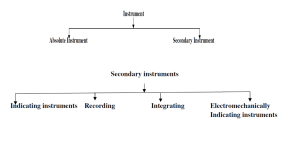

1 UNIT - I ➢ ➢ ➢ ➢ ➢ ➢ ➢ ➢ ➢ ➢ Analog Ammeter and Voltmeters: Classification deflecting - control and damping torques PMMC -Construction - Torque equation moving iron type Construction - Torque equation electrostatic instruments - Construction - Torque equation Range extension Errors and compensations advantages and disadvantages. Instrument transformers: Current Transformer and Potential Transformerconstruction - theory - errors Numerical Problems. 2 Classification of Instruments: Classification of Instruments Absolute Instruments Secondary Instruments Gives the quantity to be measured interns of instrument constant Gives the quantity to be measured directly Classification of analog Instruments: 3 1.Indicating Instruments: These instruments provide a direct reading of the measured quantity, such as • Analog Voltmeters • Ammeters. • PMMC • MI • EMMC • Meggar 2.Recording Instruments: Instruments that continuously record the variations of the measured quantity over time. Examples: • Seismograph • electrocardiogram • Substation and generating stations load duration curves • include chart recorders • strip chart recorders. Note: Display + Recording. 3.Integrating Instruments: These are the instruments which will give the electrical energy supply to a consumer over a specific period of time. Ex: Energy meter Note: Display+ Recording+ Cumulative Addition. 4.Null Type Instrument: An instrument in which zero or null indication determines the magnitude of measured quantity such type of instrument is called a null type instrument. Ex: DC potentiometer. 4 Working Principal of Analog Instruments/ Effects Used to Produce Deflecting Torque: 1. Magnetic Field Effect 2. Electrostatic Field Effect 3. Electromagnetic Field of Attraction/ Repulsion 4. Electromagnetic Induction Effect 5. Thermal or Heating Effect. 6. Hall Effect Magnetic effect : ➢ When a current carrying conductor is placed in a magnetic field then force acts on the conductor which makes the conductor to move. ➢ One type of instrument that uses the magnetic effect is the moving coil instrument, also known as a PMMC (permanent magnet moving coil) instrument. 5 Heating Effect: When two dissimilar materials joined together to form a closed loop, these metals are mainted with different temperatures, an emf is induced in it current will flow. This current is responsible for torque. Ex: Thermocouple ammeter Electrostatic Effect: The electrostatic effect is used in voltmeters, which are instruments that measure the potential difference or voltage between two points in an electrical circuit. 6 The principle of operation of electrostatic instruments is based on the force of attraction or repulsion between two charged bodies. The instrument consists of two plates, one fixed and one movable. When a potential is applied across the plates, an electrostatic field is created and this causes a force to be exerted between the plates. This force results in a deflecting torque which causes the movable plate to move, and this movement is proportional to the potential difference being measured. Induction Effect: when AC supply is given to the magnets alternating current flows which cuts the disc. An emf is induced in it. Disc is a closed path, current flows through it, interaction of disc flux & magnetic flux, the disc rotates. This Effect is used in induction type Energy meter. Hall Effect: If a metal or a semiconductor carrying a current |is placed in a transverse magnetic field B then an emf is produced between the edges of the conductor which is proposonal to both B and I. This effect is used in hall effect transducers. Essential requirements of any Indicating Instruments: 1. Deflection system- It produces a deflecting torque(Td) 2. Controlling system - It produces a controlling torque(Tc) 3. Damping system- It avoids the oscillations of the pointer. 7 Deflecting Torque: ➢ The deflecting torque acting on the pointer to move in forward direction from its zero position. ➢ The deflecting torque can be Produce in any of the Following methods. 1. Magnetic effect 2. Electrostatic effect 3. Induction effect 4. Thermal effect Controlling Systems: The Controlling system Provides controlling torque which serves following functions 1. When the Supply is removed, pointer bring backs to original zero position. 2. It Provides equal and opposite torque to make Pointer at definite value. 3. Thus, the deflection is proportional to quantity under measurements. (It provides a proportional output to the input) There are 2 methods for controlling system 1. Spring Control method. 2. Gravity control method. Spring controlling Torque: ➢ In this method, two springs made up of phosphor bronze are used. ➢ One spring is placed above while other spring is placed below the spindle of the instrument. ➢ One end of each spring is attached to the spindle and its other end is attached to the fixed part of the instrument. . ➢ Both springs are wounded are in reverse direction to each other to compensate against temperature changes. ➢ The controlling torque in this method depends upon the twisting of springs. The twisting force of spring is proportional to the angle through which the pointer moves. 