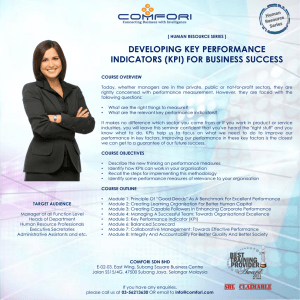

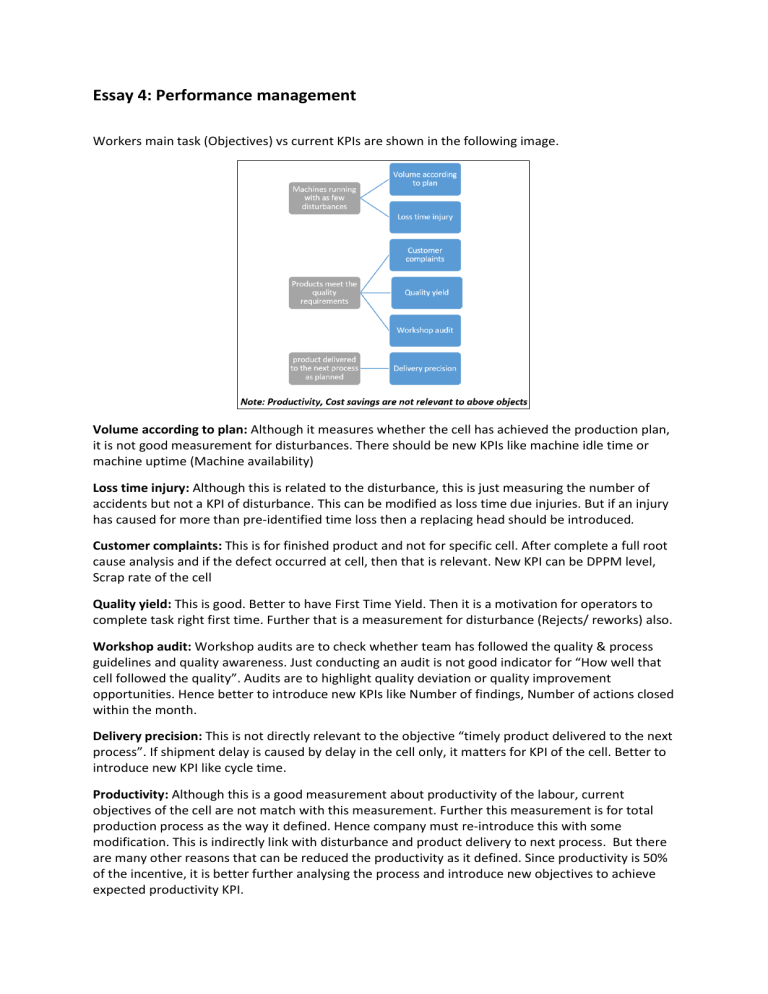

Essay 4: Performance management Workers main task (Objectives) vs current KPIs are shown in the following image. Volume according to plan: Although it measures whether the cell has achieved the production plan, it is not good measurement for disturbances. There should be new KPIs like machine idle time or machine uptime (Machine availability) Loss time injury: Although this is related to the disturbance, this is just measuring the number of accidents but not a KPI of disturbance. This can be modified as loss time due injuries. But if an injury has caused for more than pre-identified time loss then a replacing head should be introduced. Customer complaints: This is for finished product and not for specific cell. After complete a full root cause analysis and if the defect occurred at cell, then that is relevant. New KPI can be DPPM level, Scrap rate of the cell Quality yield: This is good. Better to have First Time Yield. Then it is a motivation for operators to complete task right first time. Further that is a measurement for disturbance (Rejects/ reworks) also. Workshop audit: Workshop audits are to check whether team has followed the quality & process guidelines and quality awareness. Just conducting an audit is not good indicator for “How well that cell followed the quality”. Audits are to highlight quality deviation or quality improvement opportunities. Hence better to introduce new KPIs like Number of findings, Number of actions closed within the month. Delivery precision: This is not directly relevant to the objective “timely product delivered to the next process”. If shipment delay is caused by delay in the cell only, it matters for KPI of the cell. Better to introduce new KPI like cycle time. Productivity: Although this is a good measurement about productivity of the labour, current objectives of the cell are not match with this measurement. Further this measurement is for total production process as the way it defined. Hence company must re-introduce this with some modification. This is indirectly link with disturbance and product delivery to next process. But there are many other reasons that can be reduced the productivity as it defined. Since productivity is 50% of the incentive, it is better further analysing the process and introduce new objectives to achieve expected productivity KPI. Cost savings: This is not a production cell KPI. This is a measure for company finance team to understand the profit margin. Overall Equipment Effectiveness (OEE) can be introduced as common KPI for all 3 objectives. Further it can be used to compare cells and for incentive system. Incentive system: Productivity, product delivered to the next process as planned and Volume according to plan are interconnected KPIs. Just productivity is enough for consideration but way of calculation needs to modify. Further there should be an importance for First time yield in the incentive system.