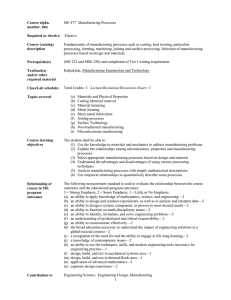

fF MAE272 Midterm 2 KEY ***USE TALLY SYSTEM COLOR CODING KEY: ● 100% CORRECT ● 75% CORRECT/GUESS ● FOR SURE WRONG Fine versus conventional blanking: ● fine blanking requires more precise, expensive tooling Flange in sheet metal can be produced: ● All are correct Lost-foam casting is: ● using expandable molds and patterns cCold forming of metals is done at ● T/Tm just below 0.3 (I) Magnetic pulse forming: ● can form thin sheets without noise and heat The threaded base (socket) of a light bulb can be prspringoduced cost-effectively by: ● None is correct **discord** Springback in sheet metal forming is a function of: ● All are correct In sheet metal forming, springback can be controlled by: ● All are correct (I) To produce 2-piece aluminum beer and soda cans, which process is ● Welding (I) ● not required: High temperature gas turbine blades can be produced by: ● Single crystal casting (chegg) PM distinguishes from conventional metals because of: ● All correct (II) ● What is the difference between AA 6061-T4 and AA 6061-T6? T6 is naturally aged, T4 is furnace aged then work-hardened. Which process is not required to produce 3-piece welded cans ● Deep Drawing) The frame of an off-the-shelf beach cruiser bicycle is usually made from: ● Drawn or extruded Which is investment casting: ● wax pattern is melted out for recycyling before pouring (chegg)(III) also book pg 300 Large rings can be produced by cost-effectively by: ● Ring rolling (II) Travelers are ● updated cost estimates after receiving P.O. Nesting in sheet metal manufacturing is:supe ● to reduce material usage, energy and tooling costs (chegg) ● can have percent Superplastic materials: elongations up to 1000% **correct answer from discord** Minimum bending radius: ● depends on the hardness and rolling direction of the metal before bending (chegg) A rectangular keyway in a round shaft can be produced by: ● None is correct (chegg) An open riser helps: ● reduce porosity, thus should not solidify before the casting (chegg; III) Anisotropy in sheet metals ● can cause dog-ears and non-uniform wall thickness in deep drawing (Pg 398; II) Engine blocks for V-6 hybrid engines can be produced in large quantity by: ● No answer is correct (chegg)(I) Temperature built up during machining: ● Will shorten tool life (II) Continuous casting of metals: ● None of the answers is correct Knurling performed on a round shaft ● All are correct (I) Which are traditional joining processes? ● All but water jet? (II) Minimum bend radius for AA 7075-O is: ● 0 (page 403) (I) Centrifugal forces can be used to ● Cast hollow and solid objects spin casting uses interia forces to produce ● Ferrous and non-ferrous Risers help ● None of the above (I) Casting can be used to: ● Manufacture high-volume production parts (Chegg)F In sheet metal fab, anisotropy can: ● cause variations of properties in different directions (chegg; II) Superalloy and nickel-based alloys... ● vacuum casting using ceramic molds (chegg) Cam shafts in a 16-valve 4-cylinder engine can be turned on: ● High speed CNC machining centers Engine hoods, fenders, boot lids, etc., of mid-size SUVs are usually: ● Stretched formed and/ or deep drdrawawn Progressive dies are preferred over compound dies due to: ● Simpler design and low maintenance cost (I) toleranc Tolerances will vary less during production due to: ● Raw By agreement, sheet metals are defined as such: ● Less than 5 in thick plates ● when one dimension is less than 2.5 mm, and much smaller the other two (chegg) ( i dont think this is correct. Cause it says less than 6mm everywhere) EDM can produce very large parts with cycle time 60-90 pieces/min that are: none of the following too expensive to sand cast materials consistency Hardness increase during machining can: ● All are correct ?(I) Sand casting of metals is: ● None of the answers is correct (chegg) idk.... Draw beads used are used occasionally: ● in deep drawing to control metal flow and flange forming Vickers (HV) is: ● None is correct In sheet metal fabrication, minimum bending radius for AA 6061-0 is: ●0 ● In the production of 2-piece aluminum cans, the lid is connected to the can body by: ● Seaming and sealing (III) Rubber forming or hydroforming of sheet metals can be of cost advantage due to: ● Low tooling cost (I) In rolling, spreading should be avoided by: ● reducing Cold forming of metals is done at: Sand casting of metals is: Hot rolling of metals can produce: An estimate for job cost as per customer's RfQ should include: Progressive dies are preferred over compound dies due to: the reduction in thickness (bite) ● T/Tm just below 0.3 (chegg) ● None of the above (I) ● All answers are correct (III) ● All are correct (chegg) extremely high production rates (chegg) 2 upvotes on chegg **also Friction in manufacturing should be reduced or eliminated except: High temperature gas turbine blades can be produced by in book pg 391** (II) In rolling or friction welding (I) single crystal casting Tolerances will vary less during production due to : Consistent raw material properties (II) Hot rolling of metals can produce: All answers are correct (I) Which of the following processes is not required to produce 3-piece welded steel cans: Ironing in multiple operations (if deep drawing isn’t an option) (I) Flange in sheet metal can be produced: All are correct (today’s lecture) Not a heat treatment process: furnace brazing (chegg) Connecting rods in internal combustion engines are: designed to convert a linear motion into angular one (master sheet) Hydro and rubber forming can: Super plastic forming requires Risers in casting help Climb milling is: preferred for slender parts due to the downward forces (master sheet) Router or traveler is Document which lists sequence of operations (interned as a tooling engineer and am pretty sure this is right) Which is called the lost-wax casting: Casting using a sand mold is: Grocery and trash bags are most cost effective when produced by: Extrusion and blown-film Quality products such as aluminum foils are best produced by: MAE272 Midterm 3 ***USE TALLY SYSTEM COLOR CODING KEY: ● 100% CORRECT ● 75% CORRECT/GUESS or YESSSIIIIRRRR ● FOR SURE WRONG Friction