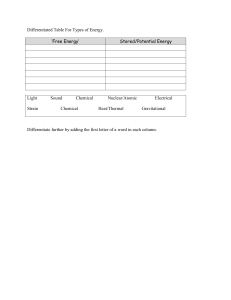

Structure and

Properties of

Materials

1

No

Course Content

Tutorial (Assignment)

Lab

Lab 1 (Material

classification)

1

Ah

Classification of materials.

-------

2

Ad

Atomic bonding.

Ass 1 (Atomic bonding) -------

3

Ad

Crystallinity of materials.

4

Ad

Crystallography

5

Ah

Imperfections and Diffusion

6

Ah

Solidification and Structure I

7

Ah

Solidification and Structure II

Mid Term

Ass 2 (Unit cell and

------theoretical density)

Ass 3 (Directions,

Planes, Linear & planar ------density)

Lab 2 (Sample

---preparation)

Ass 4 (Grain size

---measurement)

Lab 3 (Cooling

------curves)

-------------

Phase diagram I

Ass 5 (Phase diagram)

-------

10

R

R

Phase diagram II

Ass 6 (Phase diagram)

-------

11

R

Metals designation

Ass 7 (Designation)

Lab 4 (Polymer

identification)

12

Ah

Polymers

13

Ah

Ceramics

14

Ah

Mechanical Testing

15

Ah

Case study and Review

8

9

Ass 8 (Polymers Dp and

crystallinity)

As 9 (Ceramic

------structure)

Ass 10 (Mechanical

--properties)

Project

---

Quiz/ Report/ Project

Quiz 1

Report on Labs 1 & 2

Quiz 2

Report on labs 3& 4

Quiz 3

Oral and Project

discussion

2

Grading

Student Activities

25%

Practical (Oral +

Mid-Term Exam + notes+Project)

Exam

25%

10%

Final Exam

40%

Assignments 10%

Lab Report 8%

Participation 7%

References

W.D. Callister “Materials Science and Eng.- an Introduction” , 7th

edition, Wiley.

عالم الكتب، المیتالورجیا الفیزیائیة،• أحمد سالم الصباغ

3

History

https://www.scimap.tech/blog-1/materials-age

4

Materials Science vs Material

Engineering

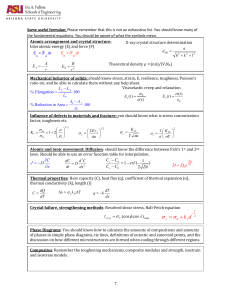

• Materials science investigates the relationships that exist between the

structures and properties of materials.

• Materials engineering is, on the basis of these structure–property

correlations, designs or engineers the structure of a material to produce a

predetermined set of properties.

• From a functional perspective, the role of a materials scientist is to develop

or synthesize new materials, whereas a materials engineer is called upon to

create new products or systems using existing materials, and/or to develop

techniques for processing materials.

5

Case : Design/materials selection for a coffee cup

Design specifications for coffee cup:

▪ Avoid burning the user’s hands

▪ Might be re-used

▪ Less danger to environment

Materials properties for coffee cup:

▪ Excellent thermal insulation Reusable

▪ Recyclable

Candidate Materials:

Ceramics & Polymers

Both appropriate due to their low thermal conductivity

However:

▪ Polymers cup (polyethylene) should not be re-used (become poisonous)

▪ Disposing polymers cause environmental damage → unrecyclable

▪ Ceramics can be reused and less danger to environment.

Proposed Material: Ceramics

6

Global relation Property-StructureProcessing-Performance

Structure: Something made up of a number of parts that are held

or put together in a particular way,

A property is a material response to a specific imposed

stimulus. Generally, definitions of properties are made

independent of material shape and size.

Important properties of solid materials may be grouped

into six different categories: mechanical, electrical,

thermal, magnetic, optical, and deteriorative.

Stimulus

Response

Load

Mech Prop (Strength)

Electric field

Elec Prop (elec conductivity)

--------

---- prop (------------)

7

Global relation Property-StructureProcessing-Performance

4-Perfermoance of

3 samples of

Aluminum oxide:

3-Property

Transparent*

Translucent

Opaque

2-Structure

a single crystal

Very small single crystals

connected together. The

boundaries scatter a portion

of the light reflected from the

printed page

Many small, interconnected

crystals, but also of a large

number of very small pores.

