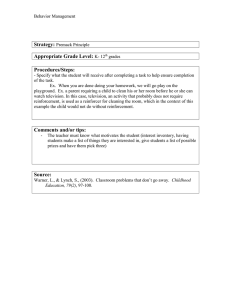

Engineering Encyclopedia Saudi Aramco DeskTop Standards Branch Connection Reinforcement Note: The source of the technical material in this volume is the Professional Engineering Development Program (PEDP) of Engineering Services. Warning: The material contained in this document was developed for Saudi Aramco and is intended for the exclusive use of Saudi Aramco’s employees. Any material contained in this document which is not already in the public domain may not be copied, reproduced, sold, given, or disclosed to third parties, or otherwise used in whole, or in part, without the written permission of the Vice President, Engineering Services, Saudi Aramco. Chapter : Piping & Valves File Reference: MEX10105 For additional information on this subject, contact K.S. Chu on 873-2648 or R. Hingoraney on 873-2649 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement CONTENTS PAGE IDENTIFYING REQUIREMENTS FOR BRANCH REINFORCEMENT ........................... 1 ASME/ANSI Code B31 ............................................................................................ 1 Area Removed By Branch Connection....................................................................... 2 Limits of Reinforcement Zone for Each ASME/ANSI Code....................................... 5 ASME/ANSI B31.3 - Process Plants ......................................................................... 5 ASME/ANSI B31.4 - Liquid Transportation Pipelines ............................................... 5 ASME/ANSI B31.8 - Gas Transmission Pipelines...................................................... 6 Identification of Areas Contributing to Reinforcement ............................................... 6 SAES-L-004 ............................................................................................................. 7 CALCULATING REQUIRED AND AVAILABLE REINFORCEMENT AREAS............... 9 Required Reinforcement Area.................................................................................... 9 ASME/ANSI B31.3 .................................................................................................. 9 ASME/ANSI B31.4 .................................................................................................10 ASME/ANSI B31.8 .................................................................................................10 Available Reinforcement Area ..................................................................................11 ASME/ANSI B31.3 .................................................................................................11 ASME/ANSI B31.4 .................................................................................................11 ASME/ANSI B31.8 .................................................................................................12 Considerations..........................................................................................................12 Determining If Reinforcement Is Needed ..................................................................13 Reinforcement Options.............................................................................................13 Determining the Need for a Full-Encirclement Reinforcement Pad ............................14 Requirements for Full-Encirclement Reinforcement ..................................................16 DESIGNING REQUIRED REINFORCEMENT PADS ......................................................17 Materials Selection ...................................................................................................17 Pad Diameter and Wall Thickness.............................................................................18 Additional Topics Not Discussed..............................................................................19 Sample Problem 1 ....................................................................................................20 Solution ...................................................................................................................21 Saudi Aramco DeskTop Standards Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement WORK AID 1: STEPS FOR CALCULATING REQUIRED AND AVAILABLE REINFORCEMENT AREAS......................................................................26 GLOSSARY........................................................................................................................29 Saudi Aramco DeskTop Standards Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement IDENTIFYING REQUIREMENTS FOR BRANCH REINFORCEMENT This section discusses the requirements for reinforcement of branch connections that are contained in: • ASME/ANSI B31. • SAES-L-004. ASME/ANSI Code B31 A pipe with a branch connection is weakened by the opening required for the branch connection. Unless the wall thickness of the pipe is sufficiently greater than that required to sustain the pressure, additional reinforcement must be provided. Reinforcement requirements are determined by calculating: • The cross-sectional area of the cut-out from the pipe due to the branch connection. • The required pressure design thickness of the pipes at the branch connection. • The sum of the cross-sectional areas in the pipe walls and additional reinforcing elements that are available for reinforcement. This section discusses the differences among the three ASME/ANSI B31 Codes with respect to branch reinforcement calculations. Each of the three ASME/ANSI B31 Codes has specific design requirements that cover the reinforcement of branch connections. Identifying and referencing the applicable code is the first step in each branch reinforcement calculation. MEX 