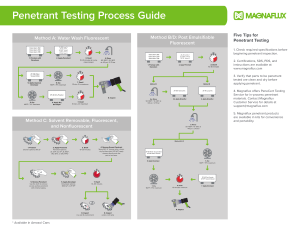

G.M. HI-TECH (UNIT-II) DOC NO:- FM/QP/27 DYE PENETRATION Procedure ISSUE:-01 ISO-3452-1-2021 REV:-00 DATE:-10.10.2021 CERTIFICATE We hereby certify that repair procedure no FM/QP/27 “Dye Penetration procedure” meets the requirement ISO-3452-1-2021 THE SIGNATURE BELOW AUTHORISE ALL PAGE OF THIS PROCEDURE FOR USE FROM THE DATE OF APPROVAL SHOWN TOTAL PAGE PREPARED BY APPROVED BY G.M. HI-TECH (UNIT-II) DOC NO:- FM/QP/27 DYE PENETRATION Procedure ISSUE:-01 ISO-3452-1-2021 REV:-00 DATE:-10.10.2021 TABLE OF CONTENTS 1. Scope 2. Reference Codes & Standards 3 4 5 6 7 8 Approved Penetrant Materials Process Sequence Test Procedure Acceptance criteria Post Examination Cleaning Recording G.M. HI-TECH (UNIT-II) DOC NO:- FM/QP/27 DYE PENETRATION Procedure ISSUE:-01 ISO-3452-1-2021 REV:-00 DATE:-10.10.2021 DYE PENETRATION PROCEDURE 1. Scope: This document specifies a method of penetrant testing used to detect discontinuities, e.g. cracks, laps, folds, porosity and lack of fusion, which are open to the surface of the material to be tested using white light or UV-A (365 nm) radiation. It is mainly applied to metallic materials, but can also be performed on other materials, provided that they are inert to the test media and not excessively porous. This document also includes requirements for process and control testing, but is not intended to be used for acceptance criteria. It gives neither information relating to the suitability of individual test systems for specific applications nor requirements for test equipment. 2. References Codes & Standards: ISO 3059, Non-destructive testing — Penetrant testing and magnetic particle testing — Viewing conditions ISO 3452-2, Non-destructive testing — Penetrant testing — Part 2: Testing of penetrant materials ISO 3452-3, Non-destructive testing — Penetrant testing — Part 3: Reference test blocks ISO 3452-4, Non-destructive testing — Penetrant testing — Part 4: Equipment ISO 3452-5, Non-destructive testing — Penetrant testing — Part 5: Penetrant testing at temperatures higher than 50 degrees C ISO 3452-6, Non-destructive testing — Penetrant testing — Part 6: Penetrant testing at temperatures lower than 10 degrees C ISO 12706, Non-destructive testing — Penetrant testing — Vocabulary 3. Approved Penetrant Materials: The dye, developer & cleaner (all of same make) used for DP test shall be of reputed brands like Magna flux, P Met, Flaw guide, Orion & NDT and shall be of spray type conforming to the specifications given in ASME sec V. Dye need not be spray type. It can be applied using paint brush. Penetrant material shall be as per ISO-3452-2 4. Process Sequence : A) Preparation and pre-cleaning (5.1) B) Application of penetrant (5.3) C) Excess penetrant removal (5.4) D) Application of developer (5.5) E) Inspection (5.6) G.M. HI-TECH (UNIT-II) DOC NO:- FM/QP/27 DYE PENETRATION Procedure ISSUE:-01 ISO-3452-1-2021 REV:-00 DATE:-10.10.2021 5. Test Procedure 5.1 PRE CLEANING: Surface & adjacent areas within 1" to be examined shall be dry & free of all dirt, grease, lint, scale, welding flux etc. that can obscure surface openings or otherwise interfere with the examination. Typical cleaning agents that may be used are detergents, organic solvents, descaling solutions & paint removers. the parts or areas of parts to be inspected shall be clean & dry before the penetrant is applied. Area under examination shall be thoroughly cleaned with the cleaner from the same group of penetrant materials. Cleaning shall be by spraying or brushing and wiping with a lint free cloth. Any traces of lint shall be removed. Drying shall be accomplished by exposure to ambient temperature & a drying time of min 30 seconds shall be provided. 5.2 Temperature Limits: The temperature of the Penetrant materials & the surface of the part to be examined shall not be below 10°C or above 50°C throughout the examination period. Temperature may be measured with 50°C thermal chalk. 5.3 Penetrant Application: Apply the Penetrant to the weld face side to be examined. During dwell time ( 10 -15 min.), if necessary, the Penetrant may be re-applied in case the first coat gets dried up. If the surface to be examined is large enough to preclude complete examination within 15 minutes of developer application, the examination shall be performed in increments. If the Penetrant dwell time exceeds the max. Of 15 mints. Then, testing shall be repeated from pre cleaning stage. 5.4 Removal Of Excess Penetrant: After the required Penetrant dwell time, excess Penetrant shall be removed as far as possible by wiping with a dry, clean cloth ( lint free) repeating the operation until most traces of Penetrant have been removed. All traces of lint shall be removed. Flushing the surface with cleaner following the application of Penetrant & prior to developing is prohibited. The part surface shall be allowed to dry by normal evaporation & a drying time of minimum 30 seconds shall be allowed prior to application of developer. G.M. HI-TECH (UNIT-II) DOC NO:- FM/QP/27 DYE PENETRATION Procedure ISSUE:-01 ISO-3452-1-2021 REV:-00 DATE:-10.10.2021 5.5 Application Of Developer: Application of developer on the face side to check surface defects shall be by spraying to assure complete coverage with a thin & even film. Developer shall be applied as soon as possible after removal of excess penetrant but within 10 minutes maximum. Interpretation & evaluation of the discontinuity indications shall be carried out after developer time of min. 10 minutes & max. 60 minutes. The level of luminance for removal of excess penetrant shall be at least 350 lx. For inspection, the luminance at the test surface shall be 500 lx or greater. In some cases, a minimum of 1000lx may be required 5.6 INTERPRETATION & EVALUATION OF INDICATIONS: a) Final interpretation shall be made within 10 to 15 minutes after the application of developer. b) viewing condition shall confirm to ISO 3059. c) A linear indication is one having a length greater than three times the width. d) A round indication is one of circular or elliptical shape with the length equal to or less than three times the width. E) Any questionable or doubtful indications shall be re-examined to determine whether or not they are relevant. F) Any adjacent indication separated by less than the major dimension of the smaller shall be assessed as a single continuous indication. 6 ACCEPTANCE CRITERIA: The acceptance standards shall apply unless specified is ISO 5817 quality level C. 7 POST EXAMINATION CLEANING: Post examination cleaning shall be carried out as soon as practical with a cloth soaked with cleaner. 8 Record Liquid Penetrant examination report shall be prepared and submit to purchaser for review. Prepared By:- Approved By:-