Navigating the Extrusion Process: A Guide to Selecting the Ideal Purging Compound

advertisement

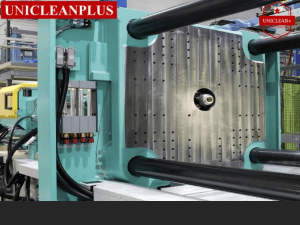

Navigating the Extrusion Process: A Guide to Selecting the Ideal Purging Compound In the complex world of extrusion, maintaining the efficiency and cleanliness of the machinery is crucial for optimal performance. Purging Compounds play a vital role in this process, helping to remove residue and contaminants. Selecting the right Purging Compound for Extruders is a nuanced decision that involves considerations such as material compatibility, application requirements, and cost-effectiveness. This guide breaks down the key factors to consider when choosing the ideal Purging Compound. Material Compatibility: Before selecting a Purging Compound, it is essential to consider the compatibility with the materials processed in the extruder. Different polymers and resins have distinct processing temperatures and characteristics. The ideal Purging Compound should be compatible with the existing material and be able to effectively clean the extruder and die without causing any adverse reactions. Checking the compound’s compatibility with both the current and subsequent materials is crucial to prevent contamination and ensure a smooth transition between production runs. Cleaning Efficiency: The primary purpose of a Purging Material is to clean the extruder and remove any residual material or contaminants. The efficiency of Purging Compounds is critical in minimizing downtime and ensuring a quick and effective transition between different materials or colours. Look for Purging Compounds that offer fast and thorough cleaning, reaching all areas of the extruder, including the screw, barrel, and die. Temperature Stability: Extruders operate at varying temperatures depending on the materials being processed. The ideal Purging Compounds should have excellent temperature stability to perform effectively across a range of processing temperatures. This ensures that the compound remains consistent and reliable, even in high-temperature processing environments, preventing degradation or incomplete cleaning. Ease of Use: User-friendly Purging Compounds can significantly impact the efficiency of the purging process. Consider factors such as ease of handling, loading, and purging procedures. Look for compounds that require minimal downtime for application and removal. Userfriendly compounds contribute to overall operational efficiency and make the purging process more manageable for operators. Residue-Free Performance: High-quality Purging Compounds should leave no residues or trace elements in the extruder system. Residue-free performance is crucial to prevent contamination in subsequent production runs, ensuring the final product’s quality and consistency. Carefully evaluate the Purging Compound’s formulation to confirm its ability to leave the extruder system completely clean. Cost-Effectiveness: While selecting ideal Purging Compounds, it’s essential to strike a balance between performance and costeffectiveness. Consider the compound’s dosage requirements, efficiency in cleaning, and the potential for reducing downtime. Investing in a high-quality Purging Compound that minimizes machine downtime and optimizes production processes can lead to long-term cost savings. Selecting the ideal Purging Material for Extruders is a critical decision that directly impacts production efficiency and product quality. Material compatibility, cleaning efficiency, temperature stability, ease of use, residue-free performance, and cost-effectiveness are key considerations when evaluating different Purging Compounds. By carefully assessing these factors, manufacturers can make informed decisions to purchase a Purging Compound from UNICLEANPLUS and ensure a smooth and reliable extrusion process while maintaining the longevity and performance of their equipment. Call them at +91 9021232809 to place your order or request free samples. To Read Our Published Blog: https://unicleanplus.weebly.com/blog/navigating-the-extrusion-process-a-guide-toselecting-the-ideal-purging-compound Thank You! UNICLEANPLUS Address : Bharatipolychem Pvt Ltd, Plot No-451 City: Lesliganj State: Jharkhand Zip: 822118 Country: India Phone: +91 9021232809 Website: https://www.unicleanplus.com/ Email: sales@bharatipolychem.com