101.01 discussed the scope of these codes and how to determine the governing code for a particular piping system. Each of the ASME/ANSI B31 Codes contains specific design rules for determining the required branch reinforcement. These reinforcement rules apply for both welded and extruded outlet-type branch connections. Branch connections can also be made using forged or wrought fittings (i.e., tees, laterals, crosses, a coupling, or a half-coupling), or an integrally reinforced branch connection (i.e., a weldolet or sweepolet). No reinforcement calculations are required for these forged or wrought types of branch connections, because inherently, they have adequate reinforcement and have been designed and tested to meet ASME/ANSI requirements. Forged and wrought fitting types were discussed in MEX 101.04. This module will discuss only branch connections that are fabricated by welding a branch pipe to the run pipe or header. Saudi Aramco DeskTop Standards 1 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement Area Removed By Branch Connection A volume of metal is removed from a pipe wall when a hole is cut in it for a branch connection. However, a simplification is made when evaluating branch reinforcement requirements. An imaginary plane is passed through the branch and run pipes, and the intersection is viewed in cross-section. The removed volume of pipe wall is then looked at as an area. Figure 1 is taken from ASME/ANSI B31.3 and shows this cross-sectional view, along with the nomenclature applicable to the ASME/ANSI B31.3 rules. Figures 2 and 3 are similar figures that provide the nomenclature for ASME/ANSI B31.4 and B31.8, respectively. ASME/ANSI B31.3 WELDED BRANCH CONNECTION NOMENCLATURE Source: ASME/ANSI B31.3 - 1988. With permission from the American Society of Mechanical Engineers. FIGURE 1 Saudi Aramco DeskTop Standards 2 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement ASME/ANSI B31.4 WELDED BRANCH CONNECTION NOMENCLATURE "Area of Reinforcement" Enclosed by _____ __ __ ______ Lines Reinforcement Area Required AR = dth Area Available As Reinforcement = A1 + A2 + A3 A1 = (Th - th)d A2 = 2 (Tb - tb)L A3 = Summation of Area of All Added Reinforcement, Including Weld Areas That Lie Within the "Area of Reinforcement" A1 + A2 + A3 Must be Equal to or Greater Than AR where: Th Tb tb th d = = = = = M = Source: Nominal Wall Thickness of Header Nominal Wall Thickness of Branch Design Branch Wall Thickness Required by Paragraph 404.1.2 Design Header Wall Thickness Required by Paragraph 404.1.2 Length of the Finished Opening in the Header Wall (Measured Parallel to the Axis of the Header) Actual (By Measurement) or Nominal Thickness of Added Reinforcement ASME/ANSI B31.4 - 1989. With permission from the American Society of Mechanical Engineers. FIGURE 2 Saudi Aramco DeskTop Standards 3 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement ASME/ANSI B31.8 WELDED BRANCH CONNECTION NOMENCLATURE "Area of Reinforcement" Enclosed by _____ __ __ ______ Lines Reinforcement Area Required AR = dt Area Available As Reinforcement = A1 + A2 + A3 A1 = (H - t) (d) (If Negative, Use Zero for Value of A1) A2 = 2 (B - tb)L A3 = Summation of Area of All Added Reinforcement, Including Weld Areas That Lie Within the "Area of Reinforcement" A1 + A2 + A3 Must be Equal to or Greater Than AR where: H = B = tb = t = d = M = Source: Nominal Wall Thickness of Header Nominal Wall Thickness of Branch Required Nominal Wall Thickness of the Branch (under the Appropriate Section of the Code) Required Nominal Wall Thickness of the Header (under the Appropriate Section of the Code) Inside Diameter of the Branch Connection Actual (By Measurement) or Nominal Thickness of Added Reinforcement ASME/ANSI B31.8 - 1989. With permission from the American Society of Mechanical Engineers. FIGURE 3 Saudi Aramco DeskTop Standards 4 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement Limits of Reinforcement Zone for Each ASME/ANSI Code The branch connection must have adequate reinforcement to compensate for the weakening caused by cutting a hole in the run pipe. This reinforcement must be located reasonably close to the opening to provide any practical benefit. The reinforcement may be located in the branch pipe, the run pipe, or both. Each of the three piping codes defines a "reinforcing zone." The reinforcing zone is the region where credit may be taken for any reinforcement that is present. Additional material located outside of this zone is not considered to be effective for reinforcement. ASME/ANSI B31.3 - Process Plants Refer to Figure 1 for ASME/ANSI B31.3 piping systems. A distance d2 is indicated starting at the branch connection centerline, and extending on both sides of it along the length of the header pipe. This defines the length of the reinforcement zone along the header pipe. A distance L4 is measured along the length of the branch pipe from the outside surface of the header pipe. This defines the length of the reinforcement zone along the branch pipe. Additional material located outside of these zones is not considered to be effective for reinforcement. Numerical values for these distances are calculated using equations that are contained in Work Aid 1. ASME/ANSI B31.4 - Liquid Transportation Pipelines The reinforcement zone limits for ASME/ANSI B31.4 are calculated in a similar manner as for ASME/ANSI B31.3, with the following primary differences: • The mill tolerances of the branch and header pipes are not accounted for. • Corrosion allowance is not considered. • The nomenclature differs. Referring to Figure 2: where: d = The length of the finished opening in the header wall, measured parallel to the header