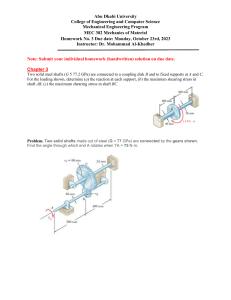

SHAFTINGS, KEYS & SPLINES, COUPLINGS M A C H I N E D E S I G N & S H O P P R A C T I CE “Satisfaction lies in the effort, not the attainment. Full effort is full victory.” - Mahatma Gandhi SHAFTINGS Shaft • a rotating machine element which is used to transmit power from one place to another. Axle • a stationary machine element and is used for the transmission of bending moment only. • It simply acts as a support for some rotating body such as hoisting drum, a car wheel or a rope sheave. Spindle • short shaft that imparts motion either to a cutting tool (e.g. drill press spindles) or to a work piece (e.g. lathe spindles). SHAFTINGS Types of Shafts: 1. Transmission shafts • These shafts transmit power between the source and the machines absorbing power. • Example: counter shafts, line shafts, over head shafts and all factory shafts 2. Machine shafts • These shafts form an integral part of the machine itself. • Example: crank shaft SHAFTINGS Analysis for shaftings: • Ductile materials Based on strength is controlled by the maximum shear theory. • Brittle materials Designed on the basis of the maximum normal stress theory. STRESSES ON SHAFTS Shear Stress (torsional load) Tc Ss = I 𝟏𝟔𝐓 𝐒𝐬 = 𝛑𝐃𝟑 𝐒𝐬 = 𝟏𝟔𝐓𝐃𝐨 𝛑 𝐃𝟒𝐨 − 𝐃𝟒𝐢 Bending Stress (tension or compression) Mc Sb = I 𝟑𝟐𝐌 𝐒𝐛 = 𝛑𝐃𝟑 𝐒𝐛 = 𝟑𝟐𝐌𝐃𝐨 𝛑 𝐃𝟒𝐨 − 𝐃𝟒𝐢 Axial stress (axial loads) F Sa = A 𝐅𝐚 𝐒𝐚 = 𝛑 𝟐 𝐃 𝟒 𝐅𝐚 𝐒𝐚 = 𝛑 𝟐 𝟐 𝐃 − 𝐃 𝐢 𝟒 𝐨 STRESSES ON SHAFTS Combined Torsion and Bending Stresses Ductile materials (maximum shear stress) 𝐒𝐬−𝐦𝐚𝐱 = 𝟏 𝐒𝐛 𝟐 𝟐 + 𝐒𝐬−𝐦𝐚𝐱 𝐒𝐬𝟐 𝟏𝟔 𝟐 + 𝐓𝟐 = 𝐌 𝛑𝐃𝟑 Brittle materials (maximum normal stress) 𝟏 𝐒𝐛 𝟐 𝟐 𝐒𝐭−𝐦𝐚𝐱 𝟏 = 𝐒𝐛 + 𝟐 𝐒𝐭−𝐦𝐚𝐱 𝟏𝟔 𝟐 + 𝐓𝟐 = 𝐌 + 𝐌 𝛑𝐃𝟑 + 𝐒𝐬𝟐 Note: if factor of Safety, N, is considered. 𝑺𝒚𝒔 𝑺𝒔−𝒎𝒂𝒙 = 𝑵 𝑺𝒚 𝑺𝒕−𝒎𝒂𝒙 = 𝑵 Where: 𝑺𝒚𝒔 = 𝟎. 𝟓𝑺𝒚 STRESSES ON SHAFTS Combined Torsion and Bending with shock & fatigue factors Ductile materials (maximum shear stress) 𝐒𝐬𝐦𝐚𝐱 = 𝐒𝐬𝐦𝐚𝐱 𝟏 𝐤 𝐛 𝐒𝐛 𝟐 𝟏𝟔 = 𝛑𝐃𝟑 𝟐 + 𝐤 𝐬 𝐒𝐬 𝐤𝐛𝐌 𝟐 𝟐 + 𝐤𝐬𝐓 𝟐 Brittle materials (maximum normal stress) 𝐒𝐭−𝐦𝐚𝐱 𝐒𝐭−𝐦𝐚𝐱 𝟏 = 𝐤 𝐛 𝐒𝐛 + 𝟐 𝟏 𝐤 𝐛 𝐒𝐛 𝟐 𝟏𝟔 = 𝐤𝐛𝐌 + 𝟑 𝛑𝐃 𝟐 𝐤𝐛𝐌 + 𝐤 𝐬 𝐒𝐬 𝟐 + 𝐤𝐬𝐓 𝟐 𝟐 SHAFTINGS Power Transmitted by Shaft 𝐏 = 𝟐𝛑𝐓𝐍 From Machinery’s Handbook: Allowable twisting moment (of any cross-section) 𝟔𝟑, 𝟎𝟎𝟎 𝑷 𝑻 = 𝑺𝒔 𝒁𝑷 = 𝑵 Note: units Diameter of Solid Circular Shaft 𝑫= 𝟑 𝟓. 𝟏𝑻 = 𝑺𝒔 𝟑 𝟑𝟐𝟏, 𝟎𝟎𝟎 𝑷 𝑵𝑺𝒔 Ss (shear stress) – psi Zp (polar section modulus) – in3 P (power transmitted) – hp T (torque transmitted) – in-lbf N (rotative speed) – rpm D (shaft diameter) – in SHAFTINGS From Machinery’s Handbook: Power Transmitted by Shaft Note: units Main Transmitting Shaft (Ss = 4000 psi) P (power transmitted) – hp N (rotative speed) – rpm 𝑫𝟑 𝑵 𝑷= D (shaft diameter) – in 𝟖𝟎 Line shafts carrying pulleys (Ss = 6000 psi) 𝑫𝟑 𝑵 𝑷= 𝟓𝟑. 