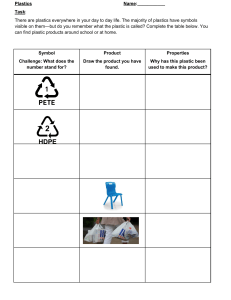

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/364379693 Converting plastics to fuel using solar energy Converting Plastics to Fuel using Solar Energy Article in AIP Conference Proceedings · October 2022 DOI: 10.1063/5.0108262 CITATIONS READS 0 163 8 authors, including: Uma Mageswari Bibin Chidambaranathan RMK Engineering College R.M.K. COLLEGE OF ENGINEERING AND TECHNOLOGY 24 PUBLICATIONS 112 CITATIONS 75 PUBLICATIONS 621 CITATIONS SEE PROFILE All content following this page was uploaded by Uma Mageswari on 20 January 2023. The user has requested enhancement of the downloaded file. SEE PROFILE Converting plastics to fuel using solar energy Cite as: AIP Conference Proceedings 2527, 030013 (2022); https://doi.org/10.1063/5.0108262 Published Online: 14 October 2022 Senthil Kumar Srinivasan, Uma Mageswari Deivasigamani, Bibin Chidambaram, et al. AIP Conference Proceedings 2527, 030013 (2022); https://doi.org/10.1063/5.0108262 © 2022 Author(s). 2527, 030013 Converting Plastics to Fuel using Solar Energy Senthil Kumar Srinivasan1,a), Uma Mageswari Deivasigamani2,b), Bibin Chidambaram1,c),Guru Prasaath Raju1,d), Yuvaraaj Kamaraj1,e), Chella Sudheer Manikantan1,f), Kishore Raj Sivasankar1,g), Jeyakumar Rengaraj3,h) 1 Department of Mechanical Engineering, RMK College of Engineering and Technology, Chennai, India. 2 3 Department of Science and Humanities, RMK Engineering College, Chennai, India. Department of Mechanical Engineering, Sri Krishna College of Engineering and Technology, Coimbatore, Tamilnadu-641008 a) Corresponding author: senthilkumar@rmkcet.ac.in b) sdu.mba@rmkcec.ac.in bibinmech@rmkcet.ac.in d) guru19me008@rmkcet.ac.in e) yuva19me034@rmkcet.ac.in f) chel19me005@rmkcet.ac.in g) kish19me017@rmkcet.ac.in h) jeyakumar@skcet.ac.in c) Abstract. Waste Management is a very important problem for the whole world. Plastic waste management is a major problem for today's generation. if we ignore this then in future the world would be covered with plastics and in India, the fuel rate is kept on increasing nowadays so our project deals with both and give an alternate solution .as we have the process of converting light plastics into fuel. Because hard plastics can be recycled to other products whereas light plastics are a huge problem s it cannot be recycled or reused by us. so, we are going to convert light plastics into fuel. and many had worked in this and also had succeeded but they use fossil fuels in the conversion process which is using fossil fuel and getting fossil fuel which is a non-profitable method. the plastics can be converted to fuel by heating the plastics at 380 to 400-degree Celsius not burning them as it creates harmful gases. and we have to heat it with the absence of oxygen because in the presence of oxygen it catches fire. For heating we are going to use parabolic monocrystalline solar panels with concentrators. INTRODUCTION Plastics are an inseparable part of our everyday existence. It is produced on a large scale globally and its production is over 150 million tonsannually. According to the CPCB, India produces approximately 5.6 million tons of plastic garbage each year. Plastic controls our lives in a variety of ways, including shopping and rubbish bags, packaging films, fluid containers, clothes, toys, furniture, material wrapping, packaging materials, beverage bottles, domestic, and industrial items, and so on. Due to the enormous consumption of plastics, the waste generated from plastic is also huge. The recycling rate of plastic is high except in municipal areas. There are some ingenious approaches by municipal corporations in Maharashtra in the recycling of plastics. They convert plastic waste into fuel. One such plant is in Pune, Rudra Environmental Solution (India) Ltd. Pune Municipal Corporation also started a similar plant in the Pune's Dhankewadi ward. This facility transforms 9000 kg of plastic into 5400 liters of gasoline every month. International Conference on Advancements in Materials and Manufacturing Engineering – ICAMME 2021 AIP Conf. Proc. 2527, 030013-1–030013-8; https://doi.org/10.1063/5.0108262 Published by AIP Publishing. 