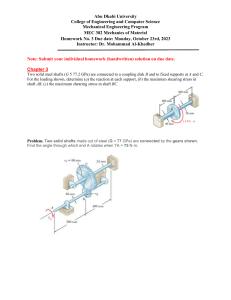

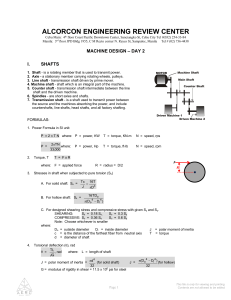

Problem 1: The design specifications of a 1.2 m long solid transmission shaft require that the angle of twist of the shaft not exceed 4° when a torque of 750 N-m is applied. Determine the required diameter of the shaft, knowing that the shaft is made of a steel with an allowable shearing stress of 90 MPa and a modulus of rigidity of 77.2 GPa. Problem 2: The electric motor exerts a 500 Nm torque on the aluminium shaft ABCD when it is rotating at a constant speed. Knowing that G=27 GPa and that the torques exerted on pulleys B and C are as shown, determine the angle of twist between (a) B and C, (b) B and D. Problem 3: For the given state of stress, determine the normal and shearing stresses after the element shown has been rotated (a) 25° clock wise, (b) 10° counter-clockwise. Problem 4: The grain of a wooden member forms an angle of 15° with the vertical. For the state of stress shown, determine (a) the in-plane shearing stress parallel to the grain, (b) the normal stress perpendicular to the grain.