axis. M = The actual (by measurement) or nominal thickness of any added reinforcement. Saudi Aramco DeskTop Standards 5 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement ASME/ANSI B31.8 - Gas Transmission Pipelines The reinforcement zone limits for ASME/ANSI B31.8 are calculated using the same basis as used for ASME/ANSI B31.4, only the nomenclature differs slightly. Referring to Figure 3: where: d = Inside diameter of the branch connection. H = Nominal wall thickness of header. B = Nominal wall thickness of branch. Identification of Areas Contributing to Reinforcement The previous section identified how the reinforcement zone is determined in each of the ASME/ANSI B31 Codes. Branch connection reinforcement located within this reinforcement zone may come from one or more of the following sources. • Excess thickness available in the branch or header pipe. • Additional reinforcement added in the form of a pad, ring, saddle or weld metal. MEX 101.03 discussed how to calculate the pipewall thickness required to resist design pressure. The final pipewall thickness is determined considering this minimum required pressure design thickness, corrosion allowance and mill tolerance. Then, a readily available standard pipe, of at least this thickness, is used. In almost every case, the actual pipewall thickness used for the header and branch pipes will exceed that required for pressure, corrosion allowance, and mill tolerance. Any excess thickness that is located within the reinforcement zone may contribute to branch reinforcement. Additional metal may also be added at the branch connection to provide reinforcement. This is done when the excess thicknesses in the branch and header pipes do not provide enough reinforcement. Credit may be taken for any added metal that is located within the reinforcement zone. The area of weld metal that attaches the branch to the header pipe, and attaches the added reinforcement, also contributes to the reinforcement area. However, the contribution of weld metal area to overall branch reinforcement is small and can normally be disregarded to simplify the calculations without incurring a major debit. Figures 1, 2, and 3 identify the components that make up the total possible reinforcement at a branch connection for each of the ASME/ANSI B31 Codes. The procedures for calculating the required and available reinforcement areas will be discussed in a later section. Saudi Aramco DeskTop Standards 6 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement SAES-L-004 As previously discussed, there are several options for providing the necessary reinforcement at branch connections. These options include butt-welded fittings, forged couplings or halfcouplings, integrally reinforced branch connections, and fabricated branch connections with or without a reinforcing pad. Saudi Aramco Engineering Standard SAES-L-004, Pressure Design of Piping Components, provides Saudi Aramco requirements with respect to branch connections. These are summarized as follows: • Butt-welded or integrally reinforced fittings are preferred over fabricated branch connections in which the branch pipe is welded directly to the run pipe (with or without added reinforcement). The rationale for this preference is that such fittings are more widely applicable with respect to pressures and temperatures, and fewer detailed design considerations and calculations are necessary. • Fabricated branch connections in all hazardous services shall be designed to match the strength of the run pipe, branch pipe, flange rating, or two times the system design pressure, whichever is lower. However, they must be designed for at least 1,030 kPa (150 psi) internal pressure. This approach ensures that there is a basic minimum strength in a welded branch connection, and that it is not the design-limiting component in a piping system. • In all hydrocarbon services, branches of 38 mm (1-1/2 in.) nominal size and smaller, on pipe runs of 75 mm (3 in.) or larger nominal size are to have a valve located as close as possible to the run pipe. In no case is the valve to be farther than three times the branch pipe diameter away from the run pipe (measured from the run pipe outside diameter to the center of the valve). This is to ensure that potential leakage in the small-diameter branch pipe can be easily blocked off from the run pipe. This will also minimize the potential for failure at the branch-to-run pipe weld. Such failure could be caused by the valve weight being applied over an excessive cantilever beam length of pipe. Pipe unions may not be installed between the run pipe and valve. • Special attention is required for branches of 38 mm (1-1/2 in.) nominal size and smaller in vibration-prone services, such as those near control valves, pressure relief valves, pumps and compressors, and in high velocity gas streams. The concern is that the vibration could cause a failure at the branch-to-run connection weld if the distance from the run pipe to the block valve is too great, and/or if this connection is not adequately braced. Saudi Aramco DeskTop Standards 7 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement If the vibration is not severe, the connection may be made by using a short piece of pipe or an extended body-type valve. Where potentially severe vibration can occur, the branch connection must be braced. Saudi Aramco Drawing No. AB-036521, Sheet No. 1, provides details for this type of connection. Note that if bracing cannot be effectively provided on piping 50 mm (2 in.) nominal size and smaller, a Schedule 160 nipple plus a reinforcing pad shall be used. • Saudi Aramco Drawing AB-036719, Sheet No. 1, provides a general summary