in manufacturing should be reduced or eliminated except: In rolling or friction welding Exam 2 Confirmed on chegg also Friction welding: None is correct Extruded metal rods and profiles can be straightened by: Roll forging Superalloy and nickel-based alloys gas turbine blades are typically made by: Vacuum casting (exam 2) A rectangular keyway in a round shaft can be produced by: None is correct (exam 2) By agreement, sheet metals are defined as such: ● when one dimension is less than 2.5 mm, and much smaller the other two (chegg) ( i dont think this is correct. Cause it says less than 6mm everywhere) Exam 2 Continuous casting of metals: none For a good TIG/MIG weld joint, the workpieces should be: Heat up parts OR compatible materials (there are two like this) of compatible materials; and the filler rod too Super plastic forming requires: slow forming process to ensure recrystallization (chegg) In polymer processing: All I believe Centrifugal forces can be used to Cast hollow and solid objects (chegg IV) ASTM grain size 7 is: Good for engine hoods and trunk lids (chegg) Quality products such as aluminum foils are best produced by: hot rolling without pickling and oiling (chegg) IC chips on PCBs are: Connected by soldering or surface mounting technique Which parts can be produced on a turret lathe with a single set-up: Cam shafts (chegg) High temperature gas turbine blades can be produced by: ● Single crystal casting (chegg) Rubber forming or hydroforming of sheet metals can be of cost advantage due to: ● Low tooling cost (I) -Exam 2 OR be cost effective for short-run, shallow sheet metal parts Temperature built up during machining:v Will shorten tool life EDM can produce very large parts with cycle time 60-90 pieces/min that are: Grocery and trash bags are most cost effective when produced by: none of the following Exam 2 Extrusion and blow film (IIII-my guess)(see page 501)(also chegg) Tolerances will vary less during production due to : - high flexibility of machine frame (chegg) - consistent raw material properties (midterm 2 doc) Annealing is investment casti thermal treatment for cold-worked metal to restore its properties and grain structures (I) For AA 6061-O the minimum bend radius is: 0 Round rivet heads can be formed by: Heading in the punch (none of the other answers make sense) Risers in casting help: Reduce porosity thus should not solidify before the casting Consumable electrodes can be: Used in tig welding fro quality welds (II, chegg and book pg 888) Camshafts for a 16v 4cyl can be turned on High speed cnc machining centers Cold forming of metals is done at: AA 6061-T4 and AA 6061-T6 are: None of the above Magnetic pulse forming: is forming by induction (chegg)(I) Mfg using centrifugal forcCast hollow and solid The threaded base of a light bulb can be produced cost-effectively by: Progressive dies are preferred over compound dies due to: Break even point is: None of the above (II) ● Simpler design and low maintenance cost (I) Exam 2 The number of parts made by two potential processes with same unit cost.(chegg) Return on investment (I) Quotation/bid in response to customer's RfQ should not include: all dimensions and tolerances A chip breaker is: used if the cutter geometry does not warrant short chips (III) Changes in bending angles after bending due to Springback are functions of: All are correct (I) Minimum bending radius ● depends on the hardness and rolling direction of the metal before bending (chegg) exam 2 Anisotropy in sheet metals ● can cause dog-ears and non-uniform wall thickness in deep drawing (Pg 398; II) -Exam 2 Cafeteria trays can be produced by: Thermoforming of reinforced plastic sheets (pg 555 in book) (top displayed google search) Fine versus conventional blanking: fine blanking requires more precise, expensive tooling Flange in sheet metal can be produced: Hot rolling of metals can produce All but blanking ● All answers are correct Sand casting of metals is: None Risers help: None is correct (midterm 2) Which is called the lost-wax casting: Connecting rods in internal combustion engines are: Which part can be produced on a turret lathe with a single setup All of the above (I) ? (chegg) Not a heat treatment process: furnace brazing (II, chegg) Hydro and rubber forming can: be cost effective for short-run, shallow sheet metal parts (chegg) Knurling performed on a round shaft: all Springback in sheet metal forming is a function of: Thread for commercial grade steel bolts is strongest when produced by Rolling then stress relieving (chegg) Guidelines for welding processes include: Heat up parts before welding to reduce distortions, and stress relieve thereafter if necessary Engine blocks for 4-cylinder in-line hybrid engines can be produced in large quantity by: Advantages of Nesting in sheet metal: assemble two hollow objects into each other lower tooling costing minimize material waste Minimum bend radius for AA 7075-O is: 0 (I) Which is called the lost-wax casting Pattern is melted out for recycling before pouring (retake doc) Engine blocks for V-6 hybrid engines can be produced in large quantity by: None of the above (I) Likely to cause cracks inside the bend (I) Die-casting of steels with ceramic molds (saw this on chegg) 2-piece aluminum beer and soda cans can be produced without: The threaded base (socket) of a light bulb can be prspringoduced cost-effectively by: Superplastic materials: welding ● None is correct Draw beads used are used occasionally: The frame of an off-the-shelf beach cruiser bicycle is usually made from Casting using a sand mold is: ● in deep drawing to control metal flow and flange forming a. All of the above appropriate for large and very high precision castings (pg. 263) Cold forming of metals is done at: ● T/Tm just below 0.3 (chegg) II An estimate for job cost as per customer's RfQ should include: ● All are correct (chegg) Which are traditional joining processes? All but water jet Which of the following processes is not required to produce 3-piece welded steel cans: Automated inspection (chegg I) Lost-foam casting is: ● using expandable molds and patterns Exam 2 PM has advantages over conventional metals because of: All are correct (chegg) Flanges in sheet