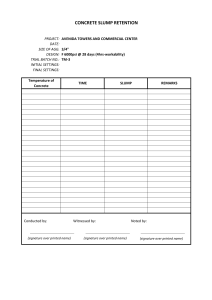

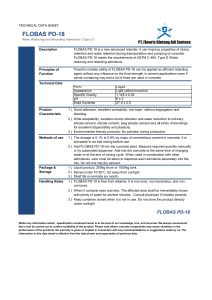

Civil Engineering Survey CE-381 Concrete Mixing Lab Lab Group 14 I pledge my honor that I have abided by the Stevens Honor System. Connor Brenna, Nicholas Rose, Vincent Principe, Amedeo Bove, Ian Staniec, and Brian Williams Objective: Preliminary calculations were performed to determine the ratio of water, cement, coarse aggregates, and fine aggregates necessitated by the concrete mixture design delegated to Group 1. Following the mixing process, each group performed a slump test to confirm that the mixture composition contained the correct amount of water. GROUP STRENGTH 14 4000 AIR ENTRAINED No SLUMP 3 Table 1: Strength Requirements Materials List: 1. Concrete Mix a. Portland cement b. Sand c. Crushed gravel d. Water 2. Four 5-Gallon Buckets to Weigh Solids and Water 3. One Field Scale 4. One Slump-Test Cone 5. One Board 6. Two Mixing Hoes 7. One Mixing Trough 8. Two 4 X 8 Cylinders for Casting 9. One Towel for Cleaning 10. One Metal Scoop 11. One Steel Trowel for Concrete Finish 12. One 1.25 lb Rubber Mallet for Tapping Concrete Cylinder 13. One 12-in Ruler to Measure Slump 14. One Large Rod to Consolidate Concrete During Slump Test 15. One Small Rod to Consolidate Concrete During Cylinder Casting 16. One Brush/Sponge for Cleanup General Methodology: Mix Design Development The objective of this group was to design a concrete mix with a strength of 3000 psi. The design should be suitable for reinforced foundation walls and footings as well as other substructures and accordingly have no more than a 3-inch slump (see Appendix A, Table 6.3.1). The mix is non-air entrained and complies with the material properties below. Table 2: Material Properties The team utilised Appendix A, Table 6.3.3 to select the appropriate mixing water quantity for ½” coarse aggregate. Subsequently, the team used Table 6.3.4(a) to determine the water-cement ratio and cement component weight. The team then used Table 6.3.6 to determine the volume of coarse aggregate needed. Mix Design Calculations Table 3 below displays the group’s computations for concrete mix with a strength of 4000 psi. Step 1 Step 2 Step 3 Step 4 Step 5 Strength = 4000.00 psi Slump = 3.00 in Max Aggregate Size = 0.75 in Water Content, Table 6.3.3 = 340.00 lb/cy Air Content, Table 6.3.3 = 2.00% lb/cy Water/Cement Ratio, 3000 psi Weight of Cement = = 0.57 596 lb/cy Step 6 Volume of Coarse Aggregate/Volume of Concrete = 0.57 cy Unit Weight, Water = 62.40 lb/cf Cubic Feet/Cubic Yard = 27.00 cf/cy Dry Weight, Coarse Aggregate = 1646 lb/cy Absolute Volume, Coarse Aggregate = 10.07 cf/cy Absolute Volume, Water = 5.45 cf/cy Absolute Volume, Entrapped Air = 0.54 cf/cy Absolute Volume, Cement Step 7 = 19.09 cf/cy Absolute Volume, Fine Aggregate = 7.91 cf/cy Dry Weight, Fine Aggregate = 1283.17 lb/cy Step 8 Coarse Aggregate, Wwet = 15.41 lbs Fine Aggregate, Wwet = 12.04 lbs Surface Water Contributed by Coarse Aggregate = 0.10% Surface Water Contributed by Fine Aggregate = 0.20% Estimated Requirement for Added Water = 335.79 lb/cy Table 3: Mix Design Calculations Tables 4 and 5 below display the calculation results per cubic yard and per 0.25 cubic feet, respectively. Mix Design, per Cubic Yard Water = 335.79 lbs/cy Cement = 596.5 lbs/cy Coarse Aggregate, Wet = 1664.03 lbs/cy Fine Aggregate, Wet = 1299.85 lbs/cy Total Weight = 3896.16 lbs/cy Table 4: Final Composition - per Cubic Yard Mix Design, per 0.25 Cubic Feet Water = 3.11 lbs/cf Cement = 5.5 lbs/cf Coarse Aggregate, Wet = 15.41 lbs/cf Fine Aggregate, Wet = 12.04 lbs/cf Total Weight = 36.08 lbs/cf Table 5: Final Composition - per 0.25 Cubic Feet Slump Test Procedures: The following steps were taken in order to conduct a slump test on the concrete mixture: 1. The cone was dampened and placed on a smooth, level surface 2. The concrete mixture was then poured into approximately ⅓ of the cone by volume. 