and wages/indirect labour Depreciation Rent (200 000 x 3/5) Electricity Sundry expenses (25 000 x 80%) Factory overhead costs 18 000 60 000 16 000 120 000 120 000 20 000 354 000 4. Selling and distribution costs Depreciation Rent (200 000 x 1/5) Electricity Sundry expenses (25 000 x 15%) Commission Selling and distribution costs 7 000 40 000 8 000 3 750 84 000 142 750 330 000 100 000 354 000 784 000 40 000 824 000 (44 000) 780 000 5. Administration costs Salaries & wages (210 000 – 100 000 – 60 000) Depreciation Rent (200 000 x 1/5) Electricity Sundry expenses (25 000 x 5%) Administration costs TASK 13.3 50 000 3 000 40 000 8 000 1 250 102 250 Kwa-Mabula Manufacturers: Statement, Income Statement Production Cost 13.3.1 NAME OF MANUFACTURER: KWA-MABULA MANUFACTURERS PRODUCTION COST STATEMENT FOR THE PERIOD ENDED 28 FEBRUARY 20.8 Note Direct / Prime costs 1 482 000 Direct material costs Direct labour costs Factory overhead costs Total manufacturing costs Work-in-process at beginning of the year 1 2 1 302 000 180 000 3 923 200 2 405 200 80 000 2 485 200 (75 200) 2 410 000 Work-in-process at end of the year[2] Cost of production of finished goods[1] [1] [2] Refer to the finished goods stock note below to get this figure. Work-in-process is the balancing figure. INCOME STATEMENT FOR THE PERIOD ENDED 28 FEBRUARY 20.8 Note Sales Cost of finished goods sold / Cost of sales 6 Gross profit Other costs Administration costs Selling & distribution costs Net profit 13.3.3 NOTES TO THE FINANCIAL STATEMENTS 1. Direct material costs Opening stock Net purchases (600 000 + 460 000 – 24 000) Carriage on purchases Closing stock Direct material cost 2. Direct labour costs Factory wages Direct labour cost 3 600 000 (2 400 000) 1 200 000 (599 500) 4 5 180 000 1 036 000 150 000 1 366 000 (64 000) 1 302 000 180 000 180 000 (182 500) (417 000) 600 500 3. Factory overhead costs Consumables stores (14 000 + 44 000 – 6 000) Salaries and wages (indirect labour) (360 000 – 180 000 – 80 000) Depreciation [(1 000 000 – 240 000) x 12%] Rent (500 000 x 60%) Electricity Sundry expenses (90 000 x 4/6) Factory overhead costs 100 000 91 200 300 000 320 000 60 000 923 200 4. Selling and distribution costs Depreciation – sales vehicles Rent (500 000 x 25%) Electricity (344 000 – 320 000 – 10 000) Sales vehicle running expenses Sundry expenses (90 000 x 1/6) Commission (3 600 000 x 5%) Selling and distribution costs 11 000 125 000 14 000 72 000 15 000 180 000 417 000 5. Administration costs Salaries Depreciation – office equipment Rent (500 000 x 15%) Electricity Sundry expenses (90 000 x 1/6) Administration costs 80 000 2 500 75 000 10 000 15 000 182 500 6. Cost of finished goods sold / Finished Goods Opening stock of finished goods Cost of finished goods produced during the year Closing stock of finished goods Cost of finished goods sold / Cost of sales 52 000 70 000 2 410 000 2 480 000 (80 000) 2 400 000 Note: Procedure to complete the Finished goods note: • The opening balance of R70 000 was given. • The closing balance of R80 000 was given. • The cost of sales can be calculated as you have the sales figure and the mark-up: 3 600 000 x 100/150 = R2 400 000 • The cost of finished goods produced becomes the balancing figure. TASK 13.4 Centipede Manufacturers: Production Statement, Income Statement, Calculations 13.4.1 NAME OF MANUFACTURER: CENTIPEDE MANUFACTURERS PRODUCTION COST STATEMENT FOR THE PERIOD ENDED 28 FEBRUARY 20.8 Note Direct / Prime costs 506 400 Direct material costs 1 246 000 Direct labour costs 2 260 400 Factory overhead costs 3 208 200 Total manufacturing costs 714 600 Work-in-process at beginning of the year 120 000 834 600 Work-in-process at end of the year (41 000) Cost of production of finished goods 793 600 13.4.2 INCOME STATEMENT FOR THE PERIOD ENDED 28 FEBRUARY 20.8 Note Sales 1 500 000 Cost of finished goods sold / Cost of sales 4 (1 049 840) Gross profit 450 160 Other costs (207 160) Administration costs Selling & distribution costs Net profit NOTES TO THE FINANCIAL STATEMENTS 1. Direct material costs Opening stock Net purchases (210 000 + 62 000)[1] Carriage on purchases (19 500 + 9 920)[2] Import duties[3] Closing stock Direct material cost (82 040) (125 120) 243 000 60 000 272 000 29 420 6 200 367 620 (121 620) 246 000 [1] £5 000 x 12.40 £800 x 12.40 [3] 62 000 x 10% [2] 2. Direct labour costs Factory wages (198 000 + 19 800) Medical Aid contributions (39 000 + 3 600) Direct labour cost 217 800 42 600 260 400 3. Factory overhead costs Consumables stores (15 000 + 45 000 – 6 000) Factory electricity (9 000 + 3 000) Maintenance on factory equipment Factory rent [72 000 + 1 200 (600 x 2)] Depreciation Factory overhead costs 54 000 12 000 24 000 73 200 45 000 208 200 Cost 4. Cost of finished goods sold / Finished Goods Opening stock of finished goods Cost of finished goods produced during the year Closing stock of finished goods Cost of finished goods sold / Cost of sales 308 040 793 600 1 101 640 (51 800) 1 049 840 13.4.3 Calculate the following: (a) (a) The unit cost of production of each pool filter. 