8 Properties of Spring Material: ✓ Spring should be conducting nature. ✓ Non magnetic, ✓ low specific resistance ✓ It should have low temperature coefficient of resistance. ✓ i.e K independent of temperature ✓ High stiffness K i.e it should have high mechanical strength. 9 Working of Spring Control Method: • When the instrument is used to measure any electrical quantity then a deflecting torque is produced and then pointer moves and one of the spring gets twisted while other spring gets unwounded. • The resultant twist produces the controlling torque. • The twist goes on increasing with the increase in the deflection of pointer and so does the controlling torque. • Position comes when the deflecting torque becomes equal to the controlling torque and pointer stops. • The controlling torque produced by spiral springs is given by, • ∴ Tc = Ebt3θ / 12L = Ks θ • where Tc is the controlling torque, Eb is the modulus of elasticity of the spring material, t is the thickness of the spring, θ is the angular deflection of the pointer, and L is the length of the spring. • The deflecting torque in an instrument is proportional to the current being measured, ∴Td α I Td =Kd I • When the instrument is in equilibrium, the deflecting torque (Td) is equal to the controlling torque (Tc). This means that ∴ Td = Tc Kd I = Ks θ ∴ θ =Kd I/Ks θ=KI ∴ The deflection is directly proportional to current through the whole range of scale and therefore the scale is uniform or linear. 10 ADVANTAGES OF SPRING CONTROL METHOD: 1. The instrument can be placed in any position i.e., horizontal as well as vertical. 2. This method does not increase the weight of the instrument as springs are light. 3. Scale is uniform in this method DISADVANTAGES OF SPRING CONTROL METHOD: Temperature Effect: In spite of good design, the change of temperature effects the length of the springs and also the controlling torque. As Temp increases K decreases Aging Effect: As time passes, the accuracy of springs also declines due to their deterioration. As T increase K Decrees spring stiffness decreases Gravity Control Method: • It uses gravity force to produce controlling torque. • Control weight and balancing weight are attached to the spindle as shown in figure. • The balancing weight is provided for mechanical balance and for zero setting. • The control and balancing weight are adjustable this can be taken towards the spindle or away from the spindle. Threads are provided for this purpose. Working of Gravity control: ➢ At zero position of the pointer the control weight W is in the vertical position and therefore no controlling torque is produced. ➢ However, under the action of the deflecting torque. the pointer deflects through an angle θ from its zero position as shown in fig ➢ When pointer moves from A to B the weight moves from C to D But due to gravity, the control weight would try to come back to its original vertical position and produces the necessary controlling torque. ➢ The pointer stops when the controlling torque becomes equal to the deflating torque, ie. 11 Tc=Td ➢ There are two components of the control weight WsinØ and WcosØ. ➢ Only the component WsinØ will provide the necessary controlling torque and helps to retain the original position Thus, Tc = (WsinØ) *l It is seen from above equation that controlling torque is directly proportional to the sine of the deflected angle. So scale is non- uniform (or) Non linear 12 Advantages of Gravity Control: 1. It is a simple and cheap method. 2. It is not affected by temperature changes. 3. The controlling torque can be varied by adjusting the position of the control weight. 4. Longer life. DISADVANTAGES OF GRAVITY CONTROL METHOD: 1. Have non-uniform scale and thus reading become difficult. 2. It has to be used in vertical position only so suitable for vertically mounted instruments 3. The control weight adds to the weight of the instrument. It decreases the torque weight ratio and reduces sensitivity of the instrument 4. Maintenance is complicated. 13 Comparisons of Spring and Gravity Control: Point of comparison Arrangement Spring control Gravity control Spring is attached to the pointer. Control weight and balance weight and attached to the spindle. Suitability Can be used for vertical and horizontal mounted instruments. Can be used only for vertically mounted instruments. Equation for controlling torque Tc = k θ Tc = W sin θ Scale of instrument Uniform Not uniform Perfect levelling of instrument Not required Required Cost Cheap Costlier than spring control. Adjustment Easy (screw) is provided for adjustment Some what (control balance position is adjusted) Effect of temperature variation Controlling torque is affected No effect Aging effect Yes No Maintenance work Easy Complicated than spring control. Weight Less More Space required Less More difficult weight weight to be 14 DAMPING FORCE: ➢ A Damping Torque/force is one which acts on the instrument only when it is moving and it always opposes the motion of pointer. ➢ Damping force in any electrical instrument is necessary because it brings the pointer at rest quickly. ➢ In the absence of damping force, due to inertia of the moving system, the pointer will oscillate about its final position for some time before coming to rest in steady position. METHODS OF PRODUCING DAMPING FORCE/TORQUE: 1. Air friction Damping 2. Fluid Friction Damping 3. Eddy Current Damping 1.Air friction Damping: Case:1 When the pointer moves clockwise When the pointer moves clockwise the piston comes out of the air chamber so that the pressure inside the chamber becomes less as compared to the atmospheric pressure outside the chamber and as a result the piston(and the moving system of the instrument) are opposed in their rapid motion, i.e., their movement is checked. 