metal can be All but blanking Advantages of Nesting in sheet metal: In sheet metal forming, springback can be controlled by: All but assembling hollow objects ● All are correct (I) The letter T in AA 6061-T6511 means: Annealed or recrystallized grain structures (chegg) Which is investment casting: wax pattern is melted out for recycling before pouring (chegg) not sure To produce 2-piece aluminum beer and soda cans, which process is not required: welding Nesting in sheet metal manufacturing is: To reduce material usage, energy and tooling costs (chegg) The frame of an off-the-shelf beach cruiser bicycle is usually made from Climb milling is: preferred for slender parts due to the downward forces Progressive dies are preferred over compound dies due to: Hardness increase during machining can: Which is called the lost-wax casting: All are correct (chegg) In rolling, spreading should be avoided by reducing the reduction in thickness (bite) (chegg) Vickers (HV) is Resistance to elastic deformation None is correct (I)-unless “Hardness is resistance to indentation” is an option, then that is correct In the production of 2-piece aluminum cans, the lid is connected to the can body by: Seaming then sealing Properties of sheet metals affected by anisotrophy Can cause dog-ears and non-uniform wall thickness in deep drawing MAE272 FINAL KEY ***USE TALLY SYSTEM COLOR CODING KEY: ●100% CORRECT ●75% CORRECT/GUESS ●FOR SURE WRONG The threaded base of a light bulb can be produced cost-effectively by: None of the above (II) Hydro and rubber forming can: be cost effective for short-run, shallow sheet metal parts (chegg) Super plastic forming requires: Changes in bending angles after bending due to Springback are functions of: Superplastic materials: For a good TIG/MIG weld joint, the workpieces should be: of compatible materials; and the filler rod too (Midterm 3) For AA 6061-O the minimum bend radius is: 0 Not a heat treatment process: Furnace brazing Vickers (HV) is: None is correct An estimate for job cost as per All are correct customer's RfQ should include: Anisotropy in sht6eet metals: can cause dog-ears and non-uniform wall thickness in deep drawing AA 6061-T4 and AA 6061-T6 are: None of the above Spin casting uses inertia forces to produce Ferrous and non-ferrous solid and hollow parts EDM can produce very large parts with cycle time 60-90 pieces/min that are: None or not feasible Advantages of Nesting in sheet metal: all but assembling hollow objects Properties of sheet metals affected by anisotropy: can cause dog-ears and non-uniform wall thickness in deep drawing Magnetic pulse forming: Can form thin sheets without external force and heat input (I) Cold forming of metals is done at: ● T/Tm just below 0.3 (I) Temperature built up during machining: Which parts can be produced on a turret lathe with a single set-up: ● wWill shorten tool life (II) ○ Exam II Rotational symmetric parts (II) The letter T in AA 6061-T6511 means: Centrifugal forces can be used to: Cast hollow and solid object Quality products such as aluminum foils are best produced by: Continuous casting and rolling? (I) Fine blanking: Pg 391 in book for reference Break even point is: return of investment In the production of 2-piece aluminum cans, the lid is connected to the can body by: -seaming and sealing (I) Engine blocks for V-6 hybrid engines can be produced in large quantity by: ● No answer is correct (chegg)(I) ASTM grain size 7 is: good enough for engine hoods and trunk lids for cars Hot rolling of metals can produce: all answers are correct Round rivet heads can be formed by: Heading in the punch (none of the other answers make sense) (Midterm 3) A rectangular keyway in a round shaft can be produced by: ● None is correct (chegg) Minimum bend radius for AA 7075-O is: Likely to cause cracks Inside the bend (check?) I also saw 0 so not sure Large rings can be produced by cost-effectively by: ring rolling (Exam II) What is the difference between AA 6061-T4 and AA 6061-T6? Fine vs conventional blanking: T6 is naturally aged, T4 is furnace aged then work-hardened. fine blanking requires more precise, expensive tooling Midterm 2 doc says “none is correct” Tolerances will vary less during production due to : consistent raw material properties PM distinguishes from conventional metals because of: All are correct (I) Engine blocks for V-6 hybrid engines can be produced in large quantity by: Die-casting of steels with ceramic molds (II) Nesting in sheet metal manufacturing is: to reduce material usage, energy and tooling costs In sheet metal forming, springback can be controlled by: all are correct Climb milling is: preferred for slender parts due to the downward forces (lI) Thread for commercial grade steel bolts is the strongest when produced by: Friction welding: None is correct Engine blocks for 4-cylinder in-line hybrid engines can be produced in large quantity by: Superalloy and nickel-based alloys gas turbine blades are typically made by: die casting of steels with ceramic molds (chegg 2 upvotes) ● vacuum casting using ceramic molds (chegg) By agreement, sheet metals are defined as such: Connecting rods in internal combustion engines are: Quotation/bid in response to customer's RfQ should not include: all dimensions and tolerances Changes in bending angles after bending due to Springback are functions of: All of the above (master sheet pg 18) Rubber forming or hydroforming of sheet metals can be of cost advantage due to: Low tooling cost (I) -Exam 2 Guidelines for welding processes include: Heat up parts before welding to reduce distortions, and stress relieve thereafter if necessary Which of the following processes is not required to produce 3-piece welded steel cans: ironing in multiple operations Springback in sheet metal forming is a function of: All are correct chegg (II) Cam shafts in a 16-valve 4-cylinder engine can be turned on High speed CNC machining centers Thread for commercial grade steel bolts is the strongest when produced by Annealing is Engine hoods, fenders, boot lids, etc., of mid-size SUVs are usually: stretched formed and/or deep drawn In polymer processing: All are possible Router or traveler is IC chips on PCBs are: connected by soldering