of Saudi Aramco branch reinforcement requirements and preferences. This drawing does not include butt-welded fittings, which are also a preferred approach, as previously stated. Saudi Aramco DeskTop Standards 8 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement CALCULATING REQUIRED AND AVAILABLE REINFORCEMENT AREAS Thus far, the concepts of the area removed at a branch connection, the reinforcement zone, and the components that may contribute to branch connection reinforcement were discussed. The next step is to determine the required and available reinforcement areas. • The required reinforcement area is based on the metal area removed from the header pipe that would have been required to resist the design pressure. • The available reinforcement area must be sufficient to replace the metal area removed and must be located within the reinforcement zone. • If the header and branch pipes do not have enough excess thickness to provide the reinforcement, then additional reinforcement must be added. All the ASME/ANSI B31 Codes follow this basic approach, but there are variations which will be discussed. Required Reinforcement Area In each of the ASME/ANSI B31 Codes, the required reinforcement area is based on the metal area removed, considering the required pressure design thickness. Work Aid 1 outlines the steps for calculating required reinforcement area. ASME/ANSI B31.3 In ASME/ANSI B31.3, the required reinforcement area for internal pressure, A1, is calculated using an equation that is contained in Work Aid 1. The required pressure design thickness of the header pipe (th) is used in this calculation. However, if welded pipe is used, the weld-joint efficiency does not need to be used to calculate th for branch reinforcement calculations only. If the branch intersects a longitudinal header weld, then the weld-joint efficiency must be considered. If the branch connection is under external pressure, area A1 is one-half the area that would be required for internal pressure. Saudi Aramco DeskTop Standards 9 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement ASME/ANSI B31.4 In ASME/ANSI B31.4, the required reinforcement area, AR, is calculated as follows: AR = dth where: d = Length of the finished opening in the header wall measured parallel to the header axis. th = The required pressure design thickness of the header pipe. Considerations for welded pipe regarding joint efficiency are the same as in ASME/ANSI B31.3. ASME/ANSI B31.8 In ASME/ANSI B31.8, the required reinforcement area, AR, is calculated as follows: AR = dt where: d = As defined in ASME/ANSI B31.4. t = Nominal header wall thickness required for internal pressure. The equation used for calculating "t" considers weld-joint efficiency, the location of the pipeline, and pipeline design temperature. No mention is made of not considering weldjoint efficiency if the branch does not pass through a weld. If a corrosion or erosion allowance is included in the nominal pipe wall thickness, all dimensions that are used in the calculations must assume that this allowance has been used. The required reinforcement area is calculated in a similar manner for the three ASME/ANSI B31 Codes. ASME/ANSI B31.3 is more conservative in that it also accounts for the branch connection's angle of attachment to the header. ASME/ANSI B31.3 is also the only code that explicitly states a basis for required reinforcement area for external pressure. ASME/ANSI B31.3 and B31.4 do not consider the header weld-joint efficiency if the branch does not pass through a header weld, but ASME/ANSI B31.8 does not permit this relaxation. Also note that all three ASME/ANSI B31 Codes use the header thickness required for pressure to calculate the required reinforcement area. After the required reinforcement area has been calculated, the next step is to calculate the available reinforcement area. Saudi Aramco DeskTop Standards 10 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement Available Reinforcement Area As previously discussed, the reinforcement area that may be considered available must be located within the reinforcement zone. It may be composed of three components: • Excess metal available in the header. • Excess metal available in the branch. • The area of other metal provided by welds and properly attached reinforcement. A branch connection is adequately reinforced if the sum of the three reinforcement area components is at least equal to the required reinforcement area. Work Aid 1 outlines the steps for calculating available reinforcement area. ASME/ANSI B31.3 In ASME/ANSI B31.3, the available reinforcement area is calculated using the procedure that is contained in Work Aid 1. ASME/ANSI B31.4 In ASME/ANSI B31.4, the available reinforcement area is calculated as follows: A1 = Header excess area = (Th - th)d A2 = Branch excess area = 2(Tb - tb)L A3 = Area provided by welds and added reinforcement = (Dp - Db)M + Aweld Saudi Aramco DeskTop Standards 11 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement ASME/ANSI B31.8 In ASME/ANSI B31.8, the available reinforcement area is calculated as follows: A1 = Header excess area. = (H - t)d A2 = Branch excess area. = 2(B - tb)L A3 = Area provided by welds and added reinforcement. = (Dp - Db)M + Aweld where: t = Required nominal wall thickness of the header. Considerations Note that ASME/ANSI B31.4 and B31.8 do not explicitly account for corrosion allowance. This is because it is assumed that some form of corrosion protection system will be used on a pipeline. Such a system would not normally be used for process plant piping systems within the scope of ASME/ANSI B31.3. Therefore, corrosion allowance is accounted for. In