15 Case :2 (When the pointer moves anti clock wise) • When the pointer moves anti clock wise, the piston is pushed in to the chamber; the air inside the chamber is pressed so that the pressure inside the chamber becomes higher than the atmospheric pressure out side and as result, the Piston (hence the moving system) are opposed in rapid motion ie., their speed of motion is again checked. 2.Fluid Friction Damping: ❖ This damping is similar to air friction damping except that air is replaced by a high viscosity oil. ❖ The friction between the disc and fluid is used for opposing the motion. ❖ Damping force due to fluid is greater than that of air due to viscosity. The disc is also called a vane. ❖ In this method one disc Fig. 1 (a) or more than one vanes Fig 1 (b) are attached with the spindle of the instrument. ❖ The damping torque can be increased by : 1. Using high viscosity oil. 2. Using more discs or vanes. 16 • The arrangement is shown in the figure. • It consists of a vane attached to the spindle which is completely dipped in the oil. • The frictional force between the oil and the vane is used to produce the damping torque, which opposes the oscillating behavior of the pointer. Advantages of Fluid friction damping: • Due to the more viscosity of the fluid, more damping is provided. • The oil can also be used for insulation purposes. • Due to the upthrust of oil, the load on the bearings is reduced, thus reducing the frictional errors. Disadvantages of Fluid friction damping: 1. This can be only used for instruments that are in a vertical position. 2. Due to oil leakage, the instruments cannot be kept clean. 3.Eddy Current Damping: ❖ Eddy current damping is a method of damping that utilizes the principles of Faraday's law and Lenz's law to provide a highly effective form of damping. • It is based on the principle that when a conductor (such as an aluminum disc) moves in a magnetic field, cutting the flux, an e.m.f. (electromotive force) gets induced in it. • The direction of this e.m.f. is such that it opposes the cause that produced it. 17 Working of Eddy Current Damping: ➢ In this method, an aluminum disc is connected to the spindle of the instrument. ➢ When the pointer oscillates, the aluminum disc rotates under the influence of the magnetic field of the damping magnet. ➢ As the disc cuts through the flux, it induces an e.m.f. in the disc, which creates circulating currents known as eddy currents. ➢ The direction of these eddy currents is such that they oppose the cause producing them, which is the relative motion between the disc and the field. ➢ This opposing force quickly brings the pointer to rest, making it a highly effective and efficient method of damping. Permanent Magnet Moving Coil (PMMC) instrument: Construction: • A permanent magnet is used in this type instrument. • Aluminum former is provided in the cylindrical in between two poles of the permanent magnet . • Coils are wound on the aluminum former which is connected with the spindle. • This spindle is supported with jeweled bearing. 18 • Two springs are attached on either end of the spindle. • The terminals of the moving coils are connected to the spring. Therefore, the current flows through spring 1, moving coil and spring 2. ❖ Damping: Eddy current damping is used. This is produced by aluminum former. ❖ Control: Spring control is used. Principle of operation: • When D.C. supply is given to the moving coil, D.C. current flows through it. • When the current carrying coil is kept in the magnetic field, it experiences a force. • This force produces a torque and the former rotates. The pointer is attached with the spindle. • When the former rotates, the pointer moves over the calibrated scale. • When the polarity is reversed a torque is produced in the opposite direction. Note: If A.C. is supplied, a reversing torque is produced. This cannot produce a continuous deflection. Therefore, this instrument cannot be used in A.C. Torque developed by PMMC: Let Td =deflecting torque TC = controlling torque θ = angle of deflection K=spring constant b=width of the coil l=height of the coil or length of coil N=No. of turns I=current B=Flux density A=area of the coil 19 The force produced in the coil is given by F = BIL sinθ When θ = 90 For N turns, F = NBIL produced Td = F× ⊥r distance Td = NBIL× b = NBI(L× b) = BINA Td∝ I In PMMC spring control torque is usesd ∴ Tc = Ks θ Under