3. The first layer was evenly tamped 25 times with a 5.8” X 24” tamping rod 4. The concrete mixture was then poured into approximately ⅔ of the cone by volume, and was tamped 25 times, as in Step 3. The tamping rod was not penetrated to the first layer of concrete mixture below within the cone. 5. The concrete mixture was then poured to the top of the cone and tamped again 25 times, avoiding penetrating the second layer. 6. Excess concrete from the top of the cone was removed, 7. The cone was lifted vertically and evenly to release the slump 8. The cone was then inverted and placed alongside the slump 9. The tamping rod was placed across the top of the slump cone and over the slump 10. Finally, the slump from the bottom of the rod to the top of the slumped concrete at the point of the original center of the base was measured Slump Results: First Test: Slump was 2.4 inches (too dry) Second Test: More water was added. Mix was remixed, yielding a slump of 3.1 inches Discussion of Results: The team conducted two slump tests, with the first test acting as more of a trial run. The only main difficulty stemmed from the team forgetting to record initial weights, however, this issue was fixed. The team had all of the different components in separate buckets, so the team simply recorded the weight of the buckets with the components, then the weight of the bucket itself. By subtracting the bucket from the bucket and component weight, the team was able to get the weight of the components, so this issue was solved with relative ease. The measured weights of each component are shown below. 5.52 lbs cement 15.44 lbs coarse aggregate, wet 12.10 lbs fine aggregate These values were all slightly higher than the design values that were calculated, but due to the shear number of lab groups needing to access the scales, the team decided that the higher values would be fine. The first slump test yielded a slump value of 2.4 inches. This mixture was too dry, which can be attributed to the both the higher amounts of mix components and simply not having enough water. The team added around 3.05 pounds of water, which was simply not enough. The team added another 0.2 pounds of water prior to the second slump test, which yielded much better results. The team achieved a slump value of 3.1 inches. Conclusions: From this lab, the team learned that it is incredibly important to be precise when both recording measurements and weighing out materials. The importance of both measurement taking and weighing materials was apparent from the slump test, as the team had to repeat the entire process due to having too much dry material and not enough water. In the future, the team will take their time when weighing out their materials, as it is more important to create a proper mixture while taking their time, instead of making a bad mixture while working incredibly fast. Luckily, adding the 0.20 pounds of water was sufficient, however, this may not be the case for future batches of concrete, so it is important that the team takes their time and records proper measurements. Appendices: Figure 1: initial mixture Figure 2: first mix with incorrect water content is liquified Figure 3: Slump test 1 with added cement Figure 4: Slump test 1 fails Figure 5: Slump test 2 fails after additional aggregate was added Table 1: Approximate water and air content requirements for different slumps and nominal Table 2: Relationships between water-cement or water-cementitious materials ratio and compressive strength of concrete Table 3: Volume of coarse aggregate per unit volume of concrete References: ● Appendix A - Lab manual for concrete mixing and fresh property testing