addition, neither ASME/ANSI B31.4 nor ASME/ANSI B31.8 account for the angle of the branch connection when calculating the area available in the branch. Saudi Aramco DeskTop Standards 12 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement Determining If Reinforcement Is Needed Additional branch reinforcement is needed when the required area exceeds the available area in the pipe walls. If the required area does not exceed the available area, additional reinforcement is not needed. The remainder of this module discusses: • Selecting the diameter of the reinforcement pad, consistent with ASME/ANSI B31 Code limitations. • Calculating the reinforcement pad thickness that is needed to provide adequate reinforcement area. Reinforcement Options There are several ways to provide reinforcement at a welded branch connection. Reinforcement Pad — The most common way to provide needed reinforcement is to add a reinforcing pad. The reinforcing pad cross-sectional area must be sufficient to make up the area deficiency. Other Alternatives — Another way to add reinforcement is to locally increase the wall thickness of either the header or branch pipe. In the case of the header pipe, the section within the reinforcement zone would be made thicker than necessary for pressure in order to provide sufficient excess area for reinforcement. This approach is not as efficient for the branch pipe since the branch pipe reinforcement zone length is much shorter. The most common way of adding reinforcement in the branch pipe is by using an integrally reinforced branch connection. As discussed in MEX 101.04, such an integrally reinforced connection is very thick near its attachment to the header. This extra thickness is enough to provide all the needed reinforcement, and is determined by the manufacturer for the required design conditions. The choice of which branch reinforcement approach to take is based mostly on economics. For example, using a reinforcing pad typically requires more labor time but has a lower material cost than using an integrally reinforced fitting. Thus, using such a fitting is economically attractive only in situations where the labor rates are high enough to offset the higher cost of the fitting versus that of a reinforcing pad. Saudi Aramco DeskTop Standards 13 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement There are also some technical reasons why one reinforcement approach may be preferred over another for specific applications. For example, a self-reinforced branch connection that is welded to the top of the header (i.e., a weldolet) may be acceptable in most cases. However, one that is butt-welded into the header wall (i.e., a sweepolet) may be preferred in other cases. It is also preferable not to use a reinforcing pad in very high-temperature or high-pressure applications. Because the reinforcement pad is the most common option used, it will be discussed in this module. Determining the Need for a Full-Encirclement Reinforcement Pad The following discusses the case where a reinforcing pad must be added to a branch connection to provide reinforcement. ASME/ANSI B31.4 and B31.8 contain requirements for when fullencirclement reinforcement is needed. ASME/ANSI B31.3 does not. To satisfy the area replacement rules of the ASME/ANSI B31 discussed, the outside diameter of the pad is constant, and is an equal distance from the branch opening at every point. However, there are cases where experience has shown that this approach must be extended, and a fullencirclement reinforcement provided. Full-encirclement reinforcement extends the reinforcing pad to completely wrap around the outside diameter of the header. Four details of this type of reinforcement are shown in Figure 4, taken from ASME/ANSI Code B31.4. The most common type of full-encirclement reinforcement is the sleeve-type, as shown in Figure 4. ASME/ANSI B31.4 and B31.8 contain explicit and identical requirements for full- encirclementtype reinforcement. These requirements are based on the size of the hole cut in the header relative to the header diameter, and the design hoop stress relative to the header material yield stress. The basic approach is that full encirclement is needed to strengthen the header region if the hole is too large and/or if the design stress is too close to the yield point of the header pipe material. Saudi Aramco DeskTop Standards 14 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement FULL-ENCIRCLEMENT REINFORCEMENT Optional Optional Weld Weld These longitudinal welds may be located anywhere around circumference GENERAL NOTE: GENERAL NOTE: Since Fluid Pressure is Exerted On Both Sides Provide Hole in Reinforcement to Reveal of Pipe Metal Under Tee, the Pipe Metal Does Leakage in Buried Welds and to Provide Not Provide Reinforcement. Venting During Welding and Heat Treatment [See Para. 404.3.1(d)(8)]. Not Required for Tee Type Tee Type. Sleeve Type Optional Weld Optional Weld Optional Optional Weld Saddle and Sleeve Type Weld Saddle Type GENERAL NOTE: If the Encircling Member for Tee, Sleeve or Saddle Type is Thicker Than the Header and its Ends are to be Welded to the Header, the Ends Shall be Chamfered (At Approximately 45 Deg.) Down to a Thickness Not in Excess of the Header Thickness. Source: ASME/ANSI B31.4 -1989. With permission from the American Society of Mechanical Engineers. FIGURE 4 Saudi Aramco DeskTop Standards 15 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement Requirements for Full-Encirclement Reinforcement ASME/ANSI B31.4 and B31.8 each contain a table that specifies design criteria for welded branch connections. The requirements for full-encirclement reinforcement in both of these codes are identical and are summarized below. 