𝟓 Small, Short shafts, countershafts (Ss = 8500 psi) 𝑫𝟑 𝑵 𝑷= 𝟑𝟖 SHAFTINGS Maximum Vertical Shear Stress on Shaft 𝟒𝐕 𝟏𝟔𝐕 (for “Circular” cross-section) 𝐒𝐯 = = 𝟐 𝟑𝐀 𝟑𝛑𝐃 𝟑𝐕 (for “rectangular/square” cross-section) 𝐒𝐯 = 𝟐𝐀 Shafts Angular Deformation 𝑻𝑳 𝛉= 𝑱𝑮 Note: V – maximum shear force A – cross-sectional area J – polar moment of inertia G – rigidity modulus SHAFTINGS From Machinery’s Handbook: Angle of twist “not exceeding 0.08° per foot length of shaft” 𝟒 𝑫 = 𝟎. 𝟐𝟗 𝑻 = 𝟒. 𝟔 𝟒 𝑷 𝑵 Note: units Shaft deflection “not exceeding 1° in a LP =(power 20 D”transmitted) – hp N (rotative speed) – rpm D (shaft diameter) – in 𝟑 𝑷 𝟑 T (transmitted torque) – in-lbf 𝑫 = 𝟎. 𝟏 𝑻 = 𝟒. 𝟎 𝑵 L (shaft length) – ft Shaft Linear Deflection 𝑳 = 𝟖. 𝟗𝟓 𝟑 𝟑 𝑫𝟐 𝑳 = 𝟓. 𝟐 𝑫𝟐 (for shafting subject to no bending action except its own weight) (for shafting subject to bending action of pulleys) SHAFTINGS Problem 1 Determine the torque that can be applied to a 1-in diameter circular shaft if the shearing stress is not to exceed 8000 psi A. 1570 in-lb C. 2750 in-lb B. 1750 in-lb D. 3560 in-lb Ans: 𝟏𝟓𝟕𝟎. 𝟖 𝐢𝐧 − 𝐥𝐛 SHAFTINGS Problem 2 A steel shaft is subjected to a constant torque of 2,260 N-m. The ultimate strength and yield strength of the shafting material are 668 MPa and 400 MPa respectively. Assume a factor of safety 2 based on the yield point and endurance strength in shear, determine the diameter of the shaft in inches. A. 1.521 in C. 2.321 in B. 1.915 in D. 2.417 in Ans: 𝟏. 𝟗𝟏𝟓 𝐢𝐧 SHAFTINGS Problem 3 What would be the diameter in millimeters of a main power transmitting steel shaft SAE 1040 to transmit 150 kW at 900 rpm? A. 2.3 C. 66.4 B. 2.6 D. 76.5 Ans: 𝟔𝟔. 𝟒𝟏 𝐦𝐦 SHAFTINGS Problem 4 A 3 ft length of commercial steel shafting is to transmit 50 hp at 3600 rpm through flexible coupling from an AC motor to a DC generator. What is the nearest standard shaft size? Take allowable shearing stress for commercial shafting with keyway to be 6 ksi and the combined shock and fatigue factor applied to torsional moment is unity. Ans: 𝟏𝟓 𝟏𝟔 𝐢𝐧 SHAFTINGS Problem 5 A solid steel shaft having a diameter of 3 in twists through an angle of 5 deg in 20 ft of length because of the action of a torque. Determine the maximum shearing stress in the shaft. A. 3550 psi C. 6550 psi B. 4550 psi D. 8550 psi Ans: 𝟔𝟓𝟒𝟓 𝐩𝐬𝐢 SHAFTINGS Problem 6 Determine the angular deflection in degrees of a SAE 1040 steel shaft in a length of 1/2 meter. The shear stress is 69 MPa, shaft diameter is 62 mm and steel modulus of elasticity is 79.3 GPa. A. 0.08 C. 0.1 B. 0.01 D. 0.8 Ans: 𝟎. 