steady state condition Td = Tc Ks θ = BINA θ = BINA /Ks θ∝ I ∴ In PMMC scale is Uniform. Advantages: ✓ Torque/weight is high so sensitivity and accuracy is more ✓ Power consumption is less (25-200 μW.) ✓ Scale is uniform ✓ Very accurate and reliable for DC ✓ Damping is very effective ✓ Since operating field is very strong, the effect of stray field is negligible ✓ Range of instrument can be extended Disadvantages: 20 ✓ Use only for D.C. It Cannot be used for AC measurements ✓ Cost is high ✓ Strength of permanent magnet decreases due to ageing. ✓ Friction and temperature error are present ✓ Current carrying capacity of PMMC instruments is small(100mA ) PMMC Instrument Parts, Material and their Functions: Name of part Material Function Permanent magnet ALNICO To produce magnetic flux Iron cylinder Magnetic To strengthen magnetic flux linkage Coil Copper To carry current and produce deflection Former Aluminum To support coil and to produce damping torque. Spindle Steel To support the coil and to provide means for rotation. Spring Phosphor bronze To provide leads for incoming and outgoing connection to coil, To produce controlling torque. Pointer Aluminum To show reading on calibrated scale. 21 Moving Iron Instrument Introduction: • Moving iron Instrument or Moving iron meter is used to measure the current and voltage of AC and DC. • The scale is non-uniform. • The working principle depends upon the movement of iron attracted by the magnetic field towards it and repulsion between them. • The magnetic field is produced by the current in the coil. Construction of moving iron instrument: ❖ The construction of moving iron instrument is divided into two types : 1. Attraction iron meter (Uses single iron) 2. Repulsion type moving iron meter(Uses double iron) Repulsion Type Moving Iron Instrument: • In this instrument, there are two pieces of iron placed in the magnetic field of a coil. 22 • One of the pieces is fixed while the other is movable with which a light aluminum pointer is attached When there is no current in the coil, the two iron pieces are almost touching each other and the pointer rests at the zero position of the scale. These are classified as two types. I. II. Radial vane type Co-axial vane type & concentric vane type. ➢ It consists of two vanes (fixed & movable) fixed vane is attached to coil and movable vane is attached to spindle. Principle of operation: ➢ When the current flows through the coil, a magnetic field is produced by it. So both fixed iron and moving iron are magnetized with the same polarity, since they are kept in the same magnetic field. ➢ Similar poles of fixed and moving iron get repelled. ➢ Thus the deflecting torque is produced due to magnetic repulsion. ➢ Since moving iron is attached to spindle, the spindle will move. So that pointer moves over the calibrated scale. ❖ Damping: Air friction damping is used to reduce the oscillation. ❖ Control: Spring control is used. 23 Radial vane type: Co-axial vane type & concentric: 24 Attraction Type Moving Iron Instrument construction: • In this instrument there is only one piece of iron under the influence of magnetic field of the coil. • The iron piece, which is movable may be of any shape, but usually OVAL shape is preferred, as it gives uniform scale to the instrument. • To the iron piece, a pointer is attached. Working: • When the current flows through the coil, a magnetic field is developed and the iron piece experiences an attractive force and moves into the coil • as a result the pointer also moves on the scale. • When the instrument is removed from the circuit, no current flows through the coil no magnetic field and the iron piece comes out of the coil to its original position. • The controlling torque may be provided by spring or by gravity weight. • The damping is provided through pneumatic (air friction) method. 25 Advantages of Moving Iron Instrument: ✓ These instruments are simple in construction and cheaper in cost. ✓ They can be used for ac as well dc measurements. ✓ They have a high starting torque. ✓ They can withstand overload momentarily. Disadvantages of Moving Iron Instrument: 1. They have a non-uniform scale and hence it is difficult to read them correctly. 2. They suffer from hysteresis loss in the iron piece. 3. Due to iron, they are heavy weight and consume more power. 4. They are not very sensitive. 5. During ac measurements, error is introduced due to change in the frequency. ➢ Torque developed by MI: Refer Class for this Topic ➢ Electrostatic Instruments - Construction - Torque equation Refer Class for this Topic ➢ Range extension Refer Class for this Topic 26 Errors in PMMC instrument: ✓ The aging of permanent magnet and control springs also cause errors. The weakening of magnet and springs cause opposite errors. The weakening of magnet causes less deflection while weakening of the control springs cause large deflection, for a particular value of current. The proper use of material and pre ageing during manufacturing can reduce the errors due to weakening of the control springs ✓ The permanent magnet produced error due to ageing effect. By heat treatment, this