1. The first step is based on the branch and header diameters. If the hole cut for the branch connection is greater than 50% of the nominal header diameter, then full-encirclement-type reinforcement may be required. 2. The next step, for connections which exceed the diameter limit, is based on the design hoop stress in the header, S, and the header material minimum specified yield strength, Sy. • If S/Sy ≤ 0.2, complete-encirclement reinforcement is required if a local reinforcing pad would extend around more than half the circumference of the header. • If S/Sy > 0.2, it is preferable for the branch connection to be made using smoothly contoured wrought tees or crosses of proven design, or integrally reinforced extruded headers. If these connection types are not used, then a complete-encirclement-type reinforcement must be used. The complete-encirclement reinforcement requirements are only considered after a determination is made that additional reinforcement is needed. If additional reinforcement is not needed, then the stress and branch connection hole diameter criteria need not be considered. The ASME/ANSI B31.3 does not have explicit requirements for full-encirclement reinforcement. However, there are cases where such reinforcement should be considered in ASME/ANSI B31.3 piping systems as well. These may include situations where high piping loads act on a branch connection, or for very large openings that approach the header diameter in size. Saudi Aramco DeskTop Standards 16 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement DESIGNING REQUIRED REINFORCEMENT PADS Thus far, this module has discussed how to calculate the required reinforcement area, determine the reinforcement zone, and calculate the available reinforcement area. It also discussed the special case of complete-encirclement reinforcement. This section completes the discussion of branch reinforcement by reviewing the design of the reinforcement pad. The same basic approach is used regardless of which of the ASME/ANSI B31 Codes governs. However, the focus and explicit equations that are discussed in this section will use only ASME/ANSI B31.3. ASME/ANSI B31.4 and B31.8 use a similar approach. When the available reinforcement in the branch and header pipes is less than the required reinforcement, a reinforcement pad may be added. The cross-sectional area of the reinforcement pad must be at least equal to that needed to make up the remaining area required. It is usually not worthwhile to consider the contribution of the attachment welds within the reinforcement zone in calculating this added area. There are three variables to select in designing the reinforcing pad: material, outside diameter; and wall thickness. The material selection is discussed first because it is relatively straightforward. Materials Selection The reinforcing pad material may differ from that of the header pipe. However, it must be compatible with the branch and header pipes with respect to weldability, heat treatment requirements, galvanic corrosion, thermal expansion, etc. If the allowable stress of the reinforcement pad material is less than that of the header, the calculated area of the reinforcement material must be multiplied by the ratio of the header allowable stress to the pad allowable stress. This increases the pad area required to compensate for the lower-strength pad material used. If the reinforcement pad material allowable stress exceeds that of the header, no credit is taken for its additional strength. To avoid these considerations, normal practice is to select a reinforcement pad material that has the same chemistry and is of equal strength to the header material. This is assumed to be the case in the following discussion. Saudi Aramco DeskTop Standards 17 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement Pad Diameter and Wall Thickness Disregarding the contribution of the attachment welds and assuming equal material strengths, the pad outside diameter and wall thickness determine the area that it contributes to branch reinforcement. Work Aid 1 contains the procedure for calculating the required reinforcement pad size. The following highlights the general approach that is used. If A4 equals the required area of the reinforcement pad, then: A 4 = ( D p − D b / sin β ) T r where: Dp = Outside diameter of the pad. Db = Outside diameter of the branch. Tr = Pad thickness. Use minimum thickness if made from pipe, nominal thickness if made from plate. β = The acute angle between the branch and header pipes. A4 is set equal to the difference between the required reinforcing area and that already available in the header and branch. This is a known quantity based on earlier calculations. Db is known. Therefore, Dp and Tr are selected to satisfy the equality, and there are theoretically an infinite number of possible combinations. However, practical design considerations narrow the options somewhat. The maximum pad diameter will never exceed 2d2 because anything larger would be outside the reinforcement zone, could not contribute to branch reinforcement, and thus would be wasteful. The pad thickness is normally selected to equal the pipewall thickness because material of this thickness is likely to be readily available from scrap. It is also not good practice to use a pad thickness significantly greater than that of the header because fabrication will be more difficult and the local load distribution between the pad and the header will be uneven. Common practice then is to select a pad thickness equal to the header thickness, and then calculate the required pad diameter. As long as the required pad