or surface-mounting technique In the production of 2-piece aluminum cans, the lid is connected to the can body by: Seaming and sealing Which is called the lost-wax casting: Pattern is melted out for recycling before pouring (retake doc; IIII) chegg approve also Mfg using centrifugal forces can: Cast hollow and solid objects Temperature built up during machining: Will shorten tool life Flanges in sheet metal can be produced: All but blanking Casting using a sand mold is: High temperature gas turbine blades can be produced by: Hardness increase during machining can: All are correct Which process is not required to produce 3-piece welded steel cans: Advantages of Nesting in sheet metal: Continuous casting of metals: ● Deep Drawing) (Midterm 2) All but assembling hollow objects (check?) ● None of the answers is correct(Midterm 2) Risers in casting help: Reduce porosity thus should not solidfy before the casting The threaded base (socket) of a light bulb can be produced cost-effectively by: None is correct Friction in manufacturing should be reduced or eliminated except: In rolling or friction welding (I) Extruded metal rods and profiles can be straightened by: Roll forging Flange in sheet metal can be produced: All are correct (Exam II) Quality products such as aluminum foils are best produced by: Continuous casting and rolling Fine blanking can produce shear cut without fracture surface (master sheet pg42) Draw beads used are used occasionally 2-piece aluminum beer and soda cans can be produced without: ● in deep drawing to control metal flow and flange forming welding F Cafeteria trays can be produced by: Travelers are: Risers help: Updated cost estimates after receiving P.O. ● None of the above (I) 2-piece aluminum beer and soda cans can be produced without: A chip breaker is: used if the cutter geometry does not warrant short chips (probably) A rectangular keyway in a round shaft can be produced by: none are correct... should be “end milling” A riser helps none of the following A round keyway in a round shaft can be produced by: sink EDM An estimate for job cost as per customer's RfQ should include: all answers except dimensions and tolerances An estimate for job cost as per customer's RfQ should include: All are correct An open riser helps: reduce porosity, thus should not solidify before the casting Angles such as chamfers can be measured by using: protractors Anisotropy in sheet metals: can cause dog-ears and non-uniform wall thickness in deep drawing (from Chegg but idk if true) Annealing is: residual stress OR thermal treatment (both are mentioned in book) BE CAREFUL ASTM grain size 7 Is: good enaugh for engine hoods and trunk lids for cars Break even point is: return of investment ? Brinell is: standard to determine the surface hardness of a metal By agreement, sheet metals are defined as such: When one dimension is less than 2.5 mm. And much smaller than the other two Cafeteria trays can be produced by: Cafeteria trays can be produced by: Transforming of reinforced plastic sheets Cam shafts in a 16-valve 4-cylinder engine can be turned on: high speed cnc machining center Casting can be used to: Manufacture high-volume production parts Casting using a sand mold is: none is correct Centrifugal forces can be used: cast hollow and solid objects (chegg) Changes in bending angles after bending due to Springback are functions of: all are correct (pg. 404) - cross referenced with chegg response climb milling is: preferred for slender parts due to the downward forces Cold forming of metals is done at: T/Tm just below 0.3 Connecting rods in internal combustion engines are: all are correct Consumable electrodes can be: used up during the brazing process (???) Continuous casting is none of the following Continuous casting of metals: none of the answers is correct Draw beads used are used occasionally: in deep drawing to control metal flow and flange forming During plastic deformation anisotropy in sheet metals can: can cause variations of properties in different directions EDM can produce very large parts with cycle time 60-90 pieces/min that are: none of the following or cheaper than the traditionally made parts (2 variations of same question) Engine blocks for 4-cylinder in-line hybrid engines can be produced in large quantity by: casting of steels or light alloys Engine blocks for V-6 hybrid engines can be produced in large quantity by: No answer is correct Engine hoods, fenders, boot lids, etc., of mid-size SUVs are usually: stretched formed and/or deep drawn Extruded metal rods and profiles can be straightened by: roll forging Fine blanking: is similar to counter blanking with even tighter clearance? (pg 386) Fine versus conventional blanking: fine blanking requires more precise, expensive tooling Flange in sheet metal can be produced by: all are correct Flanges in sheet metal can be: all but blanking For a good TIG/MIG weld joint, the workpieces should be: constrained to maintain shape and eliminate residual stresses Friction welding: (non is correct via chegg no likes) (nothing found in book so leads to none are correct) Grocery and trash bags are most cost effective when produced by: extrusion and blown-film? (pg. 500 diagram at bottom) Guidelines for welding processes include: Heat up parts Hardness increase during machining can: all are correct High temperature gas turbine blades can be produced by: Single crystal casting Hot rolling of metals can produce: all are correct (page 323) Hydro and rubber forming can: be cost effective for short-run, shallow sheet metal parts (from Chegg but idk if true) IC chips on PCBs are: connected by soldering or surface-mounting technique In polymer processing: all are possible In polymer processing: all are possible In rolling, spreading should be avoided by Reducing the reduction thickes (bite) In sheet metal fab, anisotropy can: cause variations of properties in different directions In sheet metal fabrication, minimum bending radius for AA 6061-0 is: 0 In sheet metal forming all are correct In sheet metal forming, springback can be controlled by: all are correct In the production of 2-piece aluminum cans, the lid is connected to the can body by: seaming and sealing Knurling