793 600 ÷ 3 280 = R241.95 (b) (b) The selling price of each pool filter. 1 500 000 ÷ 4 000 = R375 (c) (c) The mark-up % on each pool filter. /241.95 x 100 = 55% 133.05 TASK 13.5 Vilakazi Shoe Factory: Production Cost Statement, Income Statement, Calculations 13.5.1 NAME OF MANUFACTURER: VILAKAZI SHOE FACTORY PRODUCTION COST STATEMENT FOR THE PERIOD ENDED 28 FEBRUARY 20.8 Note Direct / Prime costs 775 150 Direct material costs 1 427 150 Direct labour costs 2 348 000 Factory overhead costs 3 212 500 Total manufacturing costs 987 650 Work-in-process at beginning of the year 70 000 1 057 650 Work-in-process at end of the year (124 700) Cost of production of finished goods 932 950 13.5.2 INCOME STATEMENT FOR THE PERIOD ENDED 28 FEBRUARY 20.8 Note Sales 1 080 000 Cost of finished goods sold / Cost of sales 6 (720 000) Gross profit 360 000 Other costs (252 655) Selling & distribution costs Administration costs Net profit 4 5 (125 383) (127 272) 107 345 NOTES TO THE FINANCIAL STATEMENTS 1. Direct material costs Opening stock Net purchases (280 000 + 70 000) Carriage on purchases Closing stock (balancing figure) Direct material cost 160 000 350 000 4 700 514 700 (87 550) 427 150 2. Direct labour costs Factory wages Direct labour cost 348 000 348 000 3. Factory overhead costs Consumable stores [(9 400 + 19 800 – 3 900) x 75%] Indirect labour Salary: Foreman (96 240 + 5 000 + 400 + 50) Depreciation Maintenance Insurance Rent (21 800 – 2 000 + 1 800) Factory overhead costs 18 975 39 600 101 690 6 000 12 155 12 480 21 600 212 500 4. Selling and distribution costs Salaries Depreciation Bad debts Commission on sales (1 122 + 9 678) (1 080 000 x 1%) Consumable stores Selling and distribution costs 76 000 34 300 1 120 10 800 3 163 125 383 5. Administration costs Salaries Depreciation Insurance: Administration offices (22 440 – 4 000) Sundry administration expenses Rent Consumable stores (6 325 ÷ 2) Administration costs 56 100 4 800 18 440 33 110 11 660 3 162 127 272 6. Cost of finished goods sold / Finished Goods Opening stock of finished goods Cost of finished goods produced during the year Closing stock of finished goods Cost of finished goods sold (1 080 000 x 100/150) 13.5.3 Calculate the unit cost of producing the shoes. 932 950 ÷ 23 324 = R40 13.5.4 Calculate how many shoes were sold. 40 + 50% = R60 1 080 000 ÷ R60 = 18 000 pairs 55 800 932 950 988 750 (268 750) 720 000 TASK 13.6 Tugela Water Bottle Manufacturers: Production Cost Statement, Income Statement, Unit costs 13.6.1/3 NAME OF MANUFACTURER: TUGELA WATER BOTTLE MANUFACTURERS PRODUCTION COST STATEMENT FOR THE PERIOD ENDED 28 FEBRUARY 20.8 Note Total Unit cost Direct / Prime costs 708 000 R8.74 Direct material costs Direct labour costs Factory overhead costs Total manufacturing costs Work-in-process at beginning of the year Work-in-process at end of the year Cost of production of finished goods 1 2 3 330 000 1 038 000 582 000 1 620 000 0 1 620 000 0 1 620 000 R4.07 R12.81 R7.19 R20.00 R20.00 13.6.2/3 INCOME STATEMENT FOR THE PERIOD ENDED 28 FEBRUARY 20.8 Note Total Unit cost 180 Sales [1 620 000 x /100] 2 916 000 R36.00 Cost of finished goods sold / Cost of sales 6 (1 620 000) R20.00 Gross profit 1 296 000 R16.00 Other costs (660 700) (R8.16) Selling & distribution costs 4 (465 500) (R2.41) Administration costs 5 (195 200) (R5.75) Operating profit 635 300 Interest income [66 000 – 60 000] 6 000 Operating profit before interest expense 641 300 Interest expense [200 000 x 18%] (36 000) Net profit 605 300 NOTES TO THE FINANCIAL STATEMENTS 1. Direct material costs Opening stock Purchases [240 000 + 370 000] Carriage on purchases Closing stock Direct material cost 105 000 610 000 35 000 750 000 (42 000) 708 000 2. Direct labour costs Factory wages Direct labour cost 330 000 330 000 3. Factory overhead costs Wages: Cleaner [42 000 x 4/6] Salary: Foreman Cleaning materials [(3 000 + 38 000 – 5 000) x 4/6] Rent expense [432 000 x 800/1 200] Insurance [36 000 x 800/1 200] Electricity & water [31 000 + 4 000 – 10 000] Depreciation [(500 000 – 180 000) x 20%] Factory overhead costs 28 000 129 000 24 000 288 000 24 000 25 000 64 000 582 000 4. Selling and distribution costs Wages: Cleaner [42 000 x 1/6] Sales commission [(2 880 000 – 78 000) x 5%] Cleaning materials [(3 000 + 38 000 – 5 000) x 1/6] Rent expense [432 000 x 220/1 200] Insurance [36 000 x 220/1 200] Electricity & water [(31 000 + 4 000 - 25 000) ÷ 2] Packing materials [52 000 x 80%] Bad debts Cell-phone allowances Sales vehicle expenses Depreciation [240 000 x 25%] Selling and distribution costs 7 000 140 100 6 000 79 200 6 600 5 000 41 600 78 000 12 000 30 000 60 000 465 500 5. Administration costs Wages: Cleaner [42 000 x 1/6] Salary: Office workers Cleaning materials [(3 000 + 38 000 – 5 000) x 1/6] Rent expense [432 000 x 180/1 200] Insurance [36 000 x 180/1 200] Electricity & water [(31 000 + 4 000 - 25 000) ÷ 2] Bank charges Sundry administration expenses Depreciation [(50 000 – 30 000) x 20%] Administration costs 7 000 84 000 6 000 64 800 5 400 5 000 9 000 10 000 4 000 195 200 TASK 13.7 Break-even point: Calculations Selling price per item Variable cost per item Profit per item Fixed costs (in total) R10 R24 R50 R75 R40 R80 R80 R8 R16 R30 R45 R25 R68 R54 R2 R8 R20 R30 R15 R12 R26 R60 R160 R1 000 R900 R750 R144 R624 TASK 13.8 Tau Factory: Calculations 1. Direct material cost per unit. 100 000 ÷ 10 000 = R10 2. Direct labour cost per unit. 150 000 ÷ 10 000 = R15 3. Total direct cost per unit. 250 000 ÷ 10 000 = R25 4. Factory overhead cost per unit. 200 000 ÷ 10 000 = R20 Break-even point (no. of items) 30 20 50 30 50 12 24 5. Cost of production of finished goods per unit. 450 000 ÷ 10 000 = R45 6. Selling & distribution costs per unit. 50 000 ÷ 10 000 = R5 7. Administration costs per unit. 70 000 ÷ 10 000 = R7 8. Variable costs per unit. Direct material cost (DMC) per unit + Direct labour cost (DLC) per unit + Selling & distribution cost (SDC) per unit R10 + R15 + R5 = R30 9. Fixed costs per unit. Factory overhead cost per unit (FOHC) + Administration cost (AC) per unit R20 + R7 = R27 10. Contribution per unit. Selling price per unit less Variable costs per unit R60 – R30 = R30 11. Break-even point (i.e. the point at which no profit or loss is earned). Fixed costs ÷ Contribution per unit 270 000 ÷ 30 = 9 000 units Proof of break-even point: 9 000 units sold at R60 each = R540 000 Variable costs [9 000 x R30] = R270 000 Fixed costs R270 000 Profit / Loss = NIL TASK 13.9 Icicles Factory: Production Cost Statement, Income Statement NAME OF MANUFACTURER: ICICLES FACTORY PRODUCTION COST STATEMENT FOR THE PERIOD ENDED 28 FEBRUARY 20.8 Note R Per unit Direct / Prime costs 60 000 R0.50 Direct material costs Direct labour costs Factory overhead costs Total manufacturing costs Work-in-process at beginning of the year Work-in-process at end of the year Cost of production of finished goods 36 000 24 000 96 000 156 000 0 156 000 0 156 000 R0.30 R0.20 R0.80 R1.30 R1.30 INCOME STATEMENT FOR THE PERIOD ENDED 28 FEBRUARY 20.8 Note R Sales 360 000 Cost of finished goods sold / Cost of sales (156 000) Gross profit 204 000 Other costs (114 000) Selling & distribution costs (36 000) Administration costs (78 000) Net profit 90 000 Per unit R3.00 R1.30 R1.70 (R0.95) (R0.30) (R0.65) R0.75 TASK 13.10 Analysis and Ground Leather Manufacturers: interpretation 13.10.1 Give 2 reasons why the direct material cost has decreased. Cheaper quality material being used. They may have found a cheaper supplier. May have found a supplier that was closer so transport costs are reduced. 13.10.2 Give 2 reasons why the direct labour cost has increased. Employed more labour without increasing production, workers were given an increase in salaries /wages, labour is not as productive. 13.10.3 Discuss the increase in the cost of production and explain what effect this will have on the profits of the business. The costs of production have increased from R42 to R50 (R8 increase) but the selling price has remained the same which means less profits for the business. 13.10.4 Explain why selling and distribution expenses have increased by R7 but admin costs only by R1. Various reasons: Perhaps they did more advertising and employed more sales people plus the normal increase for inflation while admin expenses have only increased due to inflation – increased costs. 13.10.5 What does the increase in the break-even point mean to the business? Explain fully. The business has to make an extra 30 items before they make a profit. 13.10.6 Do you think Groundcover made the correct decision in not increasing the selling price of the belts? Why? Learners to debate – costs have increased so they need to increase the sales price to make the same profit but sales have already decreased so maybe the demand for the product has decreased. If there was more advertising (increased selling and distribution expenses) this has not really paid off. 13.10.7 Give the owners advice on what they need to do to improve the situation for the next year. Learners to give their own opinions. Possible answers: Look for another supplier. Cut back on labour. Reduce overhead costs. Do more advertising. Reward increased productivity, etc. TASK 13.11 13.11.1 No. (a) (b) (c) (d) (e) Tick-Tock Lollies: interpretation Calculations, Analysis and