CHITTAGONG UNIVERSITY OF ENGINEERING &

TECHNOLOGY

DEPARTMENT OF ELECTRICAL & ELECTRONIC ENGINEERING

Report On

697 KVA Distribution Transformer design

Course No

Course Title

Group No

Section

Level-Term

EEE-240

Electrical Machine Design

G26

A

2-2

Submitted By:

Remarks

Pritam Bol

Id:1902044

Aritra Sarkar

Id:1902049

Objective:

To design a 697.00 kVA, 3 phase, 50 Hz, 6.6 KV/415 V, delta/star distribution

transformer.Here, we will consider:

Tapping 2.5%, 5% on high voltage side.

Cooling O N (self oil cooled)

Temperature rise over oil 600C

Load loss not more than 8 KW

Percentage impedance %Z= 4.50%

We also Calculated: efficiency at 750C on full load,75% load, and 50% load at a

unity power factor

Regulation on full load at 750C at unity power factor and 0.8 power factor

lagging.

Solution:

Voltage per turn(𝑬𝑻) :

An empirical expression that gives voltage per turn fairly

accurately for transformers is :

Et = 𝟏 √

𝟒0

𝑲𝑽𝑨×𝟏𝟎𝟎𝟎

𝑵𝒐 𝒐𝒇 𝒍𝒆𝒈𝒔

[for three-phase core type transformer; no of legs=3]

Therefore,

Et = 12.05 volts/turn

Specific Magnetic Loading:

Bmax = 1.7 Wb / m2;

Here, material for core is chosen as cold rolled grain oriented (CRGO) steel laminations of

0.35 mm thickness; mitred core construction is used; mitered at 450 Cross Section of the

core:

Et= (4.44 Bm f Ai)

Volts

Where,

Bm = flux density in wb/m2 (taken as 1.7 wb/m2)

f= 50 Hz

Ai= net cross sectional area of the core in the m2

2|Page

10.3×106

4.4×1.7×50

=

=31928.988 mm2

The diameter of the circumscribing circle for the core, d :

Here, we have chosen 7 step cores.

So, the area should be nearly circular. In the case of a 7 step core,

The core space factor, Ki= 0.88

Stacking factor for laminations, Ks= 0.92

If, d = diameter of the core section,

Ai =0.88 × 0.92 ×

𝜋𝑑2

4

2

d = 50213.88

So,

d= 224.08 mm

We choose it, d = 225 mm ;

∴Ai = 32190.404 mm2

And Bm = 1.686 wb/m2

Window area Aw :

We know, S = 3.33 Ai Aw Kw δ Bm f ×10-3

Here,

Window space factor (kw) = 0.26[taken approximately]

Aw = Window area;

𝛿 = current density taken as 2.5 A / mm2;

S = output in kVA=697.00 KVA ;

Therefore,

Aw =

697×106×103

3.33×32190.404×0.26×2.5×1.686×50

= 118664.60 mm2

3|Page

Now, we choose, window width = 0.88×225=198 mm=200 mm(approx.)

Then, the height of the window =

118664.60

200

= 593.323 mm(assume 595 mm)

Choosing the height of the window = 2 ×width of window approx

= 2×200

= 400 mm

Now, window area = 200× 400 mm2

= 80000 mm2

The main dimensions of the core are therefore:

Diameter, d = 225 mm;

distance between the centers of the adjacent limbs , D = (200+ 213.75 approximate) mm

= 413.75 mm (taken D=415)[with a 7 step

core, the largest width of the core

with d = 200mm is,

0.95×225=213.75 mm=215mm]

Here, Height of window = 595+(30×2) mm

=655mm[adjusted for yoke clearance]

Total width = (2 × 415) + 215 =1045 mm ;

Total height =( 655 + 215+215)=1085 mm

4|Page

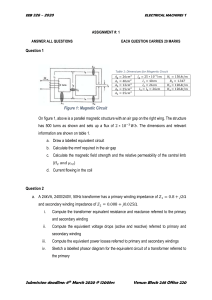

Figure 1: Dimensions of Core & yoke Assembly(all dimensions are in mm)

Number of Turns in L.V. Winding :

Voltage per phase = 415= 239.6 V (as the winding is star connected)

√3

& Turns per phase on L.v winding =239.6 = 19.88 turns=20 turns

12.05

Number of Turns in H.V. Winding :

Turns per phase on h.v. winding =

6600=

12.05

547.71 turns =548 turns;

As the winding is delta connected,

∴Tappings are applied on H.V. side:

5% more 548×1.05 =575 ; 2.5% more = 548×1.025=562

5% less 548×0.95 =521 ; 2.5% less = 548×0.975=534

Thus the turns for H.V. windings are:

5|Page

562

575

548

534

521

2.5%

5%

Normal

-2.5%

-5%tappings

L.V. Winding :

3

Current per phase Ip =697×10 = 969.6702111 A

√3×415

Here, we choose a helical cylindrical coil.