performed on a round shaft: all are correct Large rings can be produced by cost-effectively by: Ring rolling (Page 329) Lost-foam casting is: expandable molds and patterns (page 270-272) Lost-foam casting is: using expandable molds and patterns Magnetic pulse forming: can form thin sheets without noise and heat Mfg using centrifugal forces can: cast hollow and solid objects Minimum bend radius for AA 6061-0 is: 0 Minimum bend radius for AA 7075-O is: 0 Minimum bending radius: depends on the hardness of the metal before bending Minimum bending radius: depends on the hardness and rolling direction of the metal before bending (2) (398-399) Nesting in sheet metal manufacturing is: to reduce material usage, energy and tooling costs New Questions start here Not a heat treatment process: furnace brazing PM distinguishes from conventional metal because of: all are correct Progressive dies are preferred over compound dies due to simpler design and lower maintenance costs Progressive dies are preferred over compound dies due to: simpler design and lower maintenance costs Properties of sheet metals affected by anisotropy: can cause dog-ears and non-uniform wall thickness in deep drawing (from Chegg but idk if true) s Properties of sheet metals affected by anisotropy: Quality products such as aluminum foils are best produced by: continuous casting and rolling - Chegg 5likes (page 1) Question Definite Answer Quotation/bid in response to customer's RfQ should not include: all dimensions and tolerances (common sense answer I think) Risers help: none is correct Risers in casting help: reduce porosity thus should not solidify before the casting ? (pg 243) Round rivet heads can be formed by: roll forging (page 335) Router or traveler is: oplimized operation sequences with set-up and run times Rubber forming or hydroforming of sheet metals can be of cost advantage due to: low tooling cost? (pg 1156) Sand casting of metals is: None of the answers are correct SPC can be used to: predict the completion time of a job order Spin casting uses inertia forces to produce ferrous and non-ferrous solid and hollow parts Springback in sheet metal forming can be controlled by: b and c Super plastic forming requires: slow forming process to ensure recrystallization Superalloy and nickel-based alloys gas turbine blades are typically made by: Advantages of Nesting in sheet metal: Superplastic materials 10000% something Temperature built up during machining shorten tool life The frame of an off-the-shelf beach cruiser bicycle is usually made from: drawn or extruded steel or aluminum.. The threaded base (socket) of a light bulb can be produced cost-effectively by: none The threaded base of a light bulb can be produced cost-effectively by: all answers are wrong To produce 2-piece aluminum beer and soda cans, which process is not required: welding Tolerances will vary less during production due to: consistent operation procedures among shifts and operators Travelers are: updated cost estimates after receiving p.o. Vickers (HV) is None is correct What is the difference between AA 6061-T4 and AA 6061-T6? T6 is naturally aged, T4 is furnace aged then work-hardened. Which are traditional joining processes? All but jet water (1) Which is investment casting: Wax Which of the following processes is not required to produce 3-piece welded steel cans: Deep drawing Which of the following processes is not required to produce 3-piece welded steel cans: ironing in multiple operations Which parts can be produced on a turret lathe with a single set-up: rotational-symmetric parts What is called lost-wax casting? Friction in manufacturing should be reduced or eliminated except: PM has advantages over conventional metals because of: AA 6061-T4 and AA 6061-T6 are: The letter T in AA 6061-T6511 means: subsequent treatment after fabrication by thermal and/or mechanical means (google answer) Springback in sheet metal forming is a function of: all is correct Chills End milling Vu Midterm 2 From hell PUT SUGGESTED ANSWERS TO QUESTIONS IN RED 1. Hardness increase during machining can Increase energy requirement during subsequent cutting; all are correct; increase tool wear; be useful against wear due to surface hardness; be reduced by slower feed rate smaller depth of cut 2. A rectangular keyway in a round shaft can be produced by: Answers : Magnetic pulse, water-jet milling, e-chem polishing, none, wire edm 3. EDM can produce very large parts with cycle time 60-90 pieces/min that are: None, Cheaper than the traditionally made parts, Made of engineering plastics, too expensive to sand cast, too cost-prohibitive for wire-edm (he went over this one in our section. The answer is Not feasible at all) 4. Sand casting of metals is None of the answers is correct, using non-reusable sand for permanent molds??? (not so sure), using a wax pattern for the core, appropriate for large and very high precision castings, using a wooden pattern without shrinkage factor 5. Which process is not required to produce 3-piece welded steel cans: Brazing, roll forming, deep drawing, blanking, automated inspection (He told us the answer for this is deep drawing) I have “roll forming” as the answer 6. Tolerances will vary less during production due to: Low skill level of the machinist; high flexibility of machine frame; low tool life; consistent raw material properties; none of the above 7. Friction in manufacturing should be reduced or eliminated except: Hot chamber die casting, in rolling and friction welding, in powder metallurgy, tube bending, shearing 8. Fine versus conventional blanking: fine blanking requires more precise, expensive tooling; none is correct; conventional blanking dictates the generation of 3D state of stress around the shear surface; counter blanking produces a smooth shear surface albeit burr; a nd c 9. High temperature gas turbine blades can be produced by: Single crystal casting 10. By agreement, sheet metals are defined as such: When one dimension is less than 2.5 mm, and much smaller the other two; thin plates are thicker than 2.5 in.; less than 5 in. thick plates; produced by continuous profile rolling; formed in compound dies ??? i think this one is 5 in I just saw that as well Im researching it …….. Hold please (there are 2 answers) i did see on wikipedia it said sheet metal is 6.0 mm (.25 in) and under while plate metal is > 6.0 mm (.25 in) I think it’s produced by continuous profile rolling 11. Minimum bend radius for AA 7075-O is: Likely to cause cracks (isn’t this one 0?)