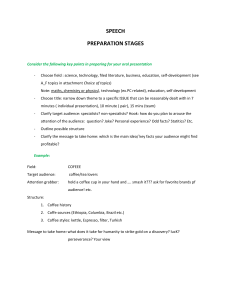

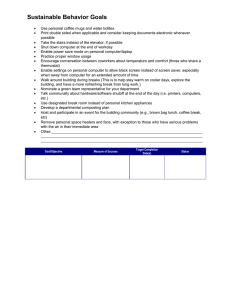

*Products and sub products covered under EUDRegulations for coffee (and its processes)* ● Coffee Sub Products (as mentioned in EUDR products and sub products document): 1. Coffee, whether or not roasted or decaffeinated; 2. coffee husks and skins; 3. coffee substitutes containing coffee in any proportion [Instant coffee, coffee capsules, flavoured coffee, coffee syrups, coffee liquor, coffee oil, ice coffee, etc] Advanced Coffee supply chain visual representation: General Coffee supply chain processes and steps: ● Farming and Harvesting: Coffee beans begin as seeds planted in large beds in shaded nurseries. After sprouting, the seedlings are moved to individual pots and eventually planted on coffee farms, mainly in tropical countries. The beans are harvested either by hand, which is labor-intensive but precise, or mechanically. ● Processing: Once harvested, the coffee cherries go through processing to remove the coffee bean from the cherry. There are two primary methods: 1. Dry Processing: The harvested cherries are spread out in the sun to dry. Workers turn them regularly to ensure even drying. 2. Wet Processing: The cherries are first soaked in water, where bad or unripe cherries float and are removed. Then, machines remove the pulp, and the beans are fermented in water to remove the mucilage before being dried. ● Milling: After drying, the beans are hulled, removing the parchment layer (in the case of wet processing) or the entire dried husk (dry processing). Further sorting and cleaning are done to remove any defective beans and to grade the coffee. ● Storage and exporting: The milled beans (one of the coffe sub products), now referred to as "green coffee," are packed into sacks and shipped to importing countries. ● Roasting: Importers and roasters taste, or "cup," the coffee to determine its quality and profile. Roasting transforms green coffee into the aromatic brown beans that are sold to consumers. The roasting process varies significantly depending on the desired flavor profile. ● Grinding and packaging: Roasted beans are then ground to a specified coarseness or fineness depending on the intended brewing method. Packaging is the final step before distribution to retailers or direct sale to consumers. ● Brewing: For traditional coffee consumption, where the end product is a cup of coffee, brewing is the process of extracting the flavors and compounds from the ground coffee beans by passing hot water through them. This step comes right after grinding the roasted coffee beans and is the final step before the coffee is ready to drink. Most of the generic processes ends here. For some sub products additional industrial processes are like this: ● Solubilizing and Drying (for instant coffee): After grinding, the coffee is brewed with highly efficient extraction methods to create a concentrated coffee solution. The coffee solution is then either freeze-dried or spray-dried. Freeze-drying involves freezing the coffee extract and then reducing the surrounding pressure to remove the ice by sublimation. Spray-drying blasts the coffee extract through hot air in a drying chamber, quickly evaporating the water, leaving behind fine coffee powder. ● Nitrogen flushing (for coffee capsules): Often, the ground coffee packed into capsules or pods is flushed with nitrogen to displace oxygen. This helps in preserving the freshness and extending the shelf life of the coffee by preventing oxidation. ● Flavour infusion (for flavoured coffee): After grinding and before packaging, the coffee grounds are mixed with flavor oils or syrups. The flavor compounds are designed to bond with the coffee grounds, ensuring that the flavor is retained during brewing. ● Concentration and sweetning (and flavouring) (for coffee syrups): After grinding and brewing, the coffee extract is further concentrated by evaporating the water. This can be done under reduced pressure to lower the boiling point and preserve the coffee's flavor. For syrups, sugar, and sometimes additional flavors, are added to the concentrated coffee to create a sweet, flavorful product. ● Infusion (for coffee liquor): While not necessarily an additional process after grinding, for coffee liquor, the ground coffee is steeped in alcohol for an extended period, allowing the flavors to infuse into the liquid. The mixture is then filtered, and additional ingredients (like sugar) may be added before bottling. ● Extraction (for coffee oil): Coffee oil can be extracted from the grounds after brewing. This process typically involves using a solvent or pressing the grounds to extract the oil. The solvent is then removed, leaving behind the pure oil. ● Cooling and flavoring (for ice coffee): After brewing, the coffee is quickly cooled down to lock in flavor. Flavorings or sweeteners may be added at this stage before the coffee is chilled or served over ice. Certifications that comes under coffee supply chain: ● ● ● ● ● Fair Trade Certification Rainforce alliance Certification UTZ Certification Specialty coffee association Certification Organic Certification ● ● ● Shade grown Certification Bird friendly Certification Direct trade Certification *User experience journey for a coffee supply chain product* 1. User onboarding and education: Welcome tour and educational resources like a brief interactive guide highlighting the system’s key features (as per EUDRegulations guidelines) and benefits or access to articles, videos, and webinars on EUDR requirements, best practices for traceability, and how to ensure compliance effectively.Also we can provide information about the importance of these certifications and how they align with sustainability and ethical practices. This helps users understand the value of sourcing certified coffee. 2. Account creation and configuration: Input basic information, including company details, product/sub-product details and role in the supply chain. Additionally, we can provide guidance on configuring the account for deforestation regulation compliance, including setting up supply chain transparency and risk assessment criteria + requirements for due digillence. Also, need users to specify if they prefer to work with suppliers that have specific certifications. This preference can be used to match them with suitable suppliers in the platform. 3. Supply chain transparency: A visual tool for users to map their entire supply chain, from raw material sourcing to final product. Also, facility to upload and manage documents proving suppliers’ compliance with deforestation regulations. When mapping the supply chain, include fields to document the certification status of each supplier. This visual representation can help users quickly identify certified partners and assess the overall sustainability of their supply chain. 4. Risk assessment and management: Analyze supply chain data to identify high-risk areas (including mixing with other products/sub-products) or suppliers in relation to deforestation. Templates and guidance for developing and implementing mitigation strategies for identified risks. We should consider certifications as positive factors in the risk assessment process. Suppliers with certain certifications may present lower risks regarding environmental sustainability and social responsibility. 5. Due diligence reporting: Pre-designed templates (as per aarti mam's document in EUDR group) that align with EUDR reporting requirements, simplifying the report creation process and a secure channel for submitting due diligence reports, with tracking and confirmation of receipt. Facilitate the upload and management of certification documents for both the user company and its suppliers. This documentation is crucial for demonstrating compliance with sustainability standards and regulatory requirements. 6. UAT: Easy-to-use feedback tools for users to report issues, suggest improvements, or rate their experience. Regular system updates informed by user feedback, regulatory changes, and technological advancements. 7. Other features that can be included in the system for better UX: ● ● ● ● ● Integration with satellite monitoring Collaboration with other products/companies that are following EUDR compliances Dashboard + Analytics for each individual company Sustainability reporting Certification updates + feedback loop Figma design for user journey in our EmerTrace platform for adding product/sub-product under coffee supply chain: Figma Link: https://www.figma.com/file/FH5JdS89bE9vgKjE1QpuA1/EUDR-Coffee-supply-chain-User-jou rney?type=whiteboard&node-id=0%3A1&t=75lbCbgTduQpPl6D-1