𝟖𝟎𝟒𝐨 SHAFTINGS Problem 7 The maximum torque that can be applied to a hollow circular steel shaft of 120 mm outside diameter and 80 mm inside diameter without exceeding a shearing stress of 80 MPa is: A. 18.46 KN-m C. 42.83 KN-m B. 36.24 KN-m D. 21.78 KN-m Ans: 𝟐𝟏. 𝟕𝟖𝟐 𝐤𝐍 − 𝐦 SHAFTINGS Problem 8 A hollow shaft with outside diameter of 14 cm and wall thickness of 0.08 cm transmits 200 kW at 400 rpm. What must be the angular deflection of the shaft if the length is 5 meters? Take G = 12,000,000 psi. A. 0.019 deg C. 1.94 deg B. 1.14 deg D. 2.44 deg Ans: 𝟏. 𝟏𝟒𝐨 SHAFTINGS Problem 9 Determine the thickness of a hollow shaft having an outside diameter of 100 mm if it is subjected to a maximum torque of 5,403.58 N-m without exceeding a shearing stress of 60 MPa or a twist of 0.5 degree per meter length of shaft. G = 83,000 Mpa. A. 15 mm C. 16.8 mm B. 30 mm D. 14.2 mm • Based on max shear: t = 7.11 mm • Based on max twist: t = 15 mm Ans: 𝟏𝟓 𝐦𝐦 SHAFTINGS Problem 10 A round steel shaft to a torque 200 rpm and is subjected to a torque of 226 N-m. the allowable shearing stress 41.4 Mpa. It is also subjected to a bending moment of 339 N-m. The allowable tensile stress is 55 MPa. Find the diameter. A. 37 mm C. 45 mm B. 41 mm D. 51 mm • Based on allowable shear: d = 36.87 mm • Based on allowable tensile: d = 41.04 mm Ans: 𝟒𝟏 𝐦𝐦 SHAFTINGS Problem 11 The shaft of a 50 hp 850 rpm electric motor is 31 in from center to center of bearings and 2.5 in. in diameter. If the magnetic pull on the armature is 1500 lb concentrated midway between the bearings, determine the maximum shear and the maximum tensile stress in the shaft. SHAFTINGS Problem 11 1500 lb 15.5 in 31 in 2.5 in 750 lb 750 lb Ans: 𝟑. 𝟗𝟖 𝐤𝐬𝐢; 𝟕. 𝟕𝟕 𝐤𝐬𝐢 SHAFTINGS Problem 12 A section of commercial shafting 5 ft long between bearings carries a 200 lb pulley at its midpoint. The pulley is keyed to the shaft and receives 20 hp at 150 rpm which is transmitted to a flexible coupling just outside the right bearing. The belt drive is horizontal and the sum of the belt tensions is 1500 lb. Assume Kt = Kb = 1.5. Calculate the necessary shaft diameter and determine the angle of twist between bearings. Take G = 12,000,000 psi. SHAFTINGS Problem 12 200 lb T1 + T2 = 1500 lb T1 2.5 ft 5 ft T2 100 lb • ½ in to 2 ½ in by 1/16 in increments • 2 5/8 in to 4 in by 1/8 in increments • 4 ¼ in to 6 in by ¼ in increments 100 lb Ans: 𝟏 𝟑. 𝟏𝟒 𝐢𝐧 ≈ 𝟑 𝟖 ; 𝟎. 𝟏𝟐𝟔° SHAFTINGS Problem 13 A solid transmission shaft is 3.5 inches in diameter. It is desired to replace it with a hollow shaft of the same material and same torsional strength but its weight should only be half as much as the solid shaft. Find the outside diameter and inside diameter of the hollow shaft in millimeters. Ans: 𝟏𝟎𝟕. 