416046016-Procedure-System-of-Flange-Management-Procedure-Site

advertisement

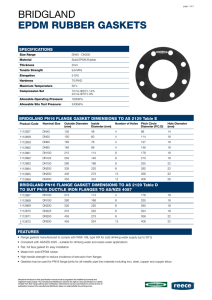

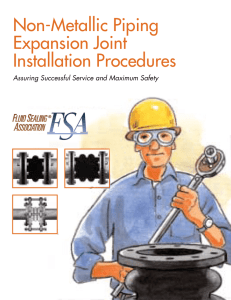

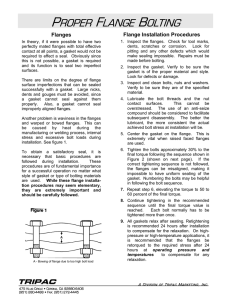

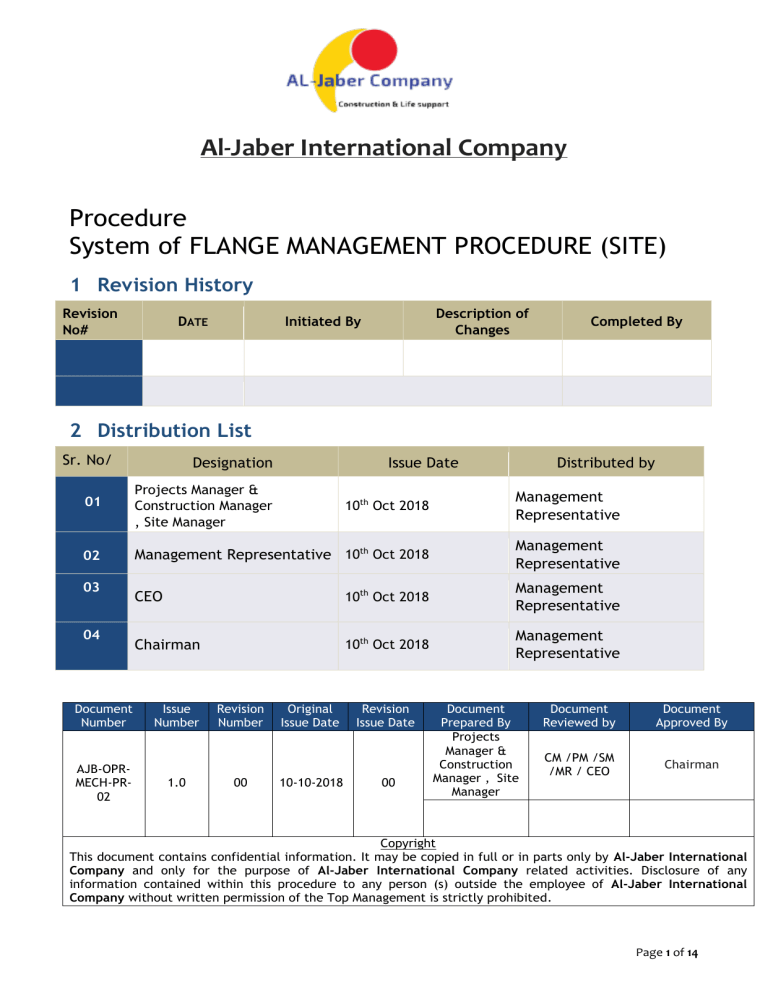

Al-Jaber International Company Procedure System of FLANGE MANAGEMENT PROCEDURE (SITE) 1 Revision History Revision No# DATE Description of Changes Initiated By Completed By 2 Distribution List Sr. No/ Designation Issue Date Distributed by 01 Projects Manager & Construction Manager , Site Manager 10th Oct 2018 Management Representative 02 Management Representative 10th Oct 2018 Management Representative CEO 10th Oct 2018 Management Representative Chairman 10th Oct 2018 Management Representative 03 04 Document Number AJB-OPRMECH-PR02 Issue Number 1.0 Revision Number 00 Original Issue Date 10-10-2018 Revision Issue Date 00 Document Prepared By Projects Manager & Construction Manager , Site Manager Document Reviewed by Document Approved By CM /PM /SM /MR / CEO Chairman Copyright This document contains confidential information. It may be copied in full or in parts only by Al-Jaber International Company and only for the purpose of Al-Jaber International Company related activities. Disclosure of any information contained within this procedure to any person (s) outside the employee of Al-Jaber International Company without written permission of the Top Management is strictly prohibited. Page 1 of 14 Al-Jaber International Company Procedure System of FLANGE MANAGEMENT PROCEDURE (Site) Doc. No: AJB-OPR-MECH-PR-02 Issue Number: 01 Revision Number: 00 Original Issue Date: 10th Oct 2018 Revision Issue date: TABLE OF CONTENTS 1. 2. ACRONYM ……………………………………………………………………………………….4 SCOPE ......................................................................................................................................... 4 3. REFERENCES ............................................................................................................................. 5 4. RESPONSIBILITIES .................................................................................................................... 5 5. PROCEDURE .............................................................................................................................. 5 5.1. Principles of Flanged Joint Assembly .................................................................................. 6 5.2. Gaskets ............................................................................................................................... 7 5.3. Bolting ................................................................................................................................. 7 5.4. Tightening Procedure .......................................................................................................... 8 5.5. Tightening of bolted joints ................................................................................................... 8 5.6. Flange Tag Details ............................................................................................................ 11 5.7. Inspection, Recording and Reporting................................................................................. 11 6. HSE ............................................................................................................................................ 12 7. ATTACHMENTS ........................................................................................................................ 