Complete the unit cost table by calculating the missing figures marked with (a) – (e). Working 200 000 ÷ 40 000 40 000 ÷ 40 000 R5 + R1 40 000 x R6 (or R200 000 + R40 000) 40 000 x R1.50 Answer R5 R1 R6 R240 000 R60 000 13.11.2 Calculate the unit cost of each lolly made during the year. R5 + R1 + R2 = R8 OR (200 000 + 40 000 + 80 000) ÷ 40 000 = R8 13.11.3 Calculate the mark-up achieved by the business. Gross profit: 12 – 8 = R4 4 /8 x 100 = 50% 13.11.4 What is the difference between a fixed and a variable cost? Give one explain of each. Fixed cost: The costs remain the same within a period of time irrespective of the number of units produced, e.g. Factory overheads, rent, etc. Variable cost: The costs vary in direct proportion to the number of units produced, e.g. raw materials, direct labour. 13.11.5 Calculate the break-even point in 20.8. 80 000 + 160 000 12 – (5 + 1 + 1.50) 240 000 4.50 53 334 units 13.11.6 Should the owner be happy with the performance of the business in terms of the breakeven? Take into account that the break-even last year was 25 000. No. He is selling 40 000 and the break-even is 53 334 which means he is making a loss on 13 334 units. His break-even has increased from 25 000 to 53 334. 13.11.7 (a) Give two possible reasons why the direct material cost per unit has increased. • Increase in the price of the goods. • Increase in transport of the goods. • More wastage. • Any other viable reason. (b) What effect has this increase had on the profits of the business? Decreased the profits. (c) Briefly discuss two suggestions the owner could consider to reduce this cost. • Find an alternative supplier. • Find a closer source so that the transport costs are reduced. • Control the wastage. Any other viable reason. 13.11.8 Factory overheads have decreased as a result of “economies of scale”. Briefly explain what is meant by this term. Factory overheads are fixed so the more you produce the total amount of the costs is divided by a larger number so the costs per unit come down. 13.11.9 Do you agree with the owner keeping the selling price of the lollies the same for 20.7 and 20.8? Why? Explain briefly. No. The cost of manufacturing each lolly in 20.7 was R6.30 but in 20.8 this increased to R8, therefore they are making less profit. OR Yes. Their sales have increased from 25 000 to 40 000 and in view of the economic climate if they increase the selling price they might not sell as much. TASK 13.12 Barney’s Toy Manufacturers (1): Internal control The purpose of this Task is for the learners to engage with the figures and real-life scenarios. There is no right or wrong answer but the discussion is what is important. However, it is important that the students can substantiate any statements made. Suggested marking rubric: Criteria Level 1 Possible Fails to identify reasons for possible reasons the stock why the stock has being used been used up. up Poor suggestions Control made for control measures measures. Poor advice that Advice does not address the issue. Possible answers: Possible reasons for the stock being used up Control measures Advice TASK 13.13 Level 2 Level 3 Level 4 Identifies some reasons why the stock has been used up. A good discussion on possibilities. An excellent discussion showing great insight. Some control measures discussed. Good discussion on control measures that are feasible. Aspects of the advice are feasible. Good advice given that is feasible. Excellent discussion on control measures to take. Excellent advice that shows great understanding. Staff stealing material, wastage, cutting out wrong pieces that need to be recut, errors, etc. Material issued must be strictly controlled, make people answerable, people to check up on each other, make people responsible for damages and losses, reward for targets met, etc. Various answers: Yes – so that there is no stoppage in production, needs strict control No – as this puts temptation in people’s way. Barney’s Toy Manufacturers (2): Ethics The focus of this Task is the ethical issues at stake. Learners need to realise that there are consequences to all actions and that they cannot take decisions into your own hand. Even though Annie has got a problem just taking the off-cuts is not ethically correct. She should rather talk to the management in an attempt to solve her problem. If Barney is to just forget the issue he is opening himself up to further issues in future but he cannot discriminate and take action against some and not others. Give the learners time to discuss this Task. You might decide that they do not need to write a report on the Task. Often assessment stunts people from expressing their views so it could therefore be done as a discussion or a debate. Suggested marking rubric: Criteria Level 1 Poor discussion on Ethical issues the