Weishaupt Gas Burner Manual WG30/40 Installation & Operation

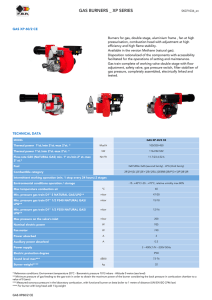

advertisement