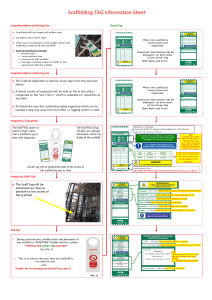

Technical information SICK RFU6xx function block SICK RFU6xx PNDP function block for Siemens S7-1200 / S7-1500 controls (TIA-Portal V12+SP1 or higher) Technical information RFU6xx PNDP FB (TIA-Portal) Table of contents 1 Version history ................................................................................................................. 3 2 About this document........................................................................................................ 4 2.1 Purpose of this document ............................................................................................ 4 2.2 Target audience ........................................................................................................... 4 3 General information ......................................................................................................... 5 4 Hardware configuration ................................................................................................... 6 4.1 Supported PLC controls ............................................................................................... 6 4.2 Supported fieldbus gateways/sensors .......................................................................... 6 4.3 Configuration in the TIA portal...................................................................................... 6 5 Module description........................................................................................................... 8 5.1 Module specifications ................................................................................................... 8 5.2 Operating principle ....................................................................................................... 9 5.3 Response to faults ......................................................................................................10 5.4 Timing .........................................................................................................................10 5.5 Value transfer .............................................................................................................11 5.5.1 Communication ....................................................................................................11 5.5.2 Single-TAG Mode: SOPAS object trigger control ..................................................14 5.5.3 Single-TAG Mode: SOPAS output format .............................................................14 5.5.4 Read TAG ............................................................................................................16 5.5.5 Write TAG ............................................................................................................17 5.5.6 Set Device Password ...........................................................................................18 5.5.7 Set TAG Password ...............................................................................................18 5.5.8 Lock TAG .............................................................................................................19 5.5.9 Kill TAG ................................................................................................................20 5.5.10 Communication test ............................................................................................20 5.5.11 Free command ...................................................................................................20 5.5.12 Reading result ....................................................................................................20 5.6 Receiving reading results > 200 bytes ........................................................................21 6 Parameter.........................................................................................................................22 7 Error codes ......................................................................................................................26 8 Examples .........................................................................................................................31 8.1 Reading transponder content ......................................................................................32 8.2 Writing TAG content ....................................................................................................34 Page 2 RFU6xx PNDP FB (TIA-Portal) Technical information 1 Version history Bundle Version V1.0 V1.1 V1.2 Date Description 21.02.2014 07.08.2014 30.03.2015 Initial version Rising edge detection (R_TRIG block calls removed) Output format (Mode 1): - Can be used optionally without a [STX]/[ETX] framing - Using an ‘x’ instead of a ‘X’ is also possible Changing the data type of the mode parameter from Boolean to unsigned short integer. 0 = Single-TAG mode 1 = Multi-TAG mode (hexadecimal) 2 = Multi-TAG mode (ASCII) - Adding TAG access/kill functions - Rename “Mode” structure to “Communication” - Moving the retry and antenna parameters into the Communication structure - Increasing the number of data that could be read to 64Words (128Bytes) - New example program added - Provide libraries for TIA12+SP1, TIA13+SP1 and TIA14 V1.3 21.04.2015 V2.0 26.5.2015 V2.1 18.10.2017 No library changes Page 3 Technical information RFU6xx PNDP FB (TIA-Portal) 2 About this document Please read these chapters carefully before you begin working with these operating instructions and the SICK RFU6xx function block. 