ethical issues at stake. Reasons for and against Poor discussion. just ‘forgetting it’ Advice Poor advice given. Level 2 Level 3 Level 4 Some ethical issues raised. Good discussion on the ethical issues. Excellent discussion on the ethical issues. Some valid reasons posed. Good discussion for and against why to just ‘forget it’. Excellent discussion for and against why to just ‘forget it’. Some advice acceptable. Good advice based on prior discussions. Excellent advice based on discussion. is Note to the Teacher: Many of the Tasks that follow are integrated with inventory valuations. These two topics can very easily be integrated in a final examination, so you are urged to allow the learners to do some of these tasks. TASK 13.14 Hopkins Manufacturers: Production Statement, Analysis and interpretation Cost 13.14.1 NAME OF MANUFACTURER: HOPKINS MANUFACTURERS PRODUCTION COST STATEMENT FOR THE PERIOD ENDED 28 FEBRUARY 20.2 Note Direct / Prime costs 678 384 Direct material costs 1 223 884 Direct labour costs [450 000 + 4 500] 454 500 Factory overhead costs Total manufacturing costs Work-in-process at beginning of the year Work-in-process at end of the year Cost of production of finished goods NOTES 1. Direct material costs Opening stock Purchases plus carriage Closing stock* Raw materials issued to production 2. Cost of finished goods sold / Finished Goods Opening stock of finished goods Goods from manufacturing department (balancing figure) Closing stock of finished goods Cost of sales (1 760 000 x 100/160) 411 616 1 090 000 110 000 1 200 000 (150 000) 1 050 000 15 400 226 340 241 740 (17 856) 223 884 112 000 1 050 000 1 162 000 (62 000) 1 100 000 *CALCULATION OF CLOSING STOCK 15 400 + 226 340 = R241 740 = (96 x 241 740) ÷ (100 + 1 200) = 23 207 040 ÷ 1 300 = R17 852 Due to rounding off the learners can get different amounts. Take this into consideration in the Production Cost Statement. 13.14.2 Briefly explain why you think Hopkins Manufacturers chose the weighted average method to value the bags of polystyrene. Discuss two reasons. • Cannot separate different bags of polystyrene. • Value is low. 13.14.3 Discuss two possible reasons for the change in direct material cost per unit in 20.2. • Found cheaper material. • Found a supplier that is closer so reduced transport costs. • Found alternative supplier. 13.14.4 Discuss two possible reasons for the change in direct labour cost per unit in 20.2. • Increase in wage rate. • Staff are not as productive. • Staff worked overtime. Do not accept increased labour force as this is a unit cost. 13.14.5 Should the owners be happy with the break-even for 20.2? Why? Explain briefly quoting figures to substantiate your answer. Yes / No. They have sold 3 520 units and break-even point is 3 240 so they are making a profit. The break-even has increased from last year. TASK 13.15 Maria: Calculations, Production Cost Statement, Analysis and interpretation 13.15.1 Raw material / Direct material issued to the production process. Opening stock 20 992 Purchases 436 300 Carriage on purchases [755 x R6] 4 530 461 822 Closing stock [62 x R578]* (35 836) Raw materials issued to production R425 986 *Working: (461 822 ÷ 755) - 44 = R578 13.15.2 NAME OF MANUFACTURER: MARIA PRODUCTION COST STATEMENT FOR THE PERIOD ENDED 31 AUGUST 20.1 Note Direct / Prime costs 749 986 Direct material costs Direct labour costs (1 500 x 216) Factory overhead costs (1 500 x 166.67) Total manufacturing costs Work-in-process at beginning of the year Work-in-process at end of the year Cost of production of finished goods 425 986 324 000 250 005 999 991 50 009 1 050 000 (60 000) 990 000 13.15.3 Calculate the unit cost of production for the year ended 31 August 20.1. 990 000 ÷ 1 500 = R660 13.15.4 (a) Give a possible reason, other than price changes, for the change in each of the unit costs provided above. Raw materials: More wastage. Direct labour: Better productivity. Factory overheads: Economies of scale. (b) Explain whether Maria should be concerned about the break-even point. Quote figures to support your answer. No. The break-even point has reduced from last year and she is producing more. Her sales are 1 464 so she is making a profit. (c) Maria sells most of her travel bags to overseas tourists. In view of this she has decided to increase her mark-up to 150%. Do you agree with her? Discuss with full explanation. Yes / No. No as the mark-up is too high and it is unethical to exploit overseas visitors. Yes if people are prepared to pay there is no reason why she cannot increase the cost. TASK 13.16 Clay Potters and Cwele Ltd: Production Cost Statement, Stock valuations, Analysis and interpretation PART A: CLAY POTTERS 13.16.1 NAME OF MANUFACTURER: CLAY POTTERS PRODUCTION COST STATEMENT FOR THE PERIOD ENDED 31 JULY 20.1 