<--thats what i put 12. To produce 2-piece aluminum beer and soda cans, which process is not required: Annealing; ironing; welding; trimming and necking; deep drawing 13. Cam shafts in a 16 valv 4 cylinder engine High speed cnc machining centers 14. Progressive dies are preferred over compound dies due to Extremely high production rates; simpler design and lower maintenance costs; simplicity of the parts such as washers; higher speed of mechanical presses; complexity of injection molded parts 15. Large rings can be produced…. Ring rolling 16. An open riser helps reduce porosity, thus should not solidify before the casting, remove flow turbulence after the solidification phase, let trapped air escape from the mold after solidification, raise strength and porosity of the casting, a must if blind risers are used 17. Draw beads used are …. In spin casting of non-axis-symmetrical parts, deep drawing of aluminum cans, in deep drawing to control metal flow and flange forming, wire drawing, none of the above 18. An estimate for job cost as per customer’s RFQ should include: Set up and run times for each operation; material, tooling and any other engineering cost; overheads and target profits; sales and G&A; All are correct 19. In the production of 2-piece aluminum cans, the lid is connected to the body of the can by: Diffusion bonding, seaming, the cantilever, seaming and sealing, EB welding 20. Knurling performed on a round shaft: Must be called out before and after, by rolling not machining, in a lathe, using standard tools, all are correct 21. Which is investment casting: Die casting without a hot chamber, wax pattern is melted out for recycling before pouring, centrifugal casting, spin casting, continuous casting 22. Engine hoods, fenders, boot lids, etc, of mid-size SUVs are usually: Rolled stretch formed backward extruded, made from powders, stretched form and/or deep drawn, stamped then profile rolled, blanked and pierced and powder coated? 23. By agreement, sheet metals are defined as such: When one dimension is less than 2.5 mm & much smaller the other two, thin plates are thicker than 2.5 in, less than 5 in thick plates, produced by continuous profile rolling, formed in compound dies 24. In sheet metal fab, anisotropy can: Produce lueder’s band inside a forgings, cause dog ears in stretch forming of large parts such as door panels on airplanes, cause variations of properties in different directions, increase porosity in the sheet, have adverse effect during the recrystallization process 25. Rubber forming and hydroforming of sheet metals can be cost advantage due to:spin cas Intricate geometry of workpiece, Short production run of limited quantity, low tooling cost, high production rate, internal vs external setups 26. The frame of an off-the-shelf beach cruiser bicycle is usually made from Spun cast tubing, turned aluminum pipes on 5-axis lathes, Drawn steel or aluminum pipes, turned composite pipes on conventional lathes, all of the above 27. What is the difference between AA 6061-T4 and AA 6061-T6? both are stress relieved by thermal input [Question asks for difference, not what is the similarity. I put None of the above] I hate Vu | Same tbh 28. Springback in sheet metal forming is a function of: E-modulus, yield strength, sheet thickness, bending dies used, All are correct 29. Magnetic pulse forming: Can form thin sheets without noise and heat 30. Centrifugal forces can be utilized to: cast hollow and solid objects 31. Superplastic materials: Are specially designed composites, can have percent elongations up to 1000%, may contain nano-carbon fibers, are spin cast alloys, super thermoplastics 32. Spin casting uses inertia forces to produce: Ferrous and non-ferrous solid and hollow parts, engine blocks, ball bearing, sun sheet metal parts, axis-symmetrical sheet metal parts 33. Which of the following processes is not required to produce 3-piece welded steel cans Roll forming; blanking; seaming; ironing in multiple operations; automated inspection 34. Cold forming of metals is done at: T/Tm just below 0.3 35. Vickers (HV) is: Hardness is resistance to indentation; resistance to elastic deformation; same as Rpmedm 36. ockwell (HR); average surface roughness; none is correct 37. Which are traditional joining processes? Fastening, riveting, soldering, all but water jet, water jet polishing 38. PM distinguishes from conventional metals because of: Ability to blend incompatible elements or compounds, impregnation and infiltration, self-lubricating effect, thin and shallow psandarts only, all are correct 39. Flange in sheet metal can be produced: by piercing to form the flange, without drilling a pilot hole, all are correct, with an increase in yield strength due to cold working, to hold more thread with the same sheet thickness 40. Superalloy and nickel-based alloys gas turbine blades are typically made by: Turning, milling then drill; vacuum casting using ceramic molds; precision machining on CNC 3 axis machining centers; conventional die casting in cold chamber; forming in steel dies at room temperature. 