12 This document is the property of Al-Jaber International Company. Any copying and distribution of this document without the approval of the Management is prohibited. Page 2 of 14 Al-Jaber International Company Procedure System of FLANGE MANAGEMENT PROCEDURE (Site) Doc. No: AJB-OPR-MECH-PR-02 Issue Number: 01 Revision Number: 00 Original Issue Date: 10th Oct 2018 Revision Issue date: LIST OF TABLES Table 1-1 Acronyms ............................................................................................................................ 4 Table 3-1 Industry Codes and Standards ............................................................................................ 5 Table 3-2 Project Specifications ........................................................... Error! Bookmark not defined. Table 5-1 Tightening Sequence for Cross Bolt Torquing ..................................................................... 9 Table 5-2 Torque Application Chart..................................................................................................... 9 Table 5-3 Rotating Equipment Flange Alignment Tolerances ............................................................ 11 This document is the property of Al-Jaber International Company. Any copying and distribution of this document without the approval of the Management is prohibited. Page 3 of 14 Al-Jaber International Company Procedure System of FLANGE MANAGEMENT PROCEDURE (Site) Doc. No: AJB-OPR-MECH-PR-02 Issue Number: 01 Revision Number: 00 Original Issue Date: 10th Oct 2018 Revision Issue date: Purpose The purpose of this program is to ensure the protection of all employees of the Al Jaber from the hazards associated with FLANGE MANAGEMENT PROCEDURE (Site).This document contains requirements for practices and procedures to protect employees from those hazards of entry into and work within permit required confined spaces. Piping Specifications 1 Having determined the piping specification number, turn to the appropriate page in the piping specification document. There the correct type of gasket, the correct grade of stud bolts, spectacle blinds, blind flanges, pipe material, pipe wall thickness and much more will be specified for the job in hand. Pipeline specification. Piping is an assembly of components that include pipe, valves, fitting, flanges, bolts, gaskets and supports used to convey distribute and control flow of fluid. Piping must also contain the conveyed fluid and accommodate internally and externally imposed loads and thermal movements ACRONYM Table 1-1 Acronyms Acronym ASME ITP HSE Description / Meaning American Society of Mechanical Engineers Inspection and Test Plan Health, Safety and Environment 2 SCOPE The purpose of this procedure is to ensure that flange tightening and tensioning activities are performed, controlled and recorded as per project specifications, Company requirements and approved ITP’s. This procedure provides a framework for the management of bolted joints. The scope of this procedure details and identifies the basic structure of the tightening & torque of high, ordinary strength bolts works used for the successful completion of the General Instructions for the installation of pipe rack spools, off skid spools, support installation activity works of SGPS Project. This document is the property of Al-Jaber International Company. Any copying and distribution of this document without the approval of the Management is prohibited. Page 4 of 14 Al-Jaber International Company Procedure System of FLANGE MANAGEMENT PROCEDURE (Site) Doc. No: AJB-OPR-MECH-PR-02 Issue Number: 01 Revision Number: 00 Original Issue Date: 10th Oct 2018 Revision Issue date: 3 REFERENCES Table 3-1 Industry Codes and Standards ASME B31.3 ASME PCC-1 ASME B16.5 ASME B16.47 ASME B18.2.1 ASME B18.2.2 ASME B16.20 Process Piping Guidelines for Pressure Boundary Bolted Flange Joint Assmbly Butt welding Ends Large Diameter Steel Flanges Square and Hex Bolts and Screws Square and Hex Nuts Metallic Gaskets for Pipe Flanges 4 RESPONSIBILITIES 1. Site Engineer