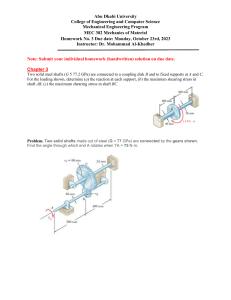

Design of Machine Element: Shaft Shaft A rotating Machine member, usually circular cross section, used to transmit power or motion. Shaft, Axle, Spindle M S Dasgupta BITS Pilani 1 Shafts Shaft may be integral part of the driver (motor shaft, engine crank shaft etc.) or may be freestanding shaft connected to another shaft by coupling. An axle is a non-rotating member that carries no torque and is used to support rotating wheels, pulleys etc. (Exception->Automotive axle) Main design criteria is either strength or deflection & rigidity. (Torsional rigidity / Lateral rigidity) Deflection is not affected by strength, but by stiffness. Mostly made of low carbon, cold-drawn or hot-rolled steel Shaft Material Cold drawn steel is more often used for small (dia<3in) and Hot rolled steel used for larger sizes Shafts usually don’t need to be surface hardened unless they serve as the actual journal of a bearing surface Typical material choices for surface hardened shaft include carburizing grades of ANSI 1020, 4320, 4820, and 8620 Hot rolled steel should be machined all over to remove the carburized outer layer. Cast iron may be specified if the gears are to be integrally cast with the shaft Stainless steel may be appropriate for some environments Mountings: Keys, Splines, Set Screws Shaft Layout • Generally, the geometry of a shaft is a stepped cylinder. • Each shoulder in the shaft serves a specific purpose Speed Reducer Reducing Stress Concentration at shoulder Suggested techniques for reducing stress concentration at a shoulder supporting a bearing with a sharp radius. (a) Large radius undercut into the shoulder. (b) Large radius relief groove into the back of the shoulder. (c) Large radius relief groove into the small diameter Estimating Stress Concentrations Stress concentrations for shoulders and keyways are dependent on size specifications that may not be known the first time through the process But these elements are usually of standard proportions, it is possible to estimate the stress concentration factors for initial design of the shaft These stress concentrations are then finetuned in successive iterations, once the details are known Estimating Stress Concentrations First iteration estimates for Stress Concentration Factors Kt Table 7–1 Design for static load (building up the formulas) Consider a non rotating shaft subjected to bending Moment M and Torsional moment T. x 32 M 16T , xy d 3 d 3 By Max Shear Stress Theorem, max x y 2 2 xy2 16 d 3 M 2 T 2 Now, let the safety factor be N S yt 32 N 2 2 2 M T N d max S y Distrotion Energy Theorem When the shaft rotates but Torsional load remain steady 1 3 32 N M 2 T 2 d S y S e 2 22 1 2 1 3 1 When both2 bending &2Torsional load 2 2 x x 2 x x xy has xy as well asxy fluctuatin part 3 xy steady x2 g 2 2 2 2 32 N 32 N Safety factor N d d M 2 S y S yt 1 3 M 3T 2M a m Sy 4 S e 2 Ta T m Se Sy 2 1 3 Shaft Design for Strength Design is for critical section. Axial stresses on shafts due to helical gears or tapered roller bearings is almost always negligible as compared to the stress due to bending moment or torsion For Solid Shaft: Where Mm and Ma are the midrange and alternating bending moments, Tm and Ta are the midrange and alternating torques, and Kf and Kf s are the fatigue stress concentration factors for bending and torsion Shaft Design for Stress Combining these and for Von Mises stresses for rotating round, solid shafts, neglecting axial loads, are given by These equivalent alternating and midrange stresses can be evaluated using an appropriate failure curve i.e Mod-Goodman, Soderberg, Gerber’s or ASME elliptic Shaft Design for Stress For example, the fatigue failure criteria for the modified Goodman line expressed as Modified Goodman Shaft Design for Stress Similar expressions can be obtained for any of the common failure criteria ASME Elliptic Soderberg Shaft Design for Stress Gerber Problem: A 50 mm diameter solid shaft is transmitting a power of 20 kW at a steady speed of 300 rpm is subjected to a completely reverse bending moment of 16000 N-mm. The shaft is made of forged steel (Sy = 480 MPa and Sut = 580 MPa) and surfaces are machined. The theoretical stress concentration factor and notch sensitivity are 2.4, 0.78 respectively for bending and 2.2, 0.85 respectively for torsion. Determine the factor of safety based on Goodman theory. Problem: The rotating solid steel shaft is simply supported by bearings at points B and C and is driven by a gear (not shown) which meshes with the spur gear at D, which has a 150-mm pitch diameter. The force F from the drive gear acts at a pressure angle of 20o. The shaft transmits a torque to point A of TA = 340 N-m. The shaft is machined from steel with Sy = 420 MPa and Sut = 560 MPa. The notch sensitivities are 0.8 and 0.9 for bending and torsion, respectively. Using a factor of safety of 2.5, determine the minimum allowable diameter of the shaft based on (a) a static yield analysis with fatigue stress concentration factors using the distortion energy theory and (b) a fatigue-failure analysis. Assume sharp fillet radii at the bearing shoulders for estimating stress concentration factors. d d Ft T F cos T 2 2 Problem: The shaft shown in the figure is driven by a gear at the right keyway, drives a fan at the left keyway, and is supported by two deep-groove ball bearings. The shaft is made from AISI 1020 cold-drawn steel. At steady-state speed, the gear transmits a radial load of 1.1 kN and a tangential load of 3 kN at a pitch diameter of 200 mm. Determine fatigue factors of safety at gear key way and fan key way locations. For bending and torsion, the critical theoretical stress concentration factors at both the key ways are 1.9 and 1.32 and notch sensitivities are 0.75 and 0.92 respectively. Problem: A transmission shaft, supported by two bearings B1 and B2, rotating at 720 rpm and transmitting power from the pulley to the spur gear G is shown in fig. The tension and Gear teeth forces are P1= 475 N, P2= 155 N, Pt= 480 N and Pr= 200 N. The weight of the pulley is 100 N. The diameter of the pulley is 120 mm and pith diameter of gear is 80 mm. The fatigue stress concentration factors for bending and torsion are 1.9 and 1.3 respectively. The shaft is made of AISI 1040 CD steel. Using a factor of safety of 2, determine the minimum allowable diameter of the shaft based on (a) a static yield analysis with fatigue stress concentration factors using the distortion energy theory and (b) a fatigue-failure analysis. Circlips / Snap rings Design of Keys and Pins Square Key Round pin Round Key Taper pin Round pin Split tubular spring pin Design of Keys and Pins Two special types of keys: (a) Gib-head key, and (b) Woodruff key Design of Keys and Pins Dimensions of rectangular and square keys: Table 7-6 and Woodruff Keys: Table 7-7 and 7-8. Most often the keys are subjected, as shown, to direct shear along ab and crushing. Here the shear area is given by A=l*t Here l is the length of the hub. T = P/(2N), where P is the power in Watts and N is the speed of the shaft in RPS. F = T/r, T= Torque being transferred. F S sy Direct shear : tl n Sy F Crushing : tl 2 n Loose Pins: The loose pin mostly used for transmitting axial load It is a double shear case, where there are two areas supporting the total shear load. Hence shear stress = (1/2)(4V/2A)