As, Current density, δ = 2.5 A / mm2 ; (assumed)

∴ 𝐴rea of l.v. conductor, a2 = 969.6702111 ÷ 2.5

= 381.868 mm2

=380 mm2

Choosing, rectangular copper conductor from IS : 1.4 : 1 specs.

[For rectangular copper conductors for electrical machines, giving area near about the

required one.]

∴1.4x2 = 194

x = 11.77

∴width = 1.4x = 16.48 mm

∴ thick = 11.8 mm

So, choosing 5 mm thickness × 38 mm width; As thickness can’t be larger than 5mm

for transformer’s copper strip.(**Reference at last page**)

2 conductor strips farming conductor of l.v. area: a2 = 5× 38× 2 =380 mm2

H.V. Winding: choosing disc coils :

Now, current in h.v. winding per phase Ip

=697×1000 =35.20 A; (being delta connected)

3×6600

Cross section of conductor for h.v. winding , a1 = 35.20 ÷ 2.5 = 14.08 mm2

Choosing round conductor where, d = diameter of conductor

We know,

d=4.234 mm = 4 mm

a1 = πd2 ÷ 4

6|Page

Copper area in window = 2 (a1T1 + a2T2)

= 2 (12.57 × 548 + 380 ×20)

= 28972.77 mm2

Now for this dimensions,

we get window space factor,

kw =(𝐴𝑟𝑒𝑎 𝑜𝑓 𝐶𝑜𝑝𝑝𝑒𝑟)/(𝐴𝑟𝑒𝑎 𝑜𝑓 𝑊𝑖𝑛𝑑𝑜𝑤)

=28972.77 ÷ 118664.60 = 0.244 [which is near about 0.24 chosen]

Design of the layout of L.V. winding:

The number of turns, T2 =20.

Size of conductor:2 strips of 38 × 5 mm, copper rectangular conductors

With paper insulation for conductors, the size of each conductor

will be:

= (38 + 0.25) mm × (5+ 0.25) mm

= 200.81 mm2

choosing 2 layers for l.v. winding,

Turns per layer = 20/2 =10

Width of conductor 38.25 mm is taken along the winding, with

2 conductor sides

=5.25 + 5.25

= 10.5 mm forming conductor per layer.

For one layer, the dimension of conductors width is 10.5 mm

and height of window wise 38.25 mm for each conductor.

Now, Height of l.v. winding in window = 10 ×38.25 = 382.5 mm =383 mm;

Thickness of l.v. coil= 10.5×2=21 mm

Distance between core and l.v. coil = 3.5 mm

Inside diameter of l.v. coil = 225+ ( 2 ×3.5 ) = 232 mm

7|Page

Outside diameter of l.v. winding = 232 + ( 2 × 21)

= 274 mm

Mean diameter of l.v. coil = 232+ 21= 253 mm

Mean length of turn of l.v. coil = π ×253= 794.8248 mm

Figure. 2: Layout of L.V. winding(all dimensions are in mm)

8|Page

Design of the layout of H.V. winding:

The distance between l.v. and h.v. = 12 mm

Inside diameter of h.v. = 274+ ( 12 × 2 ) = 298 mm

Now, Split h.v. winding in 4 coils each with turns =548/4=137

The size of conductor = 4 mm diameter.

With paper insulation on conductor, the diameter = (4 +0.25) mm=4.25 mm

Figure. 3: Layout of H.V. winding(all dimensions are in mm)

9|Page

Here we choose 7 layers ;

∴Turns per layer = 𝟏37 = 19.57=20

𝟕

& Height of winding in each h.v. coil = 20 ×4.25=85 mm

Thickness of each coil = 7 ×4.25 = 30 mm

Outside diameter of h.v. coil = 298 + ( 2 ×30 ) = 358 mm

Approximate mean diameter of h.v. coil = 298 + 30 = 328 mm

Mean length of turn = 328 × π = 1030.44 mm

Height of h.v. coils in window = ( 85 × 4 ) +8 +8+8 = 365 mm

The space required between coils and core on either side is taken as 26 mm

The height of window required:= 365 + 26 ×2 = 417 mm ; [Which is acceptable ]