2.1 Purpose of this document These instructions describe how to use the SICK_RFU6xx_PNDP function block. They are used to guide technical personnel working for the machine manufacturer/operator in project planning and commissioning the function block. 2.2 Target audience These operating instructions are aimed at specialist personnel such as technicians and engineers. Page 4 RFU6xx PNDP FB (TIA-Portal) Technical information 3 General information The SICK_RFU6xx_PNDP function block is used to facilitate communication between a Siemens S7-1200 / S7-1500 control and a SICK RFU6xx RFID interrogator. The following figure shows how the function block is represented in the function block diagram (FBD) view. Figure 1: Representation of function block in FBD Functionality of the function block: - i ii Send a software trigger via the PLC Receive telegrams sent by the device which can be configured in the SOPASi output format (reading results) Read and write transponder content (Single TAG/Multi-TAG mode) Write the UII/EPC bank using internal retries Set a TAG-Access / Kill-TAG password on the device Set a TAG-Access / Kill-TAG password on the TAG Lock/Unlock TAG regions Kill TAG permanently Execute a communication test Communication via freely selectable device commands (SICK CoLaii protocol) Address devices in a SICK CAN bus network SOPAS is an engineering tool used for configuring SICK sensors. The Command Language (CoLa) is an internal SICK protocol for communicating with SOPAS devices. Page 5 Technical information RFU6xx PNDP FB (TIA-Portal) 4 Hardware configuration 4.1 Supported PLC controls The function block only supports S7-1200 and S7-1500 PLCs with an industrial Ethernet interface. 4.2 Supported fieldbus gateways/sensors The SICK sensor communicates with the control via a fieldbus (PROFIBUS/PROFINET). If the sensor does not directly support the PROFIBUS/PROFINET fieldbuses, gateway modules can be used. The following gateways are supported by the function block: CDM 425 (PROFINET), firmware version V3.31 or higher CDF 600-2 (PROFIBUS and PROFINET) CDF 600 (PROFIBUS), firmware version V1.15 or higher CDM 420 including CMF400 PROFIBUS module, firmware version V1.100 or higher 4.3 Configuration in the TIA portal The correct sensor or gateway must be configured in the hardware configuration of the TIAPortal before the function block can be used. In the first step, the correct generic station description file (GSD/GSDML) must be imported into the TIA-Portal. The function block is specially designed for the handshake mode (HS). Only use modules from the "Handshake (HS)" category, which are defined with a length between 8 and 128 bytes. The addresses used can be configured inside or outside of the I/O area. Addresses are not permitted for use in peripheral ranges to which a partial process image and OB6x connection (synchronous alarms) are assigned as in this case consistent data transmission can no longer be achieved. Page 6 Technical information RFU6xx PNDP FB (TIA-Portal) Figure 2 shows an example configuration of the SICK RFU6xx RFID interrogator. The hardware identifications necessary for the function block are shown in the properties of the individual modules. Figure 2: Hardware configuration The size of the in/out modules indicates the amount of data which can be exchanged in one fieldbus cycle. If a telegram is longer than the projected module, the data will be transmitted fragmented over several PLC cycles (handshaking). Page 7 Technical information RFU6xx PNDP FB (TIA-Portal) 5 Module description The SICK_RFU6xx_PNDP function block simplifies the use of the RFID interrogator on S71200 / S7-1500 controls. The module enables data exchange via a PROFIBUS/PROFINET connection projected in the hardware configuration. The module automatically fragments the data as soon as it cannot be transmitted / received in one fieldbus cycle. The function block is working asynchronously, which means the processing is done via various function block call ups. Therefore it is necessary that the function block is called up cyclically in the user program. The RFU FB encapsulates the SICK_CCOM_PNDP, which facilitates communication between the PLC and the sensor. The SICK_GetValue / SICK_SetValue functions are used internally to interpret/create the device telegrams. 5.1 Module specifications Module name: Version: Supported PLCs: Modules used: PLC data types used: Optimized module access: Module call: Global variables used: Language used for module creation: SICK_RFU6xx_PNDP 2.0 S7-1200 S7-1500 DPRD_DAT DPWR_DAT MOVE_BLK TON_TIME SICK_CCOM_PNDP SICK_GetValue SICK_SetValue ST_SICK_RFU6xx yes cyclical none S7-SCL Page 8 Technical information RFU6xx PNDP FB (TIA-Portal) 5.2 Operating principle The following communication parameters must be specified before the RFU module can be used: #HWInputIdent: Hardware identification of the projected input module. The identifier can be defined during the hardware configuration (see Figure 2). #HWInputLength: Byte length for the projected input module (see Figure 2). #HWOutputIdent: Hardware identification for the projected output module. The identifier can be defined during the hardware