error can be eliminated. ✓ The spring produces error due to ageing effect. By heat treating the spring the error can be eliminated. ✓ When the temperature changes, the resistance of the coil vary and the spring also produces error in deflection. This error can be minimized by using a spring whose temperature coefficient is very low. ✓ The basic sources of errors in PMMC instruments are friction, temperature, and aging of various parts. To reduce the frictional errors, the ratio of torque to weight is made very high Temperature error: ✓ The most serious errors are produced by the heat generated or by changes in the temperature. This changes the resistance of the working coil, causing large errors. In the case of voltmeters, a large series resistance of a very low-temperature coefficient is used. This reduces the temperature errors. ✓ The swamping resistance reduces the effect of temperature on the meter. ✓ Swamping resistance is made of Magainin or constantan which have an extremely low-temperature coefficient. (20:1/30:1). 27 Hysteresis Error: ➢ This error occurs as the value of flux density is different for the same current when ascending and descending. The value of flux density is higher for descending values of current and, therefore, the instrument tends to read higher for descending values of current (and voltage) than for ascending values. ➢ This error can be minimized by making the iron parts small so that they demagnetize themselves quickly. Another method is to work the iron parts at low values of flux density so that the hysteresis effects are small. ➢ Hysteresis may produce a 2 to 3 percent error. With the use of nickel iron alloys with narrow hysteresis loops, the error may be brought down to less than 0.05 per cent. Error due to stray fields: ➢ The errors due to stray magnetic fields (fields other than the operating magnetic field) may be appreciable as the operating magnetic field is weak and hence can be easily distorted. ➢ These errors can be minimized by using an iron case or a thin iron shield over the working parts. 28 Errors in Moving Iron Instruments: Moving Iron Instrument can measure both AC and DC quantities, which makes it an excellent measurement tool. Although the instrument has the advantage of measuring AC and DC, it also results in some errors. In this article, we examine the errors that can occur in a moving iron instrument. There are two types of errors in moving iron instruments. 1. Errors which occur with both AC and DC 2. Errors which occur only with AC only. Errors with both DC and AC (i) Hysteresis Error (ii) Temperature Error. (iii) Stray Magnetic Fields. This error explanation is same as above PMMC instruments. Refer PMMC error. Frequency Errors Changes in frequency may cause errors due to changes of reactance of the working coil and also due to changes of magnitude of eddy currents set up in the metal parts of instrument. Reactance of Instrument Coil The change of reactance of the instrument coil is important in case of voltmeters where an additional resistance Rs is used in series with the instrument. Let the resistance and inductance of the instrument coil be R and L. 29 Then the current I in the instrument coil for a given applied voltage V is given by : ➢ Deflection of moving iron voltmeter depends upon the current through the coil. Therefore, deflection for a given voltage will be less at higher frequency than at low frequency. ➢ A capacitor is connected in parallel with multiplier resistance. The net reactance, ( X L − XC ) is very small, when compared to the series resistance. Thus the circuit impedance is made independent of frequency. This is because of the circuit is almost resistive. Eddy Currents These errors are caused by eddy currents induced in the iron parts of the instruments. Let the mutual inductance between the instrument coil and the iron parts be M. The induced voltage Eb due to current I in the instrument coil lags the current by 90∘. As a result of this induced voltage an eddy current Ie flows and its magnitude is Conclusion Thus, at low frequencies the eddy current error increases with square of the frequency while at high frequencies the error is practically constant. For these reasons moving iron instruments are unsuitable for frequencies above 100 Hz. In order to extend the frequency range of the Instrument, another coil, coupled with the coil of the instrument and loaded by an AC network, is used. The frequency error due to eddy currents can be kept less than 0.1 % up to a frequency range of 1000 Hz. 30 Introduction These are special type of transformers used for the measurement of voltage, current, power and energy’s name suggest, these transformers are used in conjunction with the relevant instruments such as ammeters, voltmeters, watt meters and energy meters. Types of Instrument Transformer Such transformers are of two types: 1. Current Transformer (or Series Transformer) 2. Potential Transformer (or Parallel Transformer) Current transformers are used when the magnitude of AC currents exceeds the safe value of current of measuring instruments. Potential transformers are used where the voltage of an AC circuit exceeds 750 V as it is not possible to provide adequate insulation on measuring instruments for voltage more than this. Advantages of Instrument Transformers It is used for the following two as: 1. The large voltage and current of AC Power system can be measured by using small rating measuring instrument i.e. 5 A, 110 – 120 V. 2. By using the instrument transformers, measuring instruments can be standardized. Which results in reduction of cost of measuring instruments. More ever the damaged measuring instruments can be replaced easy with healthy standardized measuring instruments. 