Percentage Reactance:

l.v. mean length of turn = 794.8248 mm

h.v. mean length of turn = 1030.44 mm

average Lmt =

794.8248+ 1030.44=

𝟐

912.63 mm

Ampere Turn =969.6702111 ×20 = 19393.40 =19393 ;

Approximate mean height of coils=𝟑65+𝟑83

𝟐

=

374 mm

Here, a = 12 mm

b1 = width of h.v. 30 mm;

b2 = width of l.v. =21mm

Now,

a1+ 𝒃𝟏+𝒃𝟐

𝟑

=29 mm

10 | P a g e

% reactance, X =

−7

𝟐×𝜋×50x4𝜋×10 ×𝟎.91263×19393×0.029

𝟎.𝟑74×12.05

= 0.044 Pu or 4.4 % [its acceptable as its between 3.5% to 4.5%]

Percentage Resistance:

Here,

ρ20 = 0.01724ohm/mm2/m

α20 =0.00393

At 75°C, ρ75 = ρ20{1+ α20(75-20)}

=0.021 /mm2/m

Resistance of low voltage (l.v.) winding: (per phase)

=

𝟎.𝟎𝟐𝟏×794.8248×20

380×1000

= 8.78× 10−4 Ω (per phase)

Resistance of high voltage (h.v.) winding: (per phase)

=

𝟎.𝟎𝟐𝟏×1030.44×548

14.08 ×1000

= 0.842 Ω (per phase)

So, Ratio of transformation = (6600) ÷ (239.6) = 27.54 =28

Now,

Equivalent resistance referred to h.v. winding (per phase)

R = 0.842 +8.78× 10−4 × (28)2

= 1.53 Ω

percentage resistance, %R =

35.20x1.53

= 0.0081 pu =0.81%

6600

11 | P a g e

Here,

Therefore,

Percentage impedance, %Z = √%R2 + %𝑥2

=√4.42 + 0.812

%

=4.47 %

Weight of Iron in Core and Yoke Assembly:

From Fig 4

The volume of the core and yoke is given by:

= Ai × { (1045× 2) + (655×3) } mm3

= 32190.404 ×4055mm3 =130532088.2

Weight of iron = 7.85 × 1000 kg /m3. For Cu

Weight of core and yoke = (130532088.2× 7.85 ) ÷ ( 1000 × 1000 )

= 1024.68 kg

Core loss at Bmax = 1.686 wb/m2 is 1.5 watts/kg

∴

Core loss in transformer= 1024.68 ×1.5

= 1537.02 watts ;

Magnetizing Volt Amperes:

For Bmax = 1.686 wb/m2, VA / kg from the curve is 10.5 VA/kg

Magnetizing volt amperes = 1024.68 × 10.5

= 10759.14 VA

Weight of low voltage winding:

We know, density of copper =8.89 g/cm3

Number of turns T2 = 20

&

a2 = 380mm2

Mean length of turn = 794.8248 mm

Weight of l.v. winding (per limb) = ( 8.89 × 380× 794.8248 ×20 )÷ 106

=53.7 kg

12 | P a g e

Weight of H.V. winding(per limb):

Number of turns T1 = 562; & normal= 548 ;

a1 = 14.08 mm2 ;

Mean length of turn = 1033.706 mm

= ( 8.89× 12.57× 1030.44× 562) ÷ (106) kg

Weight of 4 coils (one limb)

= 64.7kg ; for all turns

For normal turns,

weight of the coils (one limb) =( 8.89× 12.57× 1030.44× 548) ÷ (106) kg

= 63.1 kg

Total Weight of Copper in Transformer:

∴ 3× ( l.v. + h.v. )

= 3 (53.7+63.1)

=350.4 kg

Copper Loss and Load Loss at 750 C:

h.v. current per phase Ip= 35.2 A

Copper loss for 3 phases = 3 × I2 × r

= 3× 35.22 × 1.52

=5650.02 watts

Let, stray load loss about 7%,

Then, load loss (at 750C) = 5650.02×1.07

= 6045.52 watts

Iron loss = 1537.02watts .

Therefore ,

Total loss=(6045.52 +1537.02)

= 7582.54 watts = 7.5 KW

13 | P a g e

Calculation of Performance:

Efficiency on full load at unity power factor :

Output = 697×1000 watts.