shall be responsible for the following; a. Focal point and responsible to ensure that bolted flange connections are tightened as per this procedure. b. Comply with all site HSE rules in during application of bolt tightening activities. c. Keep all the flange management records, maintain a database updated on a daily basis and report progress. d. Ensure that the flange management check sheets are handed over for each completed system. e. To act as the coordinator for any necessary training required to monitor/improve the competency of site personnel in flange execution. f. Coordinate with QA/QC after receiving hydro test pack isometrics to number the flanged joints and form the database. 2. The QC Engineer is responsible for witness and review the data sheets, daily log sheets to ensure implementation of this procedure. 5 PROCEDURE Trained personnel will be responsible for executing the proper joint make-up as per the below guidelines and ensure protective materials required to prevent damage to joint components (e.g. flange face covers) are used. The assembly drawings will indicate the bolt length, diameter and material type and rating. Flange faces shall be cleaned to remove preservations and the gasket surfaces shall be inspected for defects. Any rust or burrs shall be removed using a hand wire brush and / or a hand file. Particular attention shall be paid to seating for ring type joints. This document is the property of Al-Jaber International Company. Any copying and distribution of this document without the approval of the Management is prohibited. Page 5 of 14 Al-Jaber International Company Procedure System of FLANGE MANAGEMENT PROCEDURE (Site) Doc. No: AJB-OPR-MECH-PR-02 5.1 Issue Number: 01 Revision Number: 00 Original Issue Date: 10th Oct 2018 Revision Issue date: Principles of Flanged Joint Assembly 1. Flange faces shall conform to the relevant specifications. 2. Flange faces and bolts holes are correct and free of any foreign material. 3. Bolt holes of mating flanges shall be aligned using a spud wrench or similar tool. Lateral alignment shall be checked by considering that bolts and studs can be inserted without force and that the alignment tool is not required to impart a significant force to achieve alignment. 4. Sealing faces flat, parallel, aligned properly and in good condition and free of defects. 5. Gasket of the correct type shall be used and shall be in proper position. Type, pressure rating, material and size of the gasket shall be checked. 6. Correct lubricated stud and nut material; correct stud length shall be used. 7. Free-running studs and nuts, in good condition, free from corrosion and thread damage shall be used. 8. For flanges installed on horizontal lines, in order to retain the gasket the lower bolts should be installed first. 9. Parallelism of the flanges shall then be checked to confirm they are within the tolerances as per the project specifications. 10. The remaining bolts and nuts shall be installed and hand tightened with the flange faces parallel. Care should be taken to assure proper seating and centring of the gasket within the allowable tolerances. 11. Bolts shall be tightened by torque wrench and inspected for tightness in accordance with this procedure. Stud bolts should have an equal protrusion through the nuts on both sides of the flanges of between 3 and 5 threads. Material, coating and size of the stud-bolts shall be checked. 12. All flanges will be aligned so that the bolt holes straddle the natural centre line. 13. Visually check the flanges for equal gap. If a larger gap appears on one side of the flange, tighten the bolt, which corresponds with the larger gap first. 