configuration (see Figure 2). #HWOutputLength: Byte length for the projected output module (see Figure 2). #Data: The function block requires an instance of PLC data type ST_SICK_RFU6xx. This data type describes input and output parameter values for the individual block functions. The ST_SICK_RFU6xx variable must be stored in a data block in order to use the data type. Afterwards it must be connected to the function block. To carry out a module block action (#TriggerOn, #ReadTag etc.), the desired function must first be selected first. Only one function can be carried out at a the same time. The #Req parameter must be triggered with a rising edge (signal change from logic zero to one) in order to carry out the function. As long as no valid response has been received, the #ReqBusy parameter is used to signal this. The FB signals the #ReqDone = TRUE output parameter when the function has been successfully completed. If data was requested from the device during this function (e.g. #ReadTag), this data is copied to the relevant data structure of the data type ST_SICK_RFU6xx (#Data). Data sent via trigger command (#TriggerOn, #TriggerOff) or directly by the device (e.g. direct trigger via a photoelectric sensor) is stored in the data structure (ReadingResult.arrResult). The #RdDone output parameter indicates that new data has been received for a PLC cycle. The data sent by the device can be changed or adapted in SOPAS output format (see Figure 6). Page 9 Technical information RFU6xx PNDP FB (TIA-Portal) 5.3 Response to faults If the function block has an incorrect input value or faulty input circuit, an error bit (#Error) is set and an error code (#Errorcode) is output. In this case, no further processing is carried out. The parameters (#Error, #Errorcode) of the function block retain their value until a new command is started. 5.4 Timing Figure 3: Timing diagram 1: Trigger the #Req input by rising edge. The desired function (#TriggerOn in this case) must be selected at the same time/in advance. Only one function is permitted for selection at the same time; otherwise an error (#Error) will terminate the function. 2: When the command has been sent and the response is received, the function is terminated with #ReqDone. If an error occurred during the function, the function is terminated with #Error. The parameter #Errorcode contains the error code that occurred if the function is terminated with #Error. Page 10 RFU6xx PNDP FB (TIA-Portal) Technical information 5.5 Value transfer The PLC data type ST_SICK_RFU6xx contains all input and output parameter values of the supported function block actions. The data structure has a fixed definition and may not be modified except for the last entry "ReadingResult.arrResult" (see chapter 5.6: Receiving reading results > 200 bytes). Figure 4: ST_SICK_RFU6xx PLC data type 5.5.1 Communication The RFU can only communicate with one transponder at the same time. For this reason, read, write and lock commands are always addressed. The function block used the UII (Unique Item Identifier) to identify the transponder. The FB supports three different modes in order to determine which transponder UII is to be communicated with: iMode = 0 (Single-TAG mode): The system always communicates with the transponder which is currently in the reading field. This mode can only be used when precisely one TAG is located within the field. Special configuration of the output format of the RFU with SOPAS (see chapter’s 0 and 5.5.3) is required for this mode. If the single TAG mode is active, a trigger is automatically activated to read the UII and the antenna with the best signal strength (RSSI). Page 11 Technical information RFU6xx PNDP FB (TIA-Portal) iMode = 1 (Multi-TAG mode [Hexadecimal-Formatted]): A user defined transponder UII is used for purposes of communication. The UII-String must be entered in a hexadecimal representation (e.g. ‘1234ABCD’). The antenna to be used must be indicated in the respective read/write parameters. iMode = 2 (Multi-TAG mode [ASCII-Formatted]): A user defined transponder UII is used for purposes of communication. The UII-String must be entered in an ASCII representation (e.g. “This is my TAG”). The antenna to be used must be indicated in the respective read/write parameters. Parameter Communication.iMode Declaration Input Data type USINT Description Addressing mode 0: 1: Communication.iAntenna Mask In/Out USINT Single-TAG mode active Multi-TAG mode active (hexadecimal formatted UII) 2: Multi-TAG mode active (ASCII formatted UII) Antenna selection for current command. A1 = antenna 1 (internal/external, depending on device type) A2 = antenna 2 (external) A3 = antenna 3 (external) A4 = antenna 4 (external) Value 1 2 4 8 A4 A3 A2 A1 X X X X In the Single-TAG mode, the antenna is selected automatically (antenna with the best signal strength). With firmware >= V1.50 it is possible to use multiple antennas with one single command. For example: iAntennaMask = 16#03 (Antenna 1+2) iAntennaMask = 16#0F (All antennas) Valid value range: [1…15] Page 12 Technical information Parameter Communication.iRetry Declaration In/Out RFU6xx PNDP FB (TIA-Portal) Data type USINT Description Number of read/write attempts to be carried out. Valid value range: LowNibble (retries on one channel) 16#[0..7] HighNibble (retries on different