Note Direct / Prime costs 527 880 Direct material costs [(240 000 + 40 000) x 80%] Direct labour costs Factory overhead costs Total manufacturing costs Work-in-process at beginning of the year Work-in-process at end of the year Cost of production of finished goods 13.16.2 • CALCULATION OF DIRECT OR (RAW) MATERIALS COST Opening stock Purchases Carriage on purchases Closing stock* Direct material cost *Calculation of Closing stock: 326 600 ÷ 230 = 1 420 1 420 x 16 = R22 720 303 880 224 000 302 120 830 000 28 000 858 000 (21 000) 837 000 28 960 269 350 28 290 326 600 (22 720) 303 880 • CALCULATION OF FACTORY OVERHEAD COST Consumable stores Rent [180 000 x 60/100] Water and electricity Depreciation Indirect labour [280 000 – 224 000] Sundry expenses Factory overhead cost • CALCULATION OF FINISHED GOODS STOCK Opening stock Cost of goods manufactured (balancing figure) Less Closing stock Cost of sales [1 376 000 x 100/160] 40 000 108 000 50 000 26 000 56 000 22 120 302 120 52 000 837 000 889 000 (29 000) 860 000 13.16.3 The owners of Clay Potters have instructed the accountant to switch between the Weighted average and FIFO method when valuing the raw materials. • Why do you think the owners would give this instruction? To show higher or lower profits depending on what he is trying to achieve. • Do you agree with the owners? Why? No. It is unethical to switch – businesses have to stick to one method in the interest of comparison. PART B: CWELE LTD UNIT COSTS: (Note that this is a separate question to Part A) 13.16.4 UNIT COST UNIT COST COSTS TOTAL 20.10 20.9 Direct / raw materials R250 000 R10 R12 Direct labour cost 375 000 R15 R11 Prime cost 625 000 R25 R23 Factory overheads R200 000 R8 R10 Administration costs R75 000 R3 R3 Selling & distribution costs R100 000 R4 R2 13.16.5 Define the following concepts and give an example of each: • Fixed costs Remains constant irrespective of the number of goods produced. Example: Rent, etc. • Variable costs Varies in direct proportion to the number of units produced. Example: Raw materials. 13.16.6 Calculate the unit cost of production for 20.10. 825 000 ÷ 25 000 = R33 13.16.7 Discuss 2 possible reasons for the change in the following costs from 20.9 to 20.10: • Direct / raw materials cost Cheaper source of material / supplier. Less wastage. • Direct labour cost Increase in wage rate. Employed more labourers. • Factory overheads Economies of scale. Costs, e.g. rent, have decreased. 13.16.8 Calculate the break-even point for 20.10. 200 000 + 75 000 60 – 29 = 275 000 31 = 8 871 units 13.16.9 The owner of Cwele Ltd is very pleased regarding the trend in the break-even point from 2.09 to 20.10. Do you agree? Why? Yes. Because the break-even is less than 20.9 so more profit is being made. TASK 13.17 Rani Manufacturers: Calculations, valuations, Analysis and interpretation Stock 13.17.1 The owner (Rani) is of the opinion that the FIFO method is the best method to use in the manufacturing of raincoats. Briefly explain why you think he is of this opinion. The stock is valued at the current prices and in times when prices are increasing (as it has during the past year) this will give a more realistic value of the stock. 13.17.2 Calculate the following: (Refer to information note no. 2 below.) (a) The value of the raw (direct) materials on hand on 28 February 20.9 using the FIFO method of stock valuation. (2 200 x 48) + (4 300 – 2 200 x 42) = 105 600 + 88 200 = R193 800 (b) Calculate the value of the raw (direct) material cost that would appear in the Production Cost Statement for the year ended 28 February 20.9. (700 x 30) + 490 600 – 193 800 = 21 000 + 490 600 – 193 800 = R317 800 13.17.3 Rani has asked you to investigate the control over the raw materials: (a) Calculate the number of metres of raw material fabric that appears to be missing. 9 100 (issued to factory) – 4 000 x 1.8 (no. of raincoats x 1.8 metres each) = 9 100 – 7 200 = 1 900 metres missing (b) Apart from theft state one possible reason for this shortage. Briefly offer Rani advice on what she could do to prevent this shortage. Discuss one point. Wastage of material. Unskilled labour that are not cutting the material properly. Any other valid reason. Proper supervision. Training of staff. Any other valid reason. 