diameter is no larger than 2d2, reinforcement may be provided in this manner. If the pad diameter must exceed 2d2 for the given thickness, another method of reinforcement must be used. Saudi Aramco DeskTop Standards 18 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement Additional Topics Not Discussed Two other topics regarding branch reinforcement will not be discussed in this course. These are reinforcement of multiple openings, and reinforcement of extruded outlet headers. • The primary factor to consider in the case of multiple openings that are located near each other is the possibility of overlapping reinforcement zones. The same area may not be considered to reinforce more than one opening. This must be considered in determining the available reinforcement, and whether additional reinforcement is required. • An extruded outlet header is a length of pipe in which one or more outlets for branch connections have been formed by extrusion, using a die or dies to control the radii of the extrusion. Each of the ASME/ANSI B31 Codes contains design requirements for extruded outlet headers that account for the required and available reinforcement areas. The appropriate sections of the ASME/ANSI B31 Codes should be referred to when either of these cases must be evaluated. Saudi Aramco DeskTop Standards 19 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement Sample Problem 1 A new steam turbine is being installed within a process plant at the Ras Tanura refinery. This will require a new 400 mm (16 in.) diameter steam supply line to be connected to an existing 600 mm (24 in.) diameter steam distribution header. The following design information has been determined: • Pipe material - Seamless, A 106/Gr. B for both the branch and header. • Design temperature - 371°C (700°F.) • Design pressure - 3,792 kPa (550 psig.) • Allowable stress - 113.8 MPa(16,500 psi.) • Nominal Pipe Thicknesses - Header: 14.3 mm (0.562 in.) - Branch: 9.5 mm (0.375 in.) • Required Pipe Thicknesses for Pressure - Header: 10 mm (0.395 in.) - Branch: 6.7 mm (0.263 in.) • Corrosion allowance Mill tolerance - 1.5 mm (0.0625 in.) - 12.5% • The branch connection is made on top of the header at a 90° angle, and does not penetrate a header weld. Work Aid 1 may be used to help solve this problem. Determine if additional reinforcement is required for this branch connection. If it is, size the reinforcing pad, neglecting the area of any welds and assuming that the pad material is equal to the header material, and that its thickness equals the header thickness. Work Aid 1 may be used to help solve this problem. Saudi Aramco DeskTop Standards 20 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement Solution Note that since this is a process plant, the design rules of ASME/ANSI Code B31.3 apply. • The required thicknesses for pressure were given. These could be calculated using information that was discussed in MEX 101.03. • Next, the value for the effective length removed from the run pipe, d1, must be calculated. This equals the corroded inside diameter of the branch connection after accounting for mill tolerance. d1 = D b − 2 (Tb − c ) sin β Tb must account for the mill tolerance. Remember that this may be 12.5% on wall thickness. d1 = 16 − 2 ( 0 . 375 x 0 . 875 − 0 . 0625 ) sin 90 ° d 1 = 15 . 469 in . • Now the required reinforcement area, A1, may be calculated. A 1 = t h d 1 ( 2 − sin β ) A 1 = 0 . 395 x 15 . 469 ( 2 − sin 90 ° ) A 1 = 6 . 11 in . Saudi Aramco DeskTop Standards 2 21 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement The available reinforcement area is now calculated. Disregard any contribution from nozzle attachment welds. • Calculate the excess area available in the header, A2. First determine d2. d1 or d ( T b − c ) + ( T h − c ) + 1 , whichever is greater but less than header 2 diameter Dh or d2 = d1 = 15.469 in. Based on the larger of d1 or the value calculated above, but not more than the header diameter: A2 = (2 x 15.469 - 15.469) (0.875 x 0.562 - 0.395 - 0.0625) A2 = 0.53 in.2 • Calculate the excess area available in the branch, A3. A3 = 2 L 4(T b − tb − c ) sin β First determine L4. L 4 = 2 . 5 ( T h − c ) , or 2 . 5 ( T b − c ) + T r , whichever is smaller Saudi Aramco DeskTop Standards . 22 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement Since Tr = 0 (no reinforcing pad) and Th is greater than Tb, L4 is based on the second equation. L4 = 2.5 (0.875 x 0.375 - 0.0625) L4 = 0.664 in. A 3 = 2 x 0 . 664 ( 0 . 875 x 0 . 375 − 0 . 263 − 0 . 0625 ) sin 90 ° A 3 = 0 . 003 • in . 2 Other Excess Area: There is no reinforcing pad and the area contribution from the branch weld is being disregarded. Therefore, A4 = 0. • Total Available Area: The total available reinforcement area is calculated by adding the contributions from each source. AT = A2 + A3 + A4 AT = 0.53 + 0.003 + 0 AT = 0.533 in.2 available reinforcement. The available total reinforcement of 0.533 in.2 is obviously much less than the required reinforcement area of 6.11 in.2. Therefore, a reinforcing pad is required. Since this is an ASME/ANSI B31.3 piping system, the reinforcing pad does not need to be full encirclement. If this were a ASME/ANSI B31.4 or B31.8 piping system, further evaluation would be necessary to determine if a full encirclement pad is needed. The reinforcement pad will now be sized. Saudi Aramco DeskTop Standards 23 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement A106, Gr. B material will be used, and it is equal to the header nominal thickness of 14.3 mm (0.562 in.). • Recalculate Available Reinforcement: Since a reinforcing pad is now being used, the available reinforcement in the branch must be recalculated. L41 = 2.5 (Th - c) L41 = 2.5 (0.875 x 0.562 - 0.0625) L41 = 1.073 in. L42 = 2.5 (Tb - c) + Tr L42 = 2.5 (0.875 x 0.375 - 0.0625) + 0.562 (0.875) L42 = 1.16 in. Therefore, L4 = 1.073 in. A3 = 2L 4(T b − t b − c) sin β A 3 = 0 . 