channels) 16#[0..5] In the Single-TAG mode, the retry value is set by default to 16#32. Communication.sUII In/Out String[120] Example: iRetry:= 16#32 executes 3 changes of the channel (4 channels) with 2 retries per channel in each case (3 repetitions), i.e. a total of 4x3= 12 attempts. Transponder Identification (UII) If no UII is indicated (empty string), the respective read/write command will be carried out unaddressed. The UII is automatically determined in the Single-TAG mode and does not have to be indicated. Communication.arrRSSI Output Array [1..4] of SInt Example: ‘DEF011111234ABCD’ Outputs the RSSI value (reception strength) of the transponder in the reading field (only on the Single-TAG mode). [1] = RSSI value from antenna 1 (internal) [2] = RSSI value from antenna 2 (external) [3] = RSSI value from antenna 3 (external) [4] = RSSI value from antenna 4 (external) Table 1: Mode parameter Page 13 Technical information RFU6xx PNDP FB (TIA-Portal) 5.5.2 Single-TAG Mode: SOPAS object trigger control The object trigger control settings define the reading gate settings. The sensor sends a reading result to the PLC control after each reading gate (open/close). The FB uses this mechanism in order to read out the UII, the PC word and RSSI values from the corresponding transponder in the Single-TAG mode. The SOPAS settings under the menu Parameter Reading configuration Object trigger control must be defined, that the trigger window is opened via a "command" and closed again when a "Good Read" result is received or after a defined period of time (1000ms in this case). Figure 5: Trigger setting (SOPAS) 5.5.3 Single-TAG Mode: SOPAS output format The output format defines the content of the telegram that is sent by the device as soon as the trigger window is closed. This telegram is evaluated by the PLC and the information for address-specific read/write processes for TAG content is read. The SOPAS output format must be structured as shown in Figure 6 in order to use the function block in the Single-TAG mode. Figure 6: SOPAS output format Page 14 RFU6xx PNDP FB (TIA-Portal) Technical information Please ensured that the format of the blocks "RSAVG1...4" are set to hexadecimal format (double-click the respective block). The "PCUII" block may not be changed. Figure 7: Settings for RSSI blocks (RSAVG1...4) Depending on the number of TAGs located in the receiving range of the RFU and the configured RSSI threshold, the following ASCII telegrams are sent by the device: Case 1: One TAG in field [STX]01;[RSSI Antenna 1] [RSSI Antenna 2] [RSSI Antenna 3] [RSSI Antenna 4] [PC+UII][ETX] Case 2: More than one TAG in field [STX]0X[ETX] Case 3: No TAGs in field [STX]00[ETX] Page 15 Technical information RFU6xx PNDP FB (TIA-Portal) 5.5.4 Read TAG The “ReadTag” function is used to read a defined data area of a TAG. This function can only be applied to one TAG. The selected mode determines which transponder the system communicates with (see chapter 5.5.1). The following parameters must be set in the "ReadTag" structure before executing this block function. Parameter Declaration Data type Description ReadTag. Input USInt Selection of the memory bank from which iBank data is to be read. ReadTag. iStartWord ReadTag. iWordCount Input UInt 0 = Reserved 1 = UII/EPC 2 = TID 3 = User memory First word (16 bits) to be read. Input UInt Number of words (16 bits) to be read. ReadTag. iDataLength Output UInt ReadTag. arrData Output Array [1..128] of Byte Valid value range: [1..64] Valid length of read content in bytes. Required in order to define which content of the array "ReadTag.arrData" is valid. Content of read data. Table 2: Read TAG parameter Page 16 Technical information RFU6xx PNDP FB (TIA-Portal) 5.5.5 Write TAG The "WriteTag" function is used to write values to a defined data area of a TAG. This function can only be applied to one TAG. The selected mode determines which transponder the system communicates with (see chapter 5.5.1). The following parameters must be set in the "WriteTag" structure before executing this block function. Parameter Declaration Data type Description This parameter is only relevant if the UII WriteTag. Input USInt is to be written (Bank 1). iTIDWordCount The TID is automatically read once a writing command is placed on the UII. It is necessary to indicate the length of the TID. Transponders of the same type have the same TID lengths. Advantage: It is possible to use the internal retries for the command. In case of a write error it could happen that only a part of the UII is changed, so addressing is not possible anymore (inconsistent UII). Example: WriteTag.iTIDWordCount:= 2 If no TID should be used when writing the UII, the parameter must be set to zero (WriteTag.iTIDWordCount:= 0). Advantage: It reduces the TAG access time because the TID doesn’t need to be read. WriteTag. iBank WriteTag. iStartWord Input Input USInt UInt Valid value range: [0..16] Selection of the memory bank to be written to. 0 = Reserved 1 = UII/EPC 2 = TID (cannot be described) 3 = User memory First word (16 bits) to be written. Page 17 RFU6xx PNDP FB (TIA-Portal) Technical information Parameter WriteTag. iWordCount WriteTag. arrData Declaration Input Data type UInt Input Array [1..64] of byte Description Number of words (16 bits) to be written. Valid value range: [1..32] Data to be