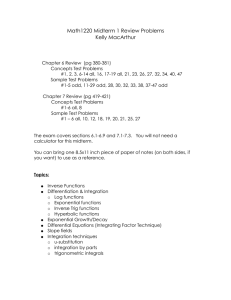

Homework Midterm • A factory that produces three types of products (ProdA, ProdB, ProdC) Source • ProdA follows the manufacturing process: • S1S2S3S4Insp • ProdB follows the manufacturing process: Source • S4S2S3S1Insp Source • ProdC follows the manufacturing process: • S2S3Insp Station 1 Station 2 Inspection Station 3 Station 4 Sink Homework Midterm • If a product fail to pass the inspection, it will return to different step of the process • ProdA has a fail probability 20%, and return to S3. • ProdB has a fail probability 10%, and return to S4. • ProdA has a fail probability 5%, and return to S2. Source Station 1 Station 2 Inspection Source Source Station 3 Station 4 Sink Homework Midterm • Make ProdA in green (default), ProdB in red, and ProdC in blue • Process Time and capacity bounds follows the following table Unit(minute) Station 1 Station 2 Station 3 Station 4 Process Time Exponential(25) Normal(20, 5) Exponential(5) Triangular(3,5,10) Uniform(1,5) Capacity Lower Bound 1 1 1 1 2 Capacity Upper Bound 3 5 5 3 5 • Interarrival Time follows the following table Unit(minute) ProdA ProdB ProdC Interarrival Time Exponential(25) Exponential(30) Exponential(20) Inspection Homework Midterm • Create an experiment of all combinations of capacity settings using lower bounds and upper bounds • Response set to entities’ average time in system • (hint: Sink1.TimeInSystem.Average) • Run 20 replications to each designs • Try OptQuest to get the best design. • Please screenshot the model, definition/properties, server properties that you implemented definition/properties to, and experiment. • Put all the screenshot and later comparison analysis into word and convert to a pdf file.