41. Minimum bending radius: Depends on surface coating and resilience of the metal; is independent on the thickness of the sheet; is a non-issue if springback can be controlled; is independent of the temper of the heat treated blank and operator’s; depends on the hardness and rolling direction of the metal before bending 42. In rolling, spreading should be avoided by Reducing the reduction in thickness (bite); increasing friction alone; using unsupported skinny rolls; using unsupported skinny rolls; cluster rolls 43. Travelers are: updated cost estimates after receiving P.O, lists of work instructions such as how to set up a machine, compositions metal alloys, required to set up climb milling if conventional milling is not feasible, instructions how to go from drawing to a sand cast part think this is wrong ^, travelers dont explain how to go from drawing to a partI ^ same i put the cost estimate one why would you get a P.O. before giving cost estimate though? What it says after It should be list of work instructions (+1) I have no idea lets keep it not highlighted then Good idea Bruh Im pretty sure its the Updated cost one ( thats why i highlighted it) Thats what i put too but they said otherwise 44. Engine blocks for V-6 hybrid engines can be produces in large quantity by: No answer is correct; casting of carbon composites in a hot chamber; profile rolling using tungsten carbide dies; open die forging; die casting of steels with ceramic molds 45. Temperature built up during machining: Creates chattering and cold welding; has no effect on surface quality; is independent of cutter materials; will shorten tool life; is bad for global warming 46. Lost-foam casting is Less accurate than sand casting, capable of producing larger than 5-ton castings, an investment strategy for mid-sized accurate parts, using expandable molds and patterns, better in terms of dimensional accuracy and surface quality than die casting. 47. Nesting in sheet metal manufacturing is: To reduce material usage, energy and tooling costs; useful for bird watching; irrelevant if progressive dies are used; only advantageous for thick sheets; same as roll forming 48. In sheet metal fabrication, minimum bending radius for AA 6061-0 is: 0 49. Question Answer 50. Who hates Vu? Everyone (15 extra points) 51. Casting can be used to: Cut a workpiece in parts, solder two workpieces of incompatible material together, make a workpiece from incompatible powders, produce parts made of high-temperature ceramics, manufacturer high-volume production parts 52. Anisotropy in sheet metals: Answer : can cause dog-ears and non-uniform wall thickness in deep drawing??? I think this is it Final: this is gonna succk dick 53. Question Changes in bending anges after bending due to Springback are functions of E modulus, yield strength, sheet thickness, bending dies used, all of the above 54. The letter T in AA 6061-T6511 means: Supposed to be T6 or T651, not T6511; major alloying elements are magnesium and silicon; subsequent treatment after fabrication by thermal and/or mechanical means; annealed or recrustallized grain structures; strain-hardened crystal structures 55. Knurling performed on a round shaft: Answer : I think this one is all correct. 56. Fine blanking: Is similar to counter blanking with even tighter clearance; can produce shear cut without fracture surface; is conventional blanking in a triple-action press; can produce sheet metal blanks without any burr; is the same like punching or stamping 57. In rolling, spreading should be avoided by: Reducing the reduction in thicknes (bite); increasing friction alone; using unsupported skinny rolls; using preload big rolls; cluster rolls 58. Round rivet heads can be formed by: Cold extrusion, heading in the punch, cross rolling, roll forging, friction welding 59. The threaded base of a light bulb can be produced cost-effectively by: Answer 60. Lost-foam casting is: Answer 61. Quality products such as aluminum foils are best produced by Continuous casting and rolling 62. Flanges in sheet metal can be: All but blanking (i think) 63. Superplastic materials: Are specially designed composites, can have percent elongations up to 1000%, may contain nano-carbon fibers, are spin cast alloys, super thermoplastics 64. Cafeteria trays can be produced by None, Thermoforming of reinforced plastic sheets, compression molding, calendering, vacuum-bag forming 65. Extruded metal rods and profiles can be straightened by: Normalizing, stretching and twisting or in-line roller leveling, roll forging, roller leveling, none is correct 66. Advantages of Nesting in sheet metal Answer : minimize material waste, reduce energy requirement, lower tooling cost, assemble two hollow objects together, all but assemble hollow objects. 67. Grocery and trash bags are most cost effective when produced by: This one should be extrusion and blown-film 68. Climb milling is: Prefered for slender parts 69. 70. IC chips on PCBs are: MIG or TIG welded together; dip brazed together; bonded together by adhesive; furnace brazed together; connected by soldering or surface-mounting 71. Thread for commercial grade steel bolts is the strongest when produced by: Rolling then stress relieving, cold rolling between flat or rotary dies, cutting and then surface hardening, casting and normalizing, cold forging then annealing 72. Hot rolling of metals can produce: Railroad tracks; recrystallized grain structure; flats sheets and profiles from ingots; all of the above; none of the above 73. Hydro and rubber forming can Produce precision performed components, make 2-piece alu cans more competitive than plastic bottles, be cost effective for short-run shallow sheet metal parts(i think this is correct, see pg 420 in textbook), advantageous for rubber bellows, replace roto forming 74. Risers help: Answer : raise the height of a workpiece on a milling machine, none is correct, remove flow turbulence after the solidification phase, trapped air escape from the mold after solidification, raise strength and increase shrinkage of the sand casting. Im not entirely sure on this one 75. Consumable electrodes can be: Used up during the brazing process 76. For a good weld joint, the workpieces should be: Constrained to maintain shape and eliminate residual stresses, of compatible materials; and the filler rod too, constrained in a fixture to avoid residual stresses in workpieces and electrodes, moved around to cool them, free lattice defects 77. Friction welding: None is correct, utilizes electrical resistance to generate heat, is capable of joining metals and china, is brazing without melting, requires filler materials which are similar to both workpieces I’m pretty sure its none because ⅔ not possible and 4 it isn’t brazing and since its not brazing can’t be 5 since filler is for brazing 78. Break even point is: The number of parts made by two potential processes with the same unit cost, when a specimen is stretched beyond its elastic limit, return of investment, even fracture at UTS, none is correct ??? Properties of