Efficiency,

697×1000

𝜂 = (697×1000)+7582.54 × 100%

= 98.92 %

Efficiency on 3/4th full load at unity power factor:

Core loss = 1537.02 watts;

Load loss on 3/4 load = 6045.52 ×(3/4)2

=3400.605 watts

Total loss = 1537.02+3400.605

= 4937.625 watts

0.75 ×697×1000

Efficiency on 3/4th of full load ,𝜂 = (0.75 ×697×1000)+4937.625

× 100%

= 99.06%

Efficiency on ½ of full load at unity power factor:

Total loss = ( 1537.02 + 6045.52 ×0.52 )

= 3048.4 watts

0.5 ×697×1000

Efficiency on 1/2 of full load ,𝜂 = (0.5 ×697×1000)+3048.4

× 100

= 99.13%

Regulation At Unity Power Factor:

% R = 0.81%,

% X = 4.47%

Now,

( V + IR )2 + ( IX )2 = E2

or, ( 1.0 + 0.0081 )2 + (0.0447)2 = E2

14 | P a g e

∴ E = 1.00909 V

%Regulation =(1.00909-1)×100%

=0.909%

𝑹𝒆𝒈𝒖𝒍𝒂𝒕𝒊𝒐𝒏 𝑨𝒕 𝟎. 𝟖 𝑷𝒐𝒘𝒆𝒓 𝑭𝒂𝒄𝒕𝒐𝒓 ∶

%Regulation = [IR cos φ + IX sin φ] %

= [0.81 ×0.8+4.47 ×0.6] %

=3.33%

Core loss current, magnetizing current, no-load current :

Core loss = 1537.02 watts.

core loss current, Ic = (1537.02) ÷ ( 3 × 6.6 × 103 )

= 0.0776 A

Magnetizing VA = 10759.14;

magnetizing current, Im = (10759.14) ÷ (3 ×6.6×103)

= 0.543 A

No load current per phase , Io = √(0.07762 + 0.5432)

= 0.549 A

Current per phase = 35.2 A

No load current = (0.549÷35.20)×100%

= 1.56% ; of full load current

Design of Tank :

Fig: 4 shows the spacing of outside diameters of h.v. coils on the cores.

Outside diameter of h.v. = 358 mm

The distance between coils on adjacent limbs =415-358=55mm(approximate);

Clearance at each end is 38 mm.

15 | P a g e

Thus, the length of the tank = 358×3+ 2 ×55 + 2 × 38 = 1260mm

Breadth of the tank = 358+ 55 × 2 mm

= 468 mm;

Choosing 470 mm

Height = 1085 + 50 mm for base + 250 oil level above core +250mm for leads;

= 1385 mm up to oil level + 250 mm for leads ;

=1635 mm

Inside dimensions of the tank of the transformer = (length × breadth ×height)

= (1260× 470 × 1635) mm3

Figure. 4: Tank dimensions (all dimensions are in mm).

16 | P a g e

Temperature Rise :

Now, for dissipation of heat, only 4 surfaces of a tank are taken into consideration.

The top and bottom are not considered.

1635 1260

×

× 2 = 4.121 𝑚2

1000 1000

The surface of the tank =

1635 470

×

× 2 = 1.5369 𝑚2

1000 1000

1635 1260

×

× 2 = 4.121 𝑚2

1000 1000

Total = 5.6579 m2

Full load loss to be dissipated = 7582.54 watts

Now, If 12.5 per m2 per 0C temperature rise is taken as dissipation due to convention and

radiation,

The temperature rise = ( 7582.54) ÷( 12.5 × 5.6579 ) = 107.210C

Now, to maintain the temperature of transformer walls limited to 600C; Then

temperature rise of the oil will be 500 Cand of coils 550C. In that case, the surface

of the tank for cooling has to be increased either by “radiators” or “tubes”

attached to the tank.

If the total surface area is considered, ‘x’ times the tank surface area, we get:

( 5.6579 ) × (x) × (8.8 + 3.7/ x ) 60=7582.54

∴ x = 2.118

Thus,

Additional area to be provided = 5.6579 ×(2.118-1)= 6.326 m2

As, 1385 mm is height up to oil level;

Height of tube is taken as 1000 mm

Surface of 1 tube of 50 mm diameter = π ×50×1000 × l0-6

=0.157 m2

Number of tubes required

=

6.326

0.157

= 41 ; approximately

17 | P a g e

Volume and weight of coil :

Volume of tank up to oil level of 1385 mm

=( 1260 /1000 ) × ( 470 /1000 ) × ( 1635/1000 )

=0.9684 m3

Volume of transformer core and copper

:

={350.4÷( 8.89 × 103 )} + {(1024.68) ÷ (7.85 × 1000 ) }

=0.17

Volume of oil =(0.9684-0.17)

= 0.7984 m3

Oil required in transformer = 0.7984 ×1000L

=798.4 liters .