written to the selected TAG area. The length is defined by the iWordCount parameter. Table 3: Write TAG parameter 5.5.6 Set Device Password This function is used to set a password for a TAG-Access / Kill-TAG on the device (RFU) side. Only when the password of the device and the TAG is matched, a TAG access is possible. The following parameters must be set in the "SetDevicePwd" structure before executing this block function. Parameter Declaration Data type Description SetDevicePwd Input USInt Type selection .iType 0 = Set a device access password 1= Set a transponder kill password SetDevicePwd .sPassword Input String[8] Valid value range: [0..1] Password This string must have exactly 8 characters. Only characters with the values [0..9 - A..F] are valid. To remove the password from the device, use the value ’00000000’ Table 4: Set device password parameter 5.5.7 Set TAG Password This function is used to set a password for a TAG-Access / Kill-TAG on the transponder side. Only when the password of the device and the TAG is matched, a TAG access is possible. The selected mode determines which transponder the system communicates with (see chapter 5.5.1). The following parameters must be set in the "SetTagPwd" structure before executing this block function. Parameter Declaration Data type Description SetTagPwd Input USInt Mode selection .iType 0 = Set a device access password 1= Set a transponder kill password Valid value range: [0..1] Page 18 RFU6xx PNDP FB (TIA-Portal) Technical information Parameter SetTagPwd .sPassword Declaration Input Data type String[8] Description Password This string must have exactly 8 characters. Only characters with the values [0..9 - A..F] are valid. To remove the password from the transponder, use the value ’00000000’ Table 5: Set TAG password parameter 5.5.8 Lock TAG This function is used to lock/unlock TAG region temporarily or permanently. The #iDataParameters defines the region of the TAG which should be locked / unlocked. The selected mode determines which transponder the system communicates with (see chapter 5.5.1). The following parameters must be set in the "LockTag" structure before executing this block function. Parameter Declaration Data type Description LockTag. Input USInt This value defines which TAG regions iDataParameshould be locked / unlocked. ter Parameter values see Valid value range: [1..32] Table 6: LockTag parameter Value Memory bank 1 UII 2 UII 3 UM 4 UM 5 TAG access password 6 TAG access password 7 TAG kill password 8 TAG kill password 9 UII+UM 10 UII+UM 11 UII+TAG access password 12 UII+TAG access password 13 14 UII+TAG access password+TAG kill password UII+TAG access password+TAG kill password 15 All memory banks 16 All memory banks Table 8: Lock parameter Action Lock temporary Lock permanent Lock temporary Lock permanent Lock temporary Lock permanent Lock temporary Lock permanent Lock temporary Lock permanent Lock temporary Lock permanent Lock temporary Lock permanent Lock temporary Lock permanent Value Memory bank 17 UII 18 UII 19 UM 20 UM 21 TAG access password 22 TAG access password 23 TAG kill password 24 TAG kill password 25 UII+UM 26 UII+UM 27 UII+TAG access password 28 UII+TAG access password 29 30 UII+TAG access password+TAG kill password UII+TAG access password+TAG kill password 31 All memory banks 32 All memory banks Action Unlock temporary Unlock permanent Unlock temporary Unlock permanent Unlock temporary Unlock permanent Unlock temporary Unlock permanent Unlock temporary Unlock permanent Unlock temporary Unlock permanent Unlock temporary Unlock permanent Unlock temporary Unlock permanent Table 7: Unlock parameter Page 19 RFU6xx PNDP FB (TIA-Portal) Technical information 5.5.9 Kill TAG This function is used to kill the whole transponder. After this function the TAG is permanently destroyed. The selected mode determines which transponder the system communicates with (see chapter 5.5.1). 5.5.10 Communication test This function performs a communication test between the PLC and the RFU. 5.5.11 Free command The free command is used to communicate with the SICK sensor via a valid device command (CoLa protocol). To be used for this purpose, the command must be stored in the string "sCommand" of the "FreeCommand" structure. The commands can be obtained from the device description or the SOPAS engineering tool. Parameter Declaration Data type Description FreeCommand. Input String Freely selectable CoLa command (for sCommand [100] commands, see device documentation). FreeCommand. Output String Answer received from the CoLa telesResult [100] gram sent. Table 9: Free command parameters 5.5.12 Reading result The "ReadingResult.arrResult" array stores data that are sent per trigger command (#TriggerOn, #TriggerOff) or directly from the device (e.g. direct trigger via photoelectric sensor). The output parameter #RdDone signals whether data were received. Parameter Declaration Data type Description ReadingResult. Output USInt The receive counter is incremented by iCounter one as soon as a new reading result is received. ReadingResult. iLength ReadingResult. arrResult Output UInt Value range: [0..255] Byte length of received reading result. Output Array [1..200] of byte Received response to a trigger signal (can be defined via the SOPAS output format). The maximum length of the received data is 200 