3. Instrument transformers provide electrical isolation between high voltage power circuit and measuring instruments. Which reduces the electrical insulation requirement for measuring instruments and protective circuits and also assures the safety of operators. 4. Several measuring instruments can be connected through a single transformer to power system. 5. Due to low voltage and current level in measuring and protective circuit, there is low power consumption in measuring and protective circuits. 6. This instrument transformers can be used to extend the range of measuring instruments like ammeters and voltmeters. 7. The power loss in instrument transformers isvery small as compared to power loss due tothe resistance of shunts and multipliers. Disadvantages of Instrument Transformer: 1. The only main drawback is that these instruments cannot be used in DC circuits. 31 Use of Instrument Transformer: Measurement of current as CT The primary winding is so connected that the current to be measured passes through it and the secondary is connected to the ammeter. The function of CT is to step down the current. Instrument Transformer as CT: Measurement of voltage by PT The primary winding is connected to the voltage side to be measured and secondary to the voltmeter. The function of PT is to steps down the voltageto the level of voltmeter. 32 Types of Current Transformers: 1. Bar type CT: The bar type transformer has only secondary windings. The conductor on which the transformer is mounted will act as primary windings of the current transformers. This type of CT is placed on the panel board to measure the current of bus bars. The bus bar whose current is to be measured is made to pass through CT. It is of circular or ring type, on which secondary winding is placed. The ammeter is connected in the secondary windings. 2. Wound type current transformer: A current transformer having a primary winding of more than one full turn wound on core. The figure below shows the wound type transformer. 33 Current Transformer (CT): A current transformer is an instrument transformer which is used to measure alternating current of large magnitude by stepping down by transformer action. The primary winding of CT is connected in series with the line in which current is to be measured and the secondary is connected to the ammeter. The secondary winding has very small load impedance which is the current coil of ammeter. The primary side has a few numbers of turns and the secondary side has large number of turns. The primary winding carries a full load current and this current is stepped down to a suitable value which is within the range of ammeter. Burden of Instrument Transformer: The operation of current transformer differs slightly from the power transformer. In case of current transformer, the secondary winding has a very small impedance or “Burden” , so the current transformer operates on short circuit conditions. 34 The rated burden of this Instrument Transformer is the voltampere loading which is permissible without errors exceeding the limits. Burden across the secondary of an instrumenttransformer is also defined as the ratio ofsecondary voltage to secondary current. ZL = secondary voltage/ secondary current =V/I Phasor Diagram: Taking flux, as the reference vector, the induced e.m.f. in the primary and secondary sides are E1 and E2 lagging behind the flux by90° are drawn. The magnitudes of e.m.f. are proportional to their respective number ofturns. The no load current I0, drawn by the primary has two components, magnetizing component and the Core loss component Ic. The secondary current I2 lags behind thevoltage by an angle ofdelta. Theangle is the angle produced by burdenconnected on the secondary side.The secondary current I2 is now transferred tothe primary by reversing I2 and multiplied by Kwhere K is the turn ratio. Equivalent Circuit of Current Transformer (CT): 35 Phasor Diagram of Current Transformer (CT): 36 Ratios of Instrument Transformer Actual or transformation Ratio(R): The actual transformation ratio is defined as the ratio of the magnitude of actual primary phasor to the corresponding magnitude of actual secondary phasor. Nominal Ratio: It is the ratio of rated primary winding current (or voltage) to therated secondary winding current (or voltage). 37 Turns Ratio: Ratio correction factor (RCF): The ratio correction factor of a transformer is the transformation ratio divided by nominal ratio. Transformation ratio = ratio correction factor x nominal ratio or R = RCF x Kn R.C.F. = Actual Ratio/ Normal Ratio =R/ Kn. 38 Errors in Instrument Transformers: There are two types of errors in these transformers: 1. Ratio error. 