978-0-7354-4202-3/$30.00 030013-1 Because plastics are very inexpensive and easily available, our society has developed a use and trash culture. Plastic waste management has become a global issue due to its non-biodegradability. As the temporary solution of landfills has reached its maximum capacity, we must move towards a permanent solution that is recycling. DISCUSSION Usage of plastics and Production of plastics waste Plastics are one of the finest innovations of all time. There are used in various ways. They are lightweight, do not rust, are cost-efficient, and conserves natural resources in some cases. Plastics conserve energy and reduce CO2 emissions. To replace all plastics in all uses and consider the life cycle, 23 million tons of crude oil would be required every year as shown in Fig.1. Due of their non-biodegradable nature, plastics have now become a major hazard. Figure 1. plastics consumed by various countries SOURCE: Google Sources and properties of plastic wastes: They are classified into industrial and municipal plastic wastes. Municipal plastic wastes (MSW) The municipal plastic wastes are collected as home garbage and hence fall under the category of municipal solid wastes. Plastic containers, packaging, throwaway cups, plates, fridge liners, electronic cases, pipe, drink's bottles, cushioning foams, thermal insulation foams, agricultural feed bags, fertilizer bags, vehicle wrecks, and other items fall into this category. Plastics recovered from MSW include polyethylene, polypropylene, polystyrene, polyethylene, terephthalate, and others.Plastic separation is required in municipal plastic recycling. Mechanical separation equipment is used to separate polystyrene and polyvinyl chloride, which have a higher density than water, from polyethylene, polypropylene, and expanded polystyrene, which have a lower density. It is still impossible to mechanically categories it (Fig.2). So waste separation in the home is required, such as paper in a separate bin and food trash in a separate bin, wood in a separate bin, and noncombustible materials such as metals, ceramics, and plastics in a separate bin. 030013-2 Figure 2. Quantity of wastes, Source: Google Industrial plastic wastes Large-scale plastics manufacture, processing, and packaging produce industrial plastic waste. The majority of industrial plastic wastes have good physical properties, are relatively clean, contamination-free, and generally available in huge numbers. Municipal plastic trash is heterogeneous in nature, but industrial plastic waste is uniform. Thermal cracking into hydrocarbons is an appropriate method of recycling in this circumstance as shown in Fig.3. Figure 3. Plastic Waste Management SOURCE: Google 030013-3 PYROLYSIS OF PLASTIC WASTE TO LIQUID FUEL Pyrolysis is the controlled burning of a material in the absence of oxygen. During the pyrolysis of plastics, the macromolecular structures of polymers are broken down into smaller molecules called oligomers. The endothermic process of pyrolysis of polyolefin’s necessitates temperatures of at least 350–500 degrees Celsius. At lower temperatures, thermal cracking causes a decrease in octane value and a rise in residue content. These pyrolysis gaseous products are not appropriate for use as fuel products; additional refinement is required before they can be utilized as fuel products. Some researchers have discovered ways to enhance waste polyolefin thermal pyrolysis without using catalysts as shown in Fig.4. Figure 4. pyrolysis SOURCE: Google PROCESS DESIGN It is designed in a way where the mixed waste plastics, which is collected from household and industries will be cleaned and separated from other substitutes like iron fillings, other metal items by using metal detectors .and then plastics are dried up for removing dirt and drying the plastics .our next step is to compress plastics to smaller volumes, now the plastics are moved to the reactor and heated up to 380 to 400 degree Celsius we should not burn the plastics because burning plastics will produce harmful gases like sulfur. so we are just going heating the plastics by solar energy