005 in . 2 A T = A2 + A3 + A 4 A T = 0 . 53 + 0 . 005 + 0 2 A T = 0 . 535 in. available Saudi Aramco DeskTop Standards reinforcement 24 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement • Calculate Additional Reinforcement Required and the Pad Dimensions: The required reinforcement area is 6.11in.2, and the available area is 0.535 in.2. Therefore, the reinforcement area required in the pad, A4, is: • A4 = 6.11 - 0.535 A4 = 5.575 in.2 Tr = 0.562 (0.875) = 0.492 in. Db = 16 in. Determine the diameter of the pad, Dp. A 4 T 4 + Db p = D p = D p = 27 . 3 in . D sin β 5 . 575 0 . 492 + 16 The pad diameter must be at least 27.3 in. to provide adequate reinforcement. Since 2d2 = 30.938 in., this pad diameter is within the reinforcement zone and is acceptable. The approach of calculating the required pad width may be used as an alternative. Saudi Aramco DeskTop Standards 0. 5 A 4 L r = L r = L r = 5 . 66 in . Tr 0 . 5 x 5 . 575 0 . 492 25 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement WORK AID 1: STEPS FOR CALCULATING REINFORCEMENT AREAS REQUIRED AND AVAILABLE For each of the ASME/ANSI B31 Codes, the general steps for calculating the required reinforcement area are: • Identify the given design information. • Determine the required pressure design thickness of the header. • Calculate the effective length removed from the run pipe. • Calculate the required reinforcement area. For each of the ASME/ANSI B31 Codes, the steps to calculate the available reinforcement area are: • Identify the given design information. • Calculate the excess area in the header. • Determine the required pressure design thickness of the branch. • Calculate the excess area in the branch. • Calculate the area of the reinforcement pad, if one is provided. The following steps summarize the branch reinforcement calculation procedure based on ASME/ANSI B31.3 requirements. A similar approach is used for ASME/ANSI B31.4 and B31.8 systems. Use Figure 1 as a reference. 1. Identify the given design information. P, design pressure DT, design temperature Dh, header outside diameter Db, branch outside diameter Th, minimum header thickness (accounting for mill tolerance) Tb, minimum branch thickness (accounting for mill tolerance) Saudi Aramco DeskTop Standards MPa (psig) oC (oF) mm (in.) mm (in.) mm (in.) mm (in.) 26 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement Tr, reinforcement pad thickness (if used) Dp, reinforcement pad diameter (if used) c, corrosion allowance β , acute angle between branch and header Materials • • • Header Branch Reinforcement mm (in.) mm (in.) mm (in.) degrees . . . 2. Determine the required pressure design thickness of the header, th, using MEX 101.03. 3. Determine the required pressure design thickness of the branch, tb, using MEX 101.03. 4. Calculate the effective length removed from the run pipe at the branch, d1. d 1 = [ D b − 2 ( T b − c ) ] / sin β 5. Calculate the required reinforcement area, A1. A 1 = t h d 1 ( 2 − sin β ) 6. Determine the "half-width" of reinforcement zone along the header, d2. Larger of: d 1 , or (T b − c ) + (T h − c ) + d 1 / 2 , but 7. never more than D h Determine height of reinforcement zone in branch pipe, L4. Smaller of: 2 . 5 ( T h − c ), or 2 . 5 (T b − c) + T r Saudi Aramco DeskTop Standards 27 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement 8. Calculate available reinforcement area. A 2 = Header excess area = ( 2 d 2 − d 1 ) (T h − t h − c ) A 3 = Branch excess area = 2 L 4 ( T b − t b − c ) / sin β A 4 = Area provided by welds and added reinforcement = ( D p − D b / sin β ) T r + A weld where: 9. A weld = Area of weld metal located within the reinforcement zone. May be neglected since it is negligible. Calculate total available reinforcement area, AT. AT = A2 + A3 + A4 10. 11. If AT _ A1, the branch connection is adequately reinforced. If AT < A1, additional reinforcement is required. If additional reinforcement is required, determine the required pad diameter a. Set Tr = Th b. Use pad material equal to the header material. c. Set the required reinforcing pad area, A4: A4 = A1 - AT d. Calculate required pad diameter, Dp: D p = A T 4 + r D b sin β Dp cannot exceed 2d2. If it does, then another method of reinforcement must be used. As an alternative, the required reinforcement pad width may be calculated, Lr. L r = 0. 5A 4 Tr Saudi Aramco DeskTop Standards 28 Engineering Encyclopedia Piping & Valves Branch Connections Reinforcement GLOSSARY branch pipe When used within the context of piping branch intersections, the branch pipe is welded to the run pipe to form an intersection. extruded outlet An extruded outlet is a branch connection formed in a length of pipe by extrusion, using a die or dies to control the radii of the extrusion. header pipe Also called "run pipe." When used within the context of piping branch intersections, the header or run pipe is the one in which a hole is cut to form the intersection of two pipes. mill tolerance Within the context of branch reinforcement calculations, the amount by which the supplied pipewall thickness may be less than the specified nominal wall thickness. This is normally 12.5%. reinforcement pad A plate used to provide additional strength at the intersection between a branch and a header pipe. reinforcement zone A parallelogram which describes the geometric region at a branch intersection in which excess metal may contribute to reinforcement. Saudi Aramco DeskTop Standards 29