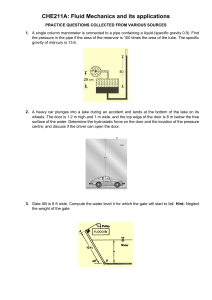

RIGID STEEL CONDUIT Informations Informations CONDUIT TRADE SIZE FITTINGS LB L BOX CONDULET line box BENDS HICKEY symbols of one's unavailability to the public CUT PIPE CUTTER a tool or machine for cutting pipe REAM REAMER THREADS ½ DIES AND DIES STOCK Die stocks can accommodate two different types of cutting tools, usually known as round head and hex head dies Supplies and Materials -Pencil -Chalk -Rag -RSC Tools and Equipment -Bench vise -Flute reamer /file -Hacksaw -Personal protective equipment GLOVES GOGGLES HARD HAT Procedure • Prepare the necessary tools, materials, equipment and PPE in performing the activity. • Wear the appropriate PPE 3. Measure and mark the location of cut. 4. Cut the conduit using the Hacksaw. 5. Ream the newly cut conduit using the flute reamer or file. 6. Measure and mark another 200mm from your marker. 7. Check if the end of the pipe is smooth. 8. Let your teacher check your work. Supplies and Materials -Pencil -Chalk -Rigid Steel Conduit Tools and Equipment -Metric rule -Try square -Hickey w ith handle -Hacksaw -Personal Protective Equipment Procedure • Prepare the necessary tools, materials, and equipment • Wear the appropriate PPE. • Draw a right angle bend on the floor using the try square 4. Draw an Arc near the corner. 5. Mark the center of the location of the bend. 6. Insert the RSC into the conduit bender/hickey where the corner of the bend is to be made. 7. Bend the RSC gradually to form a 90 degree bend, Check the desired shape by placing the conduit on the layout which can be seen in step 3. 8. Remove the bender on the right angle bent RSC. 9. Observe good housekeeping. Supplies and Materials -Pencil -Chalk -Rigid Steel Conduit Tools and Equipment -Metric rule -Try square -Hickey w ith handle -Hacksaw -Personal Protective Equipment Procedure • Prepare the necessary tools, materials, and equipment • Wear the appropriate PPE. • Measure the elevation of the box where the bend is to be fitted. 4. Draw the depth of the elevation on the floor. this w ill make two lines. 5. mark of 100mm from the end of the pipe. 6. P ut another 200mm from your first marker. 7. Insert the hickey on the second marker and bend gradually w ith a backward stroke to follow its depth. 8. Move the hickey on the first marker and bendgradually w ith a forward stroke to follow its height. 9. Remove the hickey. 10. Observe good housekeeping. so now prepare 1/2 lengthw ise Test I (identification) • It is designed to protect electrical w iring of building from electrical hazard due to faulty w iring. 2. is a set of rules and regulations which govern all electrical w iring. 3. What is the standard size of RSC 4. Are usually used when the w iring installation make sharp turns, the letter L shows that an elbow or fittings makes right angle turn . 5. After cutting the pipe w ith hacksaw or pipe cutter it leaves purrs. This must be removed to avoid damage of w iring installation when the w ires is inserted into the pipe. 6. Rigid Steel Conduit can be also be bent using a hickey or Conduit bender. It follows the same procedure as that in bending electrical metallic tubing. 7. A Conduit is cut w ith a hacksaw or pipe cutter. 8. Since Rigid Metal Conduit is commonly used in wet places, sealing of termination can be best done if the pipe is threaded 9. Contact of metal to another metal must be avoided in installing RSC to prevent the possibility of Galvanic Reaction 10. This are permitted to be installed in concrete, direct earth burial or in areas subjected to corrosive influences 11. Test II (Identify the Pictures) 12. Test II (Identify the Pictures) 13. Test II (Identify the Pictures) 14. Test II (Identify the Pictures) Test II (Identify the Pictures) 15. Thank you!