Therefore, weight of oil required

= (798.4 × 0.89) kg

= 710.576

kg

18 | P a g e

Weight of the tank :

If the thickness of the tank walls is taken as 5 mm

Weight of tank = 0.005 × [ {(1260/1000 ) × ( 470/1000 ) × 2 }+{( 1635/1000 ) ×( 1260/1000)

×2} + {( 1635/1000 ) × ( 470/1000 ) × 2} ] ×1000 × 7.85

= 268.57 kg

Volume and Weight of tank :

41 tubes each of 50 mm diameter and 1 m length.

Therefore, Volume

=(π/4) ×(50/1000)2×1×41

= 0.0805 m3,

Volume of oil in tubes = 0.0805 × 1000 = 80.5 liters.

Weight of oil in tubes = 80.5 × 0.89 = 71.64 kg

Weight of tube

= π × (50/1000) × 1 × 0.005 × 41 × 7.85 ×1000 kg

= 252.78 kg

Total weight of core and Yoke:

Weight of core and yoke assembly = 1024.68 kg

Weight of copper in windings

= 350.4 kg

Weight of tank

= 268.57 kg

Weight of tubes

=252.78 kg

Weight of oil in tank and tubes

= 710.576kg

= 71.64 kg

Total weight= 2678.646 kg

19 | P a g e

Summary:

Specifications:

kVA 697; Volts H.V. 6600 volts; Volts L.V. (no load) 415 volts; Amperes H.V. 35.2 A ;

L.V. 969.67 A (line values); 3 phase, delta/star 50 c/s; temperature rise of oil 107.210C ;

type of cooling ON ; Vector group; percentage impedance 4.47%

±2.5%and ±5% tapings on h.v. side.

Core and Yoke :

Material: CRGO (cold rolled grain oriented) steel laminations 0.35 mm thick; mitered core

construction 45° cut.

c

Flux density Bmax=1.686 Wb/m2; Net area of cross-section of core, 32190 mm2;

circumscribing circle diameter 225 mm.

Size of core, yoke and frame :width of the window, 200 mm; height of window=595 mm;

Weight of core and yoke assembly 1024.68 kg; core loss at Bmax = 1.686 wb / m2, 1.5 watts

per kg magnetizing VA = 10.5 VA / kg

Windings

L.V

H.V

Type of winding

Helical

Disc

Current density

2.5

2.5 a/mm2

Cross sectional area

ofconductor

380mm2

Conductor : Copper

2 strips of

14.08 mm2

4 mm

5×38 mm

Number Of Layers

perlimb

2

4 discs

Number of turns

20

548 normal

Number of turns per layer

10

137

20 | P a g e

Height of winding

inwindow

383 mm

365 mm

Thickness of coil

21 mm

30 mm

Inside diameter of coil

232 mm

298 mm

274 mm

358 mm

Mean length of turn

794.82 mm

1030.44 mm

Resistance at 750c

0.000878 ohms

0.842 ohms

53.7 Kg

63.1 Kg

Outside diameter of coil

Weight of copper for winding

per limb

Total Weight Of Copper

350.4

Kg

Insulation :

Insulation between core and l.v. winding: pressboard paper

Insulation for conductors: paper

Insulation between layers: Crape paper

Insulation between l.v. and h.v. windings: bakelite paper cylinder; Laminated pressedwood

sticks for spacers for cooling.

Class A insulation for O N-type transformers.Tank:

Temperature rise of oil 107.210C

Inside dimensions of tank : length 1260 mm; breadth :470 mm; height 1635 mm

Tubes 41, each of 50 mm diam; 1000 mm long.

21 | P a g e

Oil in the transformer tank

798.4 liters

Oil in tubes

80.5 liters

Weight of oil in the tank

710 kg

Weight of oil in tubes

71.64 kg

Weight of tank

268.57 kg

Weight of tubes

weight of complete transformer

252.78 kg

2678.646 kg

Performance

Percentage resistance

0.81%

Percentage reactance

4.4%

Percentage impedance

4.47%

Iron loss

1537.02

watts

Copper and stray load loss, i.e. load loss at 750C

6045.52 watts

Total loss on full load

7582.54watts

Efficiency on full load at a unity power factor

98.92%

Efficiency on 3/4 the full load at a unity power factor

99.06%

Efficiency on 1/2 full load at a unity power factor

99.13%

Regulation on full load at a unity power factor

0.909%

Regulation on full load at 0.8 power factor lagging

3.33%

Core loss current per phase

0.0776 A

Magnetizing current per phase

0.543 A

No load current per phase

0.549 A

22 | P a g e

Tapings :

562

575

548

534

521

2.5%

5%

Normal

-2.5%

-5%tappings

Reference : (From internet source and specific books.)

23 | P a g e