14. The gaskets are then to be centered between the flanges. Nuts shall be hand tightened to hold the gasket in place. When flanged joints are in horizontal lines gaskets without centring devices such as ring joints, shall be lowered to the bolts for retention and then raised into position. 15. Bolts and nuts shall be supplied with the precise specification. 16. No additional torqueing of bolts whilst piping systems are under pressure during hydrotest shall be applied if leaks are found, pressure to be released and joint re made. 17. If any doubts exist job shall be stopped and cross-reference shall be with the Responsible Engineer. 18. If any case of flange joints to be disturbed during or after testing shall be replaced with gaskets. Torqueing Specific; 1. Good quality lubricant shall be used. See Table 6-2 of Piping Fabrication, Erection, and Inspection, Testing and Cleaning Specification with No. IQWQ-KE-LSPDS-D8-0008. 2. Lubricant properly applied to ‘working’ surfaces only. 3. Sequential tightening, in stages to 100 % of specified full load, using the cross-bolt tightening method. 4. Flanges checked for squareness after each pass. 5. Final tighten at 100 % of full load. This document is the property of Al-Jaber International Company. Any copying and distribution of this document without the approval of the Management is prohibited. Page 6 of 14 Al-Jaber International Company Procedure System of FLANGE MANAGEMENT PROCEDURE (Site) Doc. No: AJB-OPR-MECH-PR-02 Issue Number: 01 Revision Number: 00 Original Issue Date: 10th Oct 2018 Revision Issue date: 5.2 Gaskets Gaskets shall be checked for size, rating, material specification and cleanliness before installation by qualified pipe fitters. Remove any grease, burrs and rust from the gasket and trial fit against the flange gasket seating surface. Under no circumstances should gasket compound or grease be applied to the gasket or flange faces. Spiral Wound Gaskets shall not be re-used, since not enough resilience is left in the gasket material to give a leak-proof joint when compressed second time. Gasket Preservation: Gaskets and seal rings shall be; 1. Stored in their original packing until to be used 2. Kept horizontal and flat 3. Where applicable, left on their original packing until to be used Installation of gaskets: After pipe fitting, the two flange ends of a flanged joint are to be checked for alignment by use of a precision level indicator placed touching the two flanges. If the alignment values are within allowable ranges as indicated in procedure, the lower bolts are first placed in place then gasket will be placed from the upper side. If the gasket does not fit smoothly into position pipe alignment is to be re-checked. Gasket shall never be forced into position. 5.3 Bolting Bolts shall be checked for correct length, diameter and conformance with material specification. Studs and nuts shall have an approved lubricant installed before installation. Only clean rust-free stud bolts and nuts should be used for making up the flange joint. Bolts and nuts can only be reused if it is known that they have not been overloaded or exceeded their yield point. Material type stamp on the bolts should be in one direction. Ensure that nuts are installed in the proper orientation. Bolt Lubrication: The application of lubricants will have a substantial impact on the torque applied. The lubrication properties vary from one lubricant to the other and shall be taken into account when torque is applied. Hydraulic bolt tensioning provides more uniform bolt stress and eliminates variations due to different lubricant. See Table 6-2 of Piping Fabrication, Erection, and Inspection, Testing and Cleaning Specification with No. IQWQ-KELSPDS-D8-0008 for lubricants to be used. On completion of the tightening activities, bolts should extend 1 1/2 to 2 threads through their nuts. This document is the property of Al-Jaber