normal using of solar panels cannot create heat up to 380 to 400 degree Celsius so we are going to shape the solar panels in parabolic shape as shown in Fig.5. Figure 5. Parabolic Solar panel SOURCE: Google 030013-4 As we are using parabolic shape solar panels we are concentrating the solar rays at a certain point so we can achieve up to 500 degrees Celsius, now we get our required amount of heat to heat our plastic which we use renewable energy to heat the plastics which is our innovation here, very important thing in this is we have heat the plastics with the absence of oxygen if we heat it with oxygen then the plastics will burn which result to produce harmful gases by heating the plastics we get the poly fuel which has even high calorific value than diesel and petrol which somewhat light yellowish color. Further reefing the poly fuel, we can use it to IC engines also if needed a high efficiency as shown in Fig.6. Figure 6. Calorific Value SOURCE: Google As we said that poly fuel has a greater Calorific value the above table proves our statement is correct as shown in Fig.7. Figure 7. Comparison Of Poly Fuel To GasolineSOURCE: Google Comparison of regular gasoline and plastic waste fuel is given in the above table the net calorific value of regular gasoline is 10460 whereas plastic waste fuel net calorific value is 10498 which is higher than the regular gasoline. 030013-5 In plastic wastes there many factors which depend on the efficiency of poly fuel. in wastes there many types of plastics are present so below given table describes what products can be obtained from waste plastics as shown in Fig.8. Figure 8. Thermal Decomposition SOURCE: Google ADVANTAGES AND DISADVANTAGES Advantages in plastic waste fuel • • • • • Cheap The fuels produced this way may be customised to a specific use, such as transportation. Makes them suitable alternatives to fossil fuels. When burned, it emits less carbon than fossil fuels. The potential to extend the materials utilised in this process to include metal trash and other materials that aren't easily recyclable is exciting. Disadvantages in plastic waste fuel • • • • The energy recovered from this waste causes health concerns. Nitrous oxides, sulphur dioxides, particulate matter, and other hazardous pollutants can be released during the combustion of solid fuels. Sweden is concerned because it relies largely on rubbish imports from other European countries. The recycling sector is concerned that the economics of other waste-to-fuel processes, such as solid waste-to-fuel, may be harmed or undermined by plastic waste-to-fuel. This procedure necessitates rigorous preparation in order to ensure that the appropriate rules are in place to ensure safety while also balancing the demands of existing recycling systems. 030013-6 CONCLUSION Plastic waste recycling and a dearth of liquid fuel in developing countries like India may both be addressed by converting waste plastic into liquid gasoline. It is possible to thermally breakdown plastic in a cost-effective manner. Temperature, pressure, catalyst amount, and other variables can all help to boost product yield. The fuel generated in this experiment was similar to conventional diesel fuel used in cars. As a result, it may be stated that "poly fuel" may be a future alternative fuel. The final residue is utilized in road construction. Because no waste is produced throughout the process, it is known as a zero-discharge or green process that does not pollute the environment. REFERENCES [1] Gaurav, Madhukar M, Arunkumar K.N., Lingegowda N.S., “Conversion of LDPE plastic waste into liquid fuel by thermal degradation”, International Journal of Mechanical and Production Engineering, Vol.2, Issue 4, April2014. [2] U. S. Energy Information Administration Report dated August 14, 2014. [3] SantoshUkmal, KetanNalawade, Anil Jadhav, T. Vijayakumar, “Extraction of plastic oil from plastic by depolymerization technique as an alternative fuel”, International Journal of Applied Engineering and Research, Vol. 8, No. 19, 2013. [4] Antony Raja and AdvaithMurli, “Conversion of Plastic Wastes into Fuels”, Journal of Material Science