2. Phase angle error. Ratio Error: For normal operation of these instrument transformers, the current transformation ratio should be constant and within the limits. Ithas been seen that this ratio are not constant but do vary with the power factor. So this error is known as Ratio Error. Ideally R=n But practically R≠ n becz of due to core loss component of no-load current. This will create an error this error is called ratio error. Since the burden of the CT is generally resistive. Therefore, the power factor of the burden is unity, and hence δ=0 Phase Angle Error: The phase angle of the current transformer is defined as the angle between the primary current Ip and secondary current Is. In the above phasor diagram, θ is the phase angle. 39 Consider the right angle triangle ABC in the above phasor diagram. 40 Since the burden of the CT is generally resistive. Therefore, the power factor of the burden is unity, and hence δ=0. The following expression gives the phase angle error of CT. Methods to minimize Errors: As we Know the ratio error mainly dependsupon the Core loss component of current and phase angle error depends upon themagnetizing component of the current. To minimise these errors, the following methodsshould be employed : 1)Designing of Core : In order to minimize these errors, thecore and magnetizing components (Ic and Im|) must be kept at low value. This is possible only by using the material of the core of high permeability, short magnetic path and large cross section area of the core. The material may be of the following types : Hot rolled silicon Cold rolled grain-oriented silicon steel Nickel iron alloys. The construction of core has minimum number of joints. Therefore, to avoid the joints in building of core, the cores are made if two types, 41 Ring type core Spiral type core 2)Primary winding current ratings: By providing a suitable turn ratio i.e. number of turns of the secondary can be reduced by one or two turns. 3)Leakage reactance: Leakage reactance also increases the ratio error.Therefore, the two windings should be closed toeach other to reduce the secondary winding leakage reactance. 4)Turns compensation: We have, actual, transformation ratio : R = n + Ie/Is Thus if we make the “nominal ratio” equal to the turns ratio the actual transformation ratio becomes more than the nominal ratio. Now if we reduce the turns ratio and keep the nominal ratio equal to the earlier value, the actual transformation ratio will be reduced.This would make actual transformation ratio nearly equal to the nominal ratio.Let us make it clear with the help of an example. 5) Use of shunts: If the current on the secondary is too large, it should be reduced by putting a shunt either of side.it also reduce phase angle error. 42 6)Wilson compensation method: It employs a few turns of wire called auxiliary secondary turns passed through a hole in the core and connected in series with the secondary winding. A short-circuited turn is placed around one position of the core to improve the phase relationships. Application of Current Transformer: The following are the applications; 1. Current transformers are used in panel board ofsubstation or grid station to measure the busbar current which is very high. 2. Current transformers are widely used in powermeasuring circuits. The current coil of thewattmeter is connected with CT. 3. Current transformers are also used in powerhouses, sub stations etc. in conjunction with therelays. Potential Transformer (PT.) These are used to measure alternating high voltage by means oflow range voltmeters or for energizing the potential coils of wattmeter and 43 energy meters. These types of transformers are also used in relays and protection schemes. The high voltage which is to be measured is fed to theprimary of PT, which is stepped down and is measured by alow range voltmeter on the secondary. The turns of primaryside are more than secondary side. The turn ratio oftransformer is so designed which keep secondary voltage 110 V when full rated voltage is applied to the primary side. The principle of operation of potential transformer is same as that of power transformer. Construction Potential Transformer: Basically, a Potential transformer (PT) is a twowinding transformer. The primary _ isconnected with high voltage and has more number of turns and the secondary which has less number of turns, steps down the voltage between 110 V to 120 V. The core of thetransformer is a shell type. The low voltagewinding (secondary) is wound first around thecore of the transformer to reduce the size of PT. The few important points are kept in mind: 1. The output of PT’s is very small and the sizeof PT is comparatively large, so there is noproblem of temperature. 44 2. The size of the core of the PT is larger ascompared to power transformers. 3. The material of core should be of highpermeability to reduce the iron losses or toreduce the ratio error and phase angle error. 