𝟑𝟏𝟓 𝐦𝐦 ; 𝟖𝟔. 𝟗𝟕 𝐦𝐦 SHAFTINGS Problem 14 A 76 mm solid shaft is to be replaced with a hollow shaft of equal torsional strength. Find the inside diameter and percentage of weight saved, if the outside diameter of the hollow shaft is 100 mm. A. 56.53 % C. 48.49 % B. 67.31% D. 72.50 % Ans: 𝟓𝟔. 𝟓𝟒𝟕 % SHAFTINGS Problem 15 A 20 feet steel line shaft has no bending action except its own weight. What power in HP can the shaft deliver at a speed of 360 rpm. Consider that the torsional deflection will not exceed 0.08 degree per ft length. A. 100 C. 55 B. 120 D. 135 Ans: 𝟏𝟎𝟎. 𝟏𝟐 𝐡𝐩 SHAFTINGS Problem 16 A 20 ft steel line shaft has bending action of pulleys. What power in hp can the shaft deliver at a speed of 360 rpm. Consider that the torsional deflection will not exceed 0.08 deg. per ft length. A. 2600 C. 1250 B. 1100 D. 900 Ans: 𝟐𝟔𝟎𝟐. 𝟕𝟒 𝐡𝐩 KEYS and SPLINES Keys • Are used to prevent relative motion between a shaft and the connected member through which torque is being transmitted. KEYS and SPLINES Splines • Are keys made integral with the shaft and usually consist of four, six, or ten in members. ANALYSIS ON KEYS Shear Stress on key: 𝐒𝐬 = 𝐅𝐭 𝐀 𝐬𝐡𝐞𝐚𝐫 𝐅𝐭 𝟐𝐓 = = 𝐰𝐋 𝐰𝐋𝐃𝐬 Compressive Stress on key: 𝐅𝐭 𝐅𝐭 𝟒𝐓 𝐒𝐜 = = = 𝟏 𝐀𝐜 𝐭𝐋 𝐭𝐋𝐃𝐬 𝟐 Note: When key and shaft are made of same material Let: L = 1.18D w = D/4 ANALYSIS ON SPLINES Shear Stress on splines: 𝐅𝐭 𝐅𝐭 𝟐𝐓 𝐒𝐬 = = = 𝐀 𝐬𝐡𝐞𝐚𝐫 𝐧𝐬 𝐰𝐋𝐧𝐬 𝐰𝐋𝐝𝐧𝐬 Compression between splines & hub: 𝐅𝐭 𝐅𝐭 𝐓 𝐒𝐜 = = = 𝟏 𝐀 𝐜 𝐧𝐬 𝐭𝐋𝐧𝐬 𝐭𝐋𝐑 𝐦 𝐧𝐬 𝟐 𝐑+𝐫 𝐃+𝐝 = 𝟐 𝟒 Total torque transmitted: 𝐓 = 𝐅𝐑 𝐦 = 𝐩𝐀𝐑 𝐦 𝐑𝐦 = Torque of one spline: 𝐓 𝐓𝐬 = 𝐱 𝟏. 𝟏 𝐧𝐬 Note: 𝐧𝐬 - number of splines 𝑹𝐦 - mean radius 𝐩 – permissible pressure COUPLINGS Couplings • Are used to connect sections of shafts or to connect the shaft of a driving machine to the shaft of a driven machine. ANALYSIS OF COUPLINGS COUPLING ELEMENT FAILURE MODE Shearing of key KEY Compression of key Shearing of bolts BOLTS FLANGE STRESS FORMULA 𝟐𝐓 𝐒𝐬 = 𝐰𝐋𝐃𝐬 𝟒𝐓 𝐒𝐜 = 𝐭𝐋𝐃𝐬 𝟐𝐓 𝐒𝐬 = 𝛑 𝟐 𝐝 𝟒 𝐛 𝐧𝐛 𝐃𝐁𝐂 Compression between bolt and flange 𝟐𝐓 𝐒𝐜 = 𝐝𝐛 𝐭 𝐟 𝐧𝐛 𝐃𝐁𝐂 Punching shear 𝟐𝐓 𝐒𝐬 = 𝛑𝐭 𝐟 𝐃𝐡 KEYS & COUPLINGS Problem 17 A 4 inches shaft using a flat key whose width is 1 inch is transmitting a torque of 63 000 in-lb. If the design shearing stress is 5000 psi the safe length is: A. 6.3 in C. 4.3 in B. 5.3 in D. none of these Ans: 𝟔. 