13.17.4 (a) Calculate the value of the direct labour cost (including contributions) that would appear in the Production Cost Statement for the year ended 28 February 20.9 (Refer to information 3 below). Basic: 5 x R5 000 x 12 = R300 000 (note the R5 000 is monthly but you are working for a year) Overtime: 180 x 5 x 70 = R63 000 Pension: R300 000 x 10% = R30 000 UIF: R300 000 x 1% = R3 000 Total = 300 000 + 63 000 + 30 000 + 3 000 = R296 000 (b) Rani is concerned about the number of hours that the workers have worked overtime. She has had the same number of employees in the factory this year as last and the overtime has increased by double. • Why do you think she should be concerned? Last year they produced 4 500 raincoats and this year this number was reduced to 4 000 but the same number of workers that worked double the time. This will increase the costs of manufacturing and thus result in lower profits. • • • • • Suggest two measures that Rani could introduce to try and cut back on the overtime. The norm time to make a raincoat must be worked out so that staff will know what is expected of them in normal working hours. There needs to be constant supervision. Staff needs to be given extra training. Any other feasible suggestion. 13.17.5 Calculate the following: (a) The total cost of production of finished goods. R317 800 + R396 000 + (4 000 x 67.55) = 317 800 + 396 000 + 270 200 = R984 000 (b) The unit cost of production of each raincoat. R984 000 ÷ 4 000 = R246 (c) Calculate the break-even point for the year ended 28 February 20.9. 350 200 350 – 215.95 350 200 134.05 2 613 raincoats (2 612.5) (Remember break-even must always be rounded up) (d) The break-even point for the year ended 28 February 20.8 was 2 273 units. Should Rani be happy with the break-even point for 20.9? Explain briefly. Yes. The business has produced 4 000 raincoats which is above the break-even point (they are making a profit on 1 387 units). OR No. The break-even point is higher than it was in 20.8 (340 units). Therefore they have to manufacture more in 20.9 before they can make a profit. 13.17.6 Discuss two possible reasons why the selling and distribution costs per unit have decreased. In your opinion has this been beneficial to the business? Discuss briefly. Two possible reasons: The salesman’s commission on sales has been reduced as they have sold fewer raincoats. Less advertising. Deliveries have been reduced. Any other feasible reason. Has this been beneficial to the business? No. The number of raincoats sold has decreased and therefore less profit will be made. TASK 13.18 BB Bakery: Production Cost Statement, Stock valuations, Analysis and interpretation 13.18.1 NAME OF MANUFACTURER: BB BAKERY PRODUCTION COST STATEMENT FOR MARCH 20.8. Direct / Prime costs Direct material costs Direct labour costs [30 000 x 1.40] Factory overhead costs Total manufacturing costs of finished loaves of bread Raw material / Direct material cost Opening stock Purchases [52 000 + 25 000] Carriage on purchases Raw materials available for production Closing stock Raw materials issued to the manufacturing process APRIL 20.8 120 000 MARCH 20.8 * 78 000 42 000 48 000 168 000 57 600 33 600 * 120 000 7 000 77 000 2 000 86 000 (8 000) 78 000 13.18.2 Calculate the unit cost of each loaf of bread in April 20.8. 168 000 ÷ 30 000 = R5.60 13.18.3 Give 2 possible reasons why the raw materials cost have increased. • Due to inflation. • Increase in transport costs. • Different supplier. • Any other reasonable reason. 13.18.4 Name 2 items that could possibly be included in factory overhead costs. • Rent. • Electricity. • Factory manager / supervisor. • Cleaning and / or maintenance staff. • Etc. 13.18.5 Calculate the break-even point in April 20.8. 48 000 + 10 500 7 – (2.60 + 1.40 + 0.50) 58 500 2.50 23 400 units 13.18.6 The owner of BB Bakery is very happy that the number of loaves of bread has increased by 6 000 since last month. He has therefore decided to take a holiday overseas in view of the increased profit he believes he is making. Is the owner correct in his assumption? Explain using figures to substantiate your answer. Calculation of profit: MARCH APRIL Sales (24 000 x R7) (30 000 x R7) 168 000 210 000 Cost of manufacturing (120 000) (168 000) Administration cost (10 000) (10 500) Selling and distribution costs (10 000) (15 000) Net profit R28 000 R16 500 No. Although the number of loaves has increased he has made less profit in April than March due to increased costs. 13.18.7 On investigation the owner has discovered that the sales figure for the month of April 20.8 was actually R8 000 less than what was expected but no bread has been left over. • Give 2 reasons why the sales are lower than budgeted. • Loaves of bread have been stolen. • There has been wastage of bread. • Any other feasible reason. • Discuss 2 measures that the owner could take to prevent this situation in future. • Introduce security measures to prevent theft. • Division of duties – somebody needs to be checking up so that there isn’t wastage or bread been badly made that cannot be sold. • Any other feasible reason. 