bytes. Chapter 5.6 describes the procedure for receiving longer data telegrams. Table 10: Reading result parameters Page 20 Technical information RFU6xx PNDP FB (TIA-Portal) 5.6 Receiving reading results > 200 bytes The function block is designed to receive reading results up to a length of 200 bytes. If longer data are to be handled, the function block must be changed at the points indicated below: Change to the PLC data type (ST_SICK_RFU6xx): In the PLC data type provided, the array size of the variable ReadingResult.arrResult must be changed (to a maximum of 500 bytes). Figure 8: Change to PLC data type Change to the program code (SICK_RFU6xx_PNDP): The newly defined array size for the reading result must be entered into the program code for the SICK_RFU6xx_PNDP block. Figure 9: Change to function block After these changes, the amended PLC blocks must be re-compiled and transmitted to the PLC. Page 21 Technical information RFU6xx PNDP FB (TIA-Portal) 6 Parameter Parameter HWInputIdent HWInputLength HWOutputIdent Declaration Data type Input HW_IO Input Input USInt HW_IO HWOutputLength Input USInt CANId Input USInt Description Hardware identification for the projected input module (see hardware configuration). Only HS modules (handshake modules) with a maximum length of 128 bytes may be used in the hardware configuration. Length of the input module used in the hardware configuration. Valid value range: [8..128] Hardware identification for the projected output module (see hardware configuration). Only HS modules (handshake modules) with a maximum length of 128 bytes may be used in the hardware configuration. Length of the output module used in the hardware configuration. Valid value range: [8..128] CAN ID of the sensor to be addressed. If no SICK CAN network is used, the CAN ID = 0 TOut Input Time The master and the multiplexer are always addressed with the CAN ID = 0 even if this is allocated another CAN ID. Period of time, after a timeout error is occured. If this parameter is not wired, the timeout period is set to 5 seconds as a default. Req Input Bool Note that some commands require longer processing periods (e.g. storage commands). Rising edge: Execute the selected block function. Page 22 Technical information Parameter TriggerOn RFU6xx PNDP FB (TIA-Portal) Declaration Data type Input Bool Description Block function: Device trigger (open a reading gate). This function requires that the object trigger control (SOPAS) for the opening of the reading gate is set to "Command". TriggerOff Input Bool The result sent from the device (defined in the SOPAS output format) is stored in the "ReadingResult.arrResult" variable (PLC data type: ST_SICK_RFU6xx). Block function: Device trigger (close a reading gate). This function requires that the object trigger control (SOPAS) for the closing of the reading gate is set to "command". ReadTag Input Bool The result sent from the device (defined in the SOPAS output format) is stored in the "ReadingResult.arrResult" variable (PLC data type: ST_SICK_RFU6xx). Block action: Read TAG content. This function requires that the parameters of the "ReadTag" structure (PLC data type: ST_SICK_RFU6xx) are assigned with valid values (see chapter 5.5.4). WriteTag Input Bool The selected function block mode determines which transponder is to be read (see chapter 5.5.1). Module function: Write TAG content. This function requires that the parameters of the "WriteTag" structure (PLC data type: ST_SICK_RFU6xx) are assigned valid values (see chapter 5.5.5). SetDevicePwd Input Bool The selected function block mode determines which transponder is to be written to (see chapter 5.5.1). Module function: Set device password This function requires that the parameters of the "SetDevicePwd" structure (PLC data type: ST_SICK_RFU6xx) are assigned valid values (see chapter 5.5.5). Page 23 Technical information Parameter SetTagPwd RFU6xx PNDP FB (TIA-Portal) Declaration Data type Input Bool Description Module function: Set TAG password This function requires that the parameters of the "SetTagPwd" structure (PLC data type: ST_SICK_RFU6xx) are assigned valid values (see chapter 5.5.5). LockTag Input Bool The selected function block mode determines which transponder should be used (see chapter 5.5.1). Module function: Lock / Unlock TAG This function requires that the parameters of the "LockTag" structure (PLC data type: ST_SICK_RFU6xx) are assigned valid values (see chapter 5.5.5). KillTag ComTest FreeCommand Input Input Input Bool The selected function block mode determines which transponder should be used (see chapter 5.5.1). Module function: Kill TAG Bool The selected function block mode determines which transponder should be used (see chapter 5.5.1). Module function: Communication test Bool #ReqDone= TRUE: communication OK #ReqDone= FALSE: communication not OK Module function: Free command (see chapter 5.5.6). The command to be transferred is defined in the variable "FreeCommand.sCommand" (PLC data type: ST_SICK_RFU6xx). Data In/Out After successful transfer (#ReqDone= TRUE), the command response in the result string "FreeCommand.sResult" is available. ST_SICK The ST_SICK_RFU6xx-type variable required _RFU6xx for configuring the block functions and storing the Tag results. This variable must be defined in a data block and linked to the function block. Page 