sheet metals influenced by anisotropy: Answer 79. Guidelines for welding processes include: Build up as much welds as feasible, then machine it flush; concentrate as many welds as possible in one area to reduce unwanted property changes; heat up parts before welding to reduce distortions, and stress relive thereafter if necessary; use TIG first before trying MIG; avoid welding whenever possible regardless of cost 80. Which parts can be produced on a turret lathe with a single set-up: 1) Connecting rods for 4-stroke diesel engines 2) 3-piece steel cans for tomatoes 3) gear housing 4) rotational-symmetic parts 5) Cam shaft Not 100% this is right 81. Mfg using centrifugal forces can produce: Answer 82. Not a heat treatment process: Answer : stress relieving, furnace brazing, quenching in oil, induction sintering, surface hardening 83. Connecting rods in internal combustion engines are: Designed to convert a linear motion into angular one; moving the vehicles backward in reverse gears; produced by casting or forging; not required in electrical cars; all are correct 84. Super plastic forming requires a. Specifically designed superplastic material, b. Isothermal forming c. Slow forming process d. Materials with up to 1000% elongation e. All of the above 84. Whichof the following is not a heat treatment process Furnace Brazing 85. Question Answer 86. Question Answer 87. Question Answer 88. Question Answer 89. Question Answer 90. Question Answer 91. Question Answer 92. Question Answer 93. Question Answer 94. Question Answer 95. Question Answer 96. Question Answer 97. Question Answer 98. Question Answer 99. Question Answer 100. Question Answer 101. Question Answer 102. Question Answer 103. Question Answer 104. Question Answer 105. Question Answer 106. Question Answer 107. Question Answer the threaded MAE 272 First Midterm Q’s and A’s 1. The threaded base of a light bulb can be produced cost-effectively by: A. Laser beam cutting B. Turning on CNC lathes C. Wire EDM D. All answers are wrong E. Sping casting 2. A round keyway in a round shaft can be produced by: a. E-chem polishing b. Water-jet milling c. Facing-off on a turret lathe d. Sink EDM e. Wire EDM 3. During plastic deformation anisotropy in sheet metals can: a. Can cause variations of properties in different directions b. Be more cost-effective if subsequent ironing is applied c. Have adverse effect during the recrystallization process d. Produce Lueders band inside a forging e. Increase porosity in the sheet 4. ASTM grain size 7 is: a. Determined by a certain number of dislocations per cubic mm b. Still considered coarse grains for all applications c. Acceptable if there is enough anisotropy present in the metal d. Associated with low strength, low hardness, and low ductility e. Good enough for engine hoods and trunk lids for cars 5. A chip breaker is: a. Used to deburr machined parts b. Used to bail the long chips for transport c. Very popular in wire-EDM d. Used if the cutter geometry does not warrant short chips e. Used to improve the surface quality of PM parts 6. Centrifugal forces can be utilized to: a. Roll steels and non-ferrous alloys b. Cast hollow and solid objects c. Injection mold of plastics d. Weld with consumable electrodes e. None of the above 7. Hot forming of metals is carried out: a. Using either conventional lathes of CNC mills b. Around the warm forging temperatures c. Around 2000 C d. At recrystallization temperatures e. Around 2200 F for most aluminum alloys 8. Annealing is: a. Restoration of TIG welded structure to its original shape b. Thermal treating a cold-worked metal to restore its properties and grain structures c. Stress relieving and/or normalizing of heavy castings d. Stress relieving to reduce/eliminate residual stressed e. Heat treating to martensite phase 9. Casting is used to: a. Make a workpiece from incompatible powders b. Solder two workpieces of incompatible materials together c. Produce parts madecontin of high-temperature ceramics d. Manufacture high-volume production parts e. Cut a workpiece in parts 10. Continuous casting is: a. None of the following b. 24-7 casting of ingots in three shifts without interruption c. Very cost-effective for large production of steel ingots with more consistent properties d. Casting and forming ingots in one process without cooling down to room temperature e. Required very extensive capital investment which rarely makes economic sense 11. Which is called the lost-wax casting: a. Spin casting b. Centrifugal casting c. Continuous casting d. Pattern is melted out for recycling before pouring e. Die casting without a hot chamber 12. Brinell is: a. Resistance to elastic deformation b. Casting method c. Average surface roughness d. Braille system e. Standard to determine the surface darkness of a metal (surface hardness?) 13. Minimum bend radius for AA 6061-O is: a. Independent of thickness b. Same for AISI 1008 of equivalent hardness c. 0 d. Independent of rolling direction e. Likely to cause cracks inside the bend 14. Router or traveler is: a. Document which lists the sequence of operations b. A road map to becoming a world-class manufacturing operation c. Driving direction from A to B d. CNC tool paths e. Optimized operation sequences with set-up and run times 15. Which of the following processes is not required to produce 3-piece welded steel cans: a. Roll forming b. Deep drawing c. Automated inspection d. Brazing e. Blanking 16. An estimate for job cost as per customer’s RFQ should include: a. All answers except dimensions and tolerances b. Overheads and target profits c. Material, tooling and any other engineering costs d. All dimensions and tolerances e. Set up and run times for each operation 17. Springback in sheet metal forming can be controlled by: a. Changing the elastic modulus without changing material b. Method of bending c. Overbending to compensate for elastic recovery d. B and c e. All of these answers 18. Engine blocks for 4-cylinder in-line hybrid engines can be produced in large quantity by: a. Casting of steels or light alloys b. Open die forging c. Profile rolling using tungsten carbide dies d. Casting of carbon composites in a hot chamber e. Dies casting steels with ceramics molds