13.18.8 In order to improve the profitability the owner has made the following proposal and has requested your comment. The standard loaf of bread weighs 700g. He is proposing reducing each loaf of bread to 680g although it will still be marked on the packet as 700g. He does not, however, intend reducing the selling price of each loaf of bread. Do you agree with his suggestion? Why? Discuss at least 2 points in your discussion to qualify your decision. No. • This is unethical – he needs to tell the customers if he is reducing the weight of the bread. • The business will get a bad reputation and they will lose customers and this will have more of an effect on the profit of the business. 13.18.9 The stock controller has recently left the bakery and the owner is not sure what method he was using in the calculation of the value of the closing stock. The owner is aware that there are two basic methods used in business, i.e. the FIFO and weighted average method. He has come to you for assistance as to which method he should use. Briefly explain which method you believe will be the most appropriate for a bakery business. Weighted average method: • The ingredients used in baking bread cannot be separated from each other – e.g. it would be impossible to separate a bin of flour in to separate purchases. • The amount of ingredients would also be large (R78 000 of raw materials were used in April). • Therefore the weighted average method would be the most appropriate. OR FIFO (This method would not be the most appropriate): • FIFO makes use of the most current prices • Therefore the stock valuation is the most realistic value. TASK 13.19 Article 13.19.1 A friend of yours has read the article but does not understand certain terms. Explain to her what the terms in bold in the text mean. Rising input costs – cost incurred in the manufacturing process, i.e. raw materials, labour and factor overheads. As these are increasing it is pushing the cost price of the articles up. 13.19.2 Explain to your friend, why in terms of the article, food prices are expected to increase. Costs have increased. Shortages of raw materials through droughts. Crop failures. 13.19.3 Why do you think it is cheaper to import some products than manufacture them locally? South Africa’s input costs are often high. For example our labour costs are much higher than in many other countries of the world. Electricity tariffs have increased considerably over the last few years. Shortages of raw materials produced locally. 13.19.4 Why is the poultry industry expected to be hard hit? Explain briefly. The poultry are fed on maize and related feeds. 13.19.5 • • • • • You have been tasked by the board of a mill to make a presentation at the next board meeting around strategies that the business should be adopting in the new year to ensure the sustainability of the mill. Give a brief report in which you discuss at least five possible strategies that the board could look at. Economise on costs, e.g. overheads. Source cheaper supplier of raw materials. Introduce incentive schemes so that labour becomes more productive. Set up the mills near the source of labour and / or raw materials to cut down on transport. Seek alternative products to manufacture. TASK 13.20 Ethics and Internal control NO. PROBLEM 13.20.1 Yes INTERNAL CONTROL ETHICAL PROBLEM Ethical problem 13.20.2 Yes Ethical problem 13.20.3 Yes / No Ethical problem 13.20.4 Yes Ethical Internal control / SUGGESTIONS If the company is going to reduce the quantity they need to inform the customers. If products are used that could be potentially dangerous then they must be clearly stated on the packaging. Depends on their contracts. If this was a condition of service then management cannot just take it away. However, if it has been a privilege then they can remove it. It could have a very demotivating effect on the workers. Under the regulations of the country all workers working more than the prescribed minimum have to be paid overtime. If management is of the opinion that staff is wasting time in order to earn overtime, then this is an internal control problem. NO. PROBLEM 13.20.5 Yes or No INTERNAL CONTROL ETHICAL PROBLEM Ethical 13.20.6 13.20.7 Yes Yes Ethical Internal control 13.20.8 Yes Internal control 13.20.9 Yes Internal control 13.20.10 Yes Unethical / SUGGESTIONS Ethically if the costs are reduced these should be passed on to the customer. However, according or market forces, if customers are prepared to pay a price the seller can charge what he wants. This is breaking the law. Management are not controlling the packaging and the quality that is been produced. Needs stricter control measures. The matter needs to be investigated and the relevant people who have made up the ghost employees need to face a disciplinary meeting. Staff must be eating more than their allowance or they are taking cereal home. If individuals are been paid to say something it must be true. Playing on the physiological impact of advertising.