24 Technical information Parameter RdDone ReqDone ReqBusy Error Error code RFU6xx PNDP FB (TIA-Portal) Declaration Data type Output Bool Output Output Output Output Bool Description Rising edge: New reading result received The reading result and the valid length are stored in the structure "ReadingResult" (PLC data type: ST_SICK_RFU6xx) (see chapter 5.5.12). Indicates whether the selected block function has been successfully completed. Bool Bool TRUE: Successfully completed FALSE: Not completed Block function in progress. Error bit: DWord FALSE: No error TRUE: Aborted with error Error status (see Error codes) Table 11: Module parameters Page 25 Technical information RFU6xx PNDP FB (TIA-Portal) 7 Error codes The #Errorcode parameter contains the following error information: - Error in the SICK_RFU6xx_PNDP function block - Error in the SICK_CCOM_PNDP function block - Error in the SICK_GetValue/SICK_SetValue functions - Error in the Siemens functions DPRD_DAT/DPWR_DAT - Error sent by the device Error code 16#0000_0000 16#0000_0001 Brief description No error Timeout (SICK_CCOM_PNDP) 16#0000_0002 Invalid module length (input) 16#0000_0003 Invalid module length (output) 16#XXXX_0004 DPWR_DAT error 16#XXXX_0005 16#0000_0006 16#0000_0009 16#XXXX_000A 16#XXXX_000F DPRD_DAT error Description No error The command could not be executed within the defined timeout period. Possible causes: - Device is not connected to the PLC - Device is not sending command responses (echo) - Processing time of the command > timeout period - CAN bus station not present The length of the input module projected in the hardware configuration is not valid. Valid module length: [8..128] The length of the output module projected in the hardware configuration is not valid. Valid module length: [8..128] Writing to the output module is not possible. Check the hardware identification and the length of the output module. XXXX: Error code for the Siemens function "DPWR_DAT" (see TIA portal information system). Reading the input module is not possible. Check the hardware identification and the length of the input module. Communication error XXXX: Error code for the Siemens function "DPRD_DAT" (see TIA portal information system). Internal communication error Reserved Reserved Page 26 Technical information Error code 16#0000_0010 16#XXXX_0011 RFU6xx PNDP FB (TIA-Portal) Brief description Timeout (SICK_CCOM_PNDP) Description The command could not be executed within the defined timeout period. Device error Possible causes: - Device is not connected to the PLC - Device is not sending command responses (echo) - Processing time of the command > timeout period - CAN bus station not present A device error occurred. XXXX = This error is sent by the device connected (see device documentation) 16#0001: Access denied 16#0002: Unknown index 16#0003: Unknown index 16#0004: Wrong condition 16#0005: Invalid data 16#0006: Unknown error 16#0007: Too many parameters 16#0008: Parameter missing 16#0009: Wrong parameter 16#000A: No write access 16#000B: Unknown command 16#000C: Unknown command 16#000D: Server busy 16#000E: Text string too long 16#000F: Unknown event 16#0010: Too many parameters 16#0011: Invalid character 16#0012: No message 16#0013: No answer 16#0014: Internal error 16#0015: Hub address: wrong 16#0016: Hub address: error 16#0017: Hub address: error 16#XXXX_0012 16#XXXX_0013 SICK_GetValue error SICK_SetValue error For a detailed description of the error, see the device description. Error interpreting the device command received (internal FB error). XXXX = Error code for the function SICK_GetValue (see FB description). The received device answer cannot be interpreted (internal FB error). XXXX = Error code for the function SICK_SetValue (see FB description). Page 27 Technical information Error code 16#0000_0014 16#0000_0015 16#0000_0016 16#XXXX_0017 16#XXXX_001F 16#0000_0020 16#0000_0021 16#0000_0022 16#0000_0023 RFU6xx PNDP FB (TIA-Portal) Brief description #CANId > 63 No block function selected, or more than one block function selected Invalid command response received Reserved FreeCommand.sCommand > arrCommand (500 bytes) Response to free command > result string (FreeCommand.sResult [100 characters]) No TAG in field There is more than one TAG in the field or the RSSImin evaluation condition has not been met. Description Invalid CAN ID Valid value range: [0..63] Only one block function can be carried out at the same time. The selected block function was not carried out as the expected device response did not correspond to the request sent. This can have the following causes, depending on function: - Incorrect trigger setting in the SOPAS device configuration - Device is not in "Run mode" - Send/receive power insufficient - Tag not long enough in field - Access to a not-existent TAG range (check iStartWord and iWordCount parameters) - Selected antenna cannot access the selected TAG (check iAntenna parameter). - Invalid UII (check sUII mode) - Signal strength too low - The TAG region is locked Reserved Length of free command is invalid Valid value range: [1...100] The response to the free command is longer than 100 characters. There are no TAGs in the receiving range of the RFU. This error can only occur in the Single-TAG mode. This error can signify several different things: - There is more than one