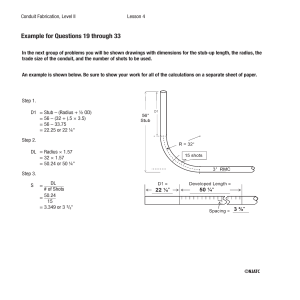

Conduit Fabrication, Level II Lesson 4 Example for Questions 34 through 43 In the next few problems you will modify the procedure that you’ve been using in order to do the calculations for segmented 90° bends which require both the stub-up and leg lengths to be fabricated as part of the bending process. By adding two additional steps you will be able to make these calculations also. This will enable you to cut and thread the conduit before the bends are made. An example is shown below. Be prepared to show your work for all of the calculations on a separate sheet of paper. Step 1. D1 = Stub – (Radius + ½ OD) = 48 – (24 + (.5 × 2.375) = 48 – 25.1875 = 22.8125 or 22 ¹³/16" Step 2. D2 = Leg – (Radius + ½ OD) = 44 – (24 + (.5 × 2.375) = 44 – 25.1875 = 18.8125 or 18 ¹³/16" Step 3. DL = Radius × 1.57 = 24 × 1.57 = 37.68 or 37 ¹¹/16" Step 4. S The conduit would be cut, threaded, and marked as shown below. Keep in mind that the reference mark for laying out the shots is the center of the developed length. DL # of Shots 37.68 = 18 = 2.09" = Step 5. TL = D1 + DL + D2 = 22.8125 + 37.68 + 18.8125 = 79.305 or 79 5/16" ©NJATC