4. The primary and secondary windings are coaxial to reduce the leakage reactance. 5. There is no danger, if the secondary side ofPT is left open circuited. Types of Potential Transformer The potential transformer is mainly classified into two types, i.e., the conventional wound types (electromagnetic types) and the capacitor voltage potential transformers. Conventional wound type transformer is very expensive because of the requirement of the insulations.Capacitor potential transformer is a combination of capacitor potential divider and a magnetic potential transformer of relatively small ratio. The circuit diagram of the capacitor potential transformer is shown in the figure below. The stack of high voltage capacitor from the potential divider, the capacitors of two sections become C1 and C2, and the Z is the burden. 45 The voltage applied to the primary of the intermediate transformer is usually of the order 10kV Phasor Diagram of a Potential Transformer The phasor diagram of the potential transformer is shown in the figure below. Where, Is – secondary current Es – secondary induced emf Vs – secondary terminal voltage Rs – secondary winding resistance Xs – secondary winding reactance 46 Ip – Primary current Ep – primarily induced emf Vp – primary terminal voltage Rp – primary winding resistance Xp – primary winding reactance Kt – turn ratio Io – excitation current Im – magnetising component of Io Iw – core loss component of Io Φm – main flux Β- phase angle error 47 Difference between C.T. and P.T.: Crrent Transformer Potential transformer 1. The secondary of a C.T can not be open circuited on any circumstance when it is under service. The secondary of a P.T can be open circuited without any damage being caused either to the operator or the transformer. 2. A CT may be considered as a P.T may be considered as a series transformer. parallel transformer. 3. The primary current in a C.T is The primary current of a P.T depends independent of the secondary upon the secondary circuit conditions circuit conditions (burden). (burden). 4. The primary winding of the CT connected in series with the line carring the current to be measured. Hence it carries of the full line current. With the help of CT, a 5A ammeter can be used measure a high current like 200A. Sl.No 5. 6. 7. 8. 9. The primary winding P.T is connected across the line of voltage to be measured. Hence the full line voltage is impressed across its terminal with the help of P.T, a 120V voltmeter can be used to measure very high voltages like 11KV. CT step-down the high current to PT step-down the high voltage levels to the safe level of current. the safe level of voltage. It has a fewer number of turns in It has a large number of turns in its its primary winding. primary winding. It has a large number of turns in It has few numbers of turns in the the secondary winding. secondary winding. It has a very high turn ratio. It has a very low turn ratio. 10. The primary winding contains full line current. 11. Current transformer can be either wound type or core type. The primary windings contain full line voltage. The potential transformer can be either electromagnetic or capacitor voltage type. 12. It is a step-up transformer. It is a step-down transformer. 13. It is used for measurement and It is used for the measurement of high monitoring of current in high voltage in power lines. power lines. 48 Chapter wise IMP questons (III- B.Tech. II Sem. Regulation: R20) UNIT I: Analog Ammeter and Voltmeters SL.NO QUESTION Derive the equation for deflection in spring controlled permanent 1. magnet Moving coil instrument with a neat sketch. Ref page No:17 List the different types of errors in PMMC Instruments and how they 2. can be overcome? Ref page No:26 List the difference between Current transformer and Potential 3. transformer. Ref page No:47 Explain the use of instrument transformers and list the advantages and 4. disadvantages. Ref page No:30 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. What is essential difference between a moving coil and a moving iron instrument? Ref Class Notes Explain the construction and working of Repulsion type Moving iron Instruments. Ref page No:21 Explain about extension of instrument ranges. Ref Class Notes Explain the following terms related to PT and CT. i) Transformation ratio. ii) Turns ratio iii) Ratio correction factor. Ref page No:36 Explain the construction and operation of moving iron instruments. Ref page No:21 Derive the expressions for the ratio and phase angle errors of a CT Ref page No:26 Explain the construction of a PMMC meter with the help of a neat sketch. Ref page No:17 What are the sources of errors in current transformer? Explain them in brief. Ref page No:26 State the advantages of CT and explain the comparison between CT and PT. Ref page No:26 Explain the following control mechanisms used in indicating instruments: i) Gravity control ii) Spring control Ref page No:07 Explain the construction and working of a current transformer with a neat equivalent circuit Ref page No:34 Explain electrostatic instruments and derive its torque Expression Ref Class Notes