TAG in the receiving range of the RFU. - The evaluation condition RSSlmin is not met (see SOPAS). This error can only occur in the SingleTAG mode. Page 28 Technical information Error code 16#0000_0024 16#0000_0025 16#0000_0026 16#0000_0027 16#0000_0028 16#0000_0029 16#0000_002A 16#0000_002B 16#0000_002C 16#0000_002D RFU6xx PNDP FB (TIA-Portal) Brief description Invalid output format Description Invalid SOPAS output format. Check the output format (see Chapter 5.5.3) ReadTag.iBank > 3 This error can only occur in the SingleTAG mode. Invalid bank (read TAG) 64 < ReadTag. iWordCount < 1 Valid value range: [0..3] The function block can read a maximum of 64 words (128 bytes) from the TAG. Reserved Reserved WriteTag.iBank > 3 Valid value range [1..64] Reserved Reserved Invalid bank (write TAG) 32 < WriteTag. iWordCount < 1 Valid value range: [0..3] The function block can write a max. of 32 words (64 bytes) to the TAG. Invalid Retry (Communication.iRetry) 15 < Communication. iAntennaMask < 1 WriteTag. iTIDWordCount > 16 Valid value range [1..32] Invalid retry parameter Valid value range: Low nibble = [0..7] High nibble = [0..5] Invalid antenna selection Valid value range: [1..15] Invalid TID length (write UII/EPC bank). This error can only occur if the UII is to be described and the parameter iTIDWordCount is <> 0. 16#0000_002E 16#0000_002F 16#0000_0030 Selected UII > 240Bit (60 characters) Reserved Reserved Valid value range: [0..16] Invalid length of selected UII. This error can only occur in the SingleTAG mode. Reserved Reserved Page 29 Technical information Error code 16#0000_0031 16#0000_0032 16#0000_0033 16#0000_0034 RFU6xx PNDP FB (TIA-Portal) Brief description Description Invalid iType value Invalid type parameter value. (SetDevicePwd/SetTagPwd) Valid value range: [0..1] Password length <> 8 char- The password for the TAG-Access / Killacters TAG function must have exactly a length of 8 characters. 32 < LockInvalid data parameter value Tag.iDataParameter < 1 Valid value range: [1..32] Communication.iMode > 2 Invalid communication mode value. #ReadingResult. Reading result > 200 bytes iLength = -1 Valid value range: [0..2] The reading result received is longer than 200 bytes. See chapter 5.6 for information on how to receive reading results > 200 bytes. Table 12: Error codes Page 30 Technical information RFU6xx PNDP FB (TIA-Portal) 8 Examples Figure 10 shows an example wiring of the SICK_RFu6xx_PNDP function block in the OB1 program of the control. In the hardware configuration, a SICK RFU6xx interrogator is projected with a process data width of 128bytes input (hardware identification: 270) and 128 bytes output (hardware identification: 271) (see Figure 2). The CAN ID is entered as null because the RFU is not operated together with other devices on a CAN network. In DB1 (SICK_RFU_Data), the variable "RFU" was stored as type ST_SICK_RFU6xx. This structure of variables contains input and output parameters for the module functions supported. Example program: Figure 10: Program code (example) Figure 11: Data block (example) Page 31 Technical information RFU6xx PNDP FB (TIA-Portal) 8.1 Reading transponder content First, it is necessary to select the transponder which should be used. If the value "Communication.iMode = 0", then the system will communicate with the transponder that is currently located in the RFID sensor's reading range. Special configuration of the RFU in SOPAS-ET (see chapters 0 and 5.5.3) is required for this mode. Figure 12: Selection of communication mode Then, it is necessary to define what content is to be read out of the transponder. Bank: Start word: Word count: 3 (User memory) 0 (Start address) 3 (Read out three words) Figure 13: Read TAG parameters The reading function (#ReadTag) is executed as soon as the bit #Req is triggered with a rising edge. Figure 14: Starting the block function (ReadTag) The reading function is completed as soon as bit #ReqDone = TRUE. The parameter mode sUII shows the UII of the selected transponder. Page 32 Technical information RFU6xx PNDP FB (TIA-Portal) The read TAG content is available in the data array "ReadTag.arrData" of the corresponding data block. The "ReadTag.iDataLength" variable specifies how many bytes have been received and valid. Figure 15: Read TAG content Page 33 RFU6xx PNDP FB (TIA-Portal) Technical information 8.2 Writing TAG content First, it is necessary to select the transponder which should be used. If the value "Communication.iMode = 1", then the system will communicate with the specified transponder. Mode: Antenna: Retry: UII: 1 (Multi-TAG mode (hexadecimal)) 1 (Internal antenna) 16#32 (Internal retries: 4 channels with 3 repetitions = 12 attempts) 3005FB63AC1F3681EC880468 Figure 16: Specification of transponder UII Subsequently, it is necessary to define what content is to be written to the TAG and where it should be stored. Bank: Start word: Word count: TID word count: Content to be written: 3 (User memory) 0 (Start address) 3 (Write three words) 0 (Is only required for writing the UII) "112233" (6 ASCII characters = 3 words) Figure 17: Write TAG parameters The writing function (#WriteTag) is executed as soon as the bit #Req is triggered with a rising edge. Figure 18: Starting the block function (WriteTag) The writing function is completed as soon as bit #ReqDone = TRUE. Page 34