and Engineering B 1 (2011) 86-89. [5] S. L. Low, M. A. Connor and G. H. Covey, “Turning mixed plastic into a useable liquid fuel”, 6th World Congress of Chemical Engineering, Melbourne, Australia, 23-27 September 2001. [6] Achilias DS, Roupakias C, Megalokonomosa P, Lappas AA, Antonakou EV. [7] Scott DS, Czernik SR, Piskorz J, Radlein DSAG. Fast pyrolysis of plastic. Energyand Fuels 1990; 4:407–11. [8] Miskolczia N, Barthaa L, Deak G, Jover B. Thermal degradation of municipalPolymer Degradationand Stability 2004; 86:357–66. [9] Uemura Y, Baba K, Ohe H, Ohzuno Y, HatateThe Journal of MaterialCycles and Waste Management 2003; 5:94–7. [10] Buekens AG, Huang H. Catalytic plastics cracking for recovery of gasolinerangeResources Conservationand Recycling 1998; 23:163–81. [11] Balakrishnan RK, Guria C. Thermal degradation of polystyreneand Stability2007; 92:1583–91. [12]Faravelli T, Pinciroli M, Pisano F, Bozzano G, Dente M, Ranzi E. Thermaldegradation of polystyrene. Journal of Analytical and Applied Pyrolysis2001;60(1):103–21. [13] Demirbas A. Pyrolysis of municipal plastic wastehydrocarbons. Journal of Analytical and Applied Pyrolysis 2004;72:97–102. [14] Mastral FJ, Esperanza E, Garcı´a P, Juste M. Pyrolysis of high-density polyethylenein a fluidised bed reactor. Influence of the temperature and residencetime. Journal of Analytical and Applied Pyrolysis 2002;63(1):1 15. [15] Garforth A, Lin YH, Sharratt PN, Dwyer J. Production of hydrocarbonslaboratory fluidisedbedreactor. Applied Catalysis A General 1998;169(2):331–42. [16] Cha WS, Kim SB, McCoy BJ. Study of polystyreneJournal of ChemicalEngineering 2002;19(2):239–45. [17] Dolezal Z, Pacakova V, Kovarova J. The effects of controlled agingJournal of Analytical and Applied Pyrolysis 2001;57(2):177. [18] Kim SS, Kim S. Pyrolysis characteristics of polystyrene and polypropylene in astirred batch reactor. Chemical Engineering Journal 2004;98(1–2):53–60. [19] Woo OS, Ayala N, Broadbelt LJ. Mechanistic interpretation of base-catalyzeddepolymerization of polystyrene. Catalysis Today 2000;55(1–2):161–71. [20] Woo OS, Broadbelt LJ. Recovery of high-valued products from styrene [21] Chan JH, Balke ST. The thermal degradation kinetics of polypropylene: Part III. [22] Hayashi J, Nakahara J, Kusakabe K, Morooka S. Pyrolysis of polypropylene inthe presence of oxygen. Fuel Processing Technology 1998;55(3):265–75. [23] Jakab E, Varhegyi G, Faix O. Thermal decomposition of polypropylene [24] Kaminsky W. Thermal recycling of polymers. Journal of Analytical andApplied Pyrolysis 1985;8:439–48. 030013-7 [25] Kaminsky W, Predel M, Sadiki A. Feedstock recycling of polymers by pyrolysisin a fluidised bed. Polymer Degradation and Stability 2004;85(3):1045–50. [26] online at OurWorldInData.org. Retrieved from:'https://ourworldindata.org/plastic- pollution' [OnlineResource] [27] Be Waste Wise (2019, March) - “Plastic Wastes and its Management”.Publishedonlineatbioenergyconsult.com. Retrievedfrom “https://www.bioenergyconsult.com/plasticwastes-management”[Online Resource] [28] Ross Marchand (2019, July 15) - “America’s Garbage ‘Problem’Concocted by Trashy Data”. Published online at bioenergyconsult.com.Retrieved from “https://catalyst.independent.org/2019/07/15/americasgarbageproblem- concocted-by-trashy-data/ ”[OnlineResource] [29] Ross Marchand (2016, September 15) - “Methods of Plastic WasteDisposal (and possible complications)”. Published online athttp://blog.nus.edu.sg/. Retrieved from“http://blog.nus.edu.sg/plasticworld/2016/09/06/xmethods-of-plastic-wastedisposal-and-possible-complications/” [OnlineResource] [30] SouravDaspatnaik - “Finding Solutions to Plastic Waste Management InIndia”. Published online at ecoideaz.com.Retrieved from “https://www.ecoideaz.com/expert-corner/findingsolutions-to-plastic-wastemanagement-in-india”[OnlineResource] [31] North EJ, Halden RU. Plastics and Environmental Health: TheRoadAhead. Rev Environ Health. 2013; 28(1):1–8.doi:10.1515/reveh-2012-0030 [32] ZhiqiangGan, Houjin Zhang - “PMBD: a Comprehensive PlasticsMicrobial Biodegradation Database Retrieved from“https://doi.org/10.1093/database/baz119” 030013-8 View publication stats