𝟑 𝐢𝐧 KEYS & COUPLINGS Problem 18 A 1200 mm cast iron pulley is fastened to a 112.5 mm shaft by means of a 28.13 mm square key 175 mm long. What force acting at the pulley rim will shear the key if shear stress of the key is 20.67 kg/mm2? A. 9538 kg C. 5839 kg B. 8593 kg D. 3859 kg KEYS & COUPLINGS Problem 18 Key| Shaft| Frim Fkey Pulley | Ans: 𝟗𝟓𝟑𝟗 𝐤𝐠 KEYS & COUPLINGS Problem 19 Determine the required length of a square key if the key and shaft are to be of the same material and of equal strength but due to stress concentration, there is a 25% torque reduction. Ans: 𝟏. 𝟏𝟖𝐃 KEYS & COUPLINGS Problem 20 A line shaft with a power of 100 kW at a speed of 1200 rpm, had a rectangular key used in its pulley connection. Consider the shearing stress of the shaft to be 40 MPa and the key to be 200 MPa, determine the width of the rectangular key if it is onefourth of the shaft diameter. A. 23.65 mm C. 11.65 mm B. 14.65 mm D. 9.65 mm Ans: 𝟏𝟏. 𝟔𝟓 𝐦𝐦 KEYS & COUPLINGS Problem 21 A solid steel machine shaft with a safe shearing stress of 7000 psi transmits a torque of 10,500 in-lb. A square key is used whose width is equal to one-fourth the shaft diameter and whose length is equal to 1 ½ times the shaft diameter. Find key dimensions. A. ½ in and 3 in C. ¾ in and 2.5 in B. ½ in and 2.5 in D. ¾ in and 3 in Ans: ½ 𝐢𝐧 𝐚𝐧𝐝 𝟑 𝐢𝐧 KEYS & COUPLINGS Problem 22 Two shafts are connected by a flange coupling. The coupling is secured by 6 bolts, 20 mm in diameter on a pitch circle diameter of 150 mm. If torque of 120 N-m is applied, find the shear stress in the bolts. A. 0.85 N/mm2 C. 0.85 Pa B. 0.85 kPa D. 0.95 Pa Ans: 𝟎. 𝟖𝟓 𝐌𝐏𝐚 KEYS & COUPLINGS Problem 23 A flanged coupling has an outside diameter of 200 mm and connects two 40 mm shafts. There are four 16 mm bolts on a 140 mm bolt circle. The radial flanged thickness is 20 mm. If the torsional stress in the shaft is not to exceed 26 MPa, determine the shear stress in the bolts if uniformly distributed A. 1.2 MPa C. 4.3 MPa B. 2.9 MPa D. 5.8 MPa Ans: 𝟓. 𝟖 𝐌𝐏𝐚 KEYS & COUPLINGS Problem 24 Two short shafts having identical diameters of 38.1 mm and rotating at 400 rpm are connected by a flange coupling having 4 bolts with a 100 mm bolt circle. The design shearing stress of the bolt is 12 N/mm2 and the design compressive stress of the flange is 15 N/mm2 . How thick should the flange be in mm? A. 11.51 mm C. 12.49 mm B. 13.60 mm D. 15.65 mm Ans: 𝟏𝟏. 𝟓𝟏 𝐦𝐦 KEYS & COUPLINGS Problem 25 A flange coupling is to be designed, using 25-mm diameter bolts at a distance of 152 mm from the center of the shaft. Allowable shearing stress on the bolt is 103 MPa. If the shaft is to transmit 5,800 hp at a speed of 1,200 rpm, how many bolts are needed in the connection? A. 2 C. 4 B. 3 D. 5 Ans: 𝟓 𝐛𝐨𝐥𝐭𝐬 “The more I PRACTICE, the Luckier I get.” -Gary Player