International Company. Any copying and distribution of this document without the approval of the Management is prohibited. Page 7 of 14 Al-Jaber International Company Procedure System of FLANGE MANAGEMENT PROCEDURE (Site) Doc. No: AJB-OPR-MECH-PR-02 Issue Number: 01 Revision Number: 00 Original Issue Date: 10th Oct 2018 Revision Issue date: 5.4 Tightening Procedure Torque wrenches shall be calibrated as per calibration schedule and have a valid certificate that must be revalidated after the wrench has been inspection and recalibrated. There are various types of tools available to achieve the proper torque value. The manufacturer’s instructions shall be followed for the operation and maintenance of all Torque wrenches used to perform tightening procedure. The pressure on the gasket shall be uniformly distributed in order to provide sealing requirements. To make sure that, the bolts shall be tightened in the following sequence; 1. Hand-tighten all nuts. (Place a duet tape around the circumference of the flange and number all the bolts) 2. Tighten bolts according to proper sequence indicated in procedure at 30 % of torque value. 3. Tighten another pair of bolts approximately 90° further round the circumference. 4. Repeat steps 2 and 3 to 60 % of the required bolt stress. 5. Repeat steps 2 and 3 to 100 % of the required bolt stress. 6. Flange alignment is completed, inspected and accepted, gasket can be placed in position. 5.5 Tightening of bolted joints 1. Tightening method shall be as per para. 6.5.1 of Piping Fabrication, Erection, Inspection, Testing and Cleaning Specification with No. IQWQ-KE-LSPDS-D8-0008. 2. Generally, bolted connections can be tightened by means of spanners, impact tools, manual torque wrenches, hydraulic torque wrenches or hydraulic bolt tensioners. The relevant equipment to be used shall be calibrated before commencing to the bolt tightening/tensioning activities. 3. Bolt tensioning performed by controlled torqueing are the most accurate methods and shall be carried out as required by IQWQ-KE-LSPDS-D8-0008. 4. Two bolts shall be installed diametrically opposite each other, one bolt half way between the previously installed bolts and nuts engaged. 5. The correct bolt tightening sequence is also of fundamental importance in ensuring an efficient, long-lasting, leak-free joint. 6. Controlled bolt tightening shall be carried out using either manual or hydraulic torque wrenches. The chosen method depends to tightening rates, access and location of the relevant bolts. 7. It is importance to ensure that the correct bolt torque figures are available prior to making up a flanged joint. Torque values for particular bolt sizes shall be taken from project specifications or from referred standards and procedures mentioned in Section-3 of this procedure. 8. The table below shows tightening sequence for cross bolt torquing. The number of passes required will be influence by the type of joint and its gasket type. For example, ring type joints can be considered as ‘soft’ joints whereas spiral This document is the property of Al-Jaber International Company. Any copying and distribution of this document without the approval of the Management is prohibited. Page 8 of 14 Al-Jaber International Company Procedure System of FLANGE MANAGEMENT PROCEDURE (Site) Doc. No: AJB-OPR-MECH-PR-02 Issue Number: 01 Revision Number: 00 Original Issue Date: 10th Oct 2018 Revision Issue date: wound gaskets can be considered as hard joints. A soft joint may require more passes to reach the required torque. Table 5-1 Tightening Sequence for Cross Bolt Torquing FlangeType 4 Bolt Tightening Sequence (Numbered clockwise around the flange) 1,3,2,4 8 Bolt 1,5,3,7,2,6,4,8 12 Bolt 1,7,4,10,2,8,5,11,3,9,6,12 16 Bolt 1,9,5,13,3,11,7,15,2,10,6,14,4,12,8,16 20 Bolt 