These pores scatter the

reflected light and render this

material opaque

1-Processing: These differences in optical properties are a consequence of

differences in structure from the way the materials were processed

8

1-Processing

Chemical

Composition

(Alloying)

2-Structure

Thermal

Heat Treatment

Mechanical

Manufacturing

Processes

9

Is the structure an unchangeable feature?

EXAMPLE: FORGING STRUCTURE

Before forging

tougher

An ingot heated to high

temperature is beaten

After forging

Crystal grains of the

metal are large and

non-uniform

Crystal grains of the metal

are small and uniform

1-Processing

2-Structure

10

Structure

Classification

Macrostructure

Microstructure

affects the

chemical,

physical, thermal,

electrical,

magnetic, and

optical properties

Nanostructure

Short- and large range

atomic arrangement

Atomic

structure

μm = 10-6 m

nm = 10-9 m

Å = 10-10 m

have a larger effect on

mechanical properties and on

the rate of chemical reaction

▪

▪

▪

▪

▪

~ > 100 μm

10 – 1000 nm

1 – 100 nm

1-10 Å

Up to 1 Å

11

Long range Vs. Short range

• Atomic positions in a crystal

exhibit a property called longrange order or translational

periodicity; positions repeat in

space in a regular array over a

long distance

• Short range order refers to the

regular

and

predictable

arrangement of atoms over a

short distance, usually with one

or

two

atom

spacing’s.

However, this regularity does

not persist over a long distance.

12

Classification of structure

Structure

Crystalline

Amorphous

13

The fundamental difference between single crystal ,

polycrystalline and amorphous solids is the length scale

over which the atoms are related to one another by

translational symmetry ('periodicity' or 'long-range

order')

Single crystals have infinite periodicity, polycrystals

have local periodicity, and amorphous solids (and

liquids) have no long-range order

14

What is a Property?

Stimulus

Response

• Property gives the same measurement regardless of the size.

• Density is a property, but mass is not

Physical

•

•

•

•

•

Color,

texture,

shape,

smell,

state of matter

(solid, liquid, and

gas),

• sound,

• taste

Chemical

• pH

• Surface energy

• Surface tension

• Specific internal

surface area

• Reactivity

• Corrosion resistance

15

Electrical

Magnetic

Optical

Thermal

• Electrical

• Permeability

• Absorptivity

•Thermal conductivity

conductivity

• Hysteresis

• Reflectivity

• Thermal diffusivity

• Permittivity

• Curie Point

• Refractive index

• Thermal expansion

• Dielectric

• Photosensitivity

• Emissivity

constant

• Transmittance

• Coefficient of thermal

• Dielectric

• Luminosity

expansion

strength

• Scattering

• Specific heat

• Piezoelectric

•Glass transition temperature

constant

• Melting point

16

Mechanical

• Tensile strength

• Ductility

• Elastic modulus

• Fatigue limit

• Hardness

• Poisson’s ratio

• Shear modulus

• Yield strength

• Fracture toughness

17

17

Materials

Engineering

Those used in

manufacture and

become parts or

products

NonEngineering

The chemicals, fuels,

lubricants, and other

materials used in the

manufacturing process

which do not become

part of the product

18

Engineering

Materials

Metals & alloys

Polymers

Ceramics

Composites

An alloy is a homogeneous

mixture of two or more

elements, at least one of

which is a metal, and where

the resulting material has

metallic properties

19

General Properties of …

Metals

• Polymers

•Metallic luster;

•Opaque;

•Corrosive;

•Relatively dense;

•Strong

(relatively

high strength);

•Deformable;

•Extremely

good

conductors

of

electricity and heat.

• Low density,

• Hard but brittle; bad

• Low melting point;

deformable

• Bad conductor to • High resistance to

heat and electricity;

high temp and harsh

• Easily affected by

environments;

environmental

• Good insulator to

factors;

heat and electricity;

• Highly Deformable.

• Chemically stable;

• May be transparent,

translucent,

or

opaque.

Ceramics

20

Composites vs. Alloys

Composites are

mixture in

macroscopic level

Alloys are mixture

in microscopic

level

2/12/2020

21

In your Text book, study:

Chapter 1. Introduction

Lab: Materials identification

visual observation of their finishes, touches, colors,

texture, luster, and fracture appearance.

22