1,11,6,16,3,13,8,18,5,15,10,20,,12,7,17,4,14,9,19 24 Bolt 1,13,7,19,4,16,10,22,2,14,8,20,5,17,11,23,6,18,12,24,3,15,9,21 28 Bolt 1,15,8,22,4,18,11,25,6,20,13,27,2,16,9,23,5,19,12,26,3,17,10,24,7,21,14,28 32 Bolt 1,17,9,25,5,21,13,29,3,19,11,27,7,23,15,31,2,18,10,26,6,22,14,30,8,24,16,32,4,20,12,28 In order to achieve uniform tightness the nuts and bolts are tightened as follows and values given in below table as per Piping Installation, Fabrication, Erection, and Testing Specification with No. IQWQ-KE-LSPDS-D8-0008. a. 1 st Pass: 30 % of specified torque value b. 2 nd Pass: 60 % of specified torque value c. 3 rd Pass: 100 % of specified torque value, d. Final Pass: This will be a repeat pass followed by clockwise direction at 100 % of specified torque (Attachment-1) value to verify that required torque has been evenly applied throughout. Table 5-2 Torque Application Chart Bolt Size mm (NPS) 12.7 (1/2) 15.9 (5/8) 19 (3/4) 22.2 (7/8) 25.4 (1) 28.6 (1 1/8) 31.8 (1 1/4) 1st Pass 18 33 57 90 135 Torque (Nm) 2nd Pass Final Pass 36 60 66 110 114 190 180 300 270 450 207 414 690 288 576 960 This document is the property of Al-Jaber International Company. Any copying and distribution of this document without the approval of the Management is prohibited. Page 9 of 14 Al-Jaber International Company Procedure System of FLANGE MANAGEMENT PROCEDURE (Site) Doc. No: AJB-OPR-MECH-PR-02 Issue Number: 01 Revision Number: 00 Original Issue Date: 10th Oct 2018 Revision Issue date: 34.9 (1 390 780 1300 3/8) 38.1 (1 513 1026 1710 1/2) 41.3 (1 657 1314 2190 5/8) 44.5 (1 825 1650 2750 3/4) 47.6 (1 1026 2052 3420 7/8) 50.8 (2) 1251 2502 4170 57.1 (2 1794 3588 5980 1/4) 63.5 (2 2478 4956 8260 1/2) 70 (2 3006 6012 10020 3/4) 76.2 (3) 3915 7830 13050 82.6 (3 5001 10002 16670 1/4) 88.9 (3 6270 12540 20900 1/2) 95.3 (3 7731 15462 25770 3/4) 101.6 (4) 9405 18810 31350 107.9 (4 8925 17850 29750 1/4) 114.3 (4 10614 21228 35380 1/2) The table for rotating equipment flange alignment tolerances is below, taken from the project specification . This document is the property of Al-Jaber International Company. Any copying and distribution of this document without the approval of the Management is prohibited. Page 10 of 14 Al-Jaber International Company Procedure System of FLANGE MANAGEMENT PROCEDURE (Site) Doc. No: AJB-OPR-MECH-PR-02 Issue Number: 01 Revision Number: 00 Original Issue Date: 10th Oct 2018 Revision Issue date: Table 5-3 Rotating Equipment Flange Alignment Tolerances 5.6 Flange Tag Details The flanged joints are uniquely numbered on isometric drawings according to hydro test packs. The flanges need to be tagged in order to be visibly traceable. Tags should be made from suitable non-perishable material and shall contain following details, a. Line Class b. Joint Reference and size c. Torque Value Applied as per Flange Protocol List d. Assembled / Torqued By e. Date and Signature f. Remarks 5.7 Inspection, Recording and Reporting A visual inspection shall be carried out on the flange sealing faces and the bore of the pipe noting any damage or indication of corrosion or erosion. Any damage notes shall be accurately sketched and where possible photograph taken and the Company representative advised. Before bolting, mating gasket contact surfaces shall be aligned to each other within 1mm in 200mm, measured across any diameter as per ASME B31.3-2014. Flange bolt holes shall aligned within 3mm max. Offset as per ASME B31.3-2014. After completion of the bolt torqueing works flange joints will be hydrostatically tested as per Hydrostatic Test Procedure with No.IQWQ-KE-LPHYT-D8-0001. Joints to be witnessed by Company shall be selected before commencement of the work and results of inspection shall be recorded on a Flange Alignment Report (See attachment -2) This document is the property of Al-Jaber International Company. Any copying and distribution of this document without the approval of the Management is prohibited. Page 11 of 14 Al-Jaber International Company Procedure System of FLANGE MANAGEMENT PROCEDURE (Site) Doc. No: AJB-OPR-MECH-PR-02 Issue Number: 01 Revision Number: 00 Original Issue Date: 10th Oct 2018 Revision Issue date: 6 HSE Tensioning should be carried out safely within a barricaded, signed area. A toolbox talk shall be conducted prior to the start of tensioning job to review the risks and hazards and to remind the necessary precautions. 7 ATTACHMENTS ATTACHMENT 1- Bolt Tension and Torque Table (1 page) ATTACHMENT 2- Flange Alignment Report (2 pages) ATTACHMENT-1 This document is the property of Al-Jaber International Company. Any copying and distribution of this document without the approval of the Management is prohibited. Page 12 of 14 Al-Jaber International Company Procedure System of FLANGE MANAGEMENT PROCEDURE (Site) Doc. No: AJB-OPR-MECH-PR-02 Issue Number: 01 Revision Number: 00 Original Issue Date: 10th Oct 2018 Revision Issue date: Notes: 1. Bolt Material used in table is the most commonly used: High strength alloy steel bolting e.g., A193 Gr-B7, B16, and A320 L7. 2. The bolt tension (force per stud) values are based on bolt stress equivalent to 50% of the minimum yield stress. For effective gasket sealing, the recommended minimum acceptable bolt stress is 207 MPa (30000 psi) for a flanged joint containing a spiral wound gasket, with lubricated bolting. 3. Lubricant coefficient of friction assumes threads and nut face are coated. Representative types of lubricant friction factors are shown along with an unlubricated (dry) coefficient factor for reference. 4. Values of torque for materials having other yield strengths may be obtained by multiplying the tabulated torque value for the relevant lubricant coefficient by the ratio of the new material's yield strength to the tabulated material's yield strength. 5. For Class 900 ring type joint (RTJ) flanges, multiply the torque values shown by 0.8 to represent a bolt tension equaling 40% of the bolt material's yield strength. For Class 1500 & 2500 ring type joints (RTJ) flanges, multiply the torque values shown by 0.6 to represent a bolt tension equaling 30% of the bolt material's yield strength. Flange Standards & Flange types For process and utilities pipe work, the two commonly used flange standards are ANSI B16.5 (American National Standards Institute) and BS 1560(British Standards).A third standard, API 6A (American Petroleum Institute) specifies flanges for Wellhead and Christmas Tree Equipment.Flanges of different standards are not normally joined. If necessary to do so, engineering advice must first be sought to ensure the compatibility of the mating flanges. This document is the property of Al-Jaber International Company. Any copying and distribution of this document without the approval of the Management is prohibited. Page 13 of 14 Al-Jaber International Company Procedure System of FLANGE MANAGEMENT PROCEDURE (Site) Doc. No: AJB-OPR-MECH-PR-02 Issue Number: 01 No. Flange type 1 Welding neck 2 Socket weld 3 Screwed 4 5 6 7 Slip on Lap joint Blind Orifice Revision Number: 00 Original Issue Date: 10th Oct 2018 Revision Issue date: Service conditions For high pressure process conditions For low pressure process and utilities For small pressure utility condition and small sizes For large sizes and limited pressures For special corrosive conditions For all pressure process and utilities For instrumentation reasons , all pressure sizes 2” and larger. This document